2009年Grunlan等用层层自组装技术在棉织物表面制备了阻燃涂层。现在,这项技术已经成为一种重要的阻燃后处理方法[1,2]。与传统的阻燃处理相比,层层自组装技术可使用多种功能性材料、能在温和的条件下操作且对环境友好。无机纳米粒子组成的具有阻隔作用的涂层,能显著提高软质聚氨酯泡沫(PUF)的阻燃性能。可用于制备阻燃层层自组装涂层的无机纳米粒子较多,包括蒙脱土[3~5]、α-磷酸锆[6~9]、层状双氢氧化物[10~12]、碳纳米管[13~15]、二氧化硅[16~18]、二氧化钛[19~21]等。这种无机纳米粒子或有机无机杂化涂层,其阻燃机理是聚集在其表面的无机纳米粒子能保护基体并促进其成炭。Patra等[22]用层层自组装方法将蛭石和勃姆石在PUF表面沉积,发现一层自组装涂层就使PUF的热释放速率峰值降低了55%。在PUF表面制备的由蒙脱土、聚烯丙胺盐酸盐和聚磷酸钠三种组分组成的自组装涂层 [23],使PUF的热释放速率峰值降低了54%。

1 实验方法

1.1 用层层自组装涂层修饰软质聚氨酯泡沫(PUF)

将10 g埃洛石粉末分散在800 mL水中,并机械搅拌且超声2 h。将3 g海藻酸钠溶液溶于200 mL水中,在超声且搅拌条件下将其逐滴滴在埃洛石悬浮液中,然后继续超声搅拌1 h,得到埃洛石与海藻酸钠的混合溶液。海藻酸钠是带负电的聚电解质,涂层中的聚乙烯亚胺是带正电的聚电解质。埃洛石表面带负电的固体纳米颗粒无法结合所有的聚乙烯亚胺上的正电荷,因此在此添加海藻酸钠补充负电解质以辅助涂层的增长。

将聚乙烯亚胺(PEI,50%(质量分数)水溶液)(5 g/L)加入水中,用1 mol/L盐酸(HCl, 37%)和1 mol/L氢氧化钠溶液将PEI溶液的pH值调至9,搅拌2 h后得到PEI溶液(5 g/L)。将聚丙烯酸钠添加到水中,用1 mol/L盐酸和1 mol/L氢氧化钠溶液将溶液的pH值调节至2,使聚丙烯酸钠完全溶解,得到聚丙烯酸钠溶液(1 g/L)。

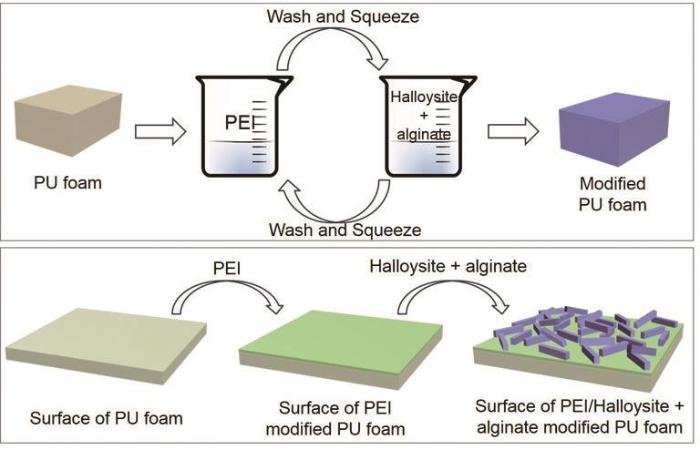

层层自组装:先将软质聚氨酯泡沫(PUF,聚醚性,DW30)在聚丙烯酸钠溶液中浸泡5 min,然后用去离子水洗涤2 min除去多余的聚丙烯酸钠,使PUF表面带负电。然后,将预处理过的PUF在PEI溶液(带正电的聚电解质溶液)和海藻酸+埃洛石混合溶液(带负电的聚电解质溶液)中交替浸泡2 min并在去离子水中洗涤2 min以除去没有结合力的聚电解质或者粒子。一个组装层(BL)由一层聚乙烯亚胺和一层海藻酸/埃洛石的混合物构成。图1给出了层层自组装过程的示意图。组装层达到需要的层数(1BL、2BL和3BL)后将PUF放入70℃烘箱中干燥12 h,然后存放在干燥器中。所有溶液的浓度、样品的层数和增重,列于表1。

图1

图1

层层自组装涂层的制备过程示意图

Fig.1

Schematic of construction of halloysite based layer-by-layer coating on PUF

表1 溶液浓度、样品制备的层数和样品增重

Table 1

| Sample | PEI (mass fraction, %) | Halloysite (mass fraction, %) | Alginate (mass fraction, %) | BL | Weight gain (mass fraction, %) |

|---|---|---|---|---|---|

| PU-0 | - | - | - | - | 0 |

| PU-1 | 0.5 | 1.0 | 0.3 | 1 | 6.7 |

| PU-2 | 0.5 | 1.0 | 0.3 | 2 | 16.1 |

| PU-3 | 0.5 | 1.0 | 0.3 | 3 | 29.1 |

1.2 样品的结构和性能表征

用FEI Sirion200型扫描电镜(SEM)对织物在自组装涂层处理前和处理后的表面进行蒸金处理,电子束电压为2.0 kV,工作距离3.0 mm。用安装在FEI Sirion200型扫描电镜上的能谱分析仪进行EDX谱分析。使用TGA Q5000热分析仪在氮气氛中进行热重分析(TGA),温度范围为室温-700℃,升温速率为20℃/min。使用锥形量热仪(CONE)按照ISO 5600标准进行实验,评价材料的可燃性。样品的尺寸为100 mm×100 mm×25 mm,将样品水平地暴露在35 kW/m2条件下。热重-红外联用:将Nicolet 6700红外光谱仪与Q5000IR热分析仪用气体传送管连接使用。

2 实验结果

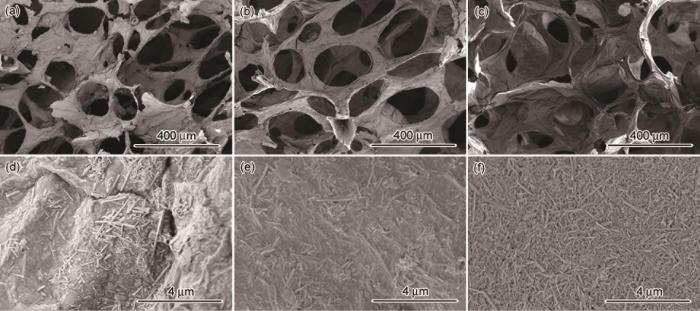

2.1 埃洛石基层层自组装涂层的形貌

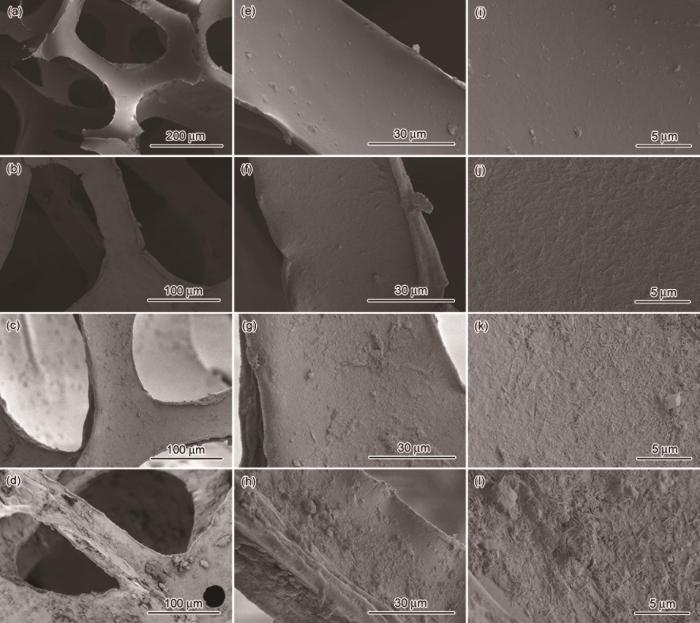

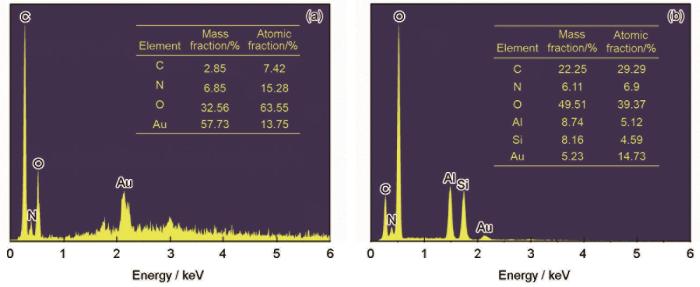

图2给出了层层自组装涂层修饰前后PUF的SEM照片,其中PU-1、PU-2和PU-3三个样品的自组装层数分别1BL、2BL和3BL。图2a、e和i给出了未用涂层修饰的PU-0的微观形貌,可见其表面干净、光滑且没有褶皱。图2b、f和j给出了PU-1的微观形貌,可见其表面出现了很多针状附着物,是沉积在PUF表面的埃洛石。在图2j中还可观察到,针状埃洛石均匀地覆盖在PUF的骨架上。在图2k(PU-2)、图2l(PU-3)中可见,这种涂层越来越厚。在PU-3表面有大量的埃洛石,表明随着层数的增加埃洛石显著增多。在表1中可见,PU-1、PU-2和PU-3的增重分别为6.7%、16.1%和29.1%。从图2d可见,PU-3在增重(质量分数)为29.1%的情况下保留了原来的泡孔结构,说明涂层只附着在PUF表面并不填充泡孔。为了进一步确认埃洛石在PUF表面沉积,对修饰前后的涂层进行了EDX分析。图3给出了PU-0和PU-3的EDX谱图。对比图3a和3b可以发现,PU-3谱图中明显出现了硅元素和铝元素,说明在PUF表面确实有埃洛石(Al2O3·2SiO2·4H2O)。

图2

图2

PU-0、PU-1、PU-2和PU-3的SEM照片

Fig.2

SEM images of PU-0 (a, e, i), PU-1 (b, f, j), PU-2 (c, g, k) and PU-3 (d, h, l)

图3

2.2 PUF的热稳定性

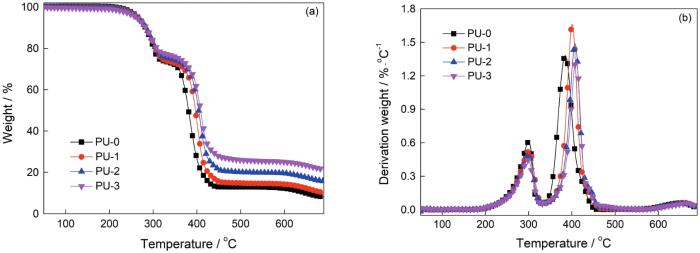

图4给出了PU-0、PU-1、PU-2和PU-3在氮气氛中的TG和DTG曲线,相关数据列于表2。可以看出,PUF的热分解分为两个阶段。第一个阶段是二异氰酸酯的降解,源于脲烷的降解和氨基官能团的二次取代;第二个阶段是其余聚多元醇段的降解[30]。从表2可见,不同层数的埃洛石基涂层对PUF的起始降解温度(T-5%)和第一次最大热分解温度(Tmax1)影响不大。但是,涂层对PUF在第二阶段的热降解有明显的延迟。PU-1、PU-2和PU-3的Tmax2比PU-0分别升高了17℃、23℃和25℃,表明埃洛石基涂层延迟了高温阶段的分解。同时,PU-0在700℃时的残炭量(质量分数)为8.1%。PU-3在700℃的残炭量为21.5%,可见有明显的提高。所有修饰后的PUF在350~700℃均表现出更高的热稳定性和固体炭渣含量,可归因于埃洛石基自组装涂层的物理隔离作用。

图4

图4

PU-0、PU-1、PU-2和PU-3在氮气气氛下的TG和DTG曲线

Fig.4

TG (a) and DTG (b) curves of PU-0, PU-1, PU-2 and PU-3 at air atmosphere

表2 修饰前后PUF的热重分析数据

Table 2

| Sample | T-5%/℃ | Tmax1/℃ | Tmax2/℃ | Residue at 700℃/%, mass fraction |

|---|---|---|---|---|

| PU-0 | 265 | 299 | 384 | 8.1 |

| PU-1 | 265 | 301 | 401 | 10.3 |

| PU-2 | 264 | 300 | 407 | 15.7 |

| PU-3 | 261 | 298 | 409 | 21.5 |

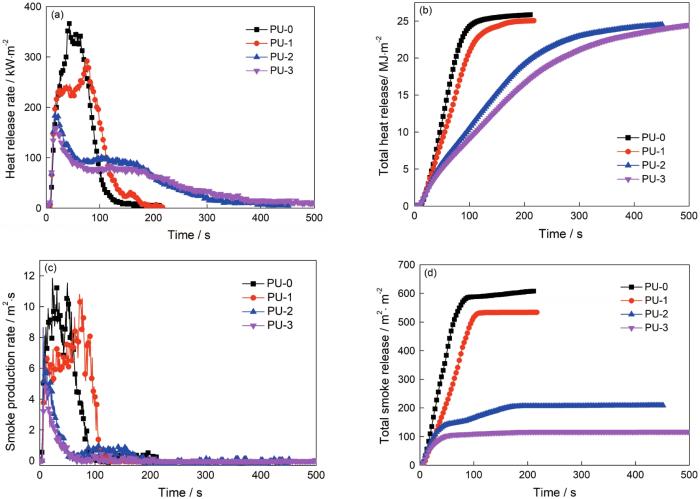

2.3 PUF的燃烧性能

锥形量热仪(Cone)基于耗氧原理,用于评价材料的可燃性。热释放速率、总热释放、烟气释放速率以及总烟气释放量,是衡量火灾的关键参数。图5分别给出了涂层修饰前后PUF的热释放速率(HRR)、总热释放(THR)、烟气释放速率(SPR)和总烟气释放(TSP)曲线。软质聚氨酯泡沫在燃烧过程中发生较大的体积变化,在燃烧初期泡沫坍塌,接着融化成低粘度的液体而发生“池火”[31]。图5中PU-0的热释放是一步完成的,其热释放速率峰值(pHRR)为366 kW·m-2。自组装埃洛石涂层后,PUF表现出两个阶段,其热释放速率比纯PUF的低。第一阶段是泡沫坍塌,此时涂层形成的骨架结构可保护泡沫的泡孔结构,抑制塌陷;第二阶段是融成低粘度液体的燃烧,涂层保护了PUF的结构而不能形成“池火”,表明涂层阻隔了热的释放。PU-1、PU-2和PU-3的pHRR分别为292 kW·m-2、184 kW·m-2和156 kW·m-2,与PU-0相比分别降低了20%、50%和57%。图5中PU-1、PU-2和PU-3的THR也比未组装涂层的PU-0有所降低,且涂层延长了燃烧时间。这表明,涂层使PUF具有阻隔热释放的性能。

图5

图5

PU-0、PU-1、PU-2和PU-3的HRR、THR、SPR和TSR曲线

Fig.5

HRR (a), THR (b), SPR (c) and TSR (d) curves of PU-0, PU-1, PU-2 and PU-3

烟和毒性气体的释放是衡量材料安全性的重要参数。与热释放速率曲线给出的结果相似,修饰后的PUF其SPR和TSP表现出显著的降低和延时释放的效果。其中PU-0的烟气释放速率峰值(pSPR)和TSP分别为11.8 m2·s和607 m2·m-2。组装了3BL埃洛石基涂层后,与PU-0相比PU-3的pSPR和TSP分别降低了58.9%和80.7%。这表明,针状埃洛石形成的网状结构在PUF表面成为一种有效的保护层,减缓了可燃性气体和烟颗粒的释放。

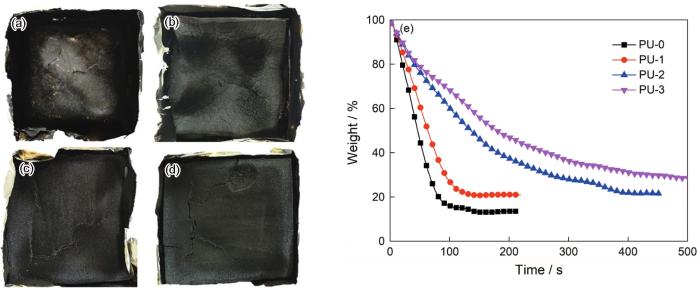

2.4 残炭和烟气

图6

图6

PU-0、PU-1、PU-2和PU-3的Cone测试完炭渣和质量损失

Fig.6

Photo of char residues of PU-0 (a), PU-1 (b), PU-2 (c) and PU-3 (d) after cone test and (e) mass loss of PU foams during cone test

图7

图7

PU-1、PU-2和PU-3的Cone测试完炭渣扫描电子显微镜图

Fig.7

SEM images of PU-1 (a, d), PU-2 (b, e) and PU-3 (c, f) after cone tests

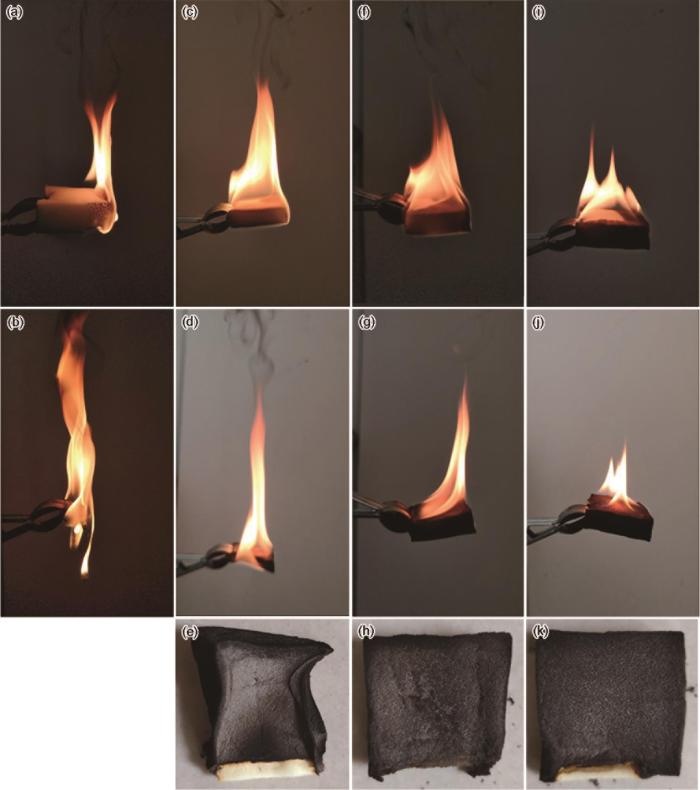

图8

图8

PU-0(a、b)、PU-1(c、d、e)、PU-2(f、g、h)和PU-3(i、j、k)燃烧过程图,点燃后10 s(a、c、f、i)、点燃后30 s(b、d、g、j)和燃烧后炭渣(e、h、k)

Fig.8

Real-time images of burning tests for PU-0 (a, b), PU-1 (c, d, e), PU-2 (f, g, h) and PU-3 (i, j, k). 10 s after ignition (a, c, f, i), 30 s after ignition (b, d, g, j) and char residues after burning (e, h, k)

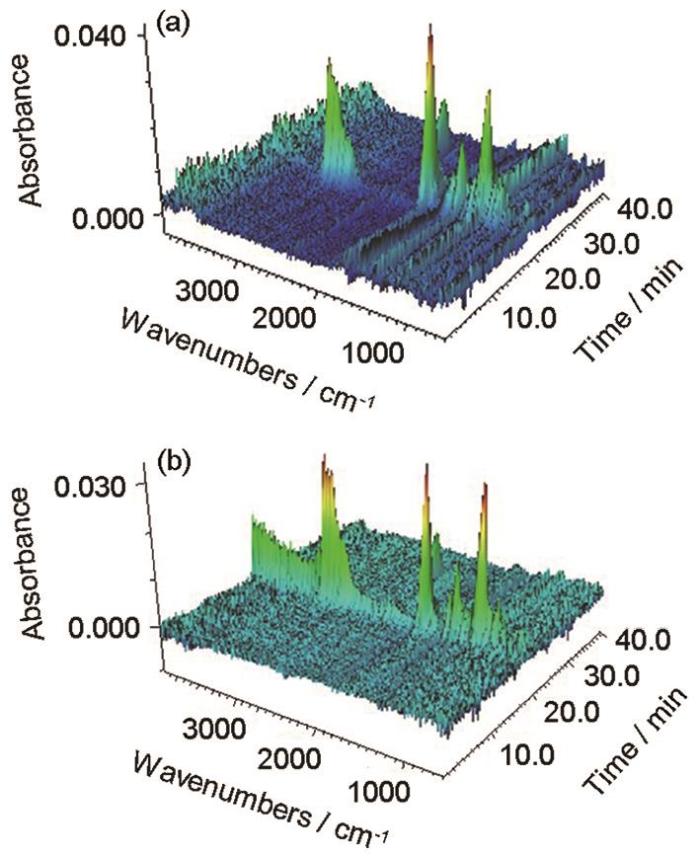

图9

图9

PU-0和PU-3气态裂解产物的3D热重-红外光谱

Fig.9

3D TG-FTIR spectra of gasified pyrolysis products for (a) PU-0 and (b) PU-3

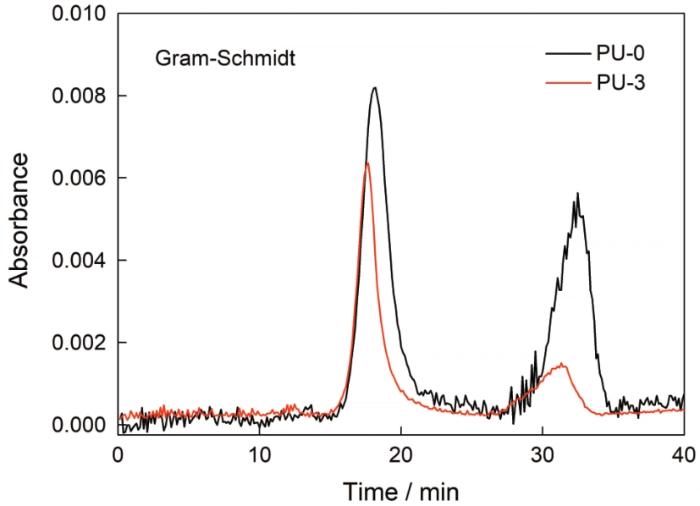

图10

图10

PU-0和PU-3的总气态热解产物吸收峰

Fig.10

Intensity of characteristic peak for pyrolysis products of PU-0 and PU-3

总之, PUF表面的埃洛石基层层自组装涂层能显著减少气态热解产物的释放,从而降低烟气释放,提高材料在火灾中的安全性。

图11给出了组装涂层后软质聚氨酯泡沫的燃烧和烟气释放模型。燃烧过程伴随着聚氨酯泡沫的热解,热解产物和燃烧产生的热量从固相转移到气相。聚氨酯软泡受热时在表面形成一层炭层,而热解产生的热量和气态热解产物在从固相到气相转移过程中必须穿过炭层。Cone的测量结果表明修饰后燃烧产生的热和烟气有明显的降低,热重-红外联用结果表明热解的气相产物也有所降低,说明涂层可阻隔基体产生的热和气相热解产物从固相转移到气相。

图11

图11

修饰后软质聚氨酯泡沫的燃烧和烟气释放模型

Fig.11

Model of smoke generation from the burning treated PU foam

3 结论

使用埃洛石、海藻酸钠和聚乙烯亚胺用层层自组装方法可在PUF表面制备涂层。3层PU-3涂层的增重为29.1%。PU-3的Tmax2比PU-0提高了25℃,PU-3在700℃的残炭量达到21.5%。涂层可提高PUF的热稳定性,使热释放速率、烟气释放速率以及总烟气释放量显著降低。涂层能减少气态热解产物的释放,使材料具有更高的火灾安全性。

参考文献

Polyelectrolyte/nanosilicate thin-film assemblies: influence of pH on growth, mechanical behavior, and flammability

[J].

Flame retardant coatings prepared using layer by layer assembly: A review

[J].

Clay-chitosan nanobrick walls: completely renewable gas barrier and flame-retardant nanocoatings

[J].

Layer double hydroxide and sodium montmorillonite multilayer coatings for the flammability reduction of flexible polyurethane foams

[J].

Polyallylamine-montmorillonite as super flame retardant coating assemblies by layer-by layer deposition on polyamide

[J].

α-Zirconium phosphate-based nanoarchitectures on polyester fabrics through layer-by-layer assembly

[J].

Construction of organic-inorganic hybrid nano-coatings containing α-zirconium phosphate with high efficiency for reducing fire hazards of flexible polyurethane foam

[J].

Unique nanobrick wall nanocoating for flame-retardant cotton fabric via layer-by-layer assembly technique

[J].

Construction of multilayer coatings for flame retardancy of ramie fabric using layer-by-layer assembly

[J].

Fabrication of flame retardant coating on cotton fabric by alternate assembly of exfoliated layered double hydroxides and alginate

[J].

Layered double hydroxide-based fire resistant coatings for flexible polyurethane foam

[J].

Synthesis of mesoporous silica@Co-Al layered double hydroxide spheres: layer-by-layer method and their effects on the flame retardancy of epoxy resins

[J].

Synergistic effect of layer-by-layer assembled thin films based on clay and carbon nanotubes to reduce the flammability of flexible polyurethane foam

[J].

Construction of flame retardant nanocoating on ramie fabric via layer-by-layer assembly of carbon nanotube and ammonium polyphosphate

[J].

Flame-retardant, electrically conductive and antimicrobial multifunctional coating on cotton fabric via layer-by-layer assembly technique

[J].

Layer-by-layer assembly of silica-based flame retardant thin film on PET fabric

[J].

Layer by layer complex architectures based on ammonium polyphosphate, chitosan and silica on polyester-cotton blends: flammability and combustion behaviour

[J].

Layer-by-layer self-assembly of organic-inorganic hybrid intumescent flame retardant on cotton fabrics

[J].

Layer-by-layer deposition of a TiO2-filled intumescent coating and its effect on the flame retardancy of polyamide and polyester fabrics

[J].

Construction of layer-by-layer assembled chitosan/titanate nanotubes based nanocoating on cotton fabrics: flame retardant performance and combustion behavior

[J].

Formation of layer-by-layer assembled titanate nanotubes filled coating on flexible polyurethane foam with improved flame retardant and smoke suppression properties

[J].

Inorganic nanoparticle thin film that suppresses flammability of polyurethane with only a single electrostatically-assembled bilayer

[J].

Phosphorous-filled nanobrick wall multilayer thin film eliminates polyurethane melt dripping and reduces heat release associated with fire

[J].

Effect of halloysite on flame retardancy intumescent flame retardant modified polypropylene

[J].

埃洛石纳米管对膨胀阻燃聚丙烯阻燃性能的影响

[J].

Recent advance in research on halloysite nanotubes-polymer nanocomposite

[J].

Thermal stability and flame retardant effects of halloysite nanotubes on poly(propylene)

[J].

Mechanical, thermal, and flame-retardant performance of polyamide 11-halloysite nanotube nanocomposites

[J].

A comprehensive study of the synergistic flame retardant mechanisms of halloysite in intumescent polypropylene

[J].

Flame retardant epoxy/halloysite nanotubes nanocomposite coatings: Exploring low-concentration threshold for flammability compared to expandable graphite as superior fire retardant

[J].

Flame retardancy and thermal decomposition of flexible polyurethane foams: Structural influence of organophosphorus compounds

[J].

Heat release and structural collapse of flexible polyurethane foam

[J].