研究表明,在热处理过程中β稳定元素(如Mo、V、Cr等)向β相中扩散,而α稳定元素Al则向α相中扩散[12~14],是钛合金中典型的元素再分配行为。固相中原子扩散的速率较低且不同元素的原子在不同相中扩散的速率也显著不同,热处理过程中元素的再分配会在α与β两相界面处产生元素的浓度梯度。Huang等[13]的研究表明,在升温过程中,α+β钛合金(Ti-6Al-4V)的中Al元素向α相内聚集并在靠近α与β界面处富集。亚稳β钛合金的单相区热处理生成较为粗大的原始β晶粒,有助于提高合金的韧性。在随后的冷却过程中β相转变为α相,相变过程必然伴随元素再分配并对β相基体中元素浓度、β相稳定性及后续时效过程中的显微组织演变产生重要的影响。因此应该对该过程进行系统研究,为深度优化高强钛合金的力学性能奠定显微组织调控基础。

β相的稳定性取决于β稳定元素的浓度,稳定性不同的β相在热处理过程中分解而生成ω、α''和α'等多种析出相[15]。上述相变,显著影响在后续的热处理过程中发生的组织演变。本文用电子探针显微分析技术(Electron probe microanalysis, EPMA)表征热处理过程中β与αGB界面附近的元素分布,研究元素再分配及其引起的元素浓度梯度对β基体稳定性和相变的影响,以及Ti-5553-0.6Fe合金的组织演变与元素再分配行为的内在联系。

1 实验方法

实验用亚稳β合金的名义成分为Ti-5Al-5Mo-5V-3Cr-0.6Fe(Ti-5553-0.6Fe)。该合金铸锭经三次真空自耗熔炼制备而成,随后经多次单相区赫和两相区锻造,制备出直径为55 mm的棒材。合金的化学成分列于表1。用金相法测出β转变温度为810 ± 5℃。为了研究不同热处理过程中合金的组织演变与元素再分配行为,设计了如下的固溶和时效热处理制度:先对实验样品进行两阶段固溶,在单相区830℃固溶1 h后缓慢炉冷至两相区750℃固溶1 h,然后水冷至室温(ST-830~750),炉冷的冷却速率约为1℃/min。再对固溶样品在350℃进行低温时效10 h,然后空冷至室温(AT-350)。对低温时效后样品在560℃终时效4 h,然后空冷至室温(AT-560)。具体的实验参数列于表2。在两阶段固溶过程中合金在单相区形成的β相随炉冷却并转变为α相,冷速较低可促进元素扩散以便于表征和研究合金元素的再分配行为。

表1 实验用Ti-5553-0.6Fe合金的化学成分

Table 1

| Elements | Al | Mo | V | Cr | Fe | Si |

|---|---|---|---|---|---|---|

| Ti-5553-0.6Fe | 5.09 | 5.23 | 4.90 | 2.78 | 0.51 | 0.01 |

表2 实验用Ti-5553-0.6Fe合金的热处理工艺参数

Table 2

| Designation | Heat-treatment parameters |

|---|---|

| ST-830~750 | 830℃/1 h furnace-cooled (1℃/min) to 750℃/1 h—W.Q. |

| AT-350 | 350℃/10 h—A.C. |

| AT-350+560 | 350℃/10 h—A.C. and 560℃/4 h—A.C. |

分别用TESCAN MIRA3扫描电子显微镜(Scanning electron microscope, SEM)和FEI TENCNAI F-30透射电子显微镜(Transmission electron microscope, TEM)表征微观结构,用EPMA(JEOL JXA-8530F)表征不同热处理阶段的元素分布。对SEM和EPMA检测样品进行机械研磨和抛光,用1%氢氟酸、1%硝酸和水溶液化学腐蚀。用双喷电解装置制备TEM检测样品,电解液为35%正丁醇、5%高氯酸和60%甲醇的溶液。使用耐驰STA 449 F5同步热分析仪,采用差示扫描量热法(Differential scanning calorimetry, DSC)测量样品在升温过程中的热量变化以确认固相转变,升温速率为20℃/min。

2 结果和讨论

2.1 热处理过程中组织的演变

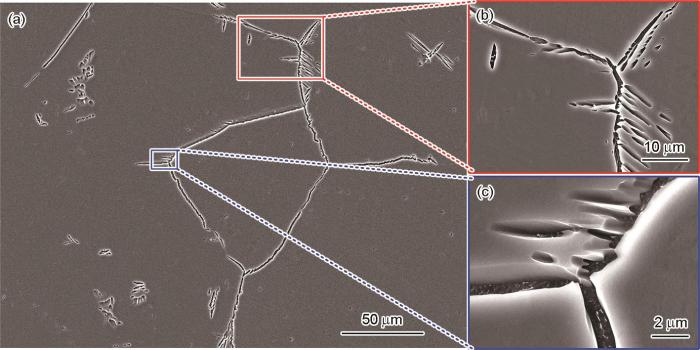

图1给出了经单相区(830℃)固溶1 h水冷至室温后Ti-5553-0.6Fe合金的金相组织。从图1中仅观察到等轴β晶粒,晶界连续且平直。图2给出了经ST-830~750固溶处理后合金的SEM显微组织。可观察到晶粒内部少量的αp,在部分晶界附近有不连续析出的αp(图2b);连续的αGB显著粗化且略有曲折,晶界的宽度约为1 μm(图2c)。在ST-830~750固溶条件下,合金先在830℃固溶后生成了连续且平直的晶界,合金中只有β相。在后续的炉冷过程中晶内αp以近似均匀的方式形核并长大,而晶界处的α相则以晶界为形核的基底,以非均匀的方式形核长大。非均匀形核所需的能量远小于均匀形核所需的能量,因此α相优先在晶界析出生成αGB;随着固溶温度的降低和时间的延长αGB界面向晶粒内部迁移而使αGB粗化[16]。炉冷的冷却速率约为1℃/min,较小的冷却速率导致较小的过冷度,因此晶内αp的形核率较低,之生成了少量的αp。在界面迁移过程中合金元素原子在界面相互扩散,而不同合金元素原子的扩散速率不同,使溶质原子在界面前沿分布不均匀而产生局部成分突变,进而生成不连续沉淀的α相,也影响晶界局部界面的迁移速度而生成锯齿状αGB(图2b)。

图1

图1

经单相区固溶后Ti-5553-0.6Fe合金的金相组织

Fig.1

Metallographic structure of the Ti-5553-0.6Fe alloy after solution treatment in β field

图2

图2

Ti-5553-0.6Fe合金固溶条件下的SEM显微形貌

Fig.2

SEM morphologies of Ti-5553-0.6Fe alloy under the condition of ST-830-750 (a), while two local magnifications were shown in (b) and (c)

图3给出了经350℃低温时效10 h后ST-830~750固溶样品的SEM和TEM形貌。在AT-350低温时效样品晶界附近约2 μm处可观察到无析出区(Precipitation free zone),而在远离晶界处的β相中可观察到颗粒状析出相(图3b)。用TEM技术分析了样品的组织,以确定β基体中的析出相。在远离晶界的明场相中观察到细小的黑色片层状αs分布在β基体中(图3c),在αs周围出现灰色絮状析出物。图3d与3e给出了[110] β 与[113] β 晶带轴方向的衍射斑点。在1/3{112} β >与2/3{112} β 处可观察到ω相衍射斑点,在1/2{112} β 处可观察到αs的衍射斑点。对图3e中红圈标记的衍射斑点进行暗场成像,如图3f所示,可观察到在基体中大量的絮状ω相。

图3

图3

低温时效Ti-5553-0.6Fe合金的SEM和TEM显微形貌

Fig.3

SEM and TEM morphologies of Ti-5553-0.6Fe alloy after low temperature aging (a) and (b) SEM microstructures of ST-830~750, (c) bright field image of α away from αGB, (d) and (e) diffraction patterns of [110] β and [113] β zone axis in (c), (f) dark field image selecting reflections in red circles in (e)

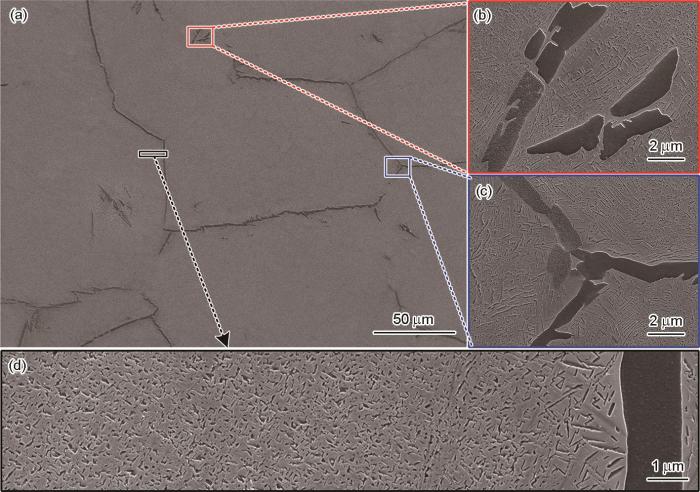

图4

图4

终时效后Ti-5553-0.6Fe合金的SEM显微形貌

Fig.4

SEM morphologies of Ti-5553-0.6Fe alloy after final aging (ST-830~750+AT-350+560) (a), while three local magnifications are shown in (b, c) and (d)

ω相可作为αs析出的异质形核点,使αs在β基体中的形核率提高,促进αs的析出并使αs片层细化[7]。经AT-350后在合金中的αGB附近形成了无析出区,其中没有ω相和αs相析出。而在远离αp和αGB的基体中则析出了大量的ω与αs片层,多数αs在絮状ω相附近析出。在终时效过程中大量的αs在ω相的辅助下形核析出并长大,生成了尺寸较小和长宽比都较小的近颗粒状αs。与之相比,在αp和αGB附近的无析出区内没有ω相辅助形核的αs其尺寸较大,呈片层状。

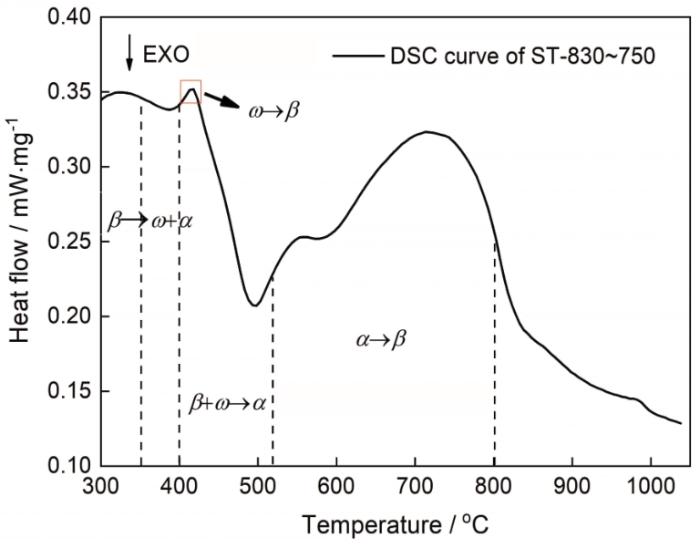

如上所述,在固溶、低温时效及终时效热处理过程中合金发生了多种相变。为了确认不同热处理各阶段的相变,对ST-830~750固溶样品进行DSC热分析,升温速率为20℃/min,其DSC热量变化曲线如图5所示。在350~400℃区间内发生了吸热的β→ω+α相变;红框中的吸热峰表示ω相转变为β相,随着温度的升高ω相逐渐不稳定并溶解而转变为β相;在400~520℃区间内发生β+ω→α相变,α相在ω的辅助下大量形核析出,而ω相消失;在520~800℃区间内发生α→β相变,随着温度的继续升高α相比例逐渐降低,先是不稳定的α相转变为β相,对应较小的吸热峰,随后大量的α相溶解转变为β相,直至在约805℃全部α相转变为β相。热分析实验结果与热处理过程中组织形貌的表征结果一致。

图5

图5

Ti-5553-0.6Fe固溶样品在持续升温过程中的DSC曲线

Fig.5

DSC curve of solution treated sample of Ti-5553-0.6Fe during continuous heating

2.2 组织演变与元素再分配

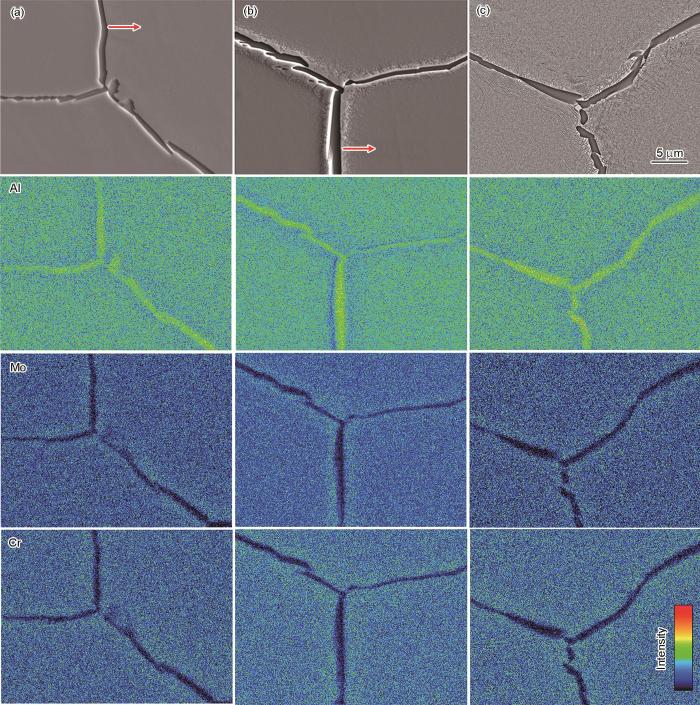

钛合金中α与β两相间的转变与合金中元素的再分配有密切的关系。固溶热处理过程后ST-830~750中只有少量的α相,因此本文的研究对象是β相。图6给出了分别经固溶、低温时效与终时效后合金中晶界附近元素的分布。可以看出,在三种热处理阶段元素的分布情况相似,αGB内α的稳定元素Al富集,β的稳定元素贫瘠,即Mo元素与Cr元素贫瘠(V元素分布情况与Mo、Cr元素相同),而β相中元素的分布情况与之相反。还观察到,在α与β界面附近约2 μm范围内出现元素分布的浓度梯度,与晶内元素的分布情况相比此处Al元素的含量较低而Mo和Cr元素的含量较高。精确测定αGB附近5 μm范围内不同位置元素的浓度,发现终时效后β基体中析出的大量α片层影响测量结果。对固溶和低温时效后样品中晶界附近元素的浓度进行精确测量(沿图6中红色箭头方向),结果在图7中给出。可以看出,ST-830~750样品中随着与αGB距离的增加Mo、V和Cr元素的含量逐渐降低,而Al元素的含量逐渐提高,浓度梯度的范围约为1.5 μm;而AT-350样品中浓度梯度较大,其范围增大到约2.5 μm。这表明,在低温时效过程中依然缓慢地发生了元素再分配。同时,对比不同合金元素的浓度梯度变化,发现扩散速率较低的Mo元素的浓度梯度大于其他合金元素,可见元素再分配与原子的扩散速率密切相关。

图6

图6

经不同热处理后Ti-5553-0.6Fe合金中元素的分布

Fig.6

Microstructures and corresponding elements distribution of Ti-5553-0.6Fe under different heat-treatments (a) ST-830-750, (b) AT-350, (c) AT-350+560

图7

图7

在固溶和低温时效条件下Ti-5553-0.6Fe合金αGB附近沿图6中箭头方向元素浓度的变化

Fig.7

Variations of quantitative elements composition near αGB along the direction as shown by the red arrows in Fig.6 (a) ST-830-750, (b) AT-350

在钛合金的升温过程中发生α→β相变,Huang等研究了相变过程中元素的再分配行为,结果表明,随着温度的升高α相的边缘溶解,Al元素向α相扩散,而V元素向β相扩散。Al与V元素在α与β两相中扩散系数的差异而使Al元素富集,但是V元素的富集不明显[13]。在钛合金的冷却过程中为了达到相平衡合金发生了β→α相变,导致αGB的粗化,即α与β相的界面逐渐向β基体内迁移。元素再分配效应的影响和相变驱动力的作用,使Al元素从附近的β基体中向α相内扩散,而β稳定元素则向附近的β相中扩散。由于原子扩散距离只有几微米,与晶粒内部β基体相比晶界附近Al元素的含量较低而β稳定元素的含量较高,并随着扩散的进行产生了浓度梯度。

ST-830~750样品中αGB附近的β稳定元素含量较高,而Al元素含量较低(图6a),此处β基体的稳定性较高,而晶粒内部β基体的稳定性较低。在低温时效(AT-350)过程中晶粒内部析出细小ω相和α相(图3c~e),而晶界附近由于β基体的稳定性较高而形成无析出区(图3b)。随着低温时效时间的延长元素再分配的持续进行使浓度梯度更显著(图6b),进一步提高了αGB附近的β基体稳定性。终时效(ST-350+560)后在ω与α的共同作用下晶粒内部生成了尺寸较小的αs。在终时效过程中ω相的辅助促进了αs的形核,而低温时效析出的细小α相阻碍αs的长大[17],在两者的共同作用下生成了细小的αs。而在无析出区,由于时效温度升高到560℃,晶界附近无析出区的β基体变得不稳定,αs直接从β基体中析出,且此处β基体稳定性较高αs形核率较低,使αs片层尺寸较大而数量较少,导致αGB附近与晶粒内部αs形貌较大的差异(图4d)。在钛合金的热处理过程中发生相变伴随着元素再分配,元素再分配影响β相的稳定性,进而影响相变和组织演变。

3 结论

(1) 对高强亚稳Ti-5553-0.6Fe钛合金进行两阶段固溶热处理后,合金中生成了连续粗大的αGB和少量的晶内αp;在低温时效过程中远离晶界的β基体析出ω相和αs,而在αGB附近形成无析出区;终时效后大量αs从β基体中析出,αGB附近的αs片层尺寸较大,晶内的αs片层尺寸较小。

(2) 受到元素再分配效应的影响,高强亚稳Ti-5553-0.6Fe钛合金中αGB附近约2 μm范围内β基体中出现明显的浓度梯度,此处Al元素的含量较低而β稳定元素的含量较高,即β基体的稳定性较高。在低温时效过程中该处的ω相析出受到抑制并形成无析出区,在终时效过程中没有ω相辅助形核并细化αs,使αGB附近αs片层的尺寸比晶内αs片层的尺寸大。

(3) 在低温时效过程中析出的絮状ω相作为高温时效中αs的异质形核点而使αs的形核率提高,从而使αs片层显著细化。

参考文献

A comparative study of the mechanical properties of high-strength β-titanium alloys

[J].

Comprehensive review on alloy design, processing, and performance of β titanium alloys as biomedical materials

[J].

A Review on high-strength titanium alloys: microstructure, strengthening, and properties

[J].

Room temperature creep behavior of Ti-6Al-4V alloy

[J].The room temperature creep behavior of Ti-6Al-4V alloy and its effect on subsequent mechanical properties were investigated. The results show that all these factors, such as macro-texture, creep stress level and pre-plastic-strain, have a significant impact on the room temperature creep behavior of Ti-6Al-4V. With the increase of the <0001> peak pole density along the loading direction, the work hardening exponent increases, and the creep exponent becomes smaller, resulting in the better room temperature creep property of Ti-6Al-4V. Enough high stress is the prerequisite for room temperature creep. The obvious room temperature creep behavior can be observed only when the creep stress is not lower than 0.85σy, and the room temperature strain increases with the creep stress level. Pre-plastic-strain can suppress the subsequent room temperature creep of Ti-6Al-4V, no matter the pre-plastic-strain comes from the monotonic loading or from the creep behavior. The pre-plastic-strain can deteriorate the fatigue property of the alloy, although it can reduce subsequent creep strain.

Ti-6Al-4V合金的室温蠕变行为

[J].研究了Ti-6Al-4V钛合金板材的室温蠕变行为及其对合金后续使用性能的影响。结果表明:合金的宏观织构、应力水平以及预塑性应变都显著影响其室温蠕变行为。在加载方向上合金的<0001>峰值极密度越高,则其加工硬化指数越大、蠕变指数越小、室温蠕变性能越好。足够大的应力,是合金发生室温蠕变的必要条件。只有在蠕变应力不小于0.85σ<sub>y</sub>的条件下才能观察到较为明显的室温蠕变,且室温蠕变效应随着蠕变应力水平的增大而增大。在室温下无论是蠕变还是单调加载引起的塑性应变,都抑制合金的后续蠕变行为。预加的塑性应变虽然抑制合金的后续蠕变应变,却使合金的后续疲劳性能恶化。

Fatigue crack propagation behavior of ultrafine grained pure titanium

[J].Four kinds of ultrafine grained (UFG) pure titanium were obtained by two-pass equal channel angular pressing (ECAP) at room temperature, ECAP+rotary swaging (RS) and ECAP+RS followed by annealing at 300℃ and 400℃ for 1 h, respectively. The fatigue crack growth tests of different UFG pure titanium were carried out, while their microstructure, the fatigue fracture morphology and the crack growth behavior were investigated by TEM and SEM. Results show that the microstructure has a significant effect on the threshold of fatigue crack growth rate and the near threshold zone of UFG pure titanium. The threshold values of fatigue crack growth rate for UFG pure titanium increase with the increase of strain, and decrease with the increase of annealing temperature after RS. The turning point occurs in the fatigue crack growth rate curve, which is affected by grain size and strength of UFG pure titanium. Before the turning point, UFG pure titanium produced by ECAP+RS has stronger resistance to fatigue crack growth than that produced only by ECAP, and the resistance to fatigue crack growth of UFG pure titanium after ECAP+RS decreases with the increase of annealing temperature. After the turning point, the fatigue crack growth rates of four kinds of UFG pure titanium are slightly different and the opposite result is presented. The threshold value before the turning point and the growth rate of the near threshold zone may play much important role in enhancing the resistance to the crack growth because the growth life of the crack of the near threshold zone before the turning point accounts for a very large part of the fatigue crack growth life.

超细晶纯钛疲劳裂纹的扩展行为

[J].对纯钛进行2道次室温等径弯曲通道变形(ECAP)、等径弯曲通道变形加旋锻复合变形(ECAP+RS)并在旋锻后在300℃和400℃退火1 h,制备出4种具有不同组织的超细晶纯钛。对这4种超细晶纯钛进行疲劳裂纹扩展实验并观察分析超细晶纯钛的显微组织和疲劳断口的形貌,研究了裂纹的扩展行为。结果表明:显微组织对超细晶纯钛的疲劳裂纹扩展门槛值和近门槛区有显著的影响;超细晶纯钛的疲劳裂纹扩展门槛值随着塑性变形量的增大而增大,随着旋锻后退火温度的提高而降低;疲劳裂纹扩展速率曲线因超细晶纯钛晶粒尺寸和强度的影响出现转折,转折前ECAP+RS复合变形纯钛的抗疲劳裂纹扩展能力比ECAP变形强,且随着退火温度的提高而降低;转折后4种超细晶纯钛的疲劳裂纹扩展速率相差较小,呈现出相反的结果。疲劳裂纹扩展寿命中转折前近门槛区裂纹扩展寿命占绝大部分,因而转折前的门槛值与近门槛区的扩展速率对抗裂纹扩展能力更为重要。

Nucleation and growth mechanism of α-lamellae of Ti alloy TA15 cooling from an α+β phase field

[J].

The mechanism of ω-assisted α phase formation in near β-Ti alloys

[J].

Revisiting ω phase embrittlement in metastable β titanium alloys: Role of elemental partitioning

[J].

The ω phase transformation during the low temperature aging and low rate heating process of metastable β titanium alloys

[J].

ω-Assisted nucleation and growth of α precipitates in the Ti-5Al-5Mo-5V-3Cr-0.5Fe β titanium alloy

[J].

The indirect influence of the omega phase on the degree of refinement of distributions of the alpha phase in metastable beta titanium alloys

[J].

Clear evidence for element partitioning effects in a Ti-6Al-4V alloy by the first-principles phase field method

[J].

Influence of thermal treatment on element partitioning in α+β titanium alloy

[J].

A study of epitaxial growth behaviors of equiaxed alpha phase at different cooling rates in near alpha titanium alloy

[J].

Effects of β-stabilizer elements on microstructure formation and mechanical properties of titanium alloys

[J].

Gibbs free-energy difference between the undercooling liquid and the beta-phase of a Ti-Cr alloy

[J].