基于离散-堆积原理的增材制造(Additive manufacturing,AM)技术,用挤压、烧结和熔融等方式将原材料完全熔化,再基于计算机模型的轮廓生成合理的扫描路径最终得到实体零件[1~3]。激光选区熔化技术(Selective laser melting,SLM)作为金属增材制造的一种主要技术途径,用高能激光热源将金属粉末快速熔化,再逐层铺粉和快速凝固制备出力学性能优良、致密度极高的实体零件。激光选区熔化技术省时、高效和节省材料,能在短时间内成形具有复杂结构的金属材料[4,5]。SLM零件经历快速熔化、快速凝固、逐线扫描、逐层累加的成形过程,具有一种可分层的精细微观结构。这种结构有利于同时增强机械强度和断裂韧性,但是打印后的零件呈现出显著的各向异性[6~8]。SLM零件的微观组织与传统锻造件不同,在成形过程中产生的制造缺陷和微观结构对疲劳性能有很大的影响。

适于用SLM技术制造的金属材料,主要有铝合金[9,10]、钛合金[11,12]、铁基合金[13]以及镍基合金[14]等。316L不锈钢是一种典型的奥氏体不锈钢,具有优异的耐腐蚀性能和机械性能,广泛应用于汽车工业、航空航天、轨道交通等领域。近年来针对SLM 316L不锈钢开展的研究,大多是工艺参数和后处理工艺对拉伸性能与硬度的影响,对疲劳寿命的研究较少。Liverani等[15]发现,激光功率参数对SLM 316L不锈钢成型件的致密度的影响最大,而打印方向和扫描间距的影响并不明显。研究结果表明,成型件微观结构和力学性能与工艺参数密切相关。余晨帆等[16]研究发现,材料晶粒内的纳米尺度胞状结构有助于提高其强度,其拉伸性能明显优于用传统手段制备的316L不锈钢。Emre等[17]主要研究了热处理温度对SLM 316L不锈钢微观组织、显微硬度和孔隙率的影响。结果表明,在850℃的热处理温度下,熔池形貌消失,能产生均匀的微观结构,硬度和孔隙率也随着热处理温度的升高而降低。Erica等[18]研究了热等静压(HIP)处理和固溶处理对SLM 316L不锈钢力学性能、硬度和微观组织的影响。结果表明,HIP处理并没有明显提高零件的致密度,其伸长率的提高是以降低屈服强度和硬度为代价,固溶处理部分改变了微观结构,其力学性能和硬度处于成型件与HIP件之间。以上研究主要关注材料的微观组织和力学性能,而成形过程中无法避免的打印缺陷也对疲劳寿命有很大的影响,尤其是气孔与未熔合缺陷等[19,20]。因此,有必要进一步了解SLM材料的疲劳行为,并研究加工缺陷对其疲劳寿命的影响。鉴于此,本文对激光选区熔化316L不锈钢进行单调拉伸和疲劳实验,根据其参考S-N曲线和参考疲劳极限评估缺陷并研究未熔合缺陷(LOF缺陷)对疲劳行为的影响,根据断口观测分析缺陷大小与疲劳极限之间的关系并统计分析试样切片的缺陷极值,为预测SLM 316L不锈钢的最大缺陷尺寸估计和疲劳极限提供偏安全的评估方法。

1 实验方法

1.1 实验用材料和试样的制备

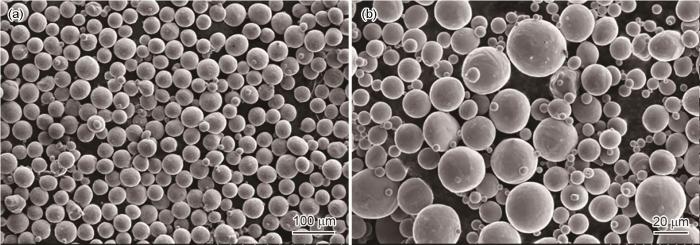

实验用316L不锈钢粉末粒径的分布范围为16~60 μm,平均粒径为36 μm(图1),化学成分(质量分数,%)为:Cr 16~18,Ni 12~15,Mo 2~3,Mn<2,Si<1,C<0.03,P<0.03,S<0.03,Fe为余量。

图1

图1

316L不锈钢粉体形貌的SEM照片

Fig.1

SEM images of 316L stainless steel powder (a) low magnification; (b) high magnification

用EP-M300激光选区熔化设备打印试样。该设备搭载的水冷光纤激光器,额定功率为1000 W,波长为1060~1090 nm。打印前先在成形腔内充入Ar气以使氧气的体积分数在3×10-3以下。用Materialise Magics软件将三维数字模型文件切片、修整并导入计算机,然后进行激光增材打印。SLM成形的工艺参数为:激光功率250 W,激光扫描速度850 mm/s,扫描间距0.12 mm,层厚0.05 mm。扫描策略为单向扫描、逐层旋转67°,考虑到材料服役环境下的受力方向采用水平(XY)方向打印。打印完成后取出基板、清理零件表面粉末并从基板上线切割试样。为了研究SLM工艺成形过程产生的缺陷对疲劳性能的影响,针对未经热处理的SLM 316L试样开展研究。

1.2 性能表征

1.2.1 微观组织和显微硬度

用砂纸(400~2000#)打磨金相试样后用粒度为0.5 μm的金刚石研磨膏抛光,使其表面成光滑镜面以致在显微镜下观测不到明显划痕,再采用不锈钢金相腐蚀液腐蚀50 s,暴露其微观组织。用OLYMPUS BX51M光学显微镜和JSM-7800F Prime扫描电子显微镜 (SEM)观察金相试样。用HVS-30型数显维氏硬度计测试试样的硬度,载荷为1 kg,保压时间20 s,测10个不同位置的硬度取其结果的平均值。

1.2.2 拉伸性能

图2

图2

INSTRON E10000电子拉扭试验机

Fig.2

INSTRON E10000 electronic tensile torsional testing machine

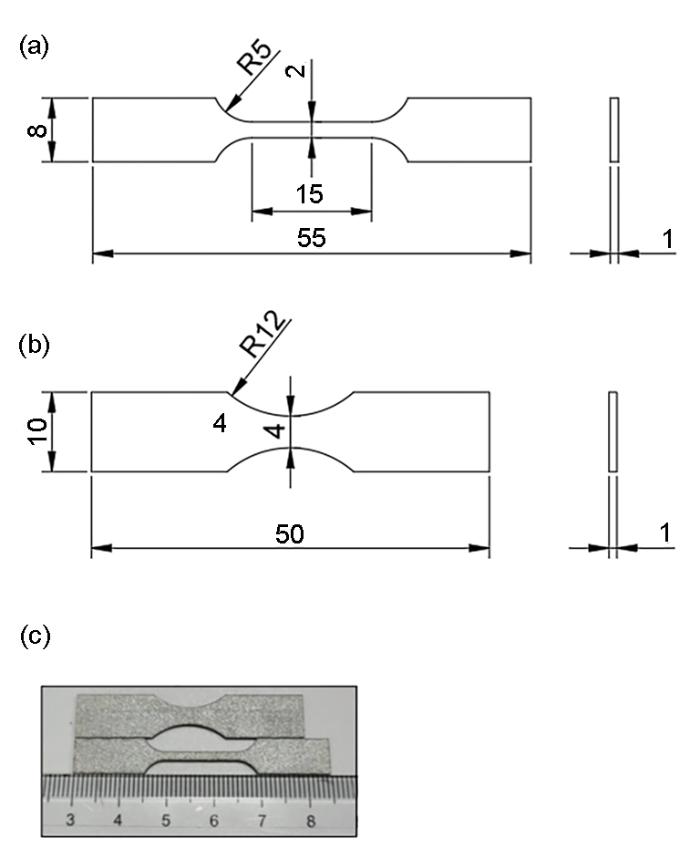

图3

图3

各种试样的尺寸和SLM成型试样

Fig.3

Various sample sizes and SLM-formed samples(a) dimensions of tensile specimens; (b) dimensions of fatigue specimens; (c) SLM-formed samples (unit: mm)

1.2.3 疲劳性能

使用INSTRON E10000电子拉扭试验机在室温环境下进行疲劳试验,试样尺寸如图3b所示。疲劳试验的加载频率为30 Hz,加载波形为正弦波,应力比R=0.1,试验前对试样的表面进行与拉伸试样相同的处理。为保证数据的可信度在每个应力幅下至少测试2个试样,试样失效或循环周次达到107 cycles时停止试验。用极大似然法拟合得到的S-N曲线,107循环周次对应的应力水平为参考疲劳极限。用SEM观察疲劳断口,以分析试样的疲劳断裂特征。

2 结果和讨论

2.1 微观形貌

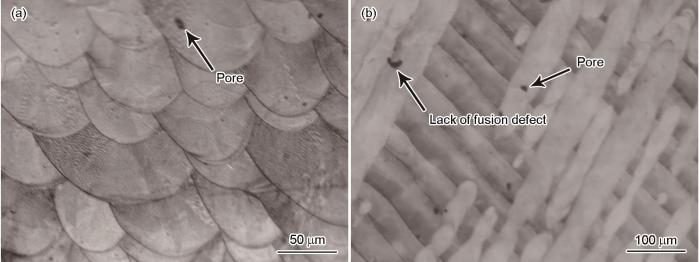

图4

图4

SLM 316L不锈钢不同方向的金相组织

Fig.4

OM microstructure of SLM 316L stainless steel in different directions (a) stacking direction; (b) scanning direction

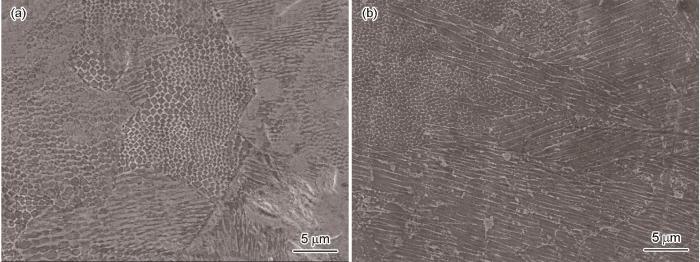

图5

图5

SLM 316L不锈钢不同方向的扫描电镜照片

Fig.5

SEM images of SLM 316L stainless steel in different directions (a) stacking direction; (b) scanning direction

2.2 拉伸性能

表1 激光选区熔化316L不锈钢的力学性能

Table 1

| Specimen | Tensile stength / MPa | Yield strength / MPa | Elongation / % |

|---|---|---|---|

| SLM 316L | 816.8 | 720.4 | 33.83 |

| Cast 316L | 548 | 268 | 52 |

2.3 疲劳性能

用极大似然法[26]拟合S-N曲线,结果以如下三参数给出:

式中S为应力水平,N为疲劳寿命,S0、m、C为材料常数。

对上式进行对数变换可得

式中Y=lgN,X=lg(S-S0),A=lgC,B=-m。由疲劳实验数据(Si,Ni ),i=1,2,3,…,n可计算出Xi 和Yi。

根据最小二乘法可得到关于参数A、B的两个方程,还需要补充反映试验数据拟合程度的参数,即拟合相关系数RXY,定义为

式中

图6

由

2.4 疲劳断口

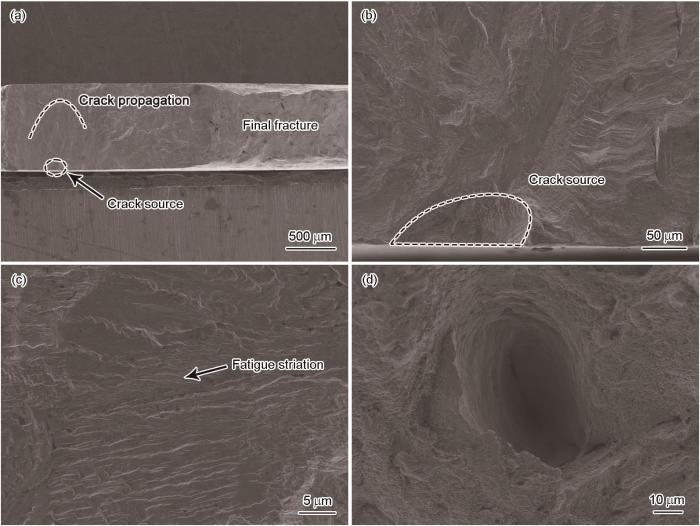

图7

图7

SLM 316L的疲劳断口

Fig.7

Fatigue fracture surface of SLM 316L sample (σ=300 MPa, Nf=1.69×106)

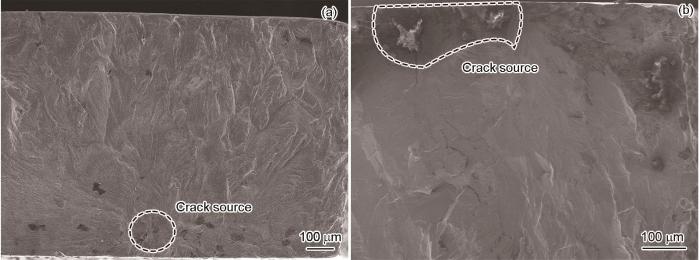

断口分析结果表明,试样内部的缺陷种类较多,形状和大小不规则,且其位置随机分布。根据缺陷位置的不同,可将其分为三类:表面缺陷、近表面缺陷和内部缺陷。部分试样中较大的缺陷,使试样的疲劳寿命极短。图8给出了最大应力为270 MPa用于求解参考S-N曲线的某试样和某异常缺陷试样的断口。图8a中的试样在其近表面的缺陷处产生应力集中,裂纹由缺陷处迅速扩展至表面最终导致断裂。图8b中试样的断裂在相邻表面未熔合缺陷萌生,缺陷间的相互作用增大了缺陷源的面积,相邻表面缺陷的尺寸明显大于近表面缺陷的尺寸。这减少了试样的寿命,使该试样的疲劳寿命仅为1.2×105 cycle,与同应力水平试样相比其寿命减少近27倍。这表明,缺陷的尺寸是影响疲劳性能的决定性因素。

图8

图8

在应力幅相同的条件下两种典型试样的疲劳源区

Fig.8

Fatigue source areas of different specimens under the same stress amplitude:(a) σ= 270 MPa, Nf= 3.2×106; (b) σ= 270 MPa, Nf=1.2×105

2.5 缺陷参数的极值统计分析

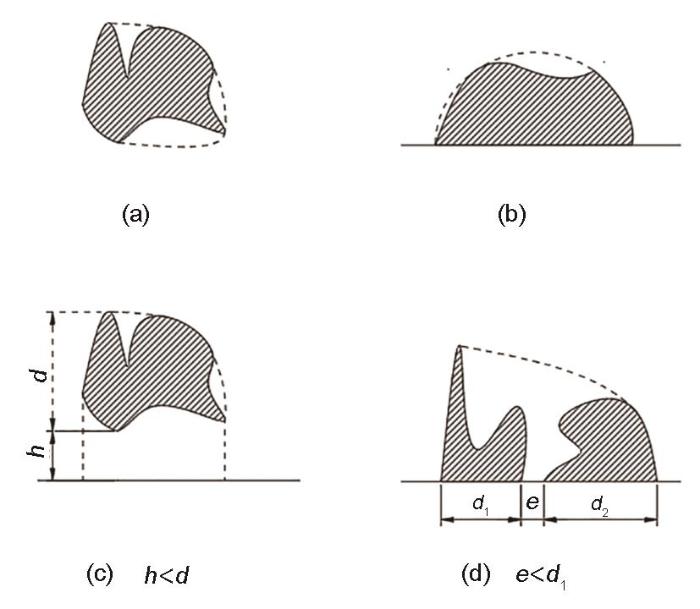

图9

图9

不规则形状缺陷的有效尺寸[29]

Fig.9

Estimation method for the effective size of irregularly shaped defects and defects near surface.

(a)irregularly shaped internal defect; (b)irregularly shaped surface defect; (c)irregularly shaped internal defect in interaction with surface; (d)interacting adjacent two surface defects

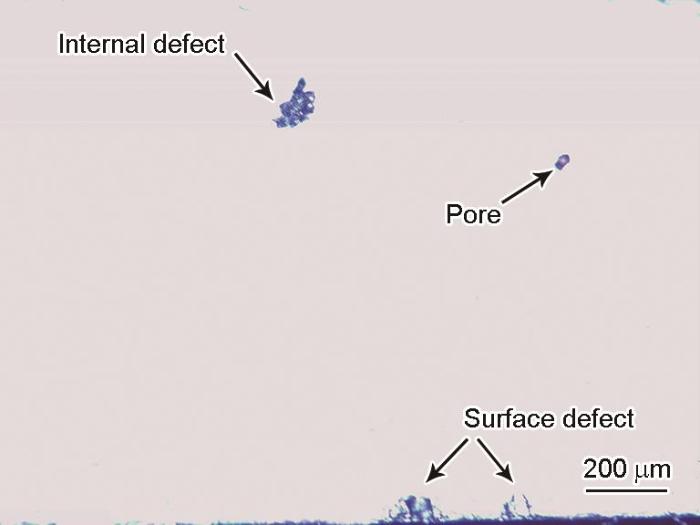

疲劳断裂在最大缺陷萌生,而用无损检测方法获取材料内部缺陷特征成本较高且难度较大。因此,本研究沿垂直最大主应力方向切割试样夹持端任意位置,得到15个SLM 316L不锈钢试样切片用于统计材料内部缺陷的尺寸。用2000#砂纸打磨试样切片并用光镜统计缺陷的尺寸,试样切片的局部光学显微镜图像如图10所示。由于缺陷的分布和试样切片位置具有随机性,试样切片中的最大缺陷尺寸并不代表真正的最大缺陷尺寸,而是用极值统计分析方法预估试样中可能出现的最大缺陷尺寸。

图10

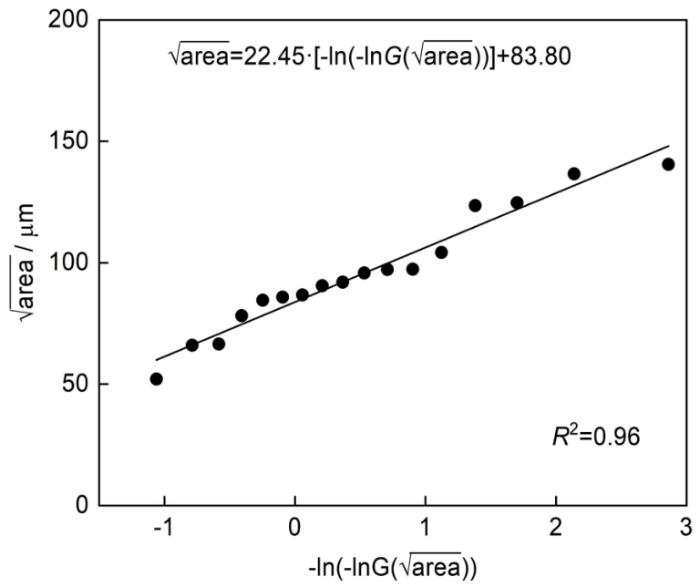

试样切片中缺陷尺寸的极大值满足Gumbel分布函数[30]

式中G(x)为变量x小于等于最大缺陷尺寸xi 的概率,λ为位置参数,α为尺寸参数。将从单个试样切片中获取的最大缺陷投影面积的平方根

式中i=1,2,…,i,…n,

取

用最小二乘法的线性拟合关系,即可确定位置参数λ和尺寸参数α。当G(

图11

图11

试样切片缺陷极值的统计分析

Fig.11

Statistical analysis of defect extremum values of sample sections

2.6 基于极值统计分析结果预测疲劳极限

式中σmax为疲劳极限对应的最大应力,HV为显微硬度;通过硬度测量得到SLM 316L不锈钢试样的硬度为226HV;

将缺陷的极值统计结果带入

3 结论

(1) SLM 316L不锈钢内有类型多样、位置与大小分布随机的不规则缺陷,其微观形貌与传统锻造材料不同,呈现出由胞状晶与柱状晶构成的亚细胞结构,使其抗拉强度和屈服强度大大提高。

(2) 随机分布的缺陷使疲劳寿命出现较大的分散性,因此必须考虑缺陷尺寸对疲劳寿命的影响。根据断裂力学,

(3) 使用Murakami提出的经验公式预测的三种不同位置缺陷的疲劳极限均与实验结果接近,误差小于10%且预测值更加保守,表明此公式适于预测SLM 316L不锈钢材料的疲劳极限。

参考文献

Designing for big area additive manufacturing

[J].Additive manufacturing (AM), more commonly referred to as 3D printing, is revolutionizing the manufacturing industry. With any new technology comes new rules and guidelines for the optimal use of said technology. Big Area Additive Manufacturing (BAAM), developed by Cincinnati Incorporated and Oak Ridge National Laboratory's Manufacturing Demonstration Facility, requires a host of new design parameters compared to small-scale 3D printing to create large-scale parts. However, BAAM also creates new possibilities in material testing and various applications in the manufacturing industry. Most of the design constraints of small-scale polymer 3D printers still apply to BAAM. Beyond those constraints, new rules and limitations exist because BAAM's large-scale system significantly changes the thermal properties associated with small-scale AM. This work details both physical and software-related design considerations for additive manufacturing. After reading this guide, one will have a better understanding of slicing software's capabilities and limitations, different physical characteristics of design and how to apply them appropriately for AM, and how to take the inherent nature of AM into consideration during the design process.

Preparation of graphene/Ni-Cu alloy composite on Ni-Cu alloy template made by selective laser melting

[J].

基于激光选区熔化成形Ni-Cu合金模板的Ni-Cu-石墨烯复合材料的制备

[J].

Additive manufacturing of structural materials

[J].

Effect of Cr-content on microstructure of 12CrNi2 alloy steel prepared by laser additive manufacturing

[J].

Cr含量对激光增材制造12CrNi2合金钢的组织结构的影响

[J].

Investigation of effects of process parameters on microstructure and hardness of SLM manufactured SS316L

[J].

Effects of bulk laser energy density on anisotropy of selective laser sintered 316L stainless steel

[J].

体激光能量密度对选区激光熔化316L不锈钢各向异性的影响

[J].

Mechanical anisotropy of additively manufactured stainless steel 316L: an experimental and numerical study

[J].

Anisotropy of mechanical properties and its correlation with the structure of the stainless steel 316L produced by the SLM method

[J].

Plasticity and fracture of cast and SLM AlSi10Mg: high-throughput testing and modeling

[J].

Impact of layer rotation on micro-structure, grain size, surface integrity and mechanical behaviour of SLM Al-Si-10Mg alloy

[J].

Anisotropy of Ti6Al4V alloy fabricated by selective laser melting

[J].The microstructure, texture and properties of samples intercepted at different deposition heights and directions of the Ti6Al4V alloy fabricated by selective laser melting were investigated by metallographic analysis, XRD and tensile test. The results show that the vertical section parallel to the building direction presents microstructure of columnar-like prior-β grains filled with acicular martensite, while the cross section perpendicular to the building direction presents a block-like microstructure. The texture for the later cross section is stronger than that for the former one. The size of the columnar prior-β grains influences the mechanical properties along the building direction of the Ti6Al4V alloy fabricated by selective laser melting. The tensile strength and yield strength decrease first and then increase with the increase of deposition height, while the elongation variation has an opposite trend. The strength and plasticity of samples perpendicular to the building direction is higher than those parallel to the building direction due to the formed defects related with the weaker-texture and poor-fusion.

选区激光熔化Ti6Al4V合金的各向异性

[J].

Cyclic plasticity and microstructure of as-built SLM Ti-6Al-4V: the effect of build orientation

[J].

Effect of heat treatment on microstructure and mechanical properties of selective laser melted 17-4PH stainless steel

[J].The laser selectively melted 17-4PH stainless steel was subjected to different post-heat treatment, i.e. vacuum heat treatment (1040℃/2 h+water quenching and 480℃/4 h+water quenching), hot isostatic pressing heat treatment (1040℃-150 MPa/2 h HIP +gas rapid cooling and vacuum 480℃-100 MPa/4 h+GRC) and combined heat treatment (1040℃-150 MPa/2 h HIP+GRC and vacuum 480℃/4 h+water quenching). Afterwards, the microstructure and mechanical performance of the laser melted steels were characterized by means of optical microscopy, electron scanning microscopy, microhardness tester and universal tensile tester. The results show that the vacuum heat treatment can reduce the inner pore size down to 3~7 μm. After hot isostatic pressing treatment, all pores almost closed and the density is almost of the theoretical value of the laser deposited 17-4PH stainless stee. After heat treatment, the 17-4PH stainless steel composed of tempered- and quenched-martensite, and the precipitates with size of 100~150 nm dispersed in grains. Vacuum heat treatment + water quenching can significantly increase the tensile strength and hardness of the deposited 17-4PH stainless steel to 1300 MPa and 448.5HV, respectively. Hot isostatic pressing heat treatment can significantly increase the tensile strength of the deposited 17-4PH stainless steel, at the same time, its elongation at break reaches 22.4%.The fracture morphology of the as deposited 17-4PH SS and the one after hot isostatic pressing heat treatment was typical ductile fracture, and the dimples of hot isostatic pressing heat treatment ones were larger in size and deeper in depth. The fracture morphologies of the deposited 17-4PH SS after vacuum heat treatment and combined heat treatment have the characteristics of partial brittle fracture and emergence of a few cracks, whilst who's plasticity decreases slightly, in comparison with that of the as deposited ones.

热处理对选区激光熔化17-4PH不锈钢力学性能的影响

[J].

Preparation and performance of spherical Ni powder for SLM processing

[J].3D printing has attracted increasing interests in the field of metallic materials as it can effectively shorten the production cycle and create parts with complex shapes, which can hardly be produced by traditional methods. However, the gas atomization, as the mainstream method of preparing metal and alloy powders to meet the requirements of the processing of selective laser melting (SLM) at present, still has some limitations, such as hollow and/or satellite balls in the powder. This influences directly the density and performance of the printing parts. Moreover, the laser absorption in the smooth surface of powder particle is generally less than 10% in the laser processing, which hinders rapid heating of the powder. It has been found that the material can obtain multiple absorption of laser energy by increasing the surface roughness of powder particles, which can effectively improve the laser absorption rate and is beneficial to get the dense printing parts. Based on this, a novel method combining low temperature spray-drying with heat treatment was developed to prepare Ni powder with high purity, good sphericity, high flowability and narrow particle size distribution. The microstructure and laser absorptivity of the prepared Ni powder were compared with those of the commercial Ni powder prepared by gas atomization, and their influences on the microstructure and properties of the 3D printed bulk materials were investigated. It is found that the laser absorptivity of the Ni powder prepared by spray-drying is more than 2 times as high as that of the commercial Ni powder. This leads to a wider melting channel, smaller surface tension and liquid-bridging force between particles in the printing process. As a result, the spheroidization phenomenon occurred on the surface of the printed bulk material can be avoided by the use of the spray-dried powder, and the relative density is achieved as 99.2% at the as-printed state. In the microstructure of the printed bulk material, in addition to the cellular crystals, there are a number of fine columnar crystals, grown across the interlaminar boundaries, which is favorable for a high bonding strength between the interlayers.

SLM球形Ni粉的制备与打印工艺性能

[J].针对选区激光熔化(SLM)的技术特点,采用低温喷雾干燥与热处理相结合的新方法,制备得到了物相纯净、球形度高、流动性好且粒径分布窄的球形Ni粉。比较分析了喷雾干燥法制备的Ni粉和气雾化法生产的商业化Ni粉的显微组织和激光吸收率及其对3D打印件组织和性能的影响。结果发现,喷雾干燥法制备Ni粉的激光吸收率是气雾化法生产Ni粉的2倍以上;打印过程中形成更宽的熔道,且颗粒熔化后表面张力和颗粒间液桥力均较小,大大减少了金属粉末打印中极易出现的表面球化现象。喷雾干燥法制备Ni粉打印件的相对密度达到99.2%,其显微组织由细小的柱状晶和胞状晶构成,且柱状晶穿过层间边界生长,使打印件具有致密的层间结合。

Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel

[J].

Tensile properties of selective laser melted 316L stainless steel

[J].Selective laser melting (SLM), as the most common additive manufacturing (AM) method, is capable of manufacturing metallic components with complex shape layer by layer. Compared with conventional manufacturing technologies such as casting or forging, the SLM technology has the advantages of high degree accuracy, high material utilization rate and environmentally friendly, and has attracted great attention in the fields of aerospace, nuclear power and medicine. The 316L austenitic stainless steel is widely used in the industrial field because of the excellent corrosion resistance and plasticity. It is also one of the commonly used material systems for SLM. In this work, the tensile properties and fracture mechanism of 316L stainless steel fabricated via SLM technology were investigated. The microstructure of the SLMed 316L specimens after tensile fracture was characterized and analyzed. The results show that the SLMed 316L stainless steel has a relatively desirable combination of strength and ductility, and its tensile performance is obviously better than that of 316L stainless steel prepared by traditional methods. The nanometer-scale cell structure inside the grain contributes to the improvement of strength. Deformation twins were observed in the SLMed 316L stainless steel after tensile test. The appearance of twins is oriented-dependent, and it is easy to occur in the grain with the direction near <110>-<111>.

选区激光熔化316L不锈钢的拉伸性能

[J].对选区激光熔化(selective laser melting,SLM) 316L不锈钢的拉伸性能及断裂机制进行了研究,并对拉伸断裂后的试样进行显微组织表征与分析,探究了拉伸变形过程中微观组织的演化规律。结果表明:采用选区激光熔化技术制备的316L不锈钢具有较好的强塑性匹配,其中晶粒内部纳米尺度胞状结构有助于强度的提升;其拉伸性能明显优于传统手段制备的316L不锈钢。选区激光熔化316L不锈钢在拉伸过程中奥氏体晶粒内部产生形变孪晶,并且形变孪晶的出现存在取向相关,在取向接近<001>的晶粒中不易出现,而在取向接近<110>-<111>的晶粒中较易出现。

Influence of heat treatment temperature on the microstructural, mechanical, and wear behavior of 316L stainless steel fabricated by laser powder bed additive manufacturing

[J].

The effects of hot isostatic pressing (HIP) and solubilization heat treatment on the density, mechanical properties, and microstructure of austenitic stainless steel parts produced by selective laser melting (SLM)

[J].

Relationship between manufacturing defects and fatigue properties of additive manufactured austenitic stainless steel

[J].

Fatigue strength of additively manufactured 316L austenitic stainless steel

[J].

Effect of initial microstructure on the deformation heterogeneities of 316L stainless steels fabricated by selective laser melting processing

[J].

Microstructure and high temperature tensile properties of 316L fabricated by laser powder-bed fusion

[J].

Effect of scanning strategies on the microstructure and mechanical behavior of 316L stainless steel fabricated by selective laser melting

[J].

Influence of Al content on microstructure and properties of casting 316L stainless steel

[J].

铝含量对铸造316L不锈钢组织和性能的影响

[J].

Effect of heat treatment on microstructure and mechanical properties of 316L stainless steel prepared by selective laser melting

[J].

热处理对激光选区熔化成形316L不锈钢组织和力学性能的影响

[J].采用激光选区熔化成形工艺制备了316L不锈钢试样,并对其分别进行了400℃×4 h的退火处理以及1020℃×0.5 h的固溶处理。采用扫描电镜、显微硬度计及电子万能试验机等研究了直接成形态、退火态和固溶态试样的微观组织、拉伸性能、布氏硬度和夏比冲击吸收能量。结果表明:直接成形态试样经400℃×4 h退火后,组织变化不明显,抗拉强度、伸长率、布氏硬度及夏比冲击吸收能量都略有提高;直接成形态经1020℃×0.5 h固溶处理后,熔池搭接边界发生溶解,层层搭接边界消失,抗拉强度、屈服强度、布氏硬度分别降低了8.8%、27.2%、13.7%,伸长率、夏比冲击吸收能量分别提高了43%和25%。与其它两种状态相比,固溶状态下,试样的性能更稳定,强度与韧性的组合较好。

A maximum likelihood method for estimating P-S-N curves

[J].

A comparison of fatigue strength sensitivity to defects for materials manufactured by AM or traditional processes

[J].

Fatigue performance evaluation of selective laser melted Ti-6Al-4V

[J].

Material defects as the basis of fatigue design

[J].

Qualification of AM parts: extreme value statistics applied to tomographic measurements

[J].