在17-4PH不锈钢的选区激光熔化成型过程中,激光参数、粉末特性以及后续热处理都影响其组织和性能[8~12]。Ponnusany等[8]研究了SLM过程中激光散焦距离对17-4PH不锈钢表面特性的影响。随着散焦距离由-6 mm减小至-4 mm零件表面的粗糙度降低,孔隙减少,显微硬度提高到414 HV;随着散焦距离继续减小至-3、-2和-1 mm表面粗糙度提高而显微硬度降低,即激光功率降低到85%散焦距离为-4 mm的零件具有最佳的表面粗糙度和显微硬度。Irrinki等[9]研究了水雾化和气雾化条件下17-4PH不锈钢粉末的SLM成形和材料的致密化。结果表明,在激光能量密度较低(64和80 J/mm3)的条件下使用气雾化和细粒径的水雾化粉末可得到较高的致密度(~97%),而使用粒径较粗的水雾化粉末的成形件其致密度较低(87%~92%);而在激光能量密度(84和104 J/mm3)较高的条件下,粉末粒度对致密度的影响较小。Sun等[10]指出,用SLM制备的17-4PH不锈钢中的氧化夹杂物主要来源于原料粉末,较粗的氧化夹杂物存在于激光熔池,使材料的疲劳和断裂性能产生各向异性,而较细小的夹杂物能抑制晶粒长大。Rashid等[11]证实,热处理可使SLM成形的17-4PH不锈钢中的回火马氏体主相均匀分布,使其硬度比锻造的高。Pasebahi等[12]指出,适当的热处理(1315℃固溶45 min、482℃时效1 h),能使水雾化17-4PH不锈钢粉末SLM成形材料达到与气雾化粉末成形件相当的性能。目前关于17-4PH不锈钢选区激光熔化成形的相关研究,主要是工艺参数优化、3D打印粉末质量的影响、热等静压(Hot isostatic pressing, HIP)致密化处理和常规热处理改性,旨在提高合金的综合力学性能[13-15]。本文优化17-4PH不锈钢的SLM成形工艺参数,对成形后的试样分别在热等静压设备中固溶时效、马弗炉中固溶时效、在热等静压设备中固溶和在马弗炉中时效,热处理制度均为1040℃固溶2 h、480℃时效4 h。观察实验后试样的微观组织并测试其力学性能,研究热处理对SLM成形17-4PH不锈钢的组织和性能的影响。

1 实验方法

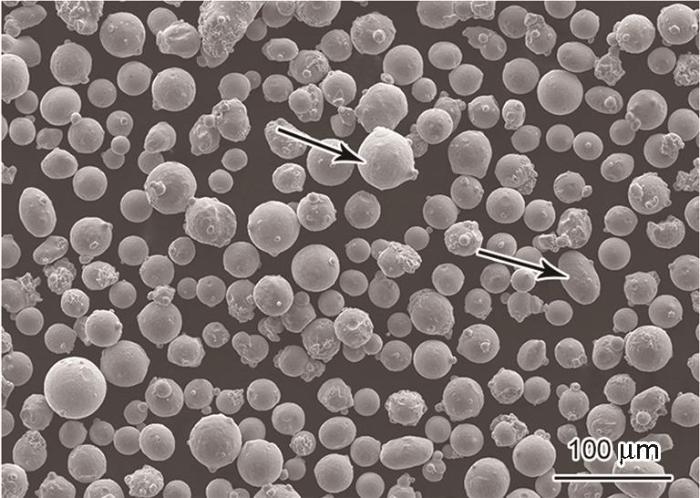

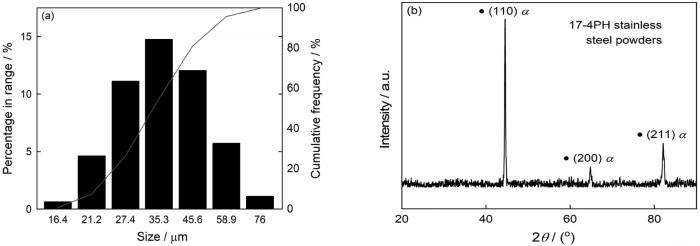

用气雾化法制备实验用17-4PH不锈钢粉末,其松装密度为4.05 g/cm3、振实密度为4.17 g/cm3和霍尔流动性能为17.7 s/50 g。用SU8220型扫描电子显微镜(Scanning electron microscopy, SEM)观察粉末的形貌。使用Mastersizer 3000激光粒度仪测量粉末的粒径,使用Rigaku D2500 X射线衍射仪分析粉末物相。

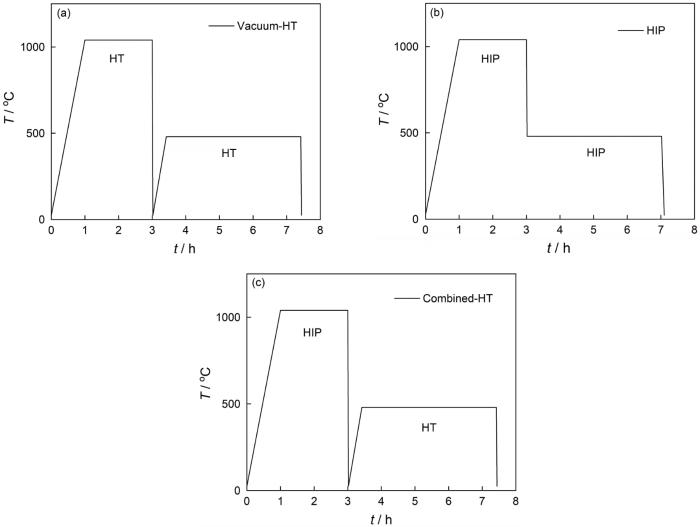

使用EOS M 290设备进行选区激光熔化成形,以氩气为保护气氛,工艺参数列于表1。打印样品的尺寸为48.5 mm×11 mm×3.5 mm。将打印样品分为4组,其中1组为没有热处理的沉积态,其余三组分别进行真空热处理、热等静压热处理以及组合热处理。①真空热处理是将打印试样封入真空玻璃管后放入热处理炉中,在1040℃固溶2 h后水淬。然后再次用真空玻璃管将样品密封,在480℃时效4 h后水冷。②用QIH-15L型热等静压机进行HIP热处理(在氩气气氛下):升温升压至1040℃和150 MPa后保温保压2 h,然后用URQ气体进行快冷(冷却速度约等于油冷速度),随后在480℃、气压大于100 MPa条件下时效4 h,再用URQ气体快冷至室温。③组合热处理,使用热等静压设备在1040℃、150 MPa条件下固溶2 h,然后用URQ气体快冷至室温。再用真空玻璃管将样品密封在480℃热处理炉中进行4 h的时效,随后水冷。工艺的示意图,如图1所示。与传统热处理相比,热等静压热处理在保证设定温度的同时还设定热处理过程的压力值。设计这三种热处理工艺,为了研究热等静压热处理固溶阶段闭合孔隙对材料性能的影响和热等静压热处理时效阶段对17-4PH不锈钢组织性能的影响。

表1 选区激光熔化工艺参数

Table 1

Laser power/W | Scanning speed /mm·s-1 | Layer thickness/μm | Hatch distance/μm |

|---|---|---|---|

| 200 | 755 | 40 | 110 |

图1

图1

选区激光熔化17-4PH不锈钢真空热处理、HIP热处理和组合热处理的工艺

Fig.1

Heat treatment processes of the SLM-processed 17-4PH stainless steels (a) vacuum heat treatment; (b) HIP heat treatment; (c) combined heat treatment

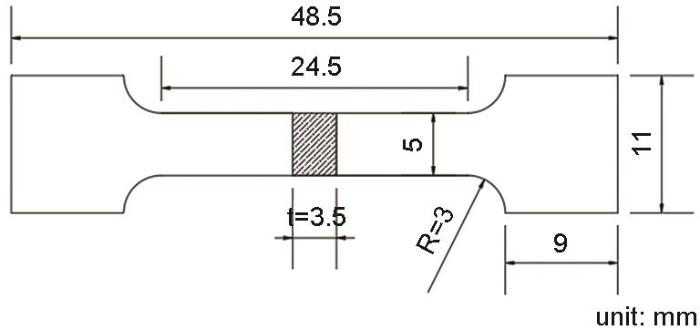

使用排水法测量样品的密度。采用DMI3000M型金相显微镜和SU8220型扫描电镜观察材料显微结构,所用腐蚀溶液为4 g CuSO4+20 mL HCl(浓度为36.5%)+20 mL H2O,腐蚀时间为10 s。使用Indentec ZHμ-S型硬度仪测量样品显微硬度,载荷为500 gf,加载时间为10 s。使用DNS200型万能拉伸试验机进行拉伸测试,拉伸样品的尺寸如图2所示,拉伸速度为1 mm/min。

图2

2 结果和讨论

2.1 17-4PH不锈钢粉末的形貌和粒度

图3

图4

图4

17-4 PH不锈钢原料粉末的粒度分布和X射线衍射谱

Fig.4

Particle size distribution (a) and X-ray diffraction spectrum (b) of initial powder of 17-4PH stainless steel

2.2 粉末样品的致密度

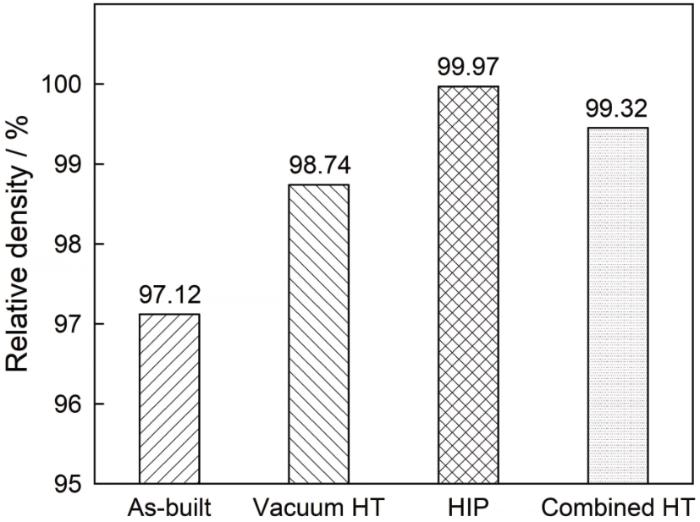

图5

图5

沉积态和热处理态17-4PH不锈钢的致密度

Fig.5

Relative densities of the as-built and heat treated 17-4PH stainless steel samples

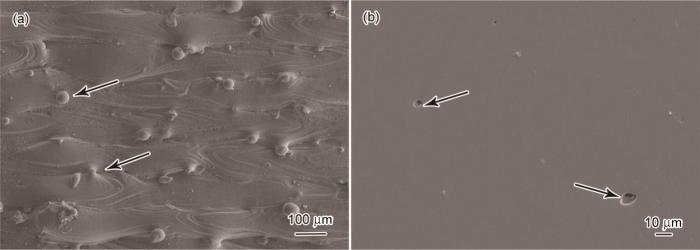

图6

图6

沉积态17-4PH不锈钢试样的表面形貌和侧面微观孔隙

Fig.6

Top (a) and side (b) view morphology of the as-built 17-4PH stainless steel sample

图7

图7

选区激光熔化17-4PH不锈钢的真空热处理、HIP热处理和组合热处理态的侧面微观孔隙

Fig.7

Micro-pores of the SLM-processed 17-4PH stainless steels after different heat treatments (a) vacuum heat treatment; (b) HIP heat treatment; (c) combined heat treatment

2.3 相组成和微观组织

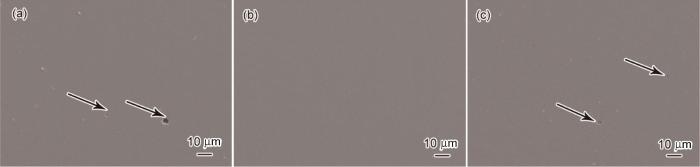

图8

图8

沉积态和不同热处理态的选区激光熔化17-4PH不锈钢的X射线衍射谱

Fig.8

XRD spectra of the as-built and heat treated 17-4PH stainless steel samples

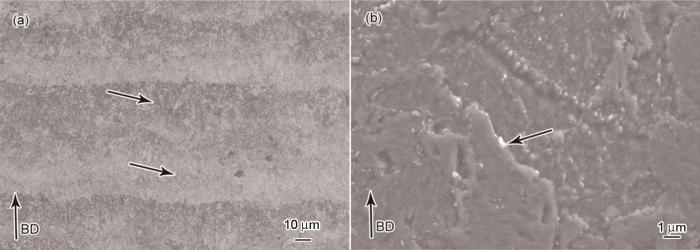

图9

图9

选区激光熔化17-4PH不锈钢的光镜和扫描电镜照片

Fig.9

Optical microscopy (a) and SEM micrographs (b) of the SLM-processed 17-4PH stainless steel sample

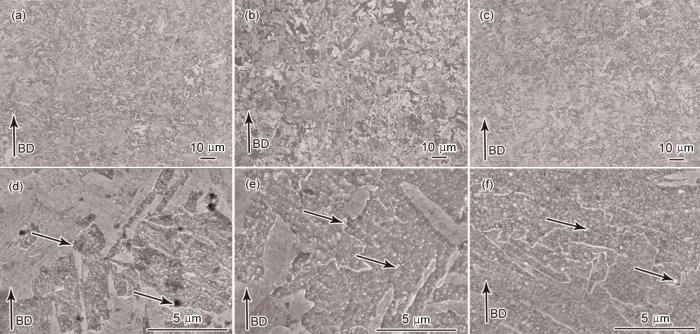

图10给出了17-4PH不锈钢热处理后的微观组织,可见黑色回火马氏体和白色淬火马氏体呈板条状和块状均匀分布,层状结构消失,还有细小弥散的沉淀相。与其余两者相比,HIP热处理马氏体和沉淀相的尺寸较大。其原因是,时效冷却时HIP热处理高压气冷的冷却速度略低于其它热处理水冷的冷却速度,使其组织稍有长大。组合热处理的微观组织与真空热处理的相似,真空热处理的孔隙较多。其原因是,组合热处理固溶阶段在热等静压设备中进行,高温高压闭合了大部分孔隙,且热等静压气冷的冷却速度略低于水冷的冷却速度,使其组织的尺寸略大。

图10

图10

选区激光熔化17-4PH不锈钢真空热处理、HIP热处理和组合热处理后的微观组织

Fig.10

Micrographs of the SLM-17-4PH stainless steel (a) and (d) vacuum heat treatment; (b) and (d) HIP treatment; (c) and (f) combined heat treatment

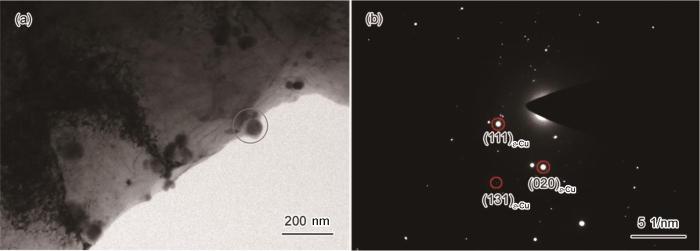

图11

图11

HIP热处理样品的TEM照片

Fig.11

HIP heat treated sample (a) TEM micrograph and (b) the corresponding selected area diffraction (SAD) pattern

2.4 17-4PH不锈钢的力学性能

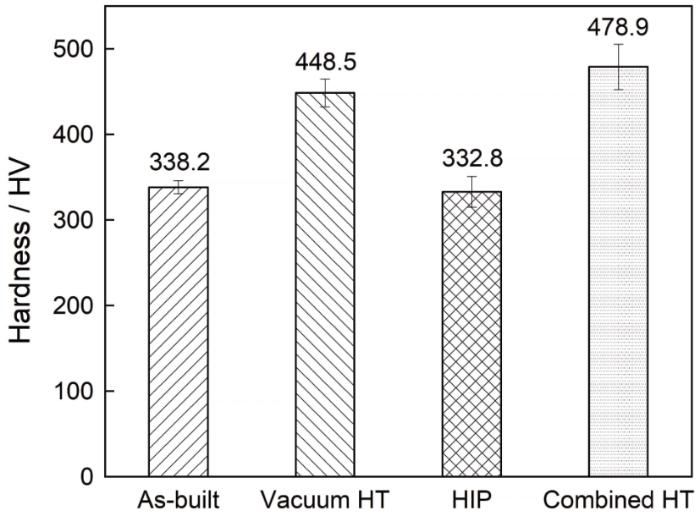

图12给出了不同状态17-4PH不锈钢的显微硬度。可以看出,沉积态样品的显微硬度达到338.2 HV。与沉积态相比,真空热处理、组合热处理样品的显微硬度分别提高了110.3HV、140.7HV,而HIP处理样品的显微硬度与沉积态的相当。其原因是,在选区激光熔化成形过程中金属粉末熔凝较快,细小的组织使其硬度较高。经真空热处理和组合热处理后材料产生马氏体结构,组织内细小弥散的沉淀相阻碍位错运动,沉淀硬化使材料的硬度有较大的提高。同时,真空热处理和组合热处理样品的显微组织相似,组合热处理样品较高的显微硬度可归因于其较低的孔隙率。固溶阶段结束后,高压气冷至480℃,使HIP热处理样品的马氏体组织的尺寸比真空热处理和组合热处理的样品大。对比图10d、e、f,可见HIP热处理样品中沉淀颗粒的尺寸较大,用透射电镜观察到其尺寸为100~150 nm。沉淀相粗化,沉淀相之间的间距增大,对位错的交互作用减弱,沉淀硬化效果减弱,使HIP热处理样品的显微硬度比真空热处理和组合热处理样品的显微硬度低。

图12

图12

不同状态的选区激光熔化17-4PH不锈钢的显微硬度

Fig.12

Microhardness of the 17-4PH stainless steel samples under various conditions

图13

图13

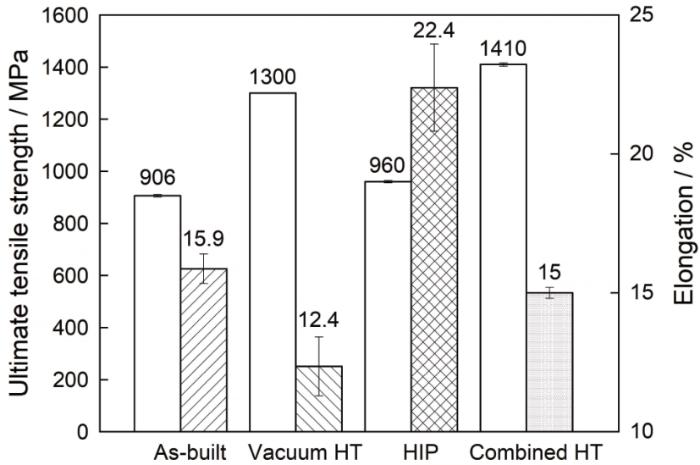

不同状态的选区激光熔化17-4PH不锈钢的抗拉强度和延伸率

Fig.13

Ultimate tensile strengths and elongations of the 17-4PH stainless steels under various conditions

图14给出了不同状态的17-4PH不锈钢样品断口的整体形貌。可以看出,沉积态和HIP热处理样品断口的形貌均有明显的剪切唇和纤维区,断面较为平滑,为典型的韧性断裂形貌。真空热处理和组合热处理的样品,有明显的山脊状断裂形貌。

图14

图14

选区激光熔化17-4PH不锈钢沉积态、真空热处理、HIP热处理和组合热处理断口的整体形貌

Fig.14

Overall appearance of Fracture of the SLM-processed samples (a) as-built; (b) vacuum heat treatment; (c) HIP heat treatment; (d) combined heat treatment

图15

图15

选区激光熔化17-4PH不锈钢沉积态、真空热处理、HIP热处理和组合热处理后断口的形貌

Fig.15

Fractography of the SLM-processed 17-4PH stainless steel samples (a) as-built; (b) vacuum heat treatment; (c) HIP heat treatment; (d) combined heat treatment

3 结论

(1) 选区激光熔化成形17-4PH不锈钢内的孔隙在热等静压致密化处理后闭合,其密度基本上达到理论值。

(2) 选区激光熔化成形的17-4PH不锈钢的沉积态具有明显的层状结构,后续热处理后层状结构消失。合金的沉积态和各种热处理态主要为马氏体相,内部有弥散分布的沉淀相。经HIP热处理后,沉淀相的颗粒尺寸为100~150 nm。

(3) 真空热处理和组合热处理可提高材料的抗拉强度和硬度,但是断裂延伸率有所下降;HIP热处理使材料的抗拉强度略有提高,使其延伸率显著提高到22.4%。

(4) 沉积态和HIP热处理材料的断口形貌为典型的韧性断裂,韧窝更深、尺寸更大。真空热处理和组合热处理材料的断口形貌具有部分脆性断裂的特征且出现裂纹,与沉积态相比其塑性略有降低。

参考文献

Present situation and development trend of 17-4PH stainless steel

[J].

17-4PH不锈钢的研究现状及发展趋势

[J].

Study on selective laser melted 17-4 PH alloy

[J].

选择性激光熔化17-4PH合金的成形研究

[J].

Antibacterial performance of 17-4 PH stainless steel

[J].

17-4PH不锈钢的抗菌性能

[J].

Study on forming technology and properties of 316L stainless steel by selective laser melting

[J].

选区激光熔化316L不锈钢成形工艺与性能研究

[J].

An analytical model for rapid predicting molten pool geometry of selective laser melting (SLM)

[J].

Statistical analysis of porosity of 17-4PH alloy processed by selective laser melting

[J].

Effect of powder particle size on wear and corrosion resistance of S136 mould steels fabricated by selective laser melting

[J].

粉末粒径对激光选区熔化成形S136模具钢的磨损与抗腐蚀性能的影响

[J].

Characterization of 17-4PH alloy processed by selective laser melting

[J].

Effects of particle characteristics on the microstructure and mechanical properties of 17-4 PH stainless steel fabricated by laser-powder bed fusion

[J].

Non-metallic inclusions in 17-4PH stainless steel parts produced by selective laser melting

[J].

Effect of scan strategy on density and metallurgical properties of 17-4PH parts printed by Selective Laser Melting (SLM)

[J].

Effects of atomizing media and post processing on mechanical properties of 17-4 PH stainless steel manufactured via selective laser melting

[J].

Effect of aging temperature on precipitation and hardening behavior of 17-4PH stainless steel

[J].

时效温度对17-4PH沉淀硬化不锈钢析出行为和硬化效果的影响

[J].

High strain rate compressive deformation behavior of an additively manufactured stainless steel

[J].

Microstructures, properties, and applications of laser sintered 17‐4PH stainless steel

[J].