1 实验方法

1.1 铌酸钾钠薄膜的制备

用溶胶凝胶法制备K0.5Na0.5NbO3(KNN)和xMn-(K0.5Na0.5)NbO3前体液,其中x分别为0.05和0.10。将原料乙醇铌在90℃水浴加热1 h溶解在乙二醇甲醚中,得到含铌溶液。一份含铌溶液用来制备氧化铌种子层的前体液。向其他铌溶液按摩尔比加入乙酸钾、乙酸钠和乙酸锰,其中钾钠过量摩尔比10%,以弥补在薄膜制备过程中钾钠的挥发。水浴加热30 min后加入乙酰丙酮为稳定剂,再用醋酸调节溶胶溶度至0.4 mol/L。然后将溶胶静置48 h。为了准备薄膜,将溶胶旋涂在衬底和带单层氧化铌种子层的衬底上,然后在热板上热解,最后置于管式炉退火,重复6次得到薄膜。其中氧化铌种子层的制备工艺与KNN薄膜和KNNM薄膜制备工艺相同。

实验中使用Pt/Ti/SiO2/Si衬底,使用匀胶机旋涂薄膜,转速为3500 r/min,时间30 s。采用层层退火的退火方式,即旋涂一次就热解和退火一次,重复6次。其中单次的热解温度和退火时间分别为200℃和700℃,对应的热解时间和退火时间为5 min和10 min。

1.2 铌酸钾钠薄膜性能的表征

用Cu Kα 辐射(λ=0.15418 nm)的X-射线衍射(XRD; Bruker D8 Advance)分析薄膜的结晶相。用FESEM(SU8000,Hitachi)表征薄膜的形态。使用Precision Premier II铁电测试系统(辐射技术)分析薄膜的铁电性能和漏电流。使用阻抗分析仪(TH2829C,同惠)测量介电常数。所有测量均在室温下进行。在进行电学测量之前,使用直流溅射在KNN膜的表面上制备金顶电极(ϕ=200 μm)。

2 结果和讨论

2.1 铌酸钾钠薄膜的相结构和表面形貌

图1给出了KNN薄膜的XRD。可以看出,薄膜样品都具有典型的钙钛矿晶体结构,没有出现第二相。KNN、5%Mn-KNN、10%Mn-KNN、NbO/5%Mn-KNN和NbO/10%Mn-KNN薄膜的(100)结晶峰位置分别位于22.326°、22.469°、22.509°、22.162°和22.080°,与纯KNN薄膜相比,掺杂Mn元素的KNN薄膜(100)结晶峰位置向更高角度偏移。这表明,Mn离子的引入不影响薄膜的晶体结构,并且Mn能进入KNN的晶格中[15~17]。掺杂Mn的KNN薄膜晶格向高角度偏移,表明晶格尺寸减小。由于Mn2+半径(0.067 nm)小于K+(0.138 nm)和Na+(0.102 nm)[18],而稍大于Nb5+半径(0.065 nm),一部分Mn2+可能是A位掺杂。而带种子层的掺杂锰的KNN薄膜的结晶峰向更低角度偏移,表明KNN薄膜的晶格尺寸增大。薄膜受到的应力可用公式

图1

图2a~d分别给出了KNN、5%Mn-KNN和NbO/5%Mn-KNN薄膜的微观表面形态和KNN截面形态。可以看出,薄膜的形态有显著的差异,未掺杂的KNN薄膜其晶粒尺寸大小不一致,厚度约为250 nm,且在薄膜表面可见明显的裂纹和缺陷。一方面,表面形态缺陷可能是薄膜内部残余应力引起的,而内部残余应力是KNN薄膜与基底的热膨胀系数不匹配所致。另一方面,钾钠在热解和退火过程中挥发也使薄膜产生晶格缺陷。图2b给出了掺杂锰元素的KNN薄膜表面形貌,可见均匀分布的晶粒和一些纳米孔和裂纹。与未掺杂的KNN薄膜相比,薄膜表面缺陷较小,表明掺杂锰元素使薄膜的表面形态改善[15]。图2c给出了带氧化铌种子层的掺杂锰元素KNN薄膜,与未带种子层的掺Mn元素的KNN薄膜相比,带种子层的KNN薄膜表面的晶粒和裂纹更细密,没有出现明显的裂纹和孔洞。作为过渡层,氧化铌种子层抑制了薄膜内部残余应力引起的裂纹。

图2

图2

薄膜的SEM形貌

Fig.2

SEM images of the films (a) KNN films; (b) 5%Mn-KNN films; (c) NbO/5%Mn-KNN films; (d) KNN films section

2.2 铌酸钾钠薄膜的电学性能

图3给出了KNN系薄膜的介电频谱,其曲线在1 kHz至1 MHz频率范围内表现出共同的特征,即介电常数值随着频率的提高而略有减小,损耗正切值先减小然后略有增加(与频率无关)。同时,在高频区域中KNN薄膜的损耗角正切值低且稳定,表明KNN薄膜材料有微波应用的潜在价值。与纯KNN薄膜相比,掺杂锰元素的KNN薄膜及带种子层的KNN薄膜的介电常数值都有所增大。在1 kHz下,KNN介电常数最小为342.98,5%Mn-KNN和10% Mn-KNN次之,分别对应为424.92和353.63,NbO/5%Mn-KNN和NbO/10%Mn-KNN薄膜的介电常数较大分别对应为492.49和475.52。掺杂锰元素能提高介电常数,其原因是Mn元素补偿了因碱金属离子挥发引起的电荷缺陷并改善了KNM薄膜的微观结构。而带有种子层的锰掺杂的KNN薄膜介电常数值的增大,可能是其晶粒和表面形貌更细密所致。

图3

图4给出了KNN系薄膜的PE电滞回线和电场在200 kV/cm下薄膜的剩余极化强度和最大极化强度值。可以看出,纯KNN薄膜只显示了在较低电场下的PE电滞回线,且随着电场强度的增大而显示出不饱和的电滞回线。与其余KNN薄膜相比,纯KNN薄膜的剩余极化值最大。其原因是,纯KNN薄膜的剩余极化值中有漏电流的较大贡献。与之相对的,即使电场强度加大两倍,锰掺杂的KNN薄膜电滞回线也表现更加饱和,表明掺杂Mn元素可提高薄膜的铁电性能。值得注意的,在掺杂锰元素的KNN薄膜中引入种子层使薄膜的电滞回线更加饱和,并且带种子层锰掺杂摩尔浓度为10%的KNN薄膜其电滞回形更加细长,表明其较大的最大极化强度和较小的剩余极化强度值。具体表现是,在600 kV/cm的电场下薄膜的最大极化值和剩余极化值分别为20.33 µC/cm2和2.94 µC/cm2,其最大极化值与剩余极化值的差值为17.39 µC/cm2。这与Zhao等[10]用锰钽复合掺杂制备的KNN薄膜报道的值相当,表现出良好的储能材料的潜在价值。图4f给出了KNN薄膜在200 kV/cm电场下的最大极化值和剩余极化值。其中横坐标分(a)、(b)、(c)、(d)和(e)分别对应KNN、5%Mn-KNN、NbO/5%Mn-KNN、10%Mn-KNN和NbO/10%Mn-KNN薄膜。结果表明,掺杂锰元素和引入种子层,能有效提高薄膜铁电性能和降低薄膜的漏电流。

图4

图4

KNN、5%Mn-KNN、NbO/5%Mn-KNN、10% Mn-KNN、NbO/10%Mn-KNN薄膜的电滞回线以及薄膜在200 kV/cm电场中的最大极化值和剩余极化值

Fig.4

Hysteresis loop of KNN films (a), 5% Mn-KNN films (b), NbO/5% Mn-KNN films (c), 10% Mn-KNN films (d), NbO/10% Mn-KNN films (e) and Maximum polarization value and residual polarization value of the films in 200 kV/cm (f)

2.3 铌酸钾钠薄膜的漏电流与漏电机制

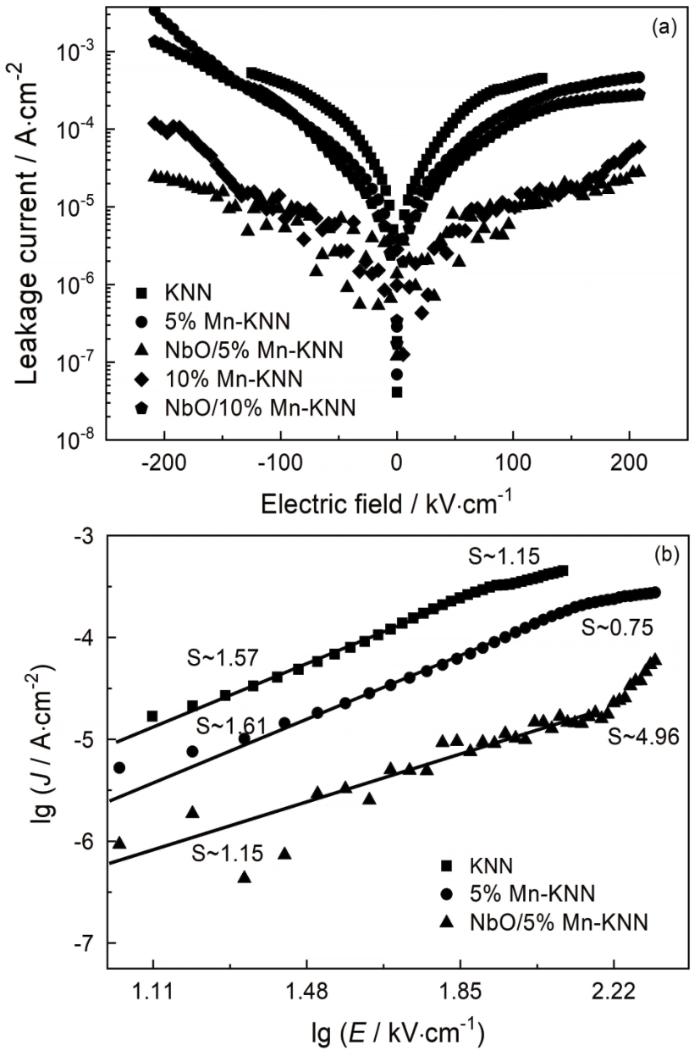

图5给出了KNN系薄膜的漏电流和电场的IE曲线。可以看出,纯KNN薄膜的漏电流最大,这是薄膜薄膜表面有较多的缺陷所致。而薄膜表面出现缺陷的原因,一方面是热解和退火过程中钾钠挥发,而另一方面是热应力失配。掺杂Mn元素可使薄膜表面缺陷减小,并且Mn元素能减少一部分钾钠挥发导致的薄膜晶格缺陷,这表现为图中比纯KNN薄膜有更小的漏电流。与其余KNN薄膜相比,带种子层且掺杂锰元素的KNN薄膜的漏电流最小,下降幅度也较大(下降一个数量级)。其原因是,一方面薄膜表面的缺陷更细小。另一方面,绝缘的氧化铌种子层进一步减小了薄膜的漏电流。Sun和Li等也观察到类似的结果[21,22]。为了进一步分析漏电流特性和传导机制,画出了KNN、5%Mn-KNN、NbO/5%Mn-KNN的漏电流与电场的关系曲线,以及lg(J)与lg(E)关系函数图,如图5b所示。施加电场达到83.3 kV/cm时,纯KNN薄膜的拟合线斜率发生改变。当电场小于83.3 kV/cm时拟合斜率接近2,表明导电机制为空间电荷传导[23]。电场大于83.3 kV/cm时拟合斜率接近1,为欧姆传导。掺杂锰元素的KNN薄膜,其导电机制与KNN薄膜类似。电场小于133.4 kV/cm时为空间电荷传导,电场大于133.4 kV/cm时为欧姆传导。带种子层且掺杂锰元素的KNN薄膜,其漏电流机制发生改变。电场小于158.5 kV/cm时,其导电机制为欧姆传导。电场大于158.5 kV/cm时其拟合斜率为4.96,表明其导电机制为肖特基发射机制[24,25]。这些结果表明,掺杂锰元素并不能改变薄膜的漏电流机制。而带种子层且掺杂锰元素的KNN薄膜,其漏电流改善的原因是漏电流机制发生改变。

图5

图5

KNN薄膜的电流密度与电场关系曲线以及KNN、5%Mn-KNN和NbO/5%Mn-KNN薄膜的In(J)与In(E)的关系曲线

Fig.5

Leakage current density (J) as a function of the applied electric field (E) for the KNN films (a) and ln(J)-ln(E) characteristics of KNN,5%Mn-KNN,NbO/5%Mn-KNN films (b)

3 结论

用溶胶凝胶法可制备K0.5Na0.5NbO3(KNN)和xMn-(K0.5Na0.5)NbO3薄膜。Mn掺杂使KNN薄膜的介电性能、铁电性能和漏电流提高,引入氧化铌种子层使薄膜的漏电流机制发生转变,使薄膜的最大极化值和更小的剩余极化值更大。

参考文献

High to ultra-high power electrical energy storage

[J].High power electrical energy storage systems are becoming critical devices for advanced energy storage technology. This is true in part due to their high rate capabilities and moderate energy densities which allow them to capture power efficiently from evanescent, renewable energy sources. High power systems include both electrochemical capacitors and electrostatic capacitors. These devices have fast charging and discharging rates, supplying energy within seconds or less. Recent research has focused on increasing power and energy density of the devices using advanced materials and novel architectural design. An increase in understanding of structure-property relationships in nanomaterials and interfaces and the ability to control nanostructures precisely has led to an immense improvement in the performance characteristics of these devices. In this review, we discuss the recent advances for both electrochemical and electrostatic capacitors as high power electrical energy storage systems, and propose directions and challenges for the future. We asses the opportunities in nanostructure-based high power electrical energy storage devices and include electrochemical and electrostatic capacitors for their potential to open the door to a new regime of power energy.

Flexible high-temperature dielectric materials from polymer nanocomposites

[J].

A dielectric polymer with high electric energy density and fast discharge speed

[J].Dielectric polymers with high dipole density have the potential to achieve very high energy density, which is required in many modern electronics and electric systems. We demonstrate that a very high energy density with fast discharge speed and low loss can be obtained in defect-modified poly(vinylidene fluoride) polymers. This is achieved by combining nonpolar and polar molecular structural changes of the polymer with the proper dielectric constants, to avoid the electric displacement saturation at electric fields well below the breakdown field. The results indicate that a very high dielectric constant may not be desirable to reach a very high energy density.

Recent progress on ferroelectric polymer-based nanocomposites for high energy density capacitors: synthesis, dielectric properties, and future aspects

[J].Dielectric polymer nanocomposites are rapidly emerging as novel materials for a number of advanced engineering applications. In this Review, we present a comprehensive review of the use of ferroelectric polymers, especially PVDF and PVDF-based copolymers/blends as potential components in dielectric nanocomposite materials for high energy density capacitor applications. Various parameters like dielectric constant, dielectric loss, breakdown strength, energy density, and flexibility of the polymer nanocomposites have been thoroughly investigated. Fillers with different shapes have been found to cause significant variation in the physical and electrical properties. Generally, one-dimensional and two-dimensional nanofillers with large aspect ratios provide enhanced flexibility versus zero-dimensional fillers. Surface modification of nanomaterials as well as polymers adds flavor to the dielectric properties of the resulting nanocomposites. Nowadays, three-phase nanocomposites with either combination of fillers or polymer matrix help in further improving the dielectric properties as compared to two-phase nanocomposites. Recent research has been focused on altering the dielectric properties of different materials while also maintaining their superior flexibility. Flexible polymer nanocomposites are the best candidates for application in various fields. However, certain challenges still present, which can be solved only by extensive research in this field.

Significantly enhanced energy storage performance promoted by ultimate sized ferroelectric BaTiO3 fillers in nanocomposite films

[J].

Photovoltaic properties of ITO/PZT-Ag2O/Pt ferroelectric diodes

[J].

ITO/PZT-Ag2O/Pt铁电薄膜的光伏特性

[J].研究了在透明导电ITO玻璃衬底上制备PZT-Ag<sub>2</sub>O铁电薄膜的工艺条件, 并测量和表征了在不同衬底温度下生长的薄膜的相结构、表面形貌、铁电性能和光电特性。结果表明: 在ITO玻璃衬底上可制备出铁电性能较好的PZT-Ag<sub>2</sub>O铁电薄膜; ITO/PZT-Ag<sub>2</sub>O/Pt铁电器件实现了可见光响应, 其短路光电流和开路电压随极化电压的变化呈回线关系; 产生这一现象的物理机制为: 光生短路电流和开路电压的大小取决于退极化场和界面肖特基势垒的综合作用, 不同的外加极化电压在PZT薄膜诱导出强度不同的退极化场, 从而使光生短路电流和开路电压与外加极化电压呈回线型关系。

Synthesis of PZT (52/48) powders by wet-acoustic chemical method

[J].

湿声化学法制备PZT(52/48)压电陶瓷粉体

[J].将湿化学法中的sol-gel技术与声化学中的超声雾化技术相结合,提出一种新的陶瓷粉体合成方法-湿声化学法, 并制备了PZT(52/48)粉体.结果表明, 用湿声化学法制备PZT(52/48)粉体, 在400℃开始形成PZT钙钛矿相,比其它制备方法的温度(500-900℃)低, 在700℃保温2 h即可得到具有纯PZT结构相的粉体.用湿声化学法制备的粉体颗粒呈圆形, 粒径小于1 um.湿声化学法使用不溶性盐ZrO2而不是sol-gel方法中必须使用的可溶性盐,从而降低了成本.

Grain size engineered lead-free ceramics with both large energy storage density and ultrahigh mechanical properties

[J].

BiFeO3-doped (K0.5, Na0.5)(Mn0.005, Nb0.995)O3 ferroelectric thin film capacitors for high energy density storage applications

[J].

Energy storage performance of (K, Na)NbO3 ferroelectric thin films with Mn-Ta and Mn-Ti Co-doping

[J].

Large recoverable energy storage density and low sintering temperature in potassium sodium niobate based ceramics for multilayer pulsed power capacitors

[J].

Enhanced dielectric breakdown strength and energy storage density in lead-free relaxor ferroelectric ceramics prepared using transition liquid phase sintering

[J].

Lead-free relaxor ferroelectric ceramics with high optical transparency and energy storage ability

[J].

Potassium-sodium niobate based lead-free ceramics: novel electrical energy storage materials

[J].

Effects of Mn doping on dielectric and ferroelectric characteristics of lead-free (K, Na, Li)NbO3 thin films grown by chemical solution deposition

[J].

Electrical properties of B site substituted (K0.48Na0.52)(W2/3Bi1/3) x Nb1- x O3 piezoceramics

[J].

Influence of Mn2+ on the electrical properties of textured KNN thick films

[J].

Optical and structural properties of X-doped (X=Mn, Mg, and Zn) PZT nanoparticles by Kramers-Kronig and size strain plot methods

[J].

Comprehensive study of ZnO films prepared by filtered cathodic vacuum arc at room temperature

[J].

Lead-free ferroelectric potassium sodium niobate thin films from solution: composition and structure

[J].

Thickness dependent response of domain wall motion in declamped {001} Pb(Zr0.3Ti0.7)O3 thin films

[J].

Improved ferroelectric photovoltaic effect in Mn-doped lead-free K0.5Na0.5NbO3 films

[J].

Effects of interfacial seed layer and element doping on the electric properties of alkaline niobate based thin films

[D].

界面种子层及元素掺杂对铌酸钾钠基薄膜电性能的影响

[D].

Strong magnetoelectric effect of Bi4Ti3O12/Bi5Ti3FeO15 composite films

[J].