鉴于此,本文系统研究微观组织和结构的调控,以揭示进行不同工艺的热处理后活塞的显微组织和力学性能的演化规律以及调控机理,以优化活塞结构和调控其整体强韧性、提高大尺寸活塞的综合性能和延长使用寿命。

1 实验方法

表1 9CrV钢的化学成分

Table 1

| C | Si | Mn | Cr | V | S | P | Fe |

|---|---|---|---|---|---|---|---|

| 0.865 | 0.326 | 0.307 | 1.863 | 0.101 | 0.003 | 0.012 | Bal. |

表2 9CrV钢的热处理参数

Table 2

| No. | Quenching temperature / ℃ | Quenching heating and holding time / h | Salt bath temperature / ℃ | Salt bath insulation time / h | Tempering heating temperature / ℃ | Tempering holding time / h | Secondary tempering heating temperature / ℃ | Secondary tempering holding time / h |

|---|---|---|---|---|---|---|---|---|

| 1# | 850 | 5 | 230 | 4 | 230 | 4 | - | - |

| 2# | 800 | 5 | 230 | 4 | 400 | 4 | - | - |

| 3# | 800 | 5 | 230 | 4 | 230 | 4 | 400 | 4 |

1#为处理制度传统工艺;2#为增韧工艺制度是降低淬火加热温度、提高回火温度;3#为结合两次回火工艺的平衡整体韧性工艺制度以实现结构优化。

用Shimadzu AG-XPlus电子万能试验机进行室温拉伸,使用圆棒标准试样(标距:ϕ5 mm×25 mm)测试其拉伸力学性能。使用标准V型缺口试样(10 mm×10 mm×55 mm、缺口深度为2 mm),在JBW-500数显冲击试验机上测试冲击韧性。使用HR-150A型洛氏硬度计测试硬度,加载力为1470 N,保荷时间8 s。将用于观察组织的样品磨光和机械抛光后用4%硝酸酒精溶液浸蚀,用Olympus-SZ61宏观体视显微镜、Leica DMi8型金相显微镜(Optical microscope,OM)和Quanta 250FEG场发射扫描电子显微镜(Sca-nning electron microscopy,SEM)观察样品显微组织和断口形貌。

2 实验结果

2.1 传统热处理后9GrV活塞的径向组织分布

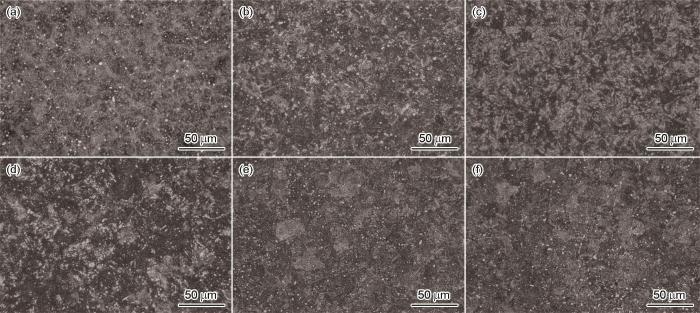

图1

图1

9CrV钢活塞的表层、距表面12 mm处、距表面20 mm处、距表面24 mm处、距表面30 mm处以及心部的组织OM形貌

Fig.1

OM images of 9CrV steel piston at different radial positions (a) surface layer, (b) 12 mm from the piston surface, (c) 20 mm from the piston surface, (d) 24 mm from the piston surface, (e) 30 mm from the piston surface and (f) piston core

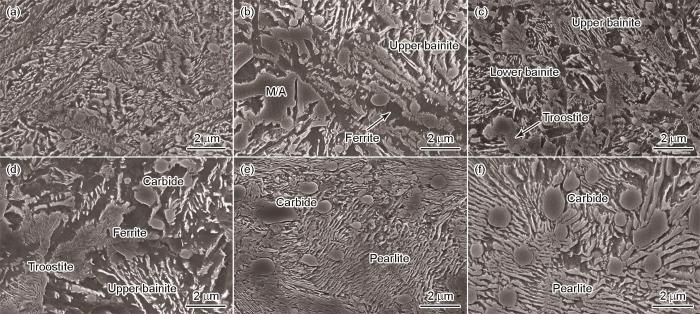

图2

图2

9CrV钢活塞的表层、距表面12 mm处、距表面20 mm处、距表面24 mm处、 距表面30 mm处以及心部组织的SEM形貌

Fig.2

SEM images of 9CrV steel piston at different radial positions (a) surface layer; (b) 12 mm from the piston surface; (c) 20 mm from the piston surface; (d) 24 mm from the piston surface; (e) 30 mm from the piston surface and (f) piston core

2.2 优化热处理后9CrV钢活塞的显微组织

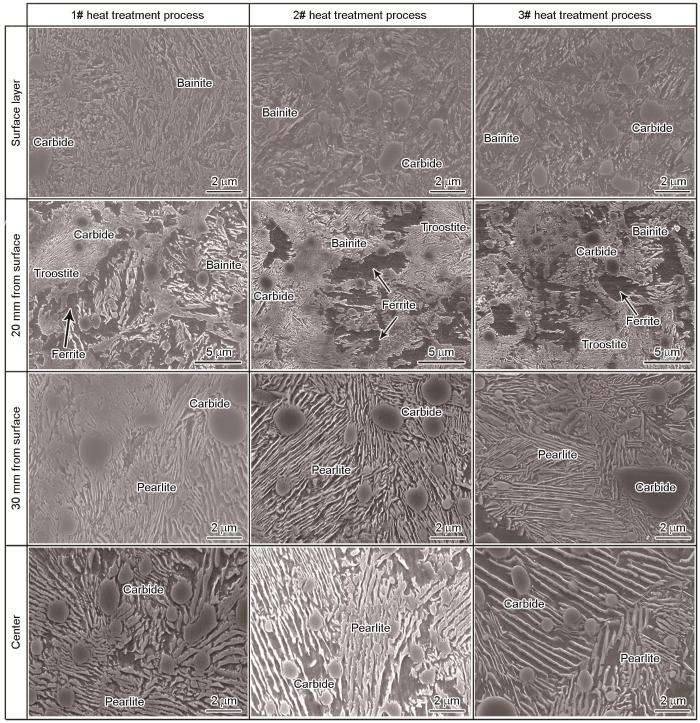

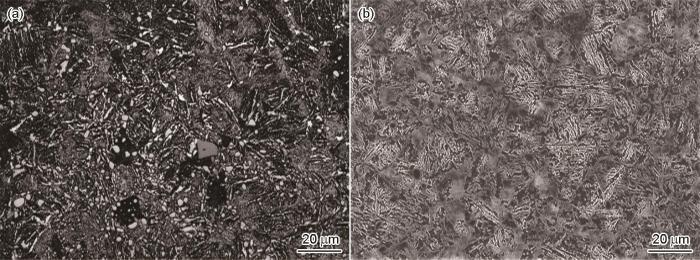

图3给出了不同工艺热处理后9CrV钢活塞各区域的显微组织。可以看出,不同工艺的热处理后活塞的组织演变规律相似。经1#传统工艺处理的活塞其表层中的下贝氏体碳化物尺寸粗大、分布致密,只有极少未溶的碳化物颗粒。与3#二次回火工艺处理相比,2#降低淬火加热温度后贝氏体碳化物的尺寸细小、分布弥散,未溶颗粒碳化物数量较多。在400℃回火后的下贝氏体不仅有弥散细小的贝氏体碳化物,还有较多的长片状碳化物(图中箭头所示),而二次回火后下贝氏体中长片状碳化物的数量明显减少。

图3

图3

不同热处理工艺条件下9CrV钢活塞各区域显微组织的SEM照片

Fig.3

SEM images of microstructure in various positions of 9CrV steel piston under different heat treatment conditions

经850℃-230℃等温淬火、230℃回火后,距活塞表面20 mm处过渡区的显微组织由铁素体、长片状碳化物的贝氏体和片层极细的屈氏体组成。经2#工艺与3#工艺处理后,过渡区的组织没有显著的变化,只是各种组织的占比与形态有所改变。由此可见,随着淬火加热温度的降低和回火温度的升高,过渡区中未溶的碳化物数量增多,下贝氏体和上贝氏体碳化物的尺寸减小,屈氏体团的体积增大。

经不同工艺热处理调控后,距活塞表面30 mm处和活塞的心部均为珠光体类组织。由距表面30 mm处到心部,珠光体片层间距不断增大,而淬火加热温度降低到800℃使珠光体的片层间距增大。

2.3 不同热处理后9CrV钢活塞的力学性能

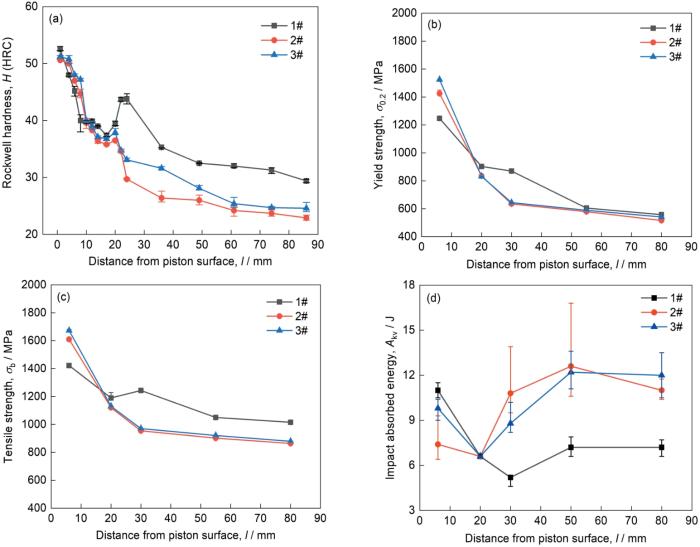

图4给出了经调控热处理的9CrV钢活塞各位置的硬度、冲击吸收功、屈服强度和抗拉强度的变化。可以看出,将淬火加热温度由850℃降至 800℃、回火温度由230℃升至400℃,则活塞表面的硬度由52.5HRC降至50.1HRC,近表层(距表面6 mm)的硬度由45.2HRC升至47.0HRC。过渡区(距表面20 mm)的硬度由39.4HRC降至36.5HRC,心部的硬度由29.4HRC降至22.9HRC。而经230℃+400℃二次回火后,活塞的整体硬度略有提高。

图4

图4

不同工艺热处理后9CrV钢活塞不同位置的硬度、屈服强度、抗拉强度以及冲击吸收功

Fig.4

Mechanical properties of 9CrV steel piston at different positions with different heat treatment processes: (a) hardness; (b) yield strength; (c) tensile strength; (d) impact absorbed energy

由图4d可见,将淬火加热温度由850℃降至 800℃、回火温度由230℃升至400℃,活塞表层的冲击吸收功由11.0 J降至7.4 J,过渡区(距表面20 mm处)的冲击吸收功仍为6.6 J,心部的冲击吸收功由7.2 J升至11.0 J。其原因是,表层中高比率的下贝氏体组织使冲击韧性降低,心部全珠光体类组织使冲击韧性明显提高。而经过二次回火后,活塞的表层和心部都表现出良好的强韧性匹配。

3 讨论

3.1 热处理调控对9CrV钢活塞显微组织的影响

图5

图5

距活塞表层20 mm处的组织形貌

Fig.5

Microstructure at 20 mm from the piston surface (a) confocal laser image and (b) low-magnification SEM image

3.2 热处理工艺调控对9CrV钢活塞力学性能的影响

由图4可见,从活塞的表面到心部硬度整体呈下降的趋势,表层贝氏体的尺寸逐渐增大。在距表面18 mm处出现片层极细的屈氏体且数量逐渐增大,硬度也随之提高。随后屈氏体组织片层间距明显增大,硬度降低。

经1#传统热处理工艺处理后,活塞上距表面30 mm处的冲击吸收功出现最低值。在850℃淬火加热温度下奥氏体的含碳量较高,使生成的珠光体类组织的含碳量也比较高。在过渡区生成的屈氏体组织不仅片层间距小渗碳体片层也比较宽,单位面积中渗碳体的占比例较高,使冲击韧性较低[23~26]。淬火加热温度降低至800℃,使未溶碳化物颗粒增多。这一方面使奥氏体的含碳量降低、生成的珠光体含碳量减少、碳化物片层宽度减小、单位面积上碳化物的占比降低,使冲击韧性提高;另一方面,奥氏体晶粒的减小增大了晶界总面积,使变形过程中裂纹扩展的阻力增加,从而使冲击韧性提高。将回火温度提高到400℃,则心部珠光体类组织的位错密度降低,使冲击韧性提高[27]。

综上所述,1#传统工艺处理的活塞表层冲击韧性良好,但是心部的冲击韧性较低。2#工艺处理的活塞心部韧性有所提高,但是表层的冲击韧性较低且心部的强度较低,使强度与韧性仍达到良好匹配。3#工艺处理的活塞其表层的硬度、强度和冲击吸收功都较为理想。同时,其距表面30 mm处的强韧性亦达到较高的水平。这些结果,可归因于淬火加热温度的降低使奥氏体晶粒细化,突出了细晶强化和细晶韧化的作用。而经230℃+400℃两次回火的活塞,其整体韧性达到了较高的水平。其原因是,先进行的230℃一次回火使表层大部分残余奥氏体转变为下贝氏体组织[28],贝氏体和铁素体长大的速度远高于碳化物,贝氏体碳化物由奥氏体析出后被铁素体包围,形成稳定的下贝氏体组织。在此后的400℃二次回火中大部分残余奥氏体完成转变,只有极少量残余奥氏体分解,抑制了碳化物薄壳析出对冲击韧性的危害。同时,以在400℃回火作为最终的热处理,使活塞心部的珠光体类组织中位错的缠结回复,位错密度的降低使韧性提高。于是,在保证表层强度和整体韧性的情况下,显著提高了表层的韧性。

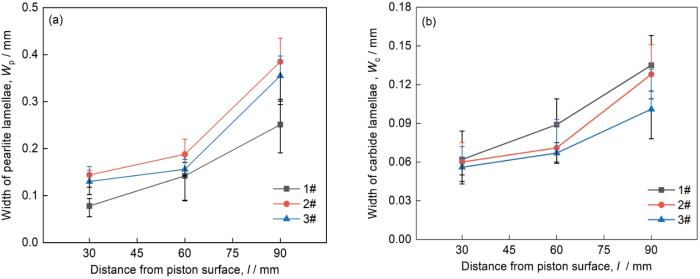

图6给出了活塞不同位置珠光体类组织的片层间距和碳化物片层的宽度。可以看出,随着到心部距离的减小珠光体类组织片层间距和碳化物片层厚度逐渐增大,而降低淬火加热温度使两者都增大。随着碳化物片层宽度所占珠光体片层间距比例的降低冲击吸收功随之增加,而活塞的冲击韧性提高。

图6

图6

不同热处理工艺9CrV钢距活塞表面不同位置处的珠光体片层间距

Fig.6

Pearlite lamellar spacing (a) and carbide lamellar width (b) of 9CrV steel piston at different positions with different heat treatment processes

3.3 断口的形貌特征和热处理调控韧化的机制

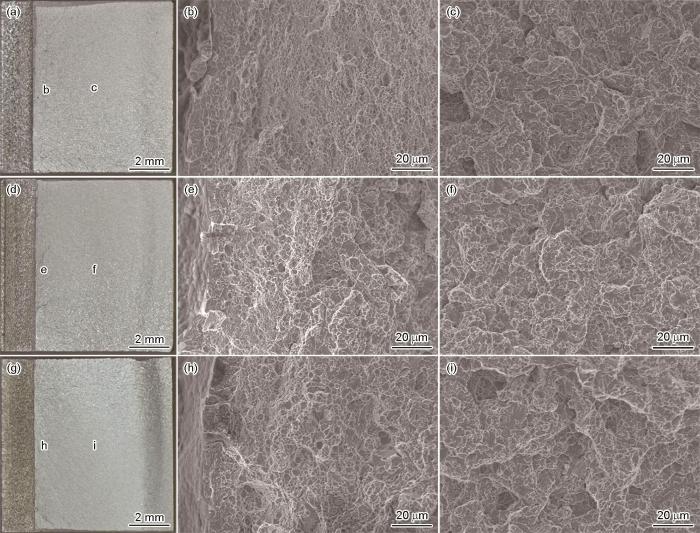

图7

图7

不同热处理工艺9CrV钢活塞表层的冲击断口形貌

Fig.7

Impact fracture morphology of 9CrV steel piston surface layer under different heat treatment (a-c) 1#; (d-f) 2#; (g-i) 3#

图8

图8

不同热处理工艺9CrV钢活塞距表面30 mm处和过渡区冲击断口的形貌

Fig.8

Impact fracture morphology of 9CrV steel piston at 30 mm from the piston surface and transition part under different heat treatment (a-c) 1#, piston 2/3 R; (d-f) 2#, piston 2/3 R; (g-i) 3#, piston transition

图7b、e、h给出了活塞表层断口纤维区的微观形貌,可见1#在230℃回火后冲击断口的纤维区有细小的韧窝,是典型的韧窝断裂。2#在400℃回火后冲击断口纤维区的韧窝尺寸虽然有所增大但是数量明显减少,且出现较多的解理刻面,表现出韧窝断裂与准解理断裂组成的混合型断裂特征,冲击韧性较差。3#经230℃一次回火、400℃二次回火后冲击断口的纤维区由大尺寸韧窝与少量解理刻面组成,大尺寸韧窝的中心出现较多的第二相粒子,比在400℃回火的冲击韧性好(图7h)。出现解理刻面的原因是,下贝氏体在400℃中温回火后贝氏体铁素体板条间的薄膜状残余奥氏体析出了碳化物薄壳,晶界处的块状残余奥氏体析出的粗大碳化物成为裂纹快速扩展通道。因此整体呈现韧窝断裂,在析出的碳化物薄壳处出现了解理刻面,呈现准解理断裂。而韧窝尺寸的增大和变深的原因,是试样断裂前经历较大的塑性变形时吸收了更多的冲击能量。这表明,以400℃作为最终热处理有利于提高钢的韧性。图7c、f、i给出了活塞表层断口扩展区的微观形貌。可以看出,三种回火工艺的冲击断口扩展区其微观形貌都是在解理刻面上分布着细小的撕裂棱和韧窝,表明属于准解理断裂。

3.4 新型大尺寸活塞的结构和制备工艺设计

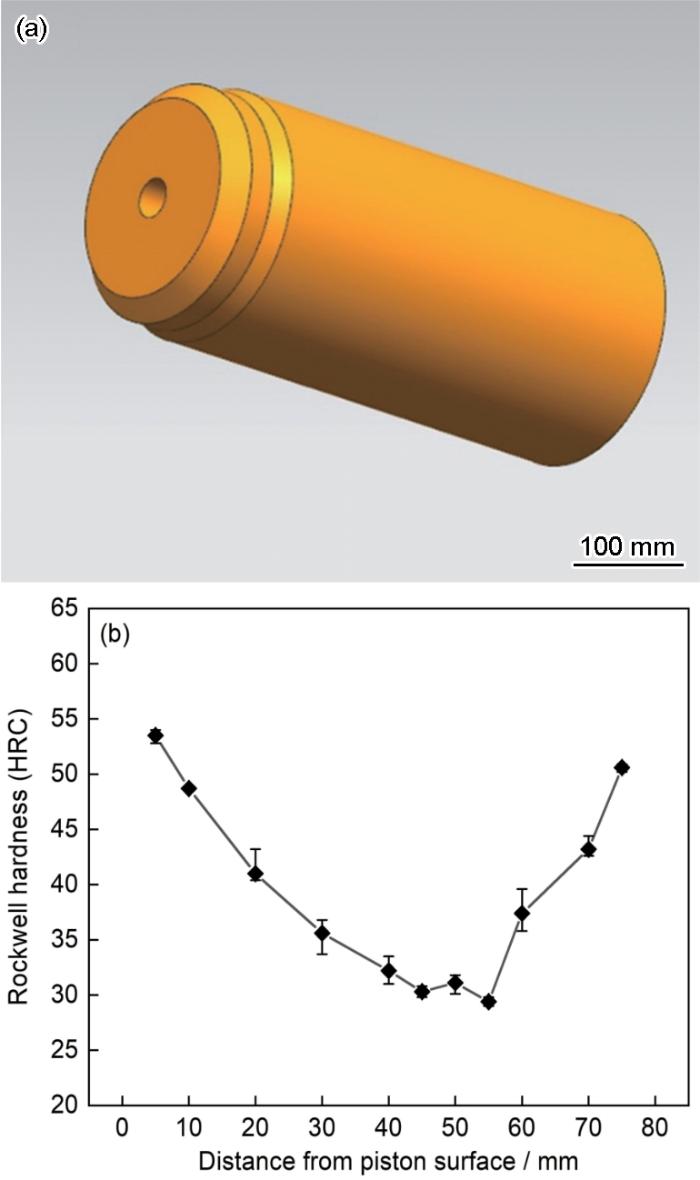

对9CrV钢活塞服役的特点和断裂特征的分析表明,大尺寸活塞横截面上的强度与韧性调控窗口过窄甚至无法平衡,使其服役过早失效。结合前述研究可以发现,在较高的淬火加热温度和较低的回火温度热处理后,活塞的表层贝氏体组织虽韧性较高但是强度偏低,且过渡区的韧性也可能较低。中温回火使表层的强度有所提高,但是表层的韧性降低。因此,本文的3#二次回火工艺在保证整体性能的前提下使活塞的表层具有较高的强度和韧性。与淬火+回火工艺相比,等温淬火+二次回火工艺既能保证活塞整体性能又能提高活塞表层韧性,可实现强度与韧性的平衡。另一方面,经3#工艺处理后,活塞表层的强度和韧性、活塞心部的韧性都比较高,但是因活塞的尺寸过大在实际生产中心部的强度难以提高。本文基于活塞热处理组织性能调控的系统研究,设计出新型活塞结构:在直径为190 mm长度为460 mm的活塞顶端机械加工出直径为30 mm长度为100 mm的中孔(图9a)。在新型结构活塞的热处理过程中,顶端表层与心部同时接触淬火介质生成贝氏体组织,使活塞心部的硬度和强度提高(图9a)。

图9

图9

大尺寸活塞顶端开孔结构的示意图

Fig.9

Button-hole piston: schematic diagram of structure (a) and hardness distribution in radial direction (b)

为了提高活塞表面的硬度和表层的韧性,进一步进行优化顶端开孔活塞的热处理工艺:将淬火加热温度提高到820℃,将二次回火温度降低到350℃。于是,优化热处理后的新型结构活塞,其硬度分布如图9b所示。可以看出,靠近活塞心部处的硬度明显提高。根据活塞的力学性能与显微组织的关系可以判断,结构调整后的新型大尺寸活塞具有较理想的整体强韧性平衡。

4 结论

(1) 对9CrV钢活塞进行850℃×5 h-230℃×4 h等温淬火、230℃×4 h回火处理后,活塞的表层为下贝氏体,心部为珠光体类,距表面20 mm处的过渡区为下贝氏体、上贝氏体、铁素体、屈氏体和残余奥氏体的混合组织。

(2)适当降低9CrV钢活塞淬火加热温度,可保留部分碳化物和细化淬火组织。淬火后的一次回火使活塞表层的大部分残余奥氏体转变为下贝氏体,二次回火使活塞心部珠光体类组织中的位错密度降低。因此,二次回火处理使活塞的整体强韧性匹配达到较理想的状态。

(3)控制大尺寸活塞的结构和二次回火热处理工艺,能显著提高活塞心部的强度、改善各位置的组织和强韧性匹配,均衡调控活塞的整体强度和韧性。

参考文献

Current situation and development trend of domestic hydraulic crusher market

[J].

国内液压破碎器市场现状及发展趋势

[J].

Status and classification of hydraulic crushing hammer in China

[J].

国内液压破碎锤的现状及分类

[J].

Causes and countermeasures of piston failure of hydraulic crushing hammer

[J].

液压破碎锤活塞失效的原因及对策

[J].

Recent development of bearing steel in Japan

[J].

Some key technologies for design and manufacture of hydraulic crushing hammer impact piston

[J].

液压破碎锤冲击活塞设计与制造的若干关键技术

[J].

Development and present situation analysis of hydraulic crushing hammer in China

[J].

我国液压破碎锤发展与现状分析

[J].

Effect of deep cryogenic treatment on mechanical property and microstructure of a low carbon high alloy martensitic bearing steel during tempering

[J].The hardness and microstructure evolution of a low carbon and high alloy martensite bearing steel after deep cryogenic treatment were studied by means of Rockwell hardness tester, X-ray diffractometer, and scanning electron microscope and transmission electron microscope. The results show that the deep cryogenic treatment promotes the transformation of retained austenite to martensite, which leads to an increase in the hardness after quenching. In addition, the hardness of the steel subjected to deep cryogenic treatment was higher than that of the non-cryogenically treated one during tempering. The deep cryogenic treatment causes the carbon atoms in the steel to segregate and precipitate as carbides during the tempering process. Compared with the steel without deep cryogenic treatment, the carbon content in the martensite matrix of the steel subjected to deep cryogenic treatment was lower after tempering, which indicated that more carbides were precipitated in the deep cryogenic treated steel during the tempering process. According to the results of transmission electron microscope images, a large number of nano-sized M2C and M6C carbides precipitated from the martensite matrix during tempering, which may be the main reason for the maintenance of high hardness of the steel after longtime tempering.

深冷处理对低碳高合金马氏体轴承钢力学性能及组织的影响

[J].利用洛氏硬度计、X射线衍射仪、扫描电子显微镜及透射电子显微镜等研究了低碳高合金马氏体轴承钢深冷处理后的硬度变化及组织演化。结果表明:深冷处理促使部分残留奥氏体转变为马氏体,导致深冷处理后实验钢的硬度较淬火态硬度有所升高。经深冷处理后实验钢在0~100 h回火过程中的硬度均比未深冷处理实验钢的硬度高。深冷处理促使钢中碳原子偏聚并在回火过程中以碳化物的形式析出,与未经深冷处理的实验钢相比,经深冷处理的实验钢回火后马氏体基体中的含碳量更低,表明实验钢经深冷处理后在回火过程中析出更多的碳化物。透射电镜分析表明,实验钢在回火过程中析出的大量弥散分布的纳米级M<sub>2</sub>C和M<sub>6</sub>C型碳化物是实验钢长时间回火后保持高硬度的主要原因。

Effect of solid solution and mesothermal phase transition treatment on microstructure and mechanical property of ball bearing steel 8Cr4Mo4V

[J].

固溶温度对8Cr4Mo4V轴承钢的中温相转变和力学性能的影响

[J].在不同温度对8Cr4Mo4V钢固溶处理后在260℃盐浴中发生相转变而生成贝氏体组织,测定了钢的硬度和冲击韧性。使用扫描电镜、电子探针和光学显微镜等手段观察钢的微观组织,分析了合金元素扩散、贝氏体形核及贝氏体尺寸与固溶温度的关系,研究了固溶处理温度对力学性能的影响。结果表明,在1050℃和1065℃固溶处理后钢中的点状碳化物仍有剩余,阻碍了晶粒的长大;在1095℃和1110℃固溶处理后点状碳化物溶解,晶粒平均尺寸增大。固溶处理促使含Cr和V的碳化物溶解,但对含Mo碳化物的影响较小;高温固溶处理后Mo元素仍然存在于碳化物中,在基体中则较少。高温固溶处理使更多的Cr和V元素溶入基体中,降低了碳元素在基体中的扩散系数和贝氏体形核数目以及贝氏体的最终生成量,使贝氏体的组织粗化;随着固溶温度的提高,钢的硬度提高,而冲击韧性降低。

Microstructure and mechanical properties of 9CrV steel controlled by heat treatment process

[J].Effect of heat treatment process on microstructure and mechanical properties of 9CrV steel for piston of large hydraulic hammer was studied. The results show that after quenching at 840℃ and tempering at 300℃, the microstructure of the 9CrV steel is tempered martensite, granular carbide and retained austenite, with hardness of 56.7 HRC and impact absorbed energy of 4.66 J. With the decrease of quenching temperature to 800℃ and the increase of tempering temperature to 400℃, the hardness of the 9CrV steel decreases to 49.8 HRC, which decreases by 12.2%, and the impact absorbed energy increases to 8.98 J, which increases by 92.7%. The reason is that the amount of undissolved carbides increases with the decrease of quenching temperature. On the one hand, the microstructure is refined. On the other hand, the carbon content of martensite decreases after quenching. Both of them provide the basis for improving the strength and toughness of quenched microstructure. The microstructure changes from tempered martensite to tempered troostite with increasing tempering temperature. The impact resistance of the 9CrV steel can be effectively improved by comprehensive control of quenching and tempering process.

热处理工艺调控9CrV钢显微组织及力学性能

[J].

Comparison of microstructure and mechanical behavior of lower bainite and tempered martensite in JIS SK5 steel

[J].

Source and formation mechanism of bainite carbides in 200Cr12 steel

[J].

200Cr12钢下贝氏体碳化物来源及形成机制

[J].

Low cycle fatigue behavior of a multiphase microalloyed medium carbon steel: comparison between fer-rite-pearlite and quenched and tempered microstructures

[J].

Experimental study on the effect of retained austenite on the impact toughness of a low-carbon martensite steel

[J].

Precipition of the carbides in lower bainite

[J].

下贝氏体中碳化物的析出

[J].

Austempering of bearing steel for improved mechanical properties

[J].

Microstructure evolution mechanism of HSLA steel

[J].

低合金高强钢微观组织转变机制

[J].

Temper bainite brittleness of structural steels

[J].

几种结构钢的回火贝氏体脆性

[J].

Microstructure and properties of high carbon bainite steel at low temperature

[J].

高碳贝氏体钢的低温转变组织与性能

[J].

Influence of low-temperature bainite transformation on toughness of medium-carbon steel

[J].

低温贝氏体转变对中碳钢韧性的影响

[J].

Effect of tempering on microstructure and mechanical properties of a nonquenched bainitic steel

[J].

Effect of heat treatment on microstructure and mechanical properties of quenching and partitioning steel

[J].

Mechanical properties of a microalloyed bainitic steel after hot forging and tempering

[J].

In situ observation of fatigue crack retardation in banded ferrite-pearlite microstructure due to crack branching

[J].

Effect of inter-lamellar spacing and test temperature on the Charpy impact energy of extremely fine pearlite

[J].