将超高温陶瓷(UHTCs)引入碳/碳(C/C)复合材料可制备出超高温陶瓷改性C/C复合材料(C/C-UHTCs)[1]。这种复合材料中的UHTCs包括IV和V族过渡金属的碳化物、氮化物和硼化物,具有硬度高、熔点高(3000℃以上)、结构稳定等优点[2]。ZrC有化学惰性好、蒸发率低、耐烧蚀性能高等特点[3],SiC在高温氧化过程中生成的低氧透过率自愈合SiO2玻璃可阻止氧气扩散进基体[4]。将抗烧蚀性能优异的ZrC和抗氧化性能优异的SiC同时引入C/C复合材料基体,可制备出兼具抗烧蚀和抗氧化性能的C/C-ZrC-SiC陶瓷基复合材料[5]。C/C-ZrC-SiC陶瓷基复合材料具有优异的高温力学性能[7],且能承受高达3000℃的温度和2000℃以上的周期性热冲击[6],是一种性能优异的热结构材料。

近年来,关于碳化物陶瓷及碳基材料在新一代核能领域应用的研究越来越多。SiC中子吸收截面低、熔点高、高温力学性能好,且能抵挡反应堆中裂变气体产生的高温高压,在先进核能系统中有很好的应用前景[8, 9]。SiC是高温气冷堆及TRISO(三结构各向同性燃料颗粒)燃料的重要组分,在核裂变(裂变燃料包壳)、核聚变(聚变反应堆第一壁材料、分流器、覆盖层)系统中得到了广泛的应用[10, 11]。许多学者研究了SiC的辐照性能。Zhang等[12]根据拉曼光谱研究了C+与He+离子注入纳米3C-SiC晶粒后的非晶化过程,发现SiC非晶化除了与辐照损伤积累有关,还与晶体/非晶体界面有关。Lin等[13]根据XRD谱和TEM观察研究了3C-SiC的辐照肿胀过程,发现辐照诱导点缺陷和Si衬底的压力是产生3C-SiC各向异性的主要原因。

作为过渡金属陶瓷,ZrC的中子吸收截面低、熔点高、硬度高(30~40 GPa)、化学稳定性好且对裂变产物有较好的保留性能,是一种性能优异的惰性基质燃料(IMF)。ZrC已选作HTGR-C(高温气冷反应器)、等离子组件(PFC)及非轻水堆替代包壳材料的候选材料[14]。在第四代核反应系统中,ZrC可用于第四代气冷堆和高温气体反应堆等的燃料组件,以及聚变堆的结构组件。对ZrC的辐照实验研究对于扩展ZrC陶瓷在核能领域的应用,也有重要的意义。Florez等[15]用强度为10 MeV的Au3+离子在800℃对ZrC陶瓷进行离子辐照,发现经30 dpa离子辐照后未发生非晶化而发生了氧化。同时,随着辐照剂量的增大ZrC晶粒中缺陷微观结构粗化。Wei等[16]用强度为4 MeV、通量为2×1016 ions/cm2的Au离子进行室温离子辐照,检测了不同化学计量ZrCx陶瓷的缺陷变化。结果表明,非化学计量的ZrCx辐照能抑制位错环的产生,表明其比化学计量ZrC有更好的辐照耐受性。

未来的核用发动机在超高温环境中服役,需要能承受高温空气烧蚀和抗辐照的热结构材料。C/C-ZrC-SiC复合材料不仅具有优异的抗烧蚀性能,其各组成组元还具有优异的辐照稳定性,可用作制造核用发动机的热结构材料。鉴于此,本文研究Si2+离子辐照前后C/C-ZrC-SiC复合材料的形貌和性能的变化。

1 实验方法

1.1 样品的制备

用反应熔渗法制备实验用C/C-ZrC-SiC复合材料。其工艺为:将原子比为6:4的Zr、Si粉混合均匀,与密度为1.3 g/cm3的C/C多孔坯体一起放入石墨罐中,在真空炉中烧结。以10℃/min的升温速率将真空炉加热到2000℃,保温2h冷却后得到C/C-ZrC-SiC复合材料。反应熔渗得到的C/C-ZrC-SiC复合材料密度为1.65 g/cm3,陶瓷组元均匀分布于C/C复合材料基体中。将C/C-ZrC-SiC复合材料切割成尺寸为10 mm×5 mm×5 mm的方块试样,并依次经400目、800目、1000目、2000目的砂纸打磨和用金刚石研磨膏抛光,再将其超声清洗后烘干。

1.2 离子辐照实验

用2×1.7 MV串列加速器在室温下进行离子束辐照实验,注入的Si2+离子能量为2 MeV,离子总通量为1.9×1016 ion/cm2。

1.3 性能表征

用Smartlab 9kW掠入射X射线衍射仪表征样品近表面区域的晶体结构变化,扫描角度范围为5°~90°,扫描速率为5(°)/min,掠入射角为1°。用型号为LabRAM HR800的显微激光拉曼光谱仪检测辐照前后晶格缺陷变化,测量光谱范围为20~2000 cm-1,光斑尺寸为1~2 µm。用型号为TI-950的纳米压痕仪测试辐照前后样品的显微力学性能变化,最大载荷为10 mN,加载速率和卸载速率均为60 mN/min,保压时间为5 s。采用准静态模式和金刚石压头,并设定最大压入深度200 nm。用型号为Quanta FEG250的扫描电子显微镜和型号为Elect plus的能量色散光谱仪观察辐照前后表面形貌及成分变化。用Talos F200X透射电子显微镜表征辐照后样品的微观形貌,并进行明场像(BF)、高分辨像(HRTEM)分析。用聚焦离子束切割减薄技术制备透射样品,用型号为Helios Nanolab 600i的双束电子显微镜观察。

2 结果和讨论

为了估计Si2+离子在C/C-ZrC-SiC复合材料中的辐照损伤及分布,使用SRIM 2008软件中的蒙特卡罗模式(Kinchin-Pease)模拟能量为2 MeV的Si2+离子在ZrC、SiC和碳中的辐照损伤过程。用于模拟计算的输入参数列于表1。根据TRIM结果可计算dpa及原子注入离子浓度(appm),计算公式分别为

表1 SRIM模拟计算的输入参数

Table 1

| Calculation type | Kinchin-Pease |

|---|---|

| Ion species | Silicon |

| Ion energy | 2 MeV |

| Target density | 6.73, 3.17 and 2.26 g/cm3 for ZrC, SiC and C respectively |

| Target composition | ZrC, SiC, C |

| Displacement energy (Ed) | C 25 eV; Zr 35 eV for ZrC; C 20 eV; Si 35 eV for SiC[30]; C 25eV for carbon fiber |

和

式中fluence (ions/cm2)为注入离子的通量,vacancies为VACANCY.txt文件中VACANCIES by IONS与ACANCIES by RECOILS相加之和,atom density (atoms/cm2)为靶材料的原子密度。ZrC、SiC和碳的原子密度分别为7.851×10-22 atoms/cm3、9.509×10-22 atoms/cm3与11.33×10-22 atoms/cm3。No. of Si-ions由RANGE.txt中得到。图1给出了辐照损伤及Si2+离子沿深度方向的分布。可以看出,随着损伤深度的增大dpa呈现先增加后降低的趋势。Si2+离子在不同靶材中的运行轨迹不同,因此Si2+离子在C/C-ZrC-SiC复合材料三种相中的损伤深度及损伤剂量不同。其中2 MeV的Si2+离子在ZrC、SiC及碳中达到离位损伤峰值的深度分别为0.84 µm、1.12 µm和1.32 µm,对应的损伤值分别为10 dpa、6.9 dpa和5.6 dpa。

图1

图1

2 MeV的Si2+离子在ZrC、SiC与C中沿深度方向的损伤和离子分布

Fig.1

Depth profiles of dpa and ion concentration in ZrC (a), SiC (b) and C (c) after irradiated by 2 MeV Si2+ ion

2.1 晶体结构的变化

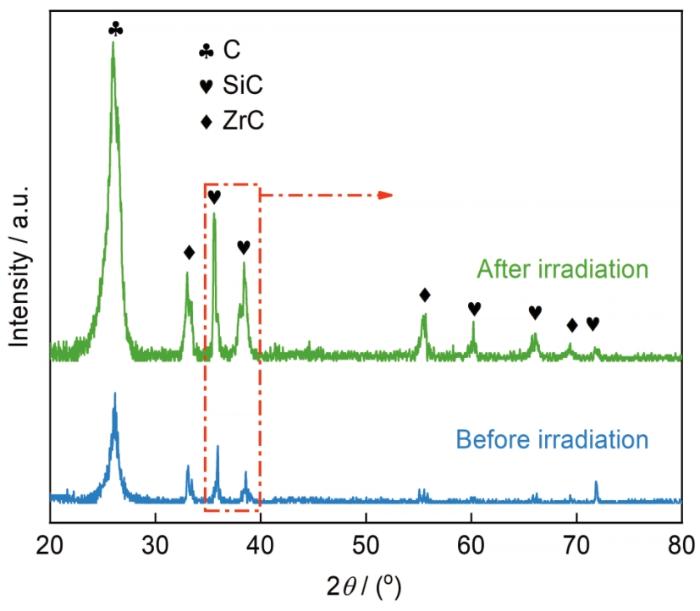

由SRIM模拟结果可知,辐照损伤发生在距离样品表面3 µm内,而普通的XRD检测深度为10~20 µm,可见测试结果受未辐照区域的影响。GIXRD可控制掠入射角度获取样品表层的信息,从而检测出辐照过程中晶体结构的变化。图2表明,在GIXRD图中未观察到非晶化,表明C/C-ZrC-SiC复合材料在离子辐照过程中的稳定性优异。辐照后ZrC、SiC和碳峰均发生宽化,因为辐照诱导材料产生了点缺陷和线缺陷。这些缺陷使晶粒产生畸变和非均匀微应变。图2的放大图表明,SiC峰在辐照后向低角度方向轻微偏移。根据Bragg公式2dsinθ=n·λ,2θ的减小表明晶面间距d增大,即辐照后SiC晶粒中产生的应力使晶格膨胀。ZrC的衍射峰位向低角度轻微偏移,表明ZrC的晶面间距几乎没有变化。与SiC相比,ZrC在辐照过程中的晶格稳定性更高。

图2

图2

C/C-ZrC-SiC复合材料辐照前后的GIXRD谱对比

Fig.2

Comparison of GIXRD patterns of C/C-ZrC-SiC composites before and after irradiation

Si2+离子辐照后碳峰的强度提高,是辐照诱导产生的碳缺陷所致,且辐照剂量增大碳峰的强度随之提高。辐照后碳峰向低2θ角度偏移,表明碳相的层间距变大[17]。使用Bragg公式计算碳峰晶面间距的结果表明,辐照后C/C-ZrC-SiC复合材料中石墨相的层面间距由0.1744 nm增大至0.1756 nm。用高斯拟合计算辐照前后碳峰的半高宽FWHM,结果表明,辐照后FWHM由1.1131 nm-1增大至1.4401 nm-1。半高宽的增大,表明晶格的无序度提高。

2.2 辐照产生的晶格损伤

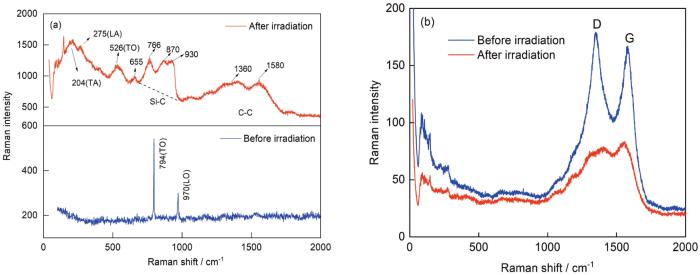

图3给出了C/C-ZrC-SiC复合材料辐照前后陶瓷基体和碳纤维的Raman谱。拉曼光谱包括光学分支和声学分支,每个分支又分为横向和纵向声子模式,因此拉曼光谱共有四种模式,分别为横向光学(TO)、纵向光学(LO)、横向声学(TA)及纵向声学(LA)模式。由陶瓷基体辐照前的Raman谱(图3a)可见,794 cm-1和970 cm-1分别对应3C-SiC的TO散射峰和LO散射峰。辐照后TO、LO峰变宽并向低波方向移动,在Si-C带区域768 cm-1、870 cm-1、924 cm-1处出现无序SiC峰,并在655 cm-1处出现新峰。根据Si-C区域的峰对SiC损伤水平的描述,可以推测TO、LO峰发生变化的原因可能是辐照后非晶态SiC团簇[20]的生成使SiC的结晶度降低[12]。辐照前化学计量的ZrC是对称的NaCl型面心立方结构,没有拉曼活性,因此辐照前没有ZrC特征峰[21]。而辐照后在204 cm-1、275 cm-1及526 cm-1处分别出现ZrC的横向声学(TA)散射峰、纵向声学(LA)散射峰及TO散射峰[15],表明离子辐照诱导ZrC产生了点缺陷和碳空位,从而出现了碳缺位对应的ZrC特征峰。同时,由于辐照后Si-C键与Zr-C键断裂和碳原子结合形成C-C键,在C-C区域出现两个新峰,是分别位于1360 cm-1处碳的sp2峰(D峰)和1580 cm-1处碳的sp3峰(G峰)。

图3

图3

辐照前后C/C-ZrC-SiC复合材料中陶瓷基体和碳纤维的Raman谱

Fig.3

Raman spectra of ceramic matrix (a) and carbon fiber (b) in C/C-ZrC-SiC composites before and after irradiation

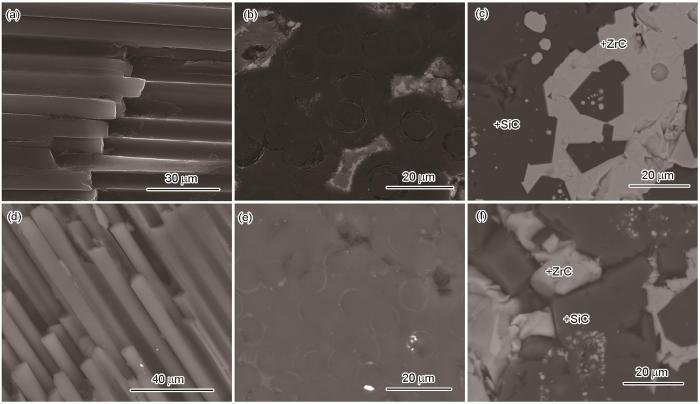

2.3 微观结构的变化

图4

图4

辐照前后碳纤维、PyC界面和陶瓷基体的SEM照片

Fig.4

SEM images of carbon fiber (a,d), PyC interface (b, e) and ceramic matrix (c, f) before and after irradiation

表2 ZrC和SiC相辐照前后的原子比

Table 2

| Atom fraction% (ZrC) | Atom fraction% (SiC) | ||||

|---|---|---|---|---|---|

| Zr | Si | C | Si | C | |

| Before irradiation | 44.61 | 2.27 | 53.12 | 70.50 | 29.50 |

| After irradiation | 34.13 | 5.83 | 60.04 | 59.31 | 40.69 |

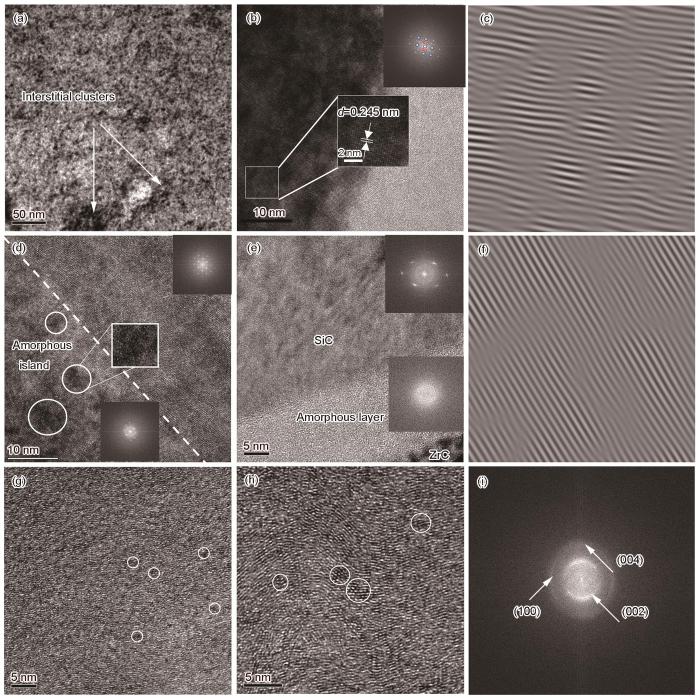

2 MeV Si2+离子辐照后C/C-ZrC-SiC复合材料中ZrC,SiC及碳纤维的表面TEM形貌,如图5所示。从图5a中ZrC的BF像可以看出,辐照后ZrC晶粒中出现了大量点缺陷和点缺陷团簇,缺陷团簇是点缺陷扩散聚集形成的。结合辐照后ZrC的傅里叶变换(FET)图可见,ZrC仍保持完整的晶体结构而未发生非晶化,表明ZrC的辐照稳定性较高。但是,在FET图(图5b)中除了与NaCl结构对应的ZrC衍射斑点还出现一些较弱的多余衍射斑点,表明ZrC辐照后发生了晶格扭曲[16]。辐照后ZrC(200)晶面间距d=0.245 nm,与标准值d=0.235 nm相比,晶格膨胀率为4.26%。导致ZrC晶格膨胀的主要原因,是ZrC辐照后发生了晶格畸变[16]。由图5c的反傅立叶变换图(IFET)可知,辐照后产生的晶格应力使ZrC的晶格条纹扭曲、变形[24]和出现层错。这表明,Si2+离子辐照后ZrC晶粒中产生了大量的点缺陷,点缺陷的聚集导致ZrC晶格畸变[25]。由图5d中SiC的HRTEM图可见,Ⅰ区域SiC晶格中出现许多非晶岛,结合FET图可知此区域SiC非晶化,而Ⅱ区域中的SiC的晶格结构仍然完整[26]。由此可以判断,SiC辐照后出现部分非晶化,但是非晶化区域不均匀。W. J. Weber等[27]研究发现,非晶化是点缺陷的积累产生的。超过临界缺陷浓度后就发生非晶化,并且陶瓷材料辐照后非晶化的程度不均匀。这就是同一表面SiC出现不同程度非晶化的原因。未完全非晶化区域中SiC的晶面间距d=0.250 nm,与SiC(200)晶面标准值d=0.235 nm相比,晶格膨胀率约为5.04%。SiC与ZrC交界区域生成非晶层(图5e),其厚度约为16 nm。这表明,ZrC与SiC两相交界处更容易发生辐照损伤。辐照后SiC晶粒的IFET图(图5f)表明,SiC晶格有序被破坏,晶格受到损伤[23]。辐照后ZrC晶格完整且未发生非晶化,而SiC出现程度不均匀的非晶化,表明ZrC比SiC的抗辐照稳定性更高。

图5

图5

辐照后ZrC的BF像、HRTEM像和IFET像、辐照后SiC的HRTEM像、IFET像、辐照后碳纤维、热解碳的HRTEM像和FET像

Fig.5

BF (a), HRTEM (b) and IFET images (c) of ZrC and HRTEM (d,e) and IFET images (f) of SiC HRTEM image of carbon fiber (g) and PyC (h); FET image of carbon fiber and PyC (i) after irradiation

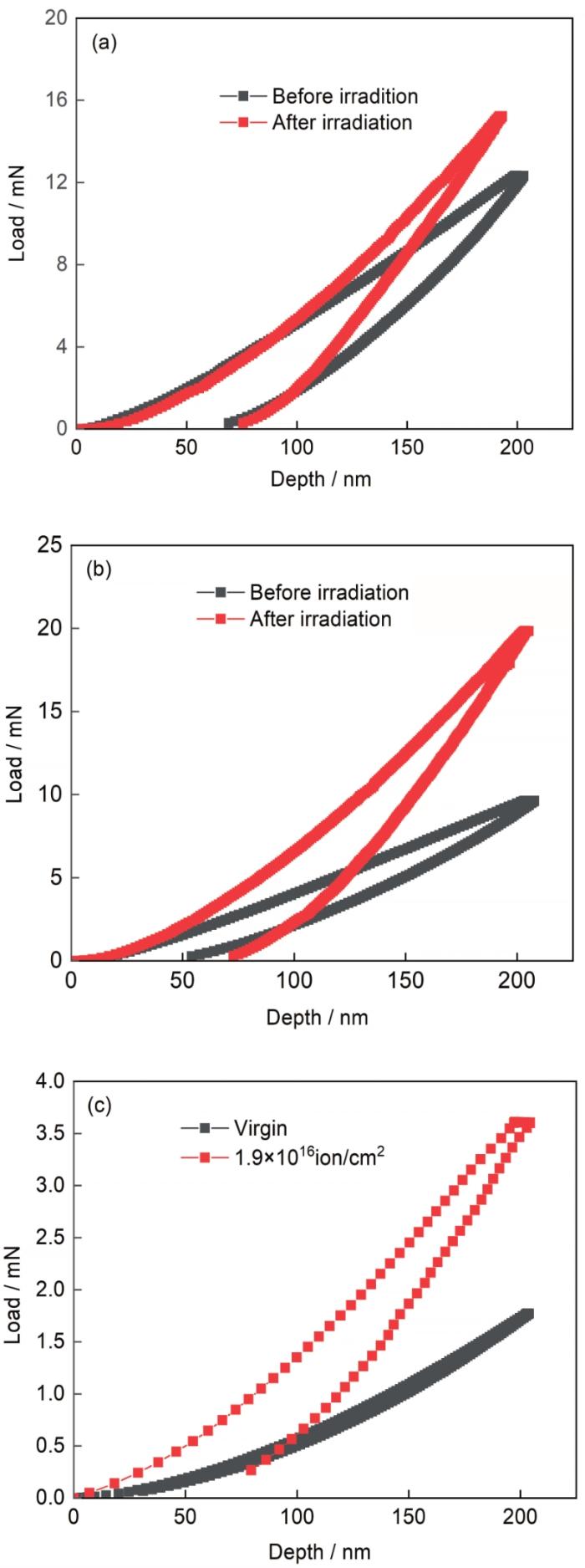

2.4 显微力学性能

式中A为接触面积,S为卸载曲线的斜率,v为材料的泊松比,vi为压针的泊松比。

图6

图6

辐照前后ZrC、SiC和碳纤维的纳米压痕载荷-位移曲线

Fig.6

Nanoindentation load-displacement curves of ZrC (a), SiC (b) and carbon fiber (c) before and after irradiation

辐照后ZrC,SiC及碳纤维的纳米硬度和弹性模量都明显提高。从表3可见,ZrC,SiC及碳纤维的纳米硬度分别提高66.04%,120.25%及94.23%,弹性模量分别提高45.45%、167.60%和124.50%。这种辐照诱导硬度的提高,称之为辐照硬化,是点缺陷团簇、位错环等微观组织变化所致[25]。晶格缺陷对位错的钉扎、晶内效应以及晶体外部的叠加结构变化,都会使模量增大[29]。辐照后SiC的硬度提高,表明SiC未完全非晶化。间隙缺陷的增加和间隙缺陷对基层位错的钉扎,使碳纤维的弹性模量发生了较大的变化。ZrC辐照后硬度和弹性模量的变化最小,表明ZrC比SiC和碳纤维的辐照稳定性更高。虽然辐照后C/C-ZrC-SiC复合材料中各相的辐照硬化程度较高,但是其整体的宏观力学性能较好,可满足核动力发动机热结构部件的服役要求。

表 3 辐照前后ZrC,SiC和碳纤维的纳米硬度和弹性模量

Table 3

| Nanohardness / GPa | Elastic modulus / GPa | |||

|---|---|---|---|---|

| Before irradiation | After irradiation | Before irradiation | After irradiation | |

| ZrC | 16.782 | 27.864 | 141.220 | 205.405 |

| SiC | 14.545 | 32.036 | 93.462 | 250.105 |

| Fiber | 2.844 | 5.524 | 15.536 | 34.878 |

3 结论

(1) 在室温下将强度为2 MeV、总通量为1.9×1016 ion/cm2的Si2+离子注入到C/C-ZrC-SiC复合材料,ZrC与SiC未发生明显的非晶化,但是辐照诱发的缺陷使晶格中产生应力。辐照后SiC晶面间距增大发生晶格膨胀,而ZrC保持完整的晶格结构其晶格膨胀率小于SiC。辐照诱导的碳缺陷使石墨层面间距及半高宽增大。

(2) 辐照后SiC结晶度降低而生成非晶态SiC团簇。辐照诱导ZrC晶粒产生的碳空位破坏了ZrC对称的晶体结构。辐照诱导Si-C键与Zr-C键断裂,碳原子结合形成C-C键。辐照后碳纤维中碳相的ID/IG值增大,表明辐照后碳纤维中缺陷增多。

(3) 辐照后ZrC晶粒中出现许多点缺陷和点缺陷的团簇,SiC晶粒出现部分非晶化,碳纤维及热解碳基质断裂、扭曲,晶格受到损伤。

(4) 辐照后ZrC,SiC及碳纤维的纳米硬度及弹性模量大幅增加,是辐照诱导点缺陷及点缺陷团簇对位错的钉扎所致。ZrC的微观力学性能变化最小,表明ZrC具有更高的辐照力学稳定性。

参考文献

Microstructure and ablation behaviors of a novel gradient C/C-ZrC-SiC composite fabricated by an improved reactive melt infiltration

[J].

Effect of CNTs addition on microstructure, ablation property and mechanism of ZrC-SiC coating for C/C-ZrC-SiC composites

[J].

Effect of the Al2O3 additive on the high temperature ablation behavior of the ZrC-ZrO2 coating for SiC-coated carbon/carbon composites

[J].

Interfacial modification and cyclic ablation behaviors of a SiC/ZrB2-SiC/SiC triple-layer coating for C/SiC composites at above 2000℃

[J].

Microstructure and mechanical properties of C/C-ZrC-SiC composites fabricated by reactive melt infiltration with Zr, Si mixed powders

[J].

Ablation behavior of C/C-ZrC-SiC composites prepared by reactive melt infiltration under oxyacetylene torch at two heat fluxes

[J].

Mechanism of ablation of 3D C/ZrC-SiC composite under an oxyacetylene flame

[J].

Evolution of amorphization and nanohardness in SiC under Xe ion irradiation

[J].

Formation of nano-twinned 3C-SiC grains in Fe-implanted 6H-SiC after 1500℃ annealing

[J].

Neutron irradiation swelling of SiC and SiCf/SiC for advanced nuclear applications

[J].

Measurement of swelling-induced residual stress in ion implanted SiC, and its effect on micromechanical properties

[J].

Raman study of amorphization in nanocrystalline 3C-SiC irradiated with C+ and He+ ions

[J].

Swelling of ion-irradiated 3C-SiC characterized by synchrotron radiation based XRD and TEM

[J].

Raman investigation of ion irradiated TiC and ZrC

[J].Single crystals of transition metal carbides from group IV, TiC1-x and ZrC1-x, have been irradiated at room temperature (RT) with 1.2 MeV gold ions for various fluences in the range 2 x 10(14)-3 x 10(16) ions/cm(2) and polycrystals for fluences between 2 x 10(13) and 4 x 10(15) ions/cm(2). The irradiated samples were characterized by micro Raman spectroscopy. For this purpose, the evolution of main parameters of Raman spectra for both types of samples (band positions, shifts, and intensities, and optical over acoustical band area ratios) versus ion fluence are reported, and discussed. All acoustic and optical bands increase and broaden with fluence. Yet no amorphization is achieved under the highest fluence for both carbides. From the lowest fluence up to 10(15) ions/cm(2), point defects like interstitials and vacancies are created. The increasing number of carbon vacancies involves a local variation in stoichiometry accompanied by carbon release. For fluence above 10(15) ions/cm(2), extended defects like dislocation loops appear, as seen by TEM observations.

The irradiation response of ZrC ceramics under 10 MeV Au3+ ion irradiation at 800℃

[J].

Microstructure evolution of nonstoichiometric ZrC0.6 with ordered carbon vacancies under ion irradiation

[J].

Irradiation effects of fiber and matrix induced by He+ ion for high-performance C/C composites

[J].

Effects of ion irradiation on the hardness properties of graphites and C/C composites by indentation tests

[J].

Heavy-ion irradiation defect accumulation in ZrN characterized by TEM, GIXRD, nanoindentation, and helium desorption

[J].

Effect of propane/silane ratio on the growth of 3C-SiC thin films on Si(100) substrates by APCVD

[J].

Structural evolution in ZrC-SiC composite irradiated by 4 MeV Au ions

[J].

Early stage oxidation of ZrC under 10 MeV Au3+ ion-irradiation at 800℃

[J].

Microstructure damage in silicon carbide fiber induced by 246.8 MeV Ar-ion irradiation

[J].

Microstructure evolution in ZrCx with different stoichiometries irradiated by four MeV Au ions

[J].ZrCx ceramics with different stoichiometries were irradiated under a four MeV Au ion beam in doses of 2 × 1016 ions/cm2 at room temperature, corresponding to ~130 dpa. Grazing incidence, X-ray diffraction and transmission electron microscopy were performed to study the radiation damage and microstructure evolution in ZrCx ceramics. With the decrease in C/Zr ratio, the expansion of ZrCx lattice became smaller after irradiation. Some long dislocation lines formed at the near-surface, while, in the area with the greatest damage (depth of ~400 nm), large amounts of dislocation loops formed in ZrC, ZrC0.9 and ZrC0.8. With the increase in carbon vacancy concentration, the size of the dislocation loops gradually decreased. Few dislocation loops were found in ZrC0.7 after irradiation, and only black-dot defects were found in the area with the greatest damage. For the non-stoichiometric ZrCx, with the increase of the intrinsic vacancies, the number of C interstitials caused by irradiation decreased, and the recombination barrier of C Frenkel pairs reduced. The above factors will reduce the total number of C interstitials after cascade cooling, suppressing the formation and growth of dislocation loops, which is significant for the enhancement of the tolerance of radiation damage.

Effects of ion irradiation on chromium coatings of various thicknesses on a zirconium alloy

[J].

Amorphization driven by defect-induced mechanical instability

[J].

Transition from irradiation-induced amorphization to crystallization in nanocrystalline silicon carbide

[J].

Irradiation damage in (Zr0.25Ta0.25-Nb0.25Ti0.25)C high-entropy carbide ceramics

[J].

Radiation effects in graphite and carbon-based materials

[J].