Al-Zn-Mg-Cu(7000系)高强铝合金具有高比强度、比刚度和良好的耐腐蚀性能,在航空航天、船舶制造、轨道交通等领域得到了广泛的应用[1,2]。添加稀土元素Sc对铝合金有显著的改性作用,使其具有高强度、高耐热性和良好的抗蚀性[3,4]。在传统7055、7075等高强铝合金中加入微量Sc元素的Al-Zn-Mg-Cu-Sc铝合金可使其具有更加优异的综合力学性能[5,6],但是用熔焊焊接高强7000系(包括含Sc)铝合金时产生的气孔和热裂纹等缺陷使接头的力学性能严重降低[7]。搅拌摩擦焊(Friction Stir Welding,FSW)是一种固相连接技术,特别适于焊接Al-Zn-Mg-Cu-Sc铝合金 [8]。

虽然FSW的热输入明显小于熔焊,但是其接头仍出现软化现象。先前的研究表明,提高时效强化铝合金接头力学性能的三种方式,分别是提高焊接速度[9,10]、采用冷却介质增加FSW过程的冷却速率[11]和焊后热处理[12~15]。焊后热处理是最有效的方式。对5.4 mm厚2219-T6铝合金FSW接头的研究表明[12],焊后人工时效热处理能显著提高焊速接头的力学性能。对6 mm厚2014-T6铝合金FSW接头的研究表明[12],焊后固溶+人工时效(T6)热处理可将接头硬度恢复到母材的水平,但是接头焊核区(Nugget zone, NZ)的晶粒发生了异常长大[13]。Robert等[14]对2519-0.36Sc铝合金进行FSW,发现焊后T6热处理使接头的整体硬度明显提高,但是NZ区的晶粒异常长大,且在NZ与热机影响区(Thermal-mechanically affected zone, TMAZ)的界面出现了孔洞,使接头的疲劳性能大幅降低。以上研究表明,焊后热处理能提高时效强化铝合金FSW接头的硬度,但是T6热处理使某些合金接头NZ出现晶粒异常长大和孔洞。在焊后T6热处理过程中FSW接头的晶粒是否异常长大,与接头的原始晶粒尺寸有密切的关系[15],而工艺参数是影响FSW接头晶粒尺寸的关键因素。Sc能抑制晶粒长大。基于此,本文对11 mm厚7055-0.1Sc-T4铝合金进行FSW,研究焊后人工时效和T6热处理对接头的组织和性能的影响。

1 实验方法

表1 7055-0.1Sc-T4轧制板材的化学成分

Table 1

| Zn | Mg | Cu | Sc | Zr | Si | Fe | Mn | Al |

|---|---|---|---|---|---|---|---|---|

| 7.6~8.4 | 1.8~2.3 | 2.0~2.6 | 0.1 | 0.08~0.25 | ≤0.1 | ≤0.15 | ≤0.05 | Bal. |

表2 7055-0.1Sc-T4轧制板材的拉伸性能

Table 2

| Yield Strength / MPa | Tensile Strength / MPa | Elongation / % |

|---|---|---|

| 595±28 | 635±36 | 9±5 |

进行FSW前,用砂纸将试板表面打磨以除去表面的氧化膜,再用酒精清除表面的油污。用FSW-SDLM 50型焊机对100 mm×300 mm板材进行对焊,搅拌头的主轴倾角为2.75°,转速为500 r/min,焊速分别为100 mm/min和250 mm/min,焊后的接头在空气中自然冷却至室温。

将接头在室温下放置20 d后,切取试样分别进行焊后人工时效(120℃×24 h)和T6(470℃×1.5 h+水淬+120℃×24 h)热处理。分别将焊态(As welded, AW)接头、焊后人工时效态(Artificial aging, AA)接头和固溶+人工时效态(T6)接头简称AW接头、AA接头和T6接头。例如,500-100-AW表示转速为500 r/min,焊速为100 mm/min的焊接态接头。

在垂直于焊接方向切取金相样品,将其磨抛后用Keller试剂(2 mL HF+3 mL HCl+5 mL HNO3+190 mL H2O)腐蚀,然后分别用体视显微镜和Leica DMI光学显微镜观察其宏观和微观组织。

沿焊接样品板厚的中线,使用Leco LM-247AT型硬度仪测试样品的显微硬度,载荷为300 g,保压时间15 s,各点间距为1.5 mm。将TEM试样预减薄至约60 μm,然后将其冲成直径为3 mm的圆片,再将其在30% HNO3+70% CH3OH溶液中双喷减薄,用液氮冷却后使用JEOL JEM-2100F型透射电镜(TEM)观察和分析接头各区域的第二相特征,加速电压为200 kV。

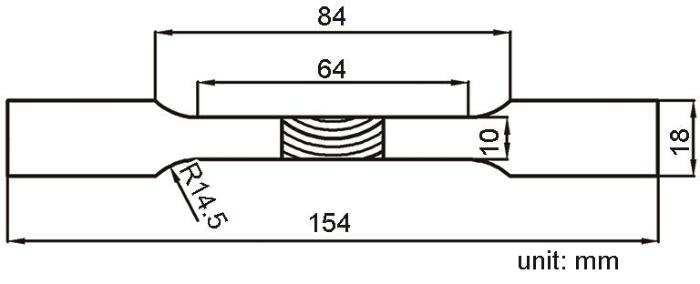

在垂直于焊接方向切取室温拉伸样品,其尺寸在图1中给出。用INSTRON 5982型拉伸机测试拉伸性能,应变速率为1×10-3 s-1,测试3个标准试样,取其结果的平均值。用Quanta 450型扫描电镜(SEM) 观察拉伸后断口的形貌。

图1

2 结果和讨论

2.1 接头的形貌

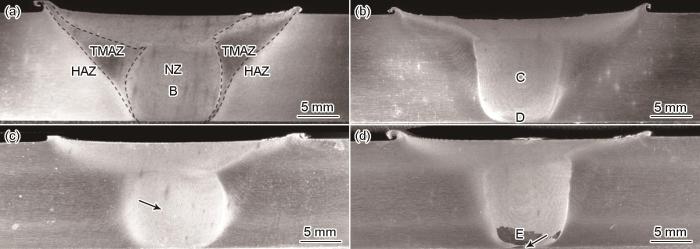

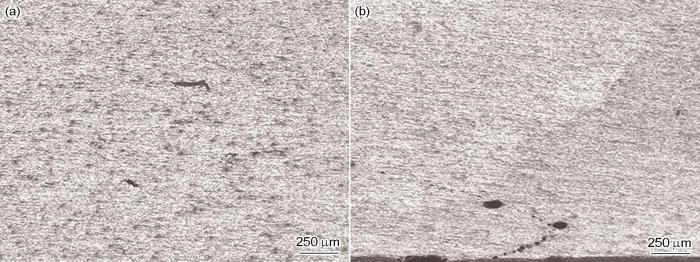

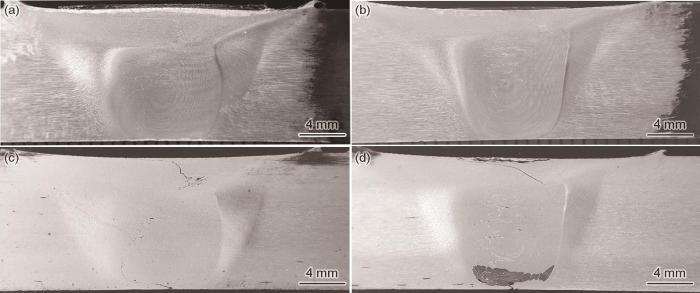

图2给出了各种FSW 7055-0.1Sc-T4接头横截面的宏观形貌。可以看出,焊接态接头均没有出现任何焊接缺陷(图2a和b),可分为NZ、TMAZ和热影响区(Heat affected zone, HAZ)三个区域。焊后T6热处理没有改变低焊速接头500-100-T6的宏观形貌(图2c),但是高焊速接头500-250-T6底部的颜色发生明显的改变(图2d)且出现了晶粒异常长大。接头500-100-T6中心和接头500-250-T6底部(图2c和d中黑色箭头所示)的抛光态局部放大图显示,在两个区域均出现了微小孔洞(图3a和b),其位置均位于接头“S”线上。与AW接头相比,人工时效热处理的FSW接头宏观和微观形貌没有变化。

图2

图2

FSW 7055-0.1Sc-T4焊接态和T6态接头横截面的宏观形貌

Fig.2

Cross-sectional macrostructure of FSW 7055-0.1Sc-T4 joints (a) 500-100-AW, (b) 500-250-AW, (c) 500-100-T6, (d) 500-250-T6

图3

图3

图2c, d中黑色箭头所示位置的放大图

Fig.3

Magnified of zones marked by the black arrows in Fig.2c, d

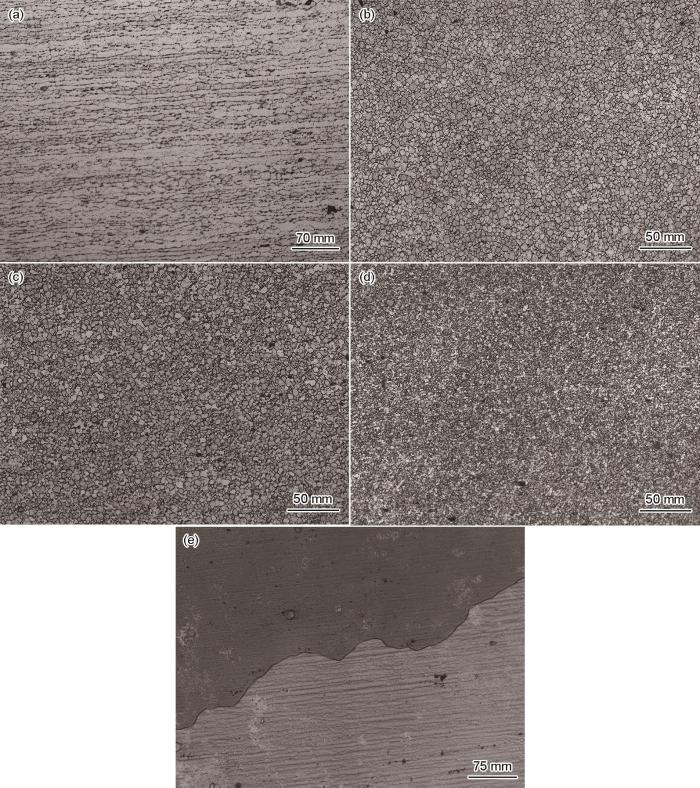

温度较低(120℃)的人工时效热处理后,FSW接头的宏观和微观形貌与焊接态接头的组织基本相同,而FSW铝合金接头在焊后T6热处理过程中晶粒异常长大[13~15]。铝合金的晶粒稳定性与晶粒尺寸和第二相分布有关[15~17]。在FSW过程中较高的热输入和剧烈塑性变形使NZ发生动态再结晶,NZ晶粒为等轴细小的再结晶晶粒,此时晶界处于高自由能状态,焊后晶界仍保持较高的能量状态,NZ底部晶粒越细其晶界能越高[18]。本文的研究中,低焊速接头500-100-AW的晶粒较大。NZ中Al3(Zr, Sc)等难溶颗粒对晶粒长大的抑制,使焊后T6热处理没有改变低焊速接头500-100-T6的晶粒形貌。但是,高焊速500-250-AW接头的晶粒更加细小,高角晶界能给二次再结晶极大的驱动力,细小晶粒与周围晶粒合并以降低晶界能,达到更稳定的组织状态[19];Al3(Zr, Sc)等相对晶界的钉扎已不能抑制其晶粒长大,因此在接头500-250-T6 NZ底部晶界能最高的位置发生晶粒异常长大(图2d和图4e)。

图4

图4

FSW 7055-0.1Sc-T4焊接态和T6态接头不同位置的微观组织

Fig.4

OM of different regions in the FSW joints (a) BM, (b)~(e) magnified NZ of position B~E in Fig.2

图5给出了FSW 7055-0.1Sc-T4接头中的“S”线分布。“S”线源自于板材原始面,由高密度的Al2O3颗粒组成[20]。从图5可以看出,转速为500 r/min、焊接速度为100 mm/min时“S”线从NZ的底部开始偏向后退侧,最后呈弧状向上曲折延伸到接头上部(图5a)。焊速由100 mm/min提高到250 mm/min,NZ材料的流动弱化[21],使后退侧更多的金属材料参与NZ成型,使接头“S”线的弯曲程度提高且集中在NZ中心区域(图5b)。与AW态相比,T6热处理的接头其“S”线形状不变,但更加直观、易于观察(图5c和d),“S”线上分布着许多黑点。本研究中的黑点形貌分布与Ren等[22]对FSW 7075-T651铝合金接头的报道类似。该报道称,T6热处理后接头沿“S”线开裂,周围有许多小孔洞。Hu等[23]观察了T6热处理后FSW接头“S”线周围出现的小孔洞,认为FSW接头的残余应力和氧化物与基体之间线膨胀系数的差异产生的热应力,是T6热处理后“S”线周围产生小孔洞的原因。这可用于解释本文实验中T6热处理后接头出现孔洞缺陷(图3a和b)。

图5

图5

FSW 7055-0.1Sc-T4焊接态和T6态接头的“S”线分布

Fig.5

Pattern of “S” line in FSW 7055-0.1Sc-T4 joints (a) 500-100-AW, (b) 500-250-AW, (c) 500-100-T6, (d) 500-250-T6

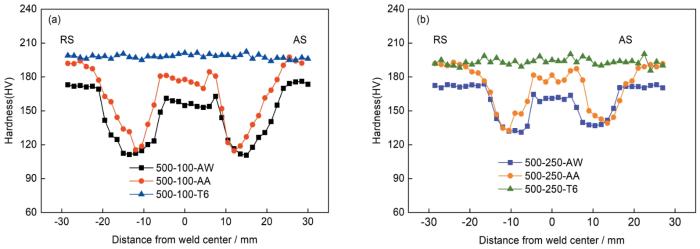

2.2 硬度分布

图6

图6

FSW 7055-0.1Sc-T4接头横截面中心线的显微硬度分布

Fig.6

Microhardness profile of FSW 7055-0.1Sc-T4 joints

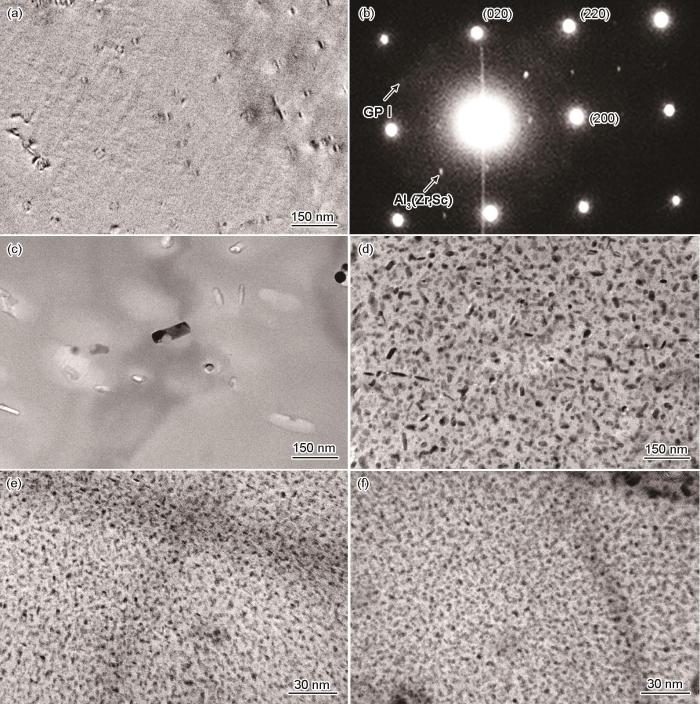

沉淀强化铝合金FSW接头的硬度分布,主要受各区域沉淀强化相演变的影响。7000系(Al-Zn-Mg-Cu)铝合金是可热处理强化铝合金,在T6热处理过程中这种合金的析出相序列为SSSS→GP Zone(I or II)→η'(MgZn2)→η(MgZn2)[9]。在7055铝合金中添加微量Sc元素,生成的Al3(Zr, Sc)与基体保持良好的共格关系[4],弥散分布在基体中有稳定晶界和弥散强化的作用。Al-Zn-Mg-Cu-Sc铝合金在较低的温度(25~100℃)时效GP区和Al3(Zr, Sc)是主要强化相[9],而在高于120℃[9]的温度时效则η'相、η相和Al3(Zr, Sc)相是主要强化相。

图7

图7

FSW 7055-0.1Sc-T4焊接态和T6接头沉淀相的分布

Fig.7

TEM micrographs (a) BF and (b) associated diffraction patterns of BM; (c) NZ and (d) LHZ of 500-100-AW; (e) NZ and (f) LHZ of 500-100-T6

2.3 拉伸性能和断裂特征

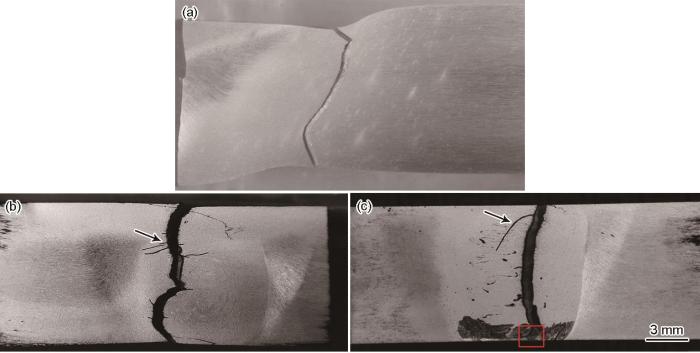

表3列出了各FSW 7055-0.1Sc-T4接头的拉伸性能。可以看出,FSW各接头的抗拉强度明显低于BM;焊后人工时效热处理使500~100和500~250接头的抗拉强度分别小幅度提高了15.9 MPa和9.1 MPa,塑性小幅度降低;而焊后T6处理使500-100-T6和500-250-T6接头的抗拉强度分别大幅度提高了156.6 MPa和86.5 MPa,其最高强度系数可达87.6%,但是接头几乎没有塑性而直接脆断。

表3 FSW 7055-0.1Sc-T4的接头热处理前后的拉伸性能

Table 3

| Number | Sample | Tensile Strength / MPa | Elongation / % | Strength coefficient / % |

|---|---|---|---|---|

| 1 | 500-100-AW | 399.9±1.4 | 8.9±0.5 | 63.0% |

| 2 | 500-250-AW | 468.5±7.8 | 6.3±0.5 | 73.8% |

| 3 | 500-100-AA | 415.8±2.1 | 4.3±0.4 | 65.5% |

| 4 | 500-250-AA | 477.6±3.5 | 3.8±0.4 | 75.2% |

| 5 | 500-100-T6 | 556.5±1.5 | Brittle fracture | 87.6% |

| 6 | 500-250-T6 | 555.0±2.0 | Brittle fracture | 87.4% |

图8

图8

FSW 7055-0.1Sc-T4焊接态和T6接头的断裂位置

Fig.8

Fracture locations of FSW 7055-0.1Sc-T4 joints (a) 500-100-AW, (b) 500-100-T6, (c) 500-250-T6

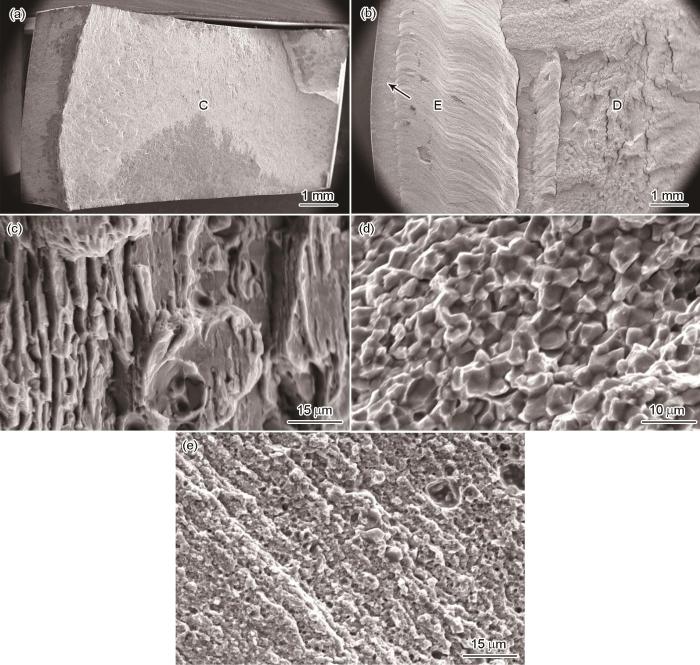

图9给出了FSW 7055-0.1Sc-T4 接头的典型断口形貌。从图9可见,500-100-AW接头断口的宏观形貌较为平坦(图9a),而500-100-T6接头的宏观断口上、下明显不同。图9b中左侧黑色箭头一侧为接头下部,呈台阶状,而上部凹凸不平。500-100-AW断口中心位置C放大后的微观形貌表明,其断裂形式主要是穿晶断裂,可观察到明显的韧窝组织,韧窝底部有沉淀相颗粒,是典型的铝合金断口形貌(图9c)。在500-100-T6接头的拉伸过程中,其NZ中部“S”线上的孔洞成为裂纹源,裂纹沿“S”线向接头上下扩展。因此,位置D和E放大后的微观形貌为解理断裂,没有明显的韧窝组织特征,为典型的脆性断裂特征(图9d和e)。需要强调的是,接头500-250-AW、500-100-AA和500-250-AA与接头500-100-AW断口的形貌类似,接头500-250-T6与接头500-100-T6的断口形貌类似。

图9

图9

FSW 7055-0.1Sc-T4焊接态和T6接头断口的形貌

Fig.9

Fracture morphologies of FSW 7055-0.1Sc-T4 joints, macrographic of (a) 500-100-AW, (b) 500-250-T6; magnified micrographs of positions C-E: (c) position C, (d) position D, (e) position E

3 结论

(1) 在转速为500 r/min、焊接速度为100~250 mm/min条件下,7055-0.1Sc-T4的FSW接头没有焊接缺陷,其最低硬度区位于热影响区。

(2) 焊后人工时效热处理使焊核区和母材区域的硬度提高,但是低硬度区的硬度没有明显变化,接头的抗拉强度小幅提高而塑性降低。

(3) T6热处理后低焊速接头焊核区的晶粒没有异常长大,但是高焊速接头焊核区底部的晶粒异常长大;T6热处理将FSW 7055-0.1Sc-T4接头各区的硬度提高到均一水平,使其强度大幅提高、强度系数提高到87.6%,但是其塑性极低。

(4) 焊接态“S”线不影响FSW 7055-0.1Sc-T4接头的拉伸性能,但是T6热处理使接头出现沿“S”线分布的孔洞,拉伸时接头沿“S”线脆断。

参考文献

Characterization and comparison of process chains for producing automotive structural parts from 7xxx aluminum sheets

[J].Due to their high specific strength, EN AW-7xxx aluminium alloys are promising materials for reducing the weight of automotive structural parts. However, their formability at room temperature is poor due to pronounced natural ageing. Therefore, we investigated hot stamping and W-temper forming for EN AW-7075 and a modified variant of EN AW-7021. For hot stamping of the modified EN AW-7021, a low-temperature stabilisation heat treatment (pre-aging at 80 °C for 1 h) was incorporated into the process chain design to inhibit natural ageing after forming. The process chains were compared with respect to dimensional accuracy, mechanical properties, microstructure, precipitation status (assessed by differential scanning calorimetry) and crashworthiness. It was found that hot stamping is suitable to form failure-free parts with good dimensional accuracy for both alloys while W-temper forming suffers from springback. Within a time-span of 21 days after forming, hardness values of hot stamped and stabilised parts did not increase significantly. Compared to non-stabilised parts, stabilised parts also showed significantly improved folding behaviour in quasi-static compression testing and absorbed approximately 15% more energy.

Mechanical properties, corrosion behavior and microstructures of a non-isothermal ageing treated Al-Zn-Mg-Cu alloy

[J].

The effects of Sc addition on the microstructure and mechanical properties of Be-Al alloy fabricated by induction melting

[J].

Microalloying Al alloys with Sc: a review

[J].

Effect of Sc on microstructure and mechanical property of 7055 Al-alloy

[J].The effect of Sc addition on the microstructure and mechanical properties of 7055 Al-alloy as-cast, as well as after homogenization-, rolling-, solution- and aging-treatment was investigated. The addition of 0.25%(mass fraction) Sc could lead to the formation of Al3(Sc, Zr) phase, which can promote the heterogeneous nucleation during casting. Therefore, the microstructure of the as cast 7055 Al-alloy was refined. The precipitation of nano-sized Al3(Sc, Zr) phase occurred during the homogenization treatment of the 7055-Sc Al-alloy, and this nano-sized Al3( Sc, Zr) phase could effectively inhibit the coarsening of Al grains during homogenization treatment, and play a role in pinning the grain boundaries, therewith inhibiting the recovery and recrystallization, thus retaining the fiber-like structure during subsequent rolling and solution treatments. Compared to the plain 7055 Al-alloy, the 7055-Sc Al alloy exhibited much higher fine grain strengthening effect due to finer grain size and showed higher tensile strength and hardness as high as 642 MPa and 218 HV, respectively.

添加Sc对7055铝合金微观结构和力学性能的影响

[J].研究了添加Sc元素对7055铝合金铸造、均匀化处理、轧制和固溶时效过程的微观结构演化以及力学性能的影响。结果表明,向7055溶液中添加质量分数为0.25%的Sc导致在铸造过程中形成初生Al<sub>3</sub>(Sc,Zr)相。这个相能促使合金发生非均质形核,显著细化合金的铸造组织。在7055-Sc铝合金的均匀化处理过程中析出高密度纳米Al<sub>3</sub>(Sc, Zr)相,不但能抑制晶粒粗化,而且在后期轧制变形和固溶时效处理过程中还起钉扎晶界、抑制回复与再结晶、保留纤维组织的作用。与7055铝合金相比,7055-Sc铝合金的晶粒尺寸更小,因此具有更有效的细晶强化效应。添加Sc的时效处理态7055铝合金的最大抗拉强度和显微硬度,分别提高到642 MPa和218 HV。

Fabrication of 7075-0.25Sc-0.15Zr alloy with excellent damping and mechanical properties by FSP and T6 treatment

[J].

A short review on aluminum alloys and welding in structural applications

[J].

Friction stir welding and processing

[J].

Influence of welding parameters on mechanical, microstructure, and corrosion behavior of friction stir welded Al 7017 alloy

[J].

Effect of process parameters on mechanical properties of friction stir welded 2195 Al-Li alloy joints

[J].

工艺参数对2195铝锂合金搅拌摩擦焊接头力学性能的影响

[J].

Micro-softening behavior and its control of 7N01-T5 Al alloy friction stir welded joint

[J].

7N01-T5铝合金搅拌摩擦焊接头微区软化行为及控制

[J].

Enhancing mechanical properties of friction stir welded 2219Al-T6 joints at high welding speed through water cooling and post-welding artificial ageing

[J].

Influence of post weld heat treatment on microstructure and mechanical properties of friction stir-welded 2014Al-T6 alloy

The influence of post-weld heat treatment on the microstructure and fatigue properties of Sc-modified AA2519 friction stir-welded joint

[J].The aim of this research was to investigate the influence of post-weld heat treatment (PWHT, precipitation hardening) on the microstructure and fatigue properties of an AA2519 joint obtained in a friction stir-welding process. The welding process was performed with three sets of parameters. One part of the obtained joints was investigated in the as-welded state and the second part of joints was subjected to the post-weld heat treatment (precipitation hardening) and then investigated. In order to establish the influence of the heat treatment on the microstructure of obtained joints both light and scanning electron microscopy observations were performed. Additionally, microhardness analysis for each sample was carried out. Fatigue properties of the samples in the as-welded state and the samples after post-weld heat treatment were established in a low-cycle fatigue test with constant true strain amplitude equal to ε = 0.25% and cycle asymmetry coefficient R = 0.1. Hysteresis loops together with changes of stress and plastic strain versus number of cycles are presented in this paper. The fatigue fracture in tested samples was analyzed with the use of scanning electron microscope. Our results show that post-weld heat treatment of AA2519 friction stir-welded joints significantly decreases their fatigue life.

Stability of nugget zone grain structures in high strength Al-alloy friction stir welds during solution treatment

[J].

Microstructural thermal stability of aluminum alloy friction stir welding joint

[J].

铝合金搅拌摩擦焊接头组织热稳定性

[J].

Suppression of abnormal grain growth in friction-stir welded Al-Cu-Mg alloy by lowering of welding temperature

[J].

Influence of welding combined plastic forming on microstructure stability and mechanical properties of friction stir-welded Al-Cu alloy

[J].

Characterizations on microstructures and properties of 7075 aluminum alloy after friction stir processing and subsequent heat treatment

[D].

7075铝合金搅拌摩擦加工及热处理后的组织性能表征研究

[D].

Effect of segregation of secondary phase particles and "S" line on tensile fracture behavior of friction stir-welded 2024Al-T351 joints

[J].

Effect of processing parameters on plastic flow and defect formation in friction-stir-welded aluminum alloy

[J].

Effect of initial butt surface on tensile properties and fracture behavior of friction stir welded Al-Zn-Mg-Cu alloy

[J].

Microstructure and mechanical properties of friction stir welding joint during post weld heat treatment with different zigzag lines

[J].

Impact of initial temper of base metal on microstructure and mechanical properties of friction stir welded AA 7055 alloy

[J].

Friction stir welding of Al alloy 2219-T8: part I-evolution of precipitates and formation of abnormal Al2Cu agglomerates

[J].

Influence of tool dimension and welding parameters on microstructure and mechanical properties of friction-stir-welded 6061-T651 aluminum alloy

[J].