Al-Zn-Mg-Cu系合金的比强度高、加工性能优良,在汽车制造、轨道交通以及航空航天等领域得到了广泛的应用 [1~4]。这类合金板材的力学性能,与其取样方向有密切的关系[5~8]。陈艳霞等[9]研究了2124铝合金样品的轴向沿不同轧制方向的的拉伸性能,发现与垂直轧制方向相比沿轧制方向的断面收缩率、断裂伸长率较高,沿两个方向的抗拉强度与屈服强度基本相同。同时,还基于Schmid因子分布及晶粒取向差分布解释了合金沿不同轧制方向的拉伸性能不同的原因。Fu等[10] 观察Al-Zn-Mg-Cu-Zr合金的显微组织并探讨了其与力学性能之间的联系,发现合金沿轧制方向的综合力学性能最佳,变形和固溶处理后在垂直轧制方向发生再结晶的程度明显高于沿轧制方向。陈军等[11]研究沿不同取向条件7475铝合金的高周疲劳性能时发现,合金板材垂直轧制方向的疲劳裂纹扩展速率远高于沿轧制方向。

Al-Zn-Mg-Cu系合金结构件在服役过程中承受交变载荷,因此研究其疲劳性能有重要的意义。Jian等[12]研究了2124铝合金高周疲劳裂纹的扩展规律,发现疲劳裂纹主要以穿晶方式扩展。粗大的第二相与晶粒间的取向差使裂纹的扩展路径发生偏折,主裂纹沿{111}晶面扩展。张笑宇等[13]研究了在低周疲劳加载条件下时效处理对Al-Zn-Mg-Cu-Zr-Sc合金性能的影响,发现在0.4%、0.5%、0.6%、0.7%的外加总应变幅条件下呈现出循环稳定;在0.8%外加总应变幅条件下,呈现出先循环软化后循环硬化;还发现,在较低总应变幅条件下回归再时效处理态合金的疲劳寿命较高。陈胤桢等[14]研究了应变对7050-T7451合金低周疲劳行为的影响,发现在对称应变条件下合金呈现出循环软化。在非对称应变条件下,合金先硬化后稳定。在非对称应变条件下,合金发生与应变幅相关的应力松弛。Zhu等[15]研究了稀土元素Sc对Al-7Zn-2Mg-1.5Cu-0.1Zr合金低周疲劳性能的影响,发现Sc的添加使合金的循环应力幅值提高,其疲劳寿命在0.4%和0.6%外加应变幅下有所提高。本文进行RD和TD方向Al-5.4Zn-2.6Mg-1.4Cu(%,质量分数)合金总应变控制的低周疲劳实验,对比研究RD和TD方向上合金的低周疲劳行为。

1 实验方法

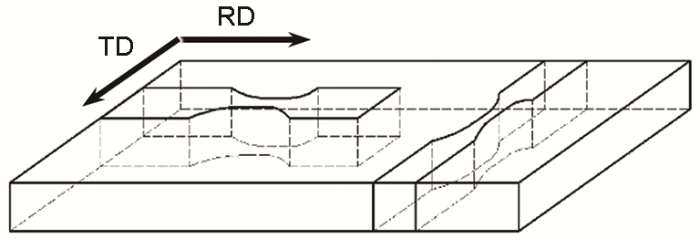

实验用材料为沿不同轧制方向取样的Al-5.4Zn-2.6Mg-1.4Cu合金板材。使用500 mm热轧实验机将Al-5.4Zn-2.6Mg-1.4Cu合金铸锭轧制为5 mm厚的合金板材,热轧温度为420℃,轧后空冷。合金板经470℃/1 h的固溶处理后进行150℃/26 h的时效处理。将热处理后的合金板材分别沿RD方向、TD方向加工成标距长度42 mm、标距宽度10 mm、试样厚度5 mm的拉伸试样与标距长度10 mm、标距宽度6 mm、试样厚度5 mm的低周疲劳试样,取样方式图如图1所示。

图1

图1

沿RD方向和TD方向取样方式示意图

Fig.1

Schematic diagram for sampling mode in RD and TD direction

用WDW-100型电子万能试验机对RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金进行拉伸试验,拉伸应变速率为1×10-2 s-1。用MTS Landmark 370.10电液伺服疲劳实验机对RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金进行名义总应变幅(Δεt/2)为0.4%、0.5%、0.6%、0.7%与0.8%的低周疲劳实验。采用正弦波形,循环频率为1 Hz,应变比为RƐ=-1。疲劳实验在循环应力幅值降为峰值的80%时停止,将其疲劳寿命确定为此时的循环周次。在每个应变幅下使用两个平行试样。

用S-3400N型扫描电子显微镜观察RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的低周疲劳断口形貌。用TenuPol-5型双喷减薄仪制备TEM样品。双喷减薄实验的电解液为30%的硝酸与70%的甲醇溶液,双喷电压为20.5 V,电解液温度为-25℃。并分别用Zeiss Gemini SEM 300场发射扫描电子显微镜、Nordlys Nano电子背散射衍射仪与JEM-2100型透射电子显微镜观察和分析RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的显微组织。

2 实验结果

2.1 拉伸性能

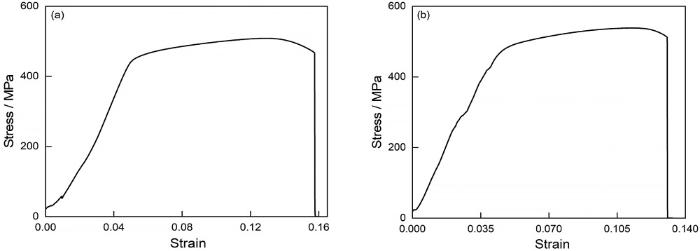

图2给出了RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的应力-应变曲线。可以看出,RD方向合金的抗拉强度为508.71 MPa,屈服强度为453.68 MPa,TD方向合金的抗拉强度为538.74 MPa,屈服强度为471.58 MPa。TD方向合金的抗拉强度和屈服强度,均高于RD方向。

图2

图2

RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的应力-应变曲线

Fig.2

Stress-strain curve of Al-5.4Zn-2.6Mg-1.4Cu alloy (a) RD direction; (b) TD direction

2.2 循环应力响应行为

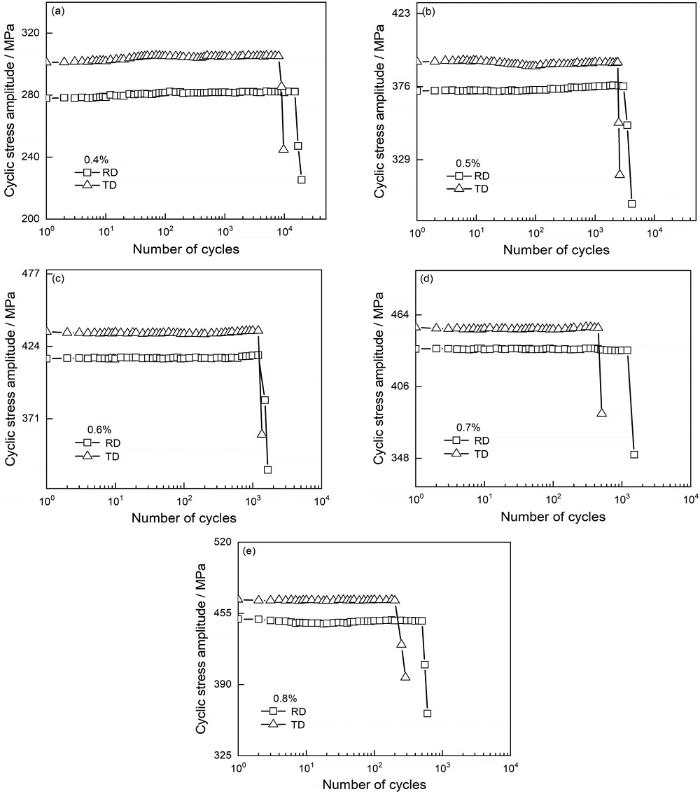

图3给出了在各个外加总应变幅下RD和TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的循环应力响应对比曲线。可以看出,在所有外加总应变幅下整个循环变形过程中RD和TD方向Al-5.4Zn-2.6Mg-1.4Cu合金均呈现出循环稳定。在相同外加总应变幅下,TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的循环应力幅值均高于其RD方向。这些结果,与TD与RD方向合金拉伸强度的差异是一致的。

图3

图3

RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的循环应力响应对比曲线

Fig.3

Cyclic stress response curves of Al-5.4Zn-2.6Mg-1.4Cu alloy with RD and TD direction at various total strain amplitudes (a) 0.4%; (b) 0.5%; (c) 0.6%; (d) 0.7%; (e) 0.8%

2.3 循环应力-应变行为

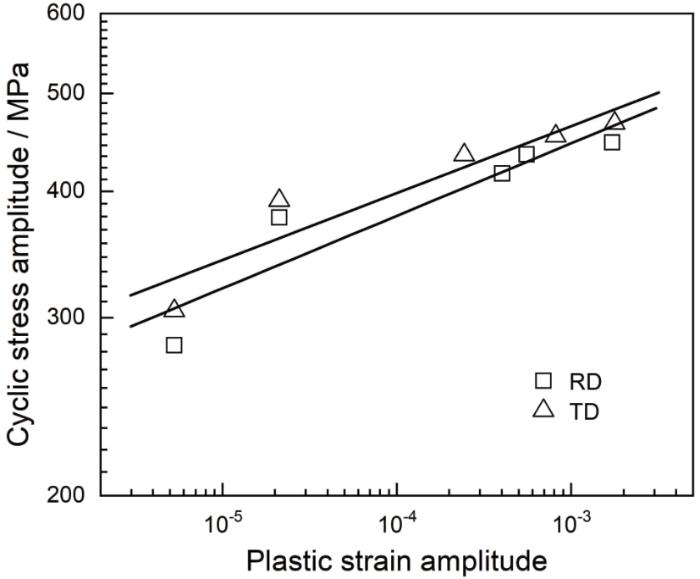

图4给出了RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的循环应力与塑性应变关系曲线。可以看出,该合金在RD与TD方向的循环应力幅和塑性应变幅之间呈单斜率线性关系。Al-5.4Zn-2.6Mg-1.4Cu合金的循环应力-应变行为遵从

图4

图4

RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的循环应力-应变曲线

Fig.4

Cyclic stress-strain curves of Al-5.4Zn-2.6Mg-1.4Cu alloy

表1 RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的应变疲劳参数

Table 1

| Sampling directions | K’ /MPa | n’ | ε’f /% | c | σ’f /MPa | b |

| RD | 732.3 | 0.072 | 161.7 | -1.63 | 1267.0 | -0.14 |

| TD | 733.0 | 0.066 | 23.7 | -1.52 | 1104.3 | -0.13 |

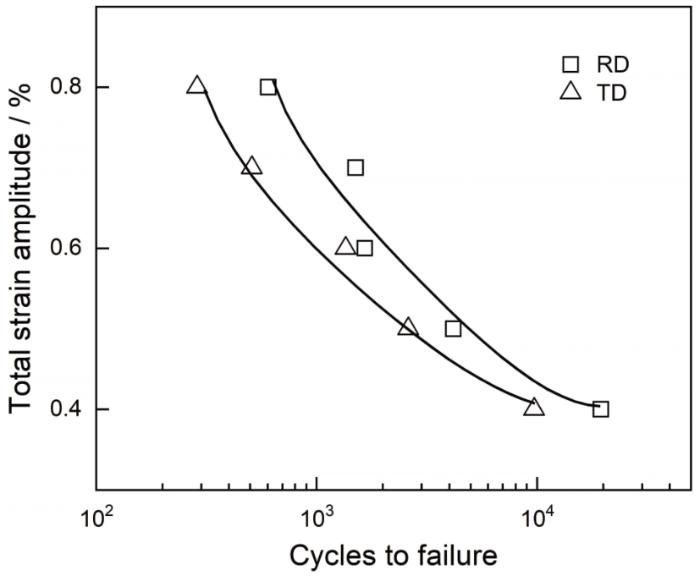

2.4 疲劳寿命行为

图5

图5

RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的疲劳寿命曲线

Fig.5

Total strain amplitude versus fatigue life for Al-5.4Zn-2.6Mg-1.4Cu alloy

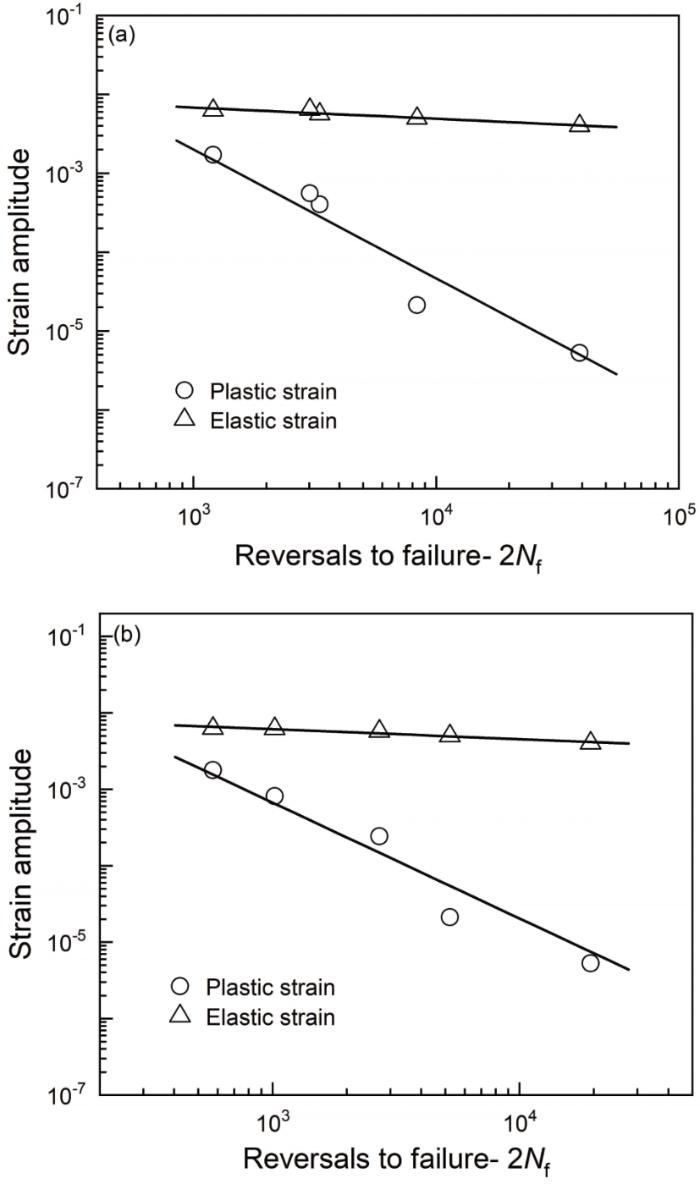

在合金发生低周疲劳变形时,塑性应变幅(Δεp/2)、弹性应变幅(Δεe/2)与载荷反向周次(2Nf)之间的关系为

其中,εf΄为疲劳延性系数,c为疲劳延性指数,σf΄为疲劳强度系数,E为Young′s模量,b为疲劳强度指数。

图6

图6

RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的应变幅-载荷反向周次关系曲线

Fig.6

Strain amplitudes versus reversals to failure curves for Al-5.4Zn-2.6Mg-1.4Cu alloy (a) RD direction; (b) TD direction

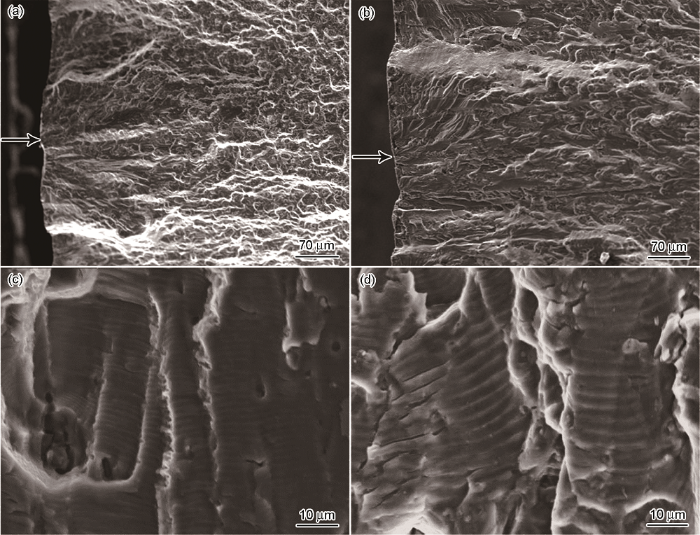

2.5 疲劳断口的形貌

图7

图7

RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的疲劳裂纹源区与裂纹扩展区形貌

Fig.7

Photographs of fatigue crack initiation and fatigue crack propagation regions of Al-5.4Zn-2.6Mg-1.4Cu alloy (a) fatigue crack initiation region, RD direction; (b) fatigue crack initiation region, TD direction; (c) fatigue crack propagation region, RD direction; (d) fatigue crack propagation region, TD direction

3 讨论

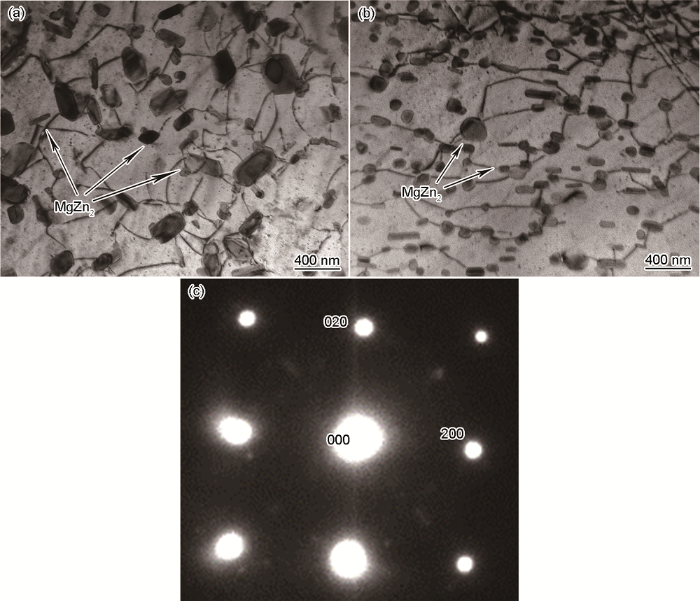

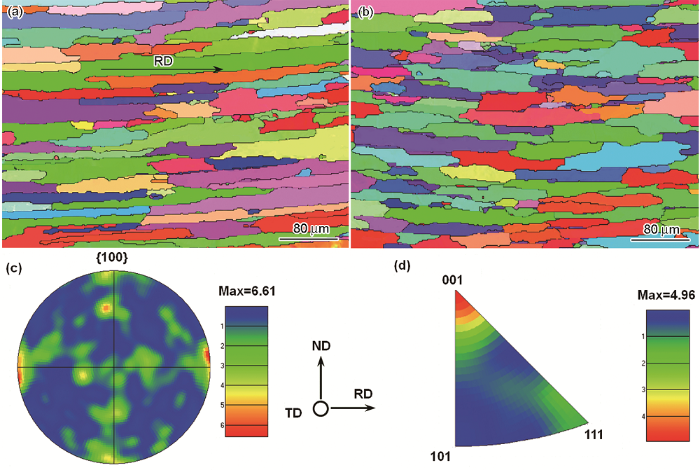

在所有外加总应变幅下TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的循环应力幅值均高于RD方向,对此可从位错与第二相的交互作用方面加以解释。第二相对位错的钉扎与阻碍作用,使位错滑移的难度增大。图8给出了外加总应变幅为0.4%时RD和TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的TEM照片与选区电子衍射花样(SAED)。由图8可见,合金中有大量呈短棒状约为50~300 nm的第二相粒子,即MgZn2相。相较于RD方向合金,第二相粒子均匀分布,TD方向合金中的MgZn2相尺寸较为细小,但数量明显增多。已有的研究表明,细小的第二相粒子对位错的阻碍作用更加明显[16]。因此,相较于RD方向Al-5.4Zn-2.6Mg-1.4Cu合金,TD方向合金中位错的运动受到MgZn2相粒子的阻碍作用更为显著,其可动性更低,使其循环应力幅值提高。同时,由图9a、9b可见,针对RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金进行的EBSD分析发现,RD方向合金的显微组织呈典型的轧制变形结构,晶粒呈纤维状并沿轧制方向明显拉长,其晶粒平均长度约为300 μm。TD方向合金的晶粒因垂直于板材方向的压应力作用而压扁,其晶粒平均宽度约为150 μm。由图9c、9d可见,Al-5.4Zn-2.6Mg-1.4Cu合金的择优取向类型主要为{001}<100>织构。已有的研究表明[17~19],晶粒尺寸和织构对合金的变形抗力有显著的影响,晶粒尺寸的差异和非等轴的形状特点造成晶界对不同方向强化作用的差异。由图9可见,TD方向合金的晶粒较小,在塑性变形过程中对位错的阻碍作用较大,即晶界对TD方向合金的强化作用较大;而RD方向合金的{001}<100>织构的形成造成该方向的塑形变形抗力低于TD方向。因此,TD方向合金的循环应力幅值高于RD方向。

图8

图8

RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的疲劳变形区TEM分析结果

Fig.8

TEM analysis results for fatigue deformation zone of Al-5.4Zn-2.6Mg-1.4Cu alloy with different rolling direction (a) RD direction; (b) TD direction; (c) SAED

图9

图9

RD和TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的EBSD照片、极图(PF)与反极图(IPF)

Fig.9

EBSD images, PF and IPF of Al-5.4Zn-2.6Mg-1.4Cu alloy (a) RD direction; (b) TD direction; (c) PF; (d) IPF

RD和TD方向Al-5.6Zn-2.4Mg-1.6Cu合金在所有外加总应幅下均表现出稳定的循环应力响应行为。在循环变形期间产生的新位错使合金中的位错密度提高,而在高密度位错的运动过程中生位错间的交互作用使不动位错等亚结构形成,加之第二相粒子对运动位错的阻碍使位错的可动性降低,产生硬化效应。另一方面,运动的异号位错相互捕捉而发生湮灭,从而引起软化。当硬化与软化效应达到平衡时,合金便表现出循环稳定。

表2 RD与TD方向Al-5.4Zn-2.6Mg-1.4Cu合金的循环应力幅值

Table 2

| Sampling direction | Δεt /2=0.4% | Δεt /2=0.5% | Δεt /2=0.6% | Δεt /2=0.7% | Δεt /2=0.8% |

| RD | 282.5 | 376.8 | 417.5 | 435.6 | 449.8 |

| TD | 305.6 | 393.0 | 435.4 | 454.1 | 467.5 |

4 结论

(1) 在所有外加总应变幅下RD和TD方向Al-5.4Zn-2.6Mg-1.4Cu合金均表现出稳定的循环应力响应行为,且TD方向合金的循环应力幅值均高于RD方向。RD方向Al-5.4Zn-2.6Mg-1.4Cu合金的低周疲劳寿命均高于TD方向。

(2) 对于RD与TD方向的Al-5.4Zn-2.6Mg-1.4Cu合金,在低周疲劳加载条件下裂纹均在疲劳试样自由表面以穿晶方式萌生和扩展。

参考文献

Effect of quenching rate on properties of automotive high strength Al-alloy

[J].oC/s to 1.8oC/s, the electrical conductivity increased by 5.7% IACS, the hardness reduction rate is 40%, and the reduction rates of tensile strength and yield strength are 24.2% and 56.9%, respectively. The hardness and strength are linearly related to the logarithm of quenching rate. With the decrease of quenching rate, the size and area fraction of quenching precipitates increase significantly, resulting in the decrease of performance. When the quenching rate is 1.8oC/s, the average size and the area fraction of the quenching precipitate are 465.6 nm×158.2 nm and 42.1%, respectively.]]>

淬火速率对汽车用高强铝合金性能的影响

[J].采用力学性能测试、电导率测试和透射电子显微镜研究了淬火速率对汽车用高强铝合金性能的影响。结果表明:淬火速率从960℃/s降低到1.8℃/s,电导率提高了5.7% IACS,硬度的下降率为40%,抗拉强度和屈服强度的下降率分别为24.2%和56.9%,硬度和强度与淬火速率的对数呈线性关系。随着淬火速率的降低,淬火析出相的尺寸和面积分数显著增大,导致性能下降。淬火速率为1.8℃/s时,淬火析出相的平均尺寸为465.6 nm×158.2 nm,析出相的面积分数为42.1%。

Preparation and cutting performance of diamond coated hard alloy cutting tools for 7075 aviation Al-alloy

[J].Diamond coatings were deposited on hard alloy cutting tool of WC-Co8% via hot filament chemical vapor deposition (HFCVD) technology. Two type of coatings, namely, monolayered coating consisted of microcrystalline with grain size of 1.2 μm and multi-layered coating consisted of nanocrystalline with grain size of 200 nm, were prepared by adjusting the methane concentration in the reaction chamber. Then the cutting performance of WC-Co8% cutting tools coated with the two coatings was comparatively assessed via machining 7075 aviation Al-alloy under dry cutting conditions without lubrication. The results show that after cutting for 2 h, coating partially spalled off and the tool edge became blunted for the tool with monolayer diamond coating, in the contrary, the tool edge remains intact and the coating does not fall off for the tool with multilayed diamond coating. Furthermore, Rockwell indentation test of flat samples of hard alloy with coatings revealed that the area of delamination induced by indentation for the multilayered coating is 1/5 to 1/10 of that for the monolayered one. Accordingly, the cracking resistance of the multilayered diamond coating should be better. It follows that the multilayered structure can be adopted to enhance the adhesion of diamond coatings to the substrate, thereby effectively increase the service performance of diamond coating tools.

加工7075航空铝合金用金刚石涂层刀具的制备及其切削性能

[J].采用热丝化学气相沉积(HFCVD)技术在WC-Co8%硬质合金刀具表面制备金刚石涂层,调节甲烷浓度等沉积工艺制备了单层金刚石涂层刀具和微米金刚石涂层(1.2 μm)、纳米金刚石涂层(200 nm)交替多层金刚石涂层刀具。以7075航空铝合金作为切削工件,在无润滑干切条件下测试了单层金刚石涂层刀具和多层金刚石涂层刀具的切削性能。实验结果表明,切削2 h后单层金刚石涂层刀具涂层脱落宽度达到35 μm,刀刃钝化;有多层金刚石涂层刀具的刃型保持完整,涂层无脱落。对单层金刚石涂层和多层金刚石涂层平面样品进行了洛氏压痕实验。结果表明,多层金刚石涂层的脱落面积约为单层金刚石涂层脱落面积的1/5到1/10,进一步说明多层金刚石涂层有更强的抵抗裂纹产生的能力。这些结果表明,金刚石多层结构能提高涂层与基体的界面结合力,延长金刚石涂层刀具的使用寿命。

Self-hardening aluminum alloys and their potential applications in the automotive industry

[J].

Effects of exposure temperature on tensile and charpy impact properties of the 7xxx aluminum alloy for aerospace applications

[J].

Anisotropy of Al-Zn-Mg-Cu aluminum alloy under different aging conditions

[J].

不同时效工艺处理Al-Zn-Mg-Cu铝合金的各向异性

[J].

Evaluation of the mechanical anisotropy and the deformation mechanism in a multi-pass friction stir processed Al-Zn-Mg-Cu alloy

[J].

Anisotropy of the cyclic crack resistance of aluminum alloys after long-term operation

[J].

Effect of Mn and Zr on the anisotropy of Al-Zn-Mg-Cu aluminum alloy

[J].

Mn和Zr对Al-Zn-Mg-Cu铝合金各向异性的影响

[J].

EBSD investigation on the anisotropy of 2124 aluminum alloy

[J].

2124铝合金各向异性的EBSD研究

[J].

Anisotropy of microstructure and properties of Al-10.22 Zn-2.87 Mg-1.2 Cu-0.213 Zr alloy

[J].

Fatigue performance of 7475-T7351 aluminum alloy plate

[J].

7475-T7351铝合金厚板的疲劳性能

[J].

EBSD analysis of fatigue crack growth of 2124 aluminum alloy for aviation

[J].

Low cycle fatigue behavior of Al-Zn-Mg-Cu alloy containing Zr and Sc

[J].

含Zr、Sc的Al-Zn-Mg-Cu合金的低周疲劳行为

[J].

Mean stress relaxation during low-cycle fatigue of aluminum alloy 7050-T7451

[J].

7050-T7451铝合金低周疲劳平均应力松弛规律

[J].

Effect of Sc addition on low-cycle fatigue properties of extruded Al-Zn-Mg-Cu-Zr alloy

[J].

Evolution of second phases and mechanical properties of 7075 Al alloy processed by solution heat treatment

[J].

Inhomogeneity of properties of 7150-T7751 aluminum alloy thick plate

[J].

7150-T7751铝合金厚板性能的不均匀性

[J].

Impact of texture and microstructure on in-plane anisotropy of ultra-high strength aluminium alloy

[J].

织构及组织结构对超高强铝合金平面力学性能的影响

[J].

Analysis of mechanical anisotropy in casting-rolling Al-Mn alloy sheet

[J].

铸轧Al-Mn合金板材的各向异性分析

[J].

Low-cycle fatigue behavior and property of TA15 titanium alloy with tri-modal microstructure

[J].