在材料表面制备的超疏水膜,其自清洁、耐腐蚀、防冰和防污等特点引起了极大的关注。因此,用各种方法在基体制备超疏水表面的研究很多。Jie等[16]将蚀刻与热处理相结合在黄铜表面制备超疏水表面,通过硬脂酸的简单改性,微纳结构黄铜表面的水接触角达到153.6°,具有良好且持久的耐腐蚀性。Zhang等[17]用一步电沉积方法使铝基板具有超疏水性,使其Icorr提高了两个数量级,水接触角达到167.4°。Sun等[18]使用硬脂酸对具有天然微/纳复合结构的锌铝涂层进行修饰,锌铝涂层表面的硬脂酸分子层阻碍了腐蚀产物的脱落与溶解,抑制了材料的腐蚀。本文借鉴天然贻贝结构,将多巴胺的自聚合反应与合适的低表面能物质ODA、PFDT结合,在超级铁素体不锈钢B44660上制备超疏水表面,研究其疏水机理以及疏水行为对超级铁素体不锈钢腐蚀行为的影响。

1 实验方法

1.1 实验用材料

表1 SFSS的化学成分组成

Table 1

| Steel | C | Si | Mn | Cr | Mo | Ni | S | P | N | Ti+Nb |

|---|---|---|---|---|---|---|---|---|---|---|

| SFSS | ≤0.03 | ≤1.0 | ≤1.0 | 25.0~28.0 | 3.0~4.0 | 1.0~3.5 | ≤0.04 | ≤0.03 | ≤0.04 | 6*(C+N)~1.0 |

表2 主要实验试剂

Table 2

| Sample | Specification | Source |

|---|---|---|

| Dopamine hydrochloride (DA) | 98% | Aladdin Reagent Co., Ltd. |

| Tris (hydroxymethyl) aminomethane | >99.9% | Aladdin Reagent Co., Ltd. |

| Octadecylamine (ODA) | 90% | Aladdin Reagent Co., Ltd. |

| 1H, 1H, 2H, 2H-Perfluorodecyl mercaptan (PFDT) | 97% | Aladdin Reagent Co., Ltd. |

| NaCl | >99.5% | Sinopharm Group Chemical Reagent Co., Ltd. |

| HCl | Premium grade | Sinopharm Group Chemical Reagent Co., Ltd. |

1.2 样品的制备

将B44660(10 mm×10 mm×1 mm)的样品分别用360#,800#,1500#和2500#的水砂纸逐级打磨,然后测量每组的平均粗糙度(表3)。用丙酮、乙醇、去离子水对试样进行超声清洗,然后放入85℃烘干箱,烘干后备用。

表3 修饰前B44660试样的平均粗糙度

Table 3

| Group | B1 | B2 | B3 | B4 |

|---|---|---|---|---|

| Average roughness/μm | 4.27±0.025 | 2.86±0.013 | 0.98±0.023 | 0.23±0.018 |

如图1所示,将试样浸入浓度为0.1 mol/L、体积为0.1 L的多巴胺(DA)反应溶液中,分别在30℃,40℃,50℃和60℃反应4 h,然后用乙醇和去离子水清洗。干燥后用接触角测量仪测试每个试样的表面的水接触角。

图1

图1

SFSS/PDA/PFDT和SFSS/PDA/ODA的制备过程示意图

Fig.1

Schematic diagram of SFSS/PDA/PFDT and SFSS/PDA/ODA preparation process

选用十八胺(ODA)和1H, 1H, 2H, 2H-perfluorodecanethiol(PFDT)两种试剂对已生成聚多巴胺薄膜的试样进行二次反应,然后用这两种低表面能物质对SFSS/PDA进行二次反应修饰,最后用乙醇和去离子水清洗,干燥后得到SFSS/PDA/PFDT和SFSS/PDA/ODA。

1.3 物理性能

测量表面薄膜的水静态接触角使其表面状态达到超疏水状态,然后用扫面电镜和能谱仪等手段观察基底表面的微观形貌、测量薄膜的状态。选取试样的中心点和同中心边长为5 mm的正方形顶点为5个测试点,观察表面形貌并检测表面元素成分。

将SFSS-B44660试样放置在自制设备内,用加湿器模拟大气潮湿环境进行水雾凝聚实验。同时,用体式显微镜观察表面水滴凝聚的时间和大小。

选取附着生物种类十分丰富的唐岛湾海域(山东青岛),对研究对象进行为期30 d的浅海挂板实验。实验周期结束后,用荧光显微镜观察清洗后的试样表面微生物富附着污损状态,判断材料表面超疏水结构对其抗海洋生物附着污损性能的影响。

1.4 耐蚀性能

将若干修饰后的SFSS-B44660试样放入3.5%NaCl水溶液中,分别进行极化曲线和阻抗谱的测试。采用三电极测试系统,工作电极为修饰后的B44660超级铁素体不锈钢试样,辅助电极为碳棒,参比电极为饱和甘汞电极。

将若干修饰后的SFSS-B44660试样在3.5%NaCl水溶液中浸泡30 d,浸泡周期结束后去除试样表面腐蚀产物,用扫描电子显微镜(SEM)观察各试样表面的微观形貌。

2 实验结果

2.1 试样的微观形貌和化学成分

图2

图2

SFSS/PDA/ODA和SFSS/PDA/PFDT表面的宏观形貌

Fig.2

Macroscopic appearance of SFSS/PDA/ODA and SFSS/PDA/PFDT surfaces

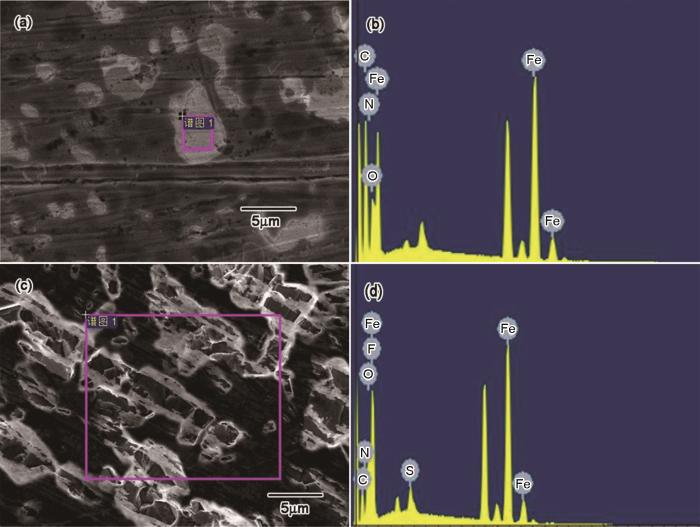

图3

图3

SFSS/PDA/ODA和SFSS/PDA/PFDT的SEM和EDS分析

Fig.3

SEM and EDS analysis of SFSS/PDA/ODA (a, b) and SFSS/PDA/PFDT (c, d)

2.2 疏水性

分别用十八胺(ODA)修饰B1-B4组不同粗糙度下的超铁B44660试样,用接触角测量仪测量得到的SFSS/PDA/ODA和经过1H, 1H, 2H, 2H-perfluorodecanethiol(PFDT)修饰后的SFSS/PDA/PFDT的平均水接触角,结果如图4所示。

图4

图4

B1-B4组不同粗糙度SFSS/PDA/ODA和SFSS/PDA/PFDT的平均水接触角

Fig.4

Average WCA of SFSS/PDA/ODA and SFSS/PDA/PFDT in different roughness of group B1-B4

2.3 水雾凝聚辅助实验

图5

图5

修饰前不同时间段SFSS-B44660 (a, b, c)和SFSS/PDA/PFDT(d, e, f)表面在体式显微镜下的水雾凝聚状态

Fig.5

Before modification of SFSS B44660 (a, b, c) and SFSS/PDA/PFDT (d, e, f) surface water mist condensation state

将在不同时间内修饰前超铁B44660和SFSS/PDA/PFDT试样表面的水雾凝聚状态比较,可知修饰前超铁B44660试样表面为亲水性,水雾快速凝聚成较大水珠,而表面为超疏水状态的SFSS/PDA/PFDT试样在2 min内并无水雾凝聚,整体水雾凝聚缓慢。因此,修饰后具有超疏水结构的超铁B44660表面不易聚集水分子,从而延缓腐蚀的发生,使耐腐蚀性能提高。

2.4 抗海洋生物的附着污损性能

图6

图6

修饰前的超铁B44660和SFSS/PDA/PFDT在荧光显微镜下微生物附着图

Fig.6

Microbial attachment diagram under fluorescence microscope (a) Modified front super iron B44660; (b) SFSS/PDA/PFDT

2.5 耐腐蚀性

2.5.1 极化曲线

将修饰前超铁B44660与修饰后的SFSS/PDA/ODA 和SFSS/PDA/PFDT试样放入3.5%NaCl水溶液中,测试其极化曲线,结果如图7所示。

图7

图7

修饰前SFSS B44660,SFSS/PDA/ODA和SFSS/PDA/PFDT在3.5%NaCl水溶液中的极化曲线

Fig.7

Before modification Super Iron B44660, SFSS/PDA/ODA and SFSS/PDA/PFDT were immer-sed in Polarization curve in 3.5% NaCl aqueous solution

使用C-View软件将修饰前超铁B44660和修饰后的SFSS/PDA/PFDT、SFSS/PDA/ODA在3.5%NaCl水溶液中的极化曲线拟合,得到的电化学参数列于表4[28,29]。修饰前的超铁B44660,SFSS/PDA/PFDT和SFSS/PDA/ODA的阳极Tafel斜率变化不明显,修饰后阴极Tafel斜率SFSS/PDA/PFDT变小,两者的自腐蚀电流密度I0与腐蚀速率均减小,SFSS/PDA/PFDT减小变化尤为明显。SFSS/PDA/PFDT在3.5%NaCl水溶液中的自腐蚀电流密度是修饰前超铁B44660的0.13倍,腐蚀速率是修饰前超铁B44660的0.08倍,SFSS/PDA/ODA的电化学参数相对于修饰前超铁B44660的变化不如SFSS/PDA/PFDT明显。综合分析结果表明,相比于修饰前超铁B44660和修饰后的SFSS/PDA/ODA,修饰后的SFSS/PDA/PFDT耐腐蚀性能更高。

表4 修饰前超铁B44660和修饰后的SFSS/PDA/ODA、SFSS/PDA/PFDT在3.5%NaCl水溶液中的电化学拟合参数

Table 4

| Sample | ba /mV | bc /mV | I0 /A·cm-2 | E0 /V | Corrosion rate/(mm/a) |

|---|---|---|---|---|---|

| SFSS | 326.42 | -255.75 | 7.4701×10-7 | -0.17773 | 0.0087039 |

| SFSS/PDA/ODA | 380.96 | -188.11 | 1.5006×10-7 | -0.031578 | 0.0017538 |

| SFSS/PDA/PFDT | 317.56 | -66.818 | 9.987×10-8 | -0.098134 | 0.0007163 |

2.5.2 电化学阻抗谱

图8

图8

修饰前超铁B44660和修饰后SFSS/PDA/ODA和SFSS/PDA/PFDT浸泡在3.5%NaCl水溶液中的电化学阻抗谱图

Fig.8

Electrochemical impedance spectroscopy of superiron B44660, SFSS/PDA/ODA and SFSS/PDA/PFDT before modification in 3.5% NaCl aqueous solution (a) Nyquist plot; (b), (c) Bode plot

图9

图9

等效电路图:(a)修饰前超铁B44660; (b) SFSS/PDA/PFDT和SFSS/PDA/ODA

Fig.9

Equivalent circuit diagram: (a) Modified front super iron B44660; (b) SFSS/PDA/PFDT and SFSS/PDA/ODA

使用Z-View软件拟合修饰前超铁B44660,SFSS/PDA/PFDT和SFSS/PDA/ODA在3.5%NaCl水溶液中的阻抗谱,得到腐蚀过程中电化学参数,如表5所示。

表5 修饰前超铁B44660,SFSS/PDA/ODA 和SFSS/PDA/PFDT浸泡在3.5%NaCl水溶液中的阻抗谱拟合参数

Table 5

| Sample | Rs /Ω·cm2 | CPE1/F·cm-2 | Rt /Ω·cm2 | CPE2/F·cm-2 | Rp /Ω·cm2 |

|---|---|---|---|---|---|

| SFSS | 13.86 | 2.267×10-5 | 3.779×104 | ||

| SFSS/PDA/ODA | 17.36 | 1.997×10-5 | 1084 | 3.739×10-5 | 9.265×104 |

| SFSS/PDA/PFDT | 63.44 | 1.092×10-6 | 4410 | 1.541×10-5 | 1.175×105 |

SFSS/PDA/PFDT的溶液电阻Rs最大,约为未处理的超铁B44660的5倍,其次是SFSS/PDA/ODA。从电荷转移电阻Rp的大小可以看出,SFSS/PDA/PFDT的腐蚀速率约为修饰前超铁B44660的0.32倍,SFSS/PDA/ODA的0.79倍。这表明,SFSS/PDA/PFDT相对于修饰前超铁B44660和修饰后的SFSS/PDA/ODA具有更高的耐腐蚀性能。

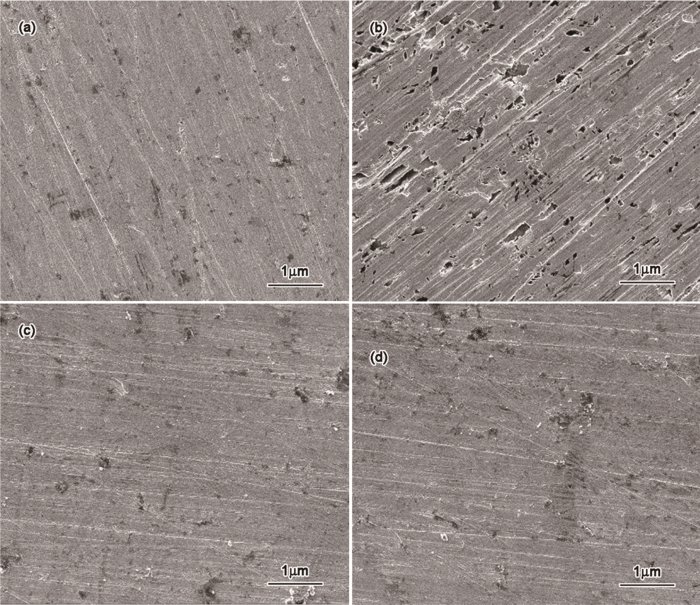

2.6 浸泡实验

用扫描电子显微镜观察修饰前超铁B44660试样和SFSS/PDA/PFDT表面前后的微观形貌变化,结果如图10所示。

图10

图10

普通浸泡实验前后试样表面的微观形貌

Fig.10

Microtopography of modified front super iron B44660 (a, b); (c, d) SFSS/PDA/PFDT

对比电化学实验和辅助实验的结果,都表明在腐蚀溶液中,SFSS/PDA/ODA和SFSS/PDA/PFDT膜能抑制腐蚀反应,从而保护超铁不锈钢不受腐蚀溶液侵蚀,SFSS/PDA/PFDT膜的保护效果最好。

2.7 腐蚀机理分析

图11

图11

SFSS涂层腐蚀机理示意图

Fig.11

Schematic diagram of corrosion mechanism (between different SFSS coatings and corrosive media) (a) SFSS; (b) SFSS/PDA/PFDT

3 结论

(1) 将多巴胺的自发聚合反应与低表面能物质ODA、PFDT结合,可在超级铁素体不锈钢表面制备SFSS/PDA/PFDT和SFSS/PDA/ODA两种具有疏水性和耐蚀性的薄膜结构,前者的疏水性和耐蚀性优于后者。

(2) 在腐蚀介质中超疏水试样表面形成一层“微纳米结构空气谷”,能阻碍强腐蚀性氯离子在溶液和固体界面间的扩散和迁移界面电化学反应腐蚀产物的脱落与溶解。与基体相比,改性后的试样阻抗提高了5个数量级,具有良好的耐蚀性。

参考文献

Study on corrosion resistance of super ferritic stainless steel S44660 welded pipe

[J].

超级铁素体不锈钢S44660焊管耐蚀性能的研究

[J].

Research on corrosion resistance enhancement of AISI430 ferritic stainless steel by laser shock peening

[D].

激光冲击强化AISI430铁素体不锈钢抗腐蚀性能研究

[D].

Effects of Cr content on the microstructure and properties of 26Cr-3.5Mo-2Ni and 29Cr-3.5Mo-2Ni super ferritic stainless steels

[J].

Study on corrosion electrochemical behavior of super ferrite stainless steel 447 in concentrated sulfuric acid

[J].

超级铁素体不锈钢447在浓硫酸中的腐蚀电化学行为的研究

[J].

Corrosion behaviour of AISI 460LI super-ferritic stainless steel

[J].

One-step hydrothermal crystallization of a layered double hydroxide/alumina bilayer film on aluminum and its corrosion resistance properties

[J].

Study on corrosion resistance of super ferrite stainless steel U-tube in sea water

[A].

超级铁素体不锈钢海优管在海水中的耐腐蚀性研究

[A].

Corrosion and toughness of experimental and commercial super ferritic stainless steels

[J].

Development of S44660 ferritic stainless steel welded pipe for seawater condenser

[J].

海水冷凝器用S44660铁素体不锈钢焊管的发展

[J].

Research on corrosion characteristics of ferritic stainless steel in condensate of exhaust system

[J].

铁素体不锈钢在排气系统冷凝液中的腐蚀特性研究

[J].

Corrosion performance of 00Cr16Sn ultra-pure ferritic stainless steel welded joints

[J].

00Cr16Sn超纯铁素体不锈钢焊接接头腐蚀性能

[J].

Corrosion resistance research on A-TIG welded joint of 444 ultra-pure ferrite stainless steel

[J].

444超纯铁素体不锈钢A-TIG焊接头腐蚀性能的研究

[J].

Corrosion resistance evaluation of 439 ultra-pure ferritic stainless steel

[J].

439超纯铁素体不锈钢耐蚀性评价

[J].

Corrosion behaviour of AISI 460LI super-ferritic stainless steel

[J].

Etching and heating treatment combined approach for superhydrophobic surface on brass substrates and the consequent corrosion resistance

[J].

Fabrication of durable anticorrosion superhydrophobic surfaces on aluminum substrates via a facile one-step electrodeposition approach

[J].

Preparation and properties of superhydrophobizted sprayed Zn-Al coating

[J].

热喷涂锌铝合金超疏水涂层的制备及性能

[J].

Preparation and condensation behavior of wear resistant Al-based superhydrophobic materials

[J].

耐磨铝基超疏水材料的制备及其动态冷凝行为

[J].

Preparation and properties of CuO superhydrophobic coating on X90 pipeline steel

[J].(

X90管线钢表面CuO超疏水涂层的制备和性能

[J].(

Fabrication of super-hydrophobic surfaces on metallic substrates and research on anti-corrosion and anti-biofilm properties

[D].

金属基体超疏水表面的制备及其海洋防腐防污功能的研究

[D].

Improving the corrosion performance of epoxy coatings by chemical modification with silane monomers

[J].

Preparation and property of superhydrophobic phosphate-cerium composite coatings on hot-dip galvanizing carbon steel

[J].

热浸镀锌层磷酸盐-铈盐复合处理制备超疏水膜层研究

[J].

Fabrication and corrosion resistance performance of superhydrophobic cuprous oxide surface

[J].

超疏水氧化亚铜表面的制备和耐腐蚀性能

[J].

Preparation of superhydrophobic poly(methyl methacrylate)-silicon dioxide nanocomposite films

[J].

Preparation and corrosion resistance of 304 super-hydrophobic stainless-steel surface

[J].

The applications of the electrochemical impedance spectroscopy in the materials researches

[J].

电化学阻抗谱在材料研究中的应用

[J].

Investigation of corrosion behaviour of stainless steel coated with polyaniline via electrochemical impedance spectroscopy

[J].

Preparation of bonded super-hydrophobic thin film

[J].