1 实验和模拟

1.1 实验用材料和模拟方法

表1 8Cr4Mo4V钢的化学成分

Table 1

| Element | C | Cr | Mo | V | Si | Mn | Fe |

|---|---|---|---|---|---|---|---|

| Content | 0.80 | 4.02 | 4.05 | 0.93 | 0.16 | 0.29 | Bal. |

表2 8Cr4Mo4V轴承钢的力学性能参数

Table 2

| Parameters | Elastic modulus, E / GPa | Poisson ratio, υ | Density, ρ / g·cm-3 |

|---|---|---|---|

| Value | 206 | 0.30 | 7.85 |

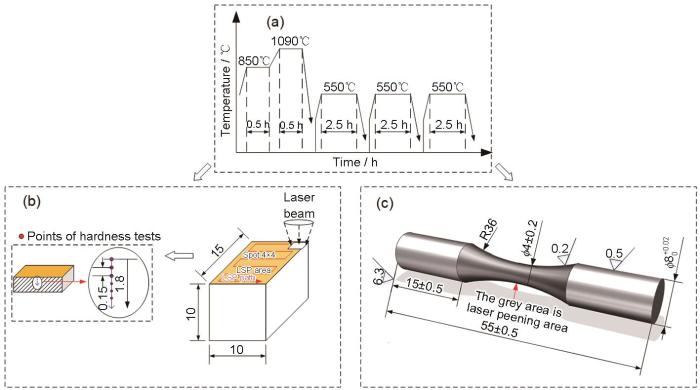

在进行激光冲击强化前对8Cr4Mo4V钢进行热处理,热处理工艺为:1090℃×30 min固溶,充入0.2 MPa氮气气淬,由1090℃冷却至200℃的冷却速率为95.65℃/min,冷却至60℃以下后冷却速率为3.75℃/min;再进行三次回火,回火工艺为550℃×2.5 h(图1a)。

图1

图1

热处理和LSP示意图

Fig.1

Schematic diagram of the heat treatment and subsequent LSP treatment (a) heat treatment; (b) hardness test and LSP treatment; (c) rotating bending fatigue test sample (unit: mm)

用维氏硬度计测量冲击面由表及里的硬度梯度(图1b),载荷为10 N,用截面硬度梯度表征冲击强化后试样的强化层深度。用扫描电镜观察经激光冲击强化后试样的微观组织和旋转弯曲疲劳断裂后试样的断口。使用的腐蚀液配比为:100 mL C2H5OH+2.5 g (NO2)3C6H2OH+5 mL HCl,腐蚀时间约30 s。用线切割从LSP处理表面切取厚度约为0.5 mm的试样,将激光冲击强化的表面粘结在工装上,然后用600#~2000#砂纸打磨线切割面以保证激光冲击强化表面为保留层,打磨后样品的厚度约为40 μm。用电解双喷仪(TenuPol-5) 将薄片试样减薄以获取高质量薄区,工作电压25 V,温度-20℃,电解液为10%HClO4+90%C2H5OH。用JEM2100型透射电镜(TEM)观察试样表面的微观组织。

将疲劳试样研磨抛光,以去除试样表面因激光冲击强化产生的损伤层。用X射线残余应力测试仪检测试样的表面残余应力。用QBWP-10000型旋转弯曲疲劳试验机检测旋转弯曲疲劳极限强度,转速为5000 r/min,试样发生疲劳断裂或转动周次达到1.0×107时停止运行,用扫描电镜观察试样的断口。

1.2 建立数学模型

1.2.1 激光冲击波峰值压力

图2

激光的功率密度为

式中E为激光能量(J);τ为脉宽(ns);S为光斑面积(cm2)。

在水约束层下冲击波的峰值压力P与激光功率密度I0的关系为

式中α为内能转化为热能部分的系数(常取0.1~0.3);Z为靶材和约束层的声折合阻抗,可表示为

式中Z1=1.6×106 g/(cm2∙s)为靶材声阻抗;Z2=0.165×106g/(cm2∙s)为约束层声阻抗。

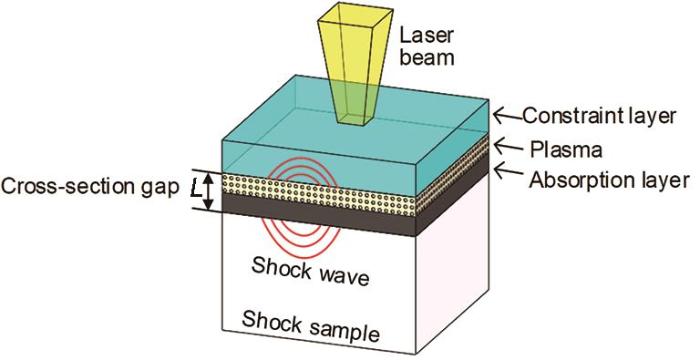

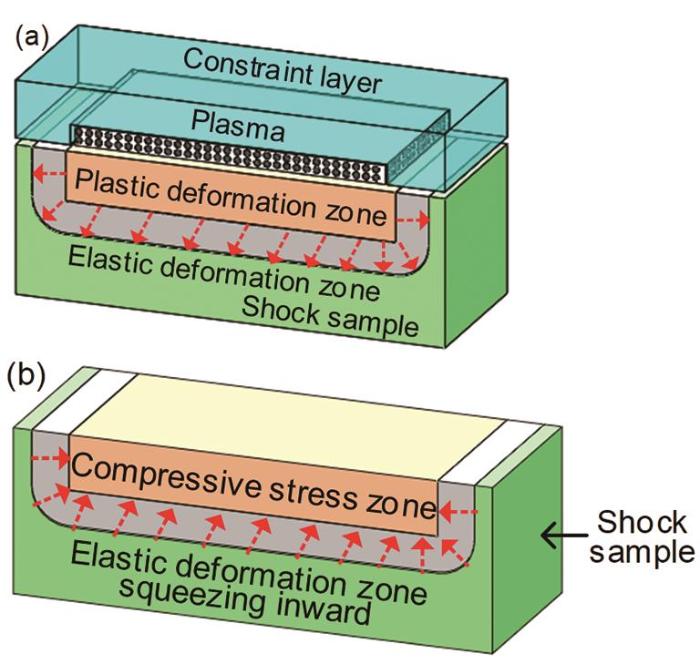

1.2.2 激光冲击强化残余应力的形成原理

在激光冲击作用下材料表面产生残余应力场的过程可分成两个阶段:第一阶段为应力加载过程(图3a)。冲击波作用于靶材表面时光斑中心使材料发生塑性变形,光斑内的能量呈高斯分布,处于光斑边缘的应力波压力小于材料的屈服极限,使材料产生弹性变形;在深度方向上由表面至内,随着应力波的衰减表层较浅的部分产生塑性变形,而深层部分产生弹性变形。第二阶段为应力卸载阶段。应力波的作用完成后,冲击面中心和表层较浅的材料发生塑性变形,不能恢复到原来的形态;而处于冲击光斑边缘和次表层的材料发生弹性变形,应力波卸载后有恢复至原来状态的趋势。因此,冲击光斑边缘的材料挤压中心处的材料 (图3b),产生一个与中心区材料变形方向相反的压力,即产生了一个残余压应力场。

图3

图3

残余应力场形成过程的示意图

Fig.3

Schematic diagram of the formation process of residual stress field (a) loading process; (b) unloading process

当作用在金属材料表面的激光功率密度大于1 GW/cm2时,在激光冲击强化过程中形成近似平面的冲击波,其压力达到GPa量级,为了便于分析将产生的应变简化为一维应变。压力足够大的冲击波,使材料屈服而进入塑性变形阶段。在产生一维应变的冲击压力条件下,材料发生屈服时的正应力

称为Hugoniot弹性极限。式中λ=Eυ/(1+υ)(1-2υ)和μ=E/2(1+υ)为拉曼系数,υ为泊松比,σ0为表面初始应力(GPa);

由冲击波峰值压力P和材料Hugoniot弹性极限σHEL,可得激光冲击强化金属部件表面塑性变形量

当峰值压力P<σHEL时材料表面只产生弹性变形,P>σHEL时产生塑性变形,有部分弹性恢复。

在材料内传播的激光冲击波逐渐衰减,在材料内P<σHEL的深度不再发生塑性变形,此深度为材料的塑性变形深度,即残余压应力的影响层

式中Cel=

已知塑性应变εP 和残余压应力影响层深度LP,依据Fabbro模型[24]激光冲击强化引起的表面残余压应力为

式中

2 结果和分析

2.1 残余应力

式中A为屈服应力(MPa);B为应变硬化系数;n为应变硬化指数;C为应变速率系数;m为热软化系数;

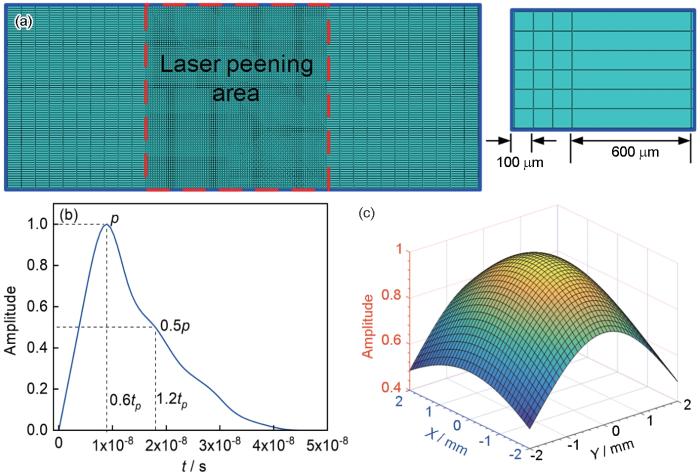

图4

图4

有限元模型和冲击波加载示意图

Fig.4

Finite element model and shock wave loading (a) mesh division of the finite element model; (b) relationship between shock wave pressure and time; (c) schematic diagram of the spatial distribution of shock wave pressure

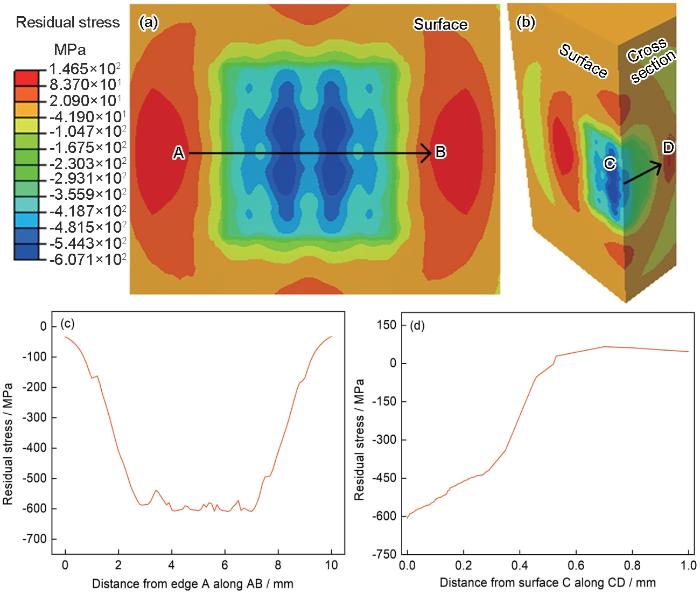

图5

图5

用有限元法计算残余应力的分布

Fig.5

LSP residual stress distribution calculated by finite element method (a) and (c) surface residual stress distribution; (b) and (d) cross sectional residual stress distribution

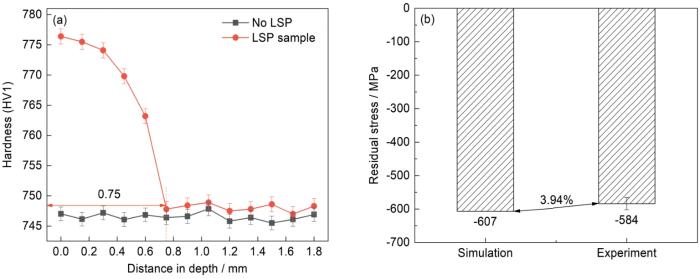

图6

图6

LSP前后8Cr4Mo4V钢的硬度和残余应力

Fig.6

Hardness and residual stress of 8Cr4Mo4V steel before and after LSP (a) hardness gradient before and after LSP; (b) simulation and experimental results of residual stress

2.2 微观组织

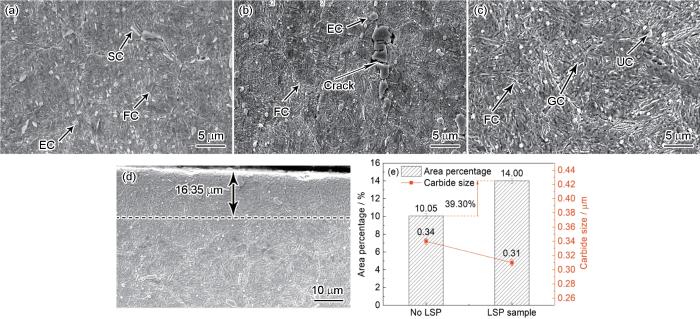

图7给出了激光冲击强化前后8Cr4Mo4V钢的微观组织和表面碳化物的统计。图7a给出了热处理后试样表面的微观组织,可见表面有共晶碳化物(EC)、短棒状碳化物(SC)和细丝状碳化物(FC)。激光冲击强化使表面的共晶碳化物碎化(图7b)。抛光去除由激光冲击强化导致的表面损伤层后,可见与原始组织(图7a)相比次表面的二次析出碳化物增多(图7c)。观察激光冲击强化后试样的纵截面,可见截面形成了由表及里约16.35 μm厚的致密组织层(图7d)。使用Image-Pro Plus软件统计图7a、c中碳化物的尺寸及其面积百分数,发现激光冲击强化后碳化物的面积比由10.05%增加到14.00%,碳化物的尺寸由0.34 μm减小到0.31 μm(图7e)。

图7

图7

LSP前后8Cr4Mo4V钢的显微组织SEM像和碳化物统计

Fig.7

SEM images of microstructure of 8Cr4Mo4V steel before (a) and after LSP (b~d) and carbide statistics (e)

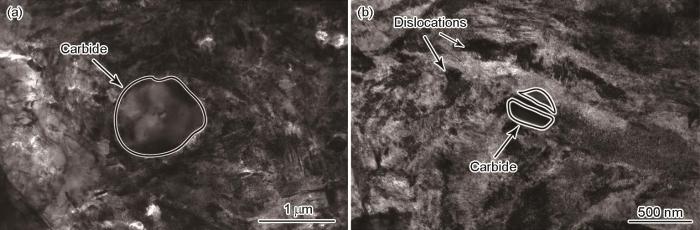

图8

图8

LSP前后8Cr4Mo4V钢的显微组织TEM像

Fig.8

TEM images of 8Cr4Mo4V steel before (a) and after (b) LSP

2.3 旋转弯曲疲劳性能

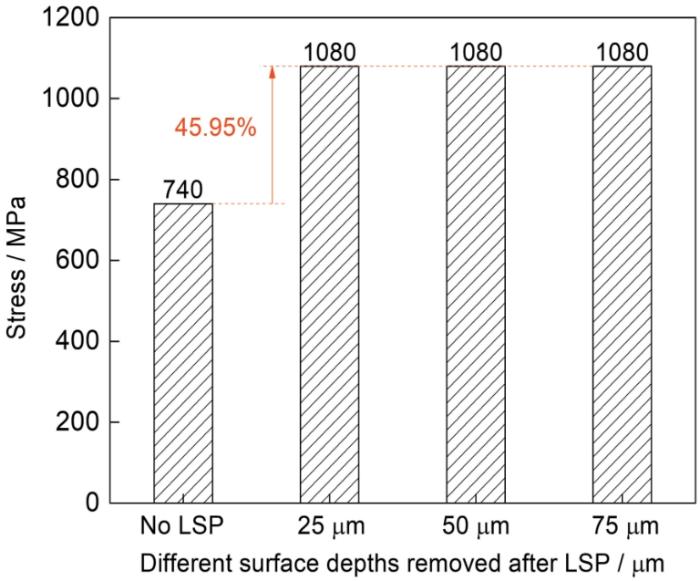

图9给出了未经激光冲击强化和激光冲击强化后去除不同表面损伤层深度时,8Cr4Mo4V钢旋转弯曲疲劳周次超过1.0×107未断裂的旋转弯曲疲劳强度。可以看出,未经激光冲击强化的8Cr4Mo4V钢旋转弯曲疲劳强度为740 MPa;经激光冲击强化并去除表面损伤层后的疲劳强度为1080 MPa,与未经激光冲击强化样品相比提高了340 MPa,提高幅度达到45.95%,表明激光冲击强化使8Cr4Mo4V轴承钢的疲劳强度显著提高。

图9

图9

未经激光冲击强化和经激光冲击强化且去除不同深度的表面损伤层8Cr4Mo4V钢的旋转弯曲疲劳强度

Fig.9

Rotating bending fatigue strength of 8Cr4Mo4V steel before LSP and after LSP with different thicknesses of damaged layers removed

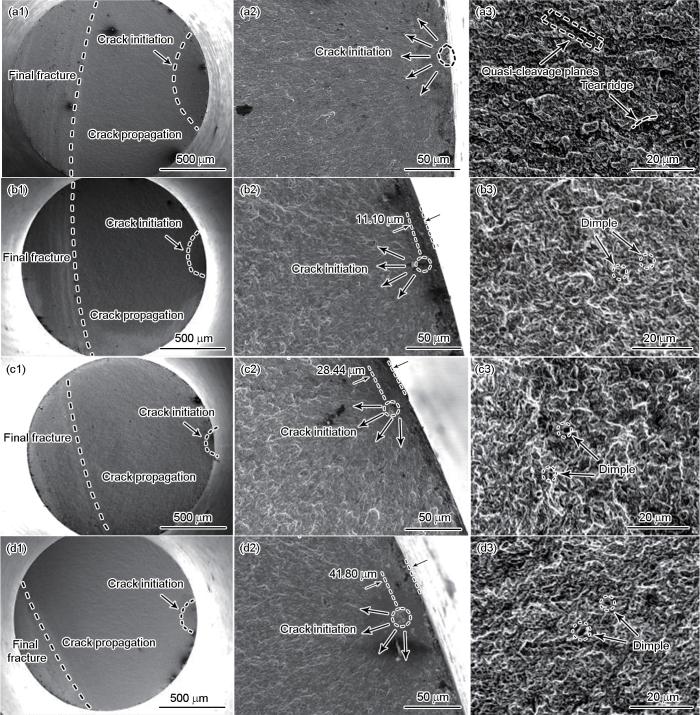

图10给出了未经激光冲击强化和经激光冲击强化且去除不同深度表面损伤层后8Cr4Mo4V钢旋转弯曲疲劳断口的形貌。由图10a1~d1可以看出,未经激光冲击强化处理的试样(图10a1)裂纹源区与瞬断区占的面积较大,而经激光冲击强化后裂纹源区与瞬断区的面积减小,且随着表面损伤层去除深度的增加裂纹源与瞬断区的面积减小(图b1~d1)。对断口的裂纹源区观察发现,未经激光冲击强化试样(图10a2)的疲劳裂纹起源于试样表面,经激光冲击强化后裂纹源转移到次表面。激光冲击强化后试样表面分别去除25、50和75 μm,发现疲劳裂纹源产生于次表层,距表面的距离分别为11.10 μm(图10b2)、28.44 μm(图10c2)、41.80 μm(图10d2),且随着表面损伤层去除深度的增加裂纹源距表面距离增大。观察裂纹扩展区的组织(图10a3~d3)可见,未经激光冲击强化试样其裂纹扩展路径较为分散,存在准解理小面和大量撕裂棱,属于脆性断裂(图10a3)。激光冲击强化后试样的裂纹扩展路径较为紧密,产生大量韧窝,具有较好的韧性,从而降低了裂纹扩展速率(图10b3~d3)。

图10

图10

未经激光冲击强化和经激光冲击强化且去除不同深度表面损伤层8Cr4Mo4V钢的旋转弯曲疲劳断口形貌

Fig.10

Rotating bending fatigue fracture morphology of 8Cr4Mo4V steel before LSP and after LSP with different thicknesses of damaged layers removed (a1~a3) without LSP; (b1~b3) surface removal of 25 μm after LSP; (c1~c3) surface removal of 50 μm after LSP; (d1~d3) surface removal of 75 μm after LSP; (a1~d1) macroscopic fracture morphology; (a2~d2) crack initiation zone; (a3~d3) crack propagation zone

3 讨论

3.1 LSP对微观组织的影响

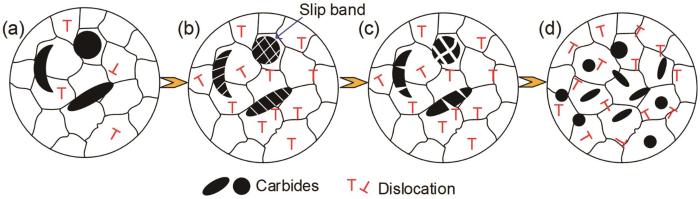

激光冲击强化不仅使表层的共晶碳化物碎化,还诱导了次表层二次碳化物析出(图7c)。图11给出了激光冲击强化8Cr4Mo4V钢表面碳化物的碎化和二次碳化物的析出过程。由图11a可见,激光冲击强化前试样表面有不同形状和大小的共晶碳化物。激光冲击强化产生的等离子体冲击波压力可达到GPa级别,其峰值压力高于材料的动态屈服强度。在冲击波的作用下产生位错(图8b),进一步滑移使8Cr4Mo4V钢表面发生塑性变形。碳化物是脆性相,应变和应变率的急剧增加使碳化物内部产生位错滑移带[27](图11b),而碳化物中的微裂纹在滑移带处萌生并沿滑移带扩展。激光冲击强化使微裂纹横穿碳化物最终使碳化物碎裂(图11c)。次表面二次碳化物析出是因为激光冲击强化时材料在超高应变率诱导的塑性变形过程中碳原子的扩散能力提高,促进了碳元素的长程扩散能力而使碳化物析出(图11d)。同时,激光冲击强化使表面产生的压应力和变形层中储存的高能量都有助于碳元素析出生成碳化物。

图11

图11

激光冲击强化使碳化物碎化和促进二次析出的示意图

Fig.11

Schematic diagram of LSP leading to carbide fragmentation and promoting secondary precipitation process of 8Cr4Mo4V steel in different states (a) no LSP; (b) formation of dislocation slip bands; (c) carbide fragmentation after LSP; (d) carbide precipitation on sub-surface after LSP

3.2 LSP对疲劳性能的影响

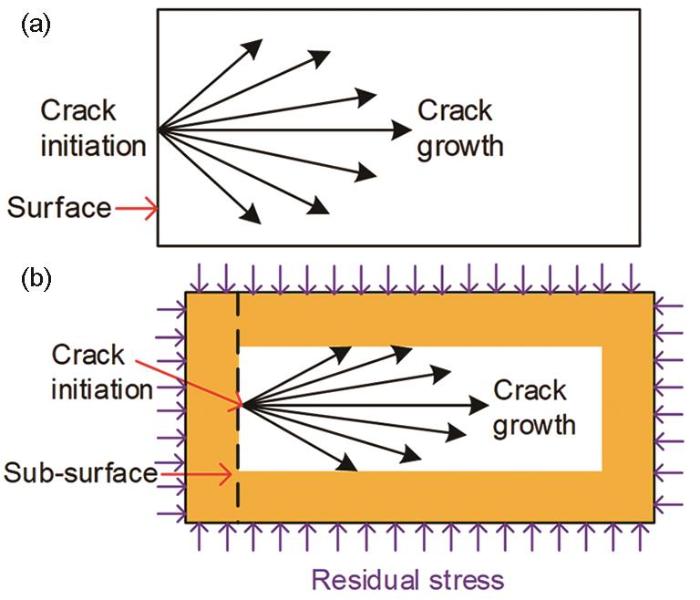

图12

图12

LSP前后8Cr4Mo4V钢在旋转弯曲疲劳过程中裂纹的萌生和扩展示意图

Fig.12

Schematic diagram of crack initiation and propagation in 8Cr4Mo4V steel before and after LSP during rotating bending fatigue process (a) no LSP; (b) after LSP

激光冲击强化在材料表层一定深度内产生了残余压应力较高的薄层。对图7和图8的分析表明,实测时最大残余压应力层位于次表层,因为激光冲击强化使表面产生碳化物碎化和脱落后形成尺寸较小的凹坑,这些表面缺陷使表面残余压应力得以释放。另一个原因是,激光冲击强化使材料表面产生较多的位错,位错运动使表面应力集中程度降低而使应力松弛[28]。较高的残余应力减缓了裂纹源的萌生并降低了裂纹的扩展速率,使材料的疲劳抗力和疲劳强度提高[29]。同时,表层较高的残余压应力使裂纹源区从表面转移到次表面,在相同的旋转弯曲疲劳实验条件下次表层萌生的裂纹受到的应力更小,也抑制了其进一步向材料内部扩展。激光冲击强化虽然使表层碳化物损伤,但是次表层二次析出了更多与基体紧密结合的细小碳化物,降低了应力集中水平。去除表面损伤层后,表面的压应力也有助于提高试样的疲劳性能。

4 结论

(1) 用有限元模拟激光冲击强化8Cr4Mo4V钢的表面残余压应力,其结果与实验检测数据相当(误差为3.94%)。数值模拟结果表明,激光冲击强化后残余应力随着距表层深度的增加而逐步减小,影响深度约为0.6 mm。激光冲击强化能提高8Cr4Mo4V钢的表面残余压应力。

(2) 激光冲击强化,使表层产生塑性变形和近表面的微观结构发生变化。等离子体爆炸冲击,引起表面碳化物碎化和促进次表面二次碳化物的析出。加工硬化和组织变化使钢的硬度由表及里呈梯度变化,形成了厚度约为0.75 mm的硬化层。

(3) 激光冲击强化使8Cr4Mo4V钢的表面残余压应力和表面硬度提高,抑制了疲劳裂纹的萌生并使裂纹源从表面转移至次表面,次表层析出更多的二次碳化物,降低了裂纹的扩展速率,使旋转弯曲疲劳强度从740 MPa提高到1080 MPa。

参考文献

Laser shock peening regulating aluminum alloy surface residual stresses for enhancing the mechanical properties: roles of shock number and energy

[J].

High-performance integrated additive manufacturing with laser shock peening-induced microstructural evolution and improvement in mechanical properties of Ti6Al4V alloy components

[J].

Enhanced high cycle fatigue resistance of Ti-17 titanium alloy after multiple laser peening without coating

[J].

Improving fatigue performance of titanium alloy simulated-blade subjected to foreign object damage by laser shock peening

[J].

激光冲击强化提高外物打伤钛合金模拟叶片高周疲劳性能

[J].

Numerical simulation and experimental verification on laser shock peening for turbine mortise

[J].

涡轮盘榫槽激光冲击强化数值模拟与试验验证

[J].

Continuous dynamic numerical analysis of residual stress field under multi-point laser shock peening

[J].

多点连续动态激光冲击强化残余应力场数值分析

[J].

Numerical simulation of residual stress field for laser shock processing

[J].

激光冲击强化残余应力场的数值仿真分析

[J].

Effects of scanning path and overlapping rate on residual stress of 316L stainless steel blade subjected to massive laser shock peening treatment with square spots

[J].

Effects of surface curvature on residual stress field of 316L stainless steel subjected to laser shock peening

[J].

The effect of surface curvature on surface residual stress field distribution of laser shock materials

[J].

表面曲率对激光冲击曲面材料表面残余应力场分布的影响

[J].

Effect of selective laser shock peening on vibration response of 2024 aluminum alloy blade

[J].

激光冲击选区强化对2024铝合金叶片振动响应特性的影响

[J].

Experimental study on influences of laser shock processing on fatigue performance of LZ50 axle steels

[J].

激光冲击强化对LZ50车轴钢疲劳性能影响试验研究

[J].

Effect of laser shock peening on combined low- and high-cycle fatigue life of casting and forging turbine blades

[J].

Thermal fatigue crack growth behavior of ZCuAl10Fe3Mn2 alloy strengthened by laser shock processing

[J].

The effect of laser shock peening on the microstructure and high-temperature mechanical properties of AZ31 alloy

[J].

Effects of multiple laser peening impacts on mechanical properties and microstructure evolution of 40CrNiMo steel

[J].

Study on enhancing fatigue life of SAE 9260 spring steel with surface defect through laser shock peening

[J].This paper presents an experimental study aimed at evaluating laser shock peening for suppressing deleterious effects of surface defects on the fatigue life of SAE 9260 spring steel specimens. The approach adopted for the study included introduction of standardized surface defects through micro-hardness indentation, peening of region in and around the surface defects with 3.5J/9 ns Nd:YAG laser and comparing the fatigue lives of unpeened and laser shock peened spring steel specimens with identical surface defects. Under the experimental test conditions, laser shock peening was found to be quite effective in enhancing fatigue life of spring steel specimens with surface defects by more than 25 times. The results of the study are important for enhancing life of the engineering components which develop surface defects during their storage (e.g., corrosion pit), handling (e.g., tool marks) or operation (e.g., erosion pit).

Surface integrity of TA19 notched simulated blades with laser shock peening and its effect on fatigue strength

[J].

Enhance fatigue resistance of nanocrystalline NiTi by laser shock peening

[J].

Application of design of experiments for laser shock peening process optimization

[J].

Effect of Austempering temperature on microstructure and mechanical properties of M50 bearing steel

[J].

Effect of graded solution treatments on microstructure and hardness of 8Cr4Mo4V steel

[J].The effect of graded solution treatments, i.e. a primary solution treatment at 1000~1060℃ and a secondary solution treatment at 1080~1100℃, on the microstructure and hardness of the 8Cr4Mo4V aviation bearing steel was assessed by means of SEM, TEM and hardness tester. The results show that with the increase of the primary solution temperature from 1000℃ to 1060℃ (the secondary solution treatment was set at 1080℃×10 min), the volume fraction of undissolved carbides in the steel decreased from 4.37% to 3.43%, but the grain growth was not obvious. However, with the increase of secondary solution temperature from 1080℃ to 1100°C (the primary solution treatment was set at 1060°C×30 min), the volume fraction of undissolved carbides gradually decreased from 3.51% to 2.84%, and the average grain size increased significantly. The tempered hardness of the steel can reach a high value when the primary solution temperature is low or the secondary solution temperature is high. In order to improve the hardness and prevent grain coarsening of the steel, the primary solution temperature within the range of 1020~1050℃ is suitable, and the secondary solution temperature is suitable within 1080~1090℃. After being solution treated according to the specifications of 1020℃×20 min+1090℃×10 min, the average grain size of the steel is 12.1 μm, the tempered hardness is 63.8 HRC, the impact absorption energy is 15.28 J, and the tensile strength of the steel is 2664.3 MPa.

分级固溶处理对8Cr4Mo4V钢的微观组织和硬度的影响

[J].对8Cr4Mo4V航空轴承钢进行分级固溶处理,即在1000~1060℃的初级固溶处理和在1080~1100℃的二级固溶处理,并观察和测试其组织和硬度,研究了分级固溶温度的影响。结果表明,随着初级固溶温度的提高(二级固溶处理为1080℃×10 min),钢中未溶碳化物的体积分数从4.37%逐渐降低到3.43%,但是晶粒没有明显长大。随着二级固溶温度的提高(初级固溶处理为1060℃×30 min),未溶碳化物的体积分数从3.51%逐渐降低到2.84%,平均晶粒尺寸显著增大。当初级固溶温度较低或二级固溶温度较高时,8Cr4Mo4V钢的回火硬度较高。为了使8Cr4Mo4V钢具有高硬度同时避免晶粒粗化,初级固溶温度宜为1020~1050℃,二级固溶温度宜为1080~1090℃。对这种钢进行1020℃×20 min+1090℃×10 min固溶处理后,其平均晶粒尺寸为12.1 μm,回火硬度为63.8 HRC,冲击吸收功为15.28 J,室温抗拉强度为2664.3 MPa。

Effect of vacuum graded quenching on microstructure and mechanical properties of 8Cr4Mo4V steel

[J].The 8Cr4Mo4V steel for aviation bearing manufacturing was subjected to graded quenching at different temperatures after being vacuum heat-treated. The effect of vacuum graded quenching on microstructure and mechanical properties of 8Cr4Mo4V steel were investigated by scanning electron microscope, XRD, Rockwell hardness tester, impact tester and rotational bending fatigue tester. Results show that the graded quenching 8Cr4Mo4V steel presents a microstructure of lower bainite, martensite/retained austenite and carbides. With the increase of graded quenching temperature, the number of precipitated carbides in the quenched and tempered steel increases, while the amount of retained austenite decreases. When the graded quenching temperature is 580℃, the bainite volume fraction of the quenched steel reaches a maximum of 13.87%, and the residual austenite volume fraction is 28.59%, and then after tempering, the precipitated carbides volume fraction and the Rockwell hardness reach the maximum namely 4.37% and 62.38 HRC respectively, in comparison to other desired graded quenching temperatures. The vacuum graded quenching can improve the comprehensive mechanical properties of 8Cr4Mo4V steel. In other word, the 580℃×10 min vacuum graded quenching treated 8Cr4Mo4V steel presents impact toughness and fatigue limit of rotational bending 23.3% and 110 MPa respectively higher than those of the traditional vacuum quenching treated ones.

真空分级淬火对8Cr4Mo4V钢组织和性能的影响

[J].在真空条件下对航空轴承用8Cr4Mo4V钢进行不同温度的分级淬火并采用扫描电镜观察其微观组织、用XRD谱进行相分析并测试洛氏硬度、冲击性能和旋转弯曲疲劳性能,研究了真空分级淬火对其微观组织和力学性能的影响。结果表明,真空分级淬火后的8Cr4Mo4V钢其微观组织由下贝氏体、马氏体/残余奥氏体和碳化物组成;随着分级淬火温度的提高,淬火和回火态钢中析出碳化物的数量增加,残余奥氏体的含量降低。分级淬火温度为580℃时淬火态钢中贝氏体的含量最高(达到13.87%),残余奥氏体的含量为28.59%。回火后析出碳化物的含量和洛氏硬度均为所有分级温度中的最大值,分别为4.37%和62.38HRC。真空分级淬火能提高8Cr4Mo4V钢的综合力学性能。与未分级真空淬火相比,进行580℃×10 min真空分级淬火的8Cr4Mo4V钢的冲击韧性提高了23.3%,旋转弯曲疲劳极限提高了110 MPa。

Physical study of laser-produced plasma in confined geometry

[J].We study in this paper the different physical processes involved in laser-produced plasma in confined geometry. With this technique, a laser irradiates a target at an intensity of a few GW/cm2, and the produced plasma is confined by a transparent overlay to the laser which covers this target. This configuration has appeared necessary for example for metallurgical applications where, for a given laser energy, enhanced pressures must be realized in order to achieve high shock pressures. Therefore, a physical study of this method is useful in order to optimize this technique. We have first developed an analytical model which describes the different steps involved in this process, points out the interest of this technique, and compares it to the direct ablation regime. In the first stage, during the laser heating, the generated pressure is typically 4–10 times greater than the corresponding one obtained in direct ablation. The second step begins after the switch-off of the laser and is characterized by an adiabatic cooling of the plasma which maintains the applied pressure over a period which is about 2 times the laser-pulse duration. Finally, the third stage concerns also the adiabatic cooling of the recombined plasma, but during this period the exerted pressure is too small to realize a plastic deformation of the material.

Investigation on finite element meshes in numerical analysis of gear laser shock processing

[J].

齿轮激光冲击强化数值模拟中有限元网格划分的研究

[J].

Simulation of residual stress induced by a laser peening process through inverse optimization of material models

[J].

Carbide-facilitated nanocrystallization of martensitic laths and carbide deformation in AISI 420 stainless steel during laser shock peening

[J].

Effect of laser shock processing on microstructure and tribological behavior of GCr15 bearing steel

[J].

激光冲击强化对GCr15轴承钢微观组织和摩擦学行为的影响

[J].

Effect of laser shock peening on residual stress and mechanical properties of TA15 titanium alloy

[J].

激光冲击强化对TA15钛合金残余应力和力学性能的影响

[J].通过对TA15钛合金进行激光冲击强化,研究了不同工艺参数对TA15钛合金残余应力和力学性能的影响。实验结果表明,激光冲击强化可以细化晶粒尺寸,有效提高材料表面显微硬度和残余压应力,且表面显微硬度和残余压应力随着激光能量和冲击次数的增加而增大。当激光能量为7 J,光斑直径为Φ2 mm,冲击3次时,激光冲击强化后表面显微硬度提高21.6%,强化层深度可达1 mm,表面残余压应力高达-730 MPa。激光冲击强化后经400℃热处理并保温5和10 h后,发现引入的残余压应力降低幅度较小,仅为8%,具有较高的热稳定性。当激光能量为5 J,光斑直径为Φ2 mm,冲击2次时,激光冲击强化后可以获得最优的疲劳性能,试样在650 MPa应力水平下的疲劳寿命大于10<sup>6</sup>次,相对于未强化试样提高了3倍,这是由于激光冲击强化使疲劳源由试样表面转移到了次表面,可以有效抑制疲劳裂纹的萌生和扩展。