商用石墨阳极的理论容量有限(372 mAh/g)和嵌锂电位较低,已经不能满足新型锂离子电池(LIBs)的需求。因此,开发和制备具有更高容量和安全性的新型负极材料(如Si、Ge、Sn、SnO2、Fe2O3、GeO2、MnO2和MoP等)取代石墨极为迫切[1]。SnO2具有理论容量高(780 mAh/g)、低毒性和低成本的优点,是一种很有前途的负极材料[2~4]。但是,在脱锂/嵌锂过程中SnO2较大的体积变化引起颗粒粉化和聚集,使纯SnO2负极的倍率能力和循环性能降低[5,6]。尽管如此,设计和制备纳米SnO2@C复合材料可提高其倍率性能和循环性能,因为炭材料可提高电极的导电性,而纳米级尺寸可缩短离子和电子的传输路径,从而缓解SnO2在长期循环过程中体积变化的影响[7~10]。常见的炭基材料,包括非晶无定形炭、炭纳米管和石墨烯等。以炭材料为基体可制备出不同形貌的SnO2/C复合材料,如SnO2/C纳米纤维[11]、SnO2/C纳米孔炭微球[12]、SnO2/核壳结构微球[13]、蜂巢纳米片结构的SnO2/石墨炭复合物[14]等。这些材料不仅储锂性能较高,在充放电过程中很少发生团聚,而且首次充放电效率也较高,可逆放电容量均高于纯纳米氧化锡,具有良好的循环性能。目前存在的问题有:(1)最常用的炭基材料碳纳米管和石墨烯[15~18],其理论储锂容量远低于锡氧化物,因此较高比例的炭影响复合材料的容量;若炭的比例过低则不能为锡氧化物提供稳定的生长网络;(2)石墨烯基体的成本较高,石墨烯片强烈的π-π堆积效应使其在循环过程中团聚,影响复合材料的循环性能;(3)两者较高的成本不利于大规模制备SnO2@C。

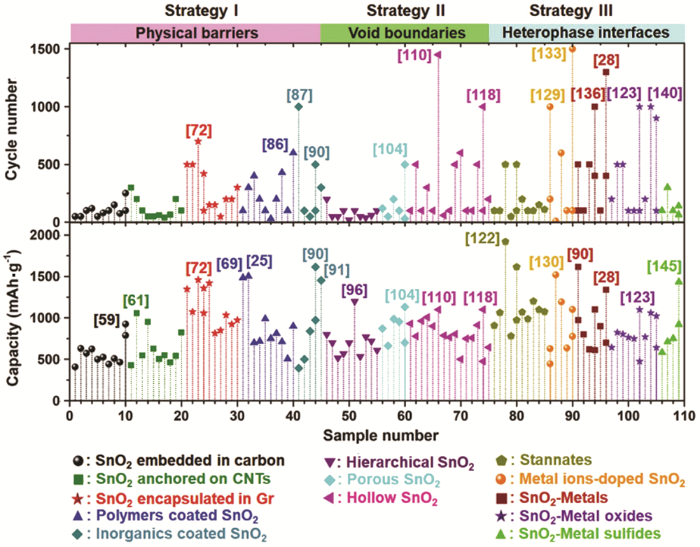

图1

1 实验方法

1.1 试样的制备

将1 g糖类前驱体和3.24 g SnCl4·5H2O溶解到80 mL去离子水中并将得到的溶液转入100 mL水热反应釜,将温度升高到180℃静置12 h后随炉冷却。釜中的溶液变为棕色,内有黑褐色沉淀物。在真空抽滤器中用去离子水对沉淀物进行充分洗涤和抽滤直至变成中性。在80℃干燥箱中将沉淀物烘干后再转入真空管式炉,通入氩气气氛后在300℃下预分解2 h,然后在500℃烧结5 h,得到最终产品。将以葡萄糖为前驱体的试样命名为TOC-G,以淀粉为前驱体的试样命名为TOC-S。

1.2 电极的制备

取质量比为8:1:1的电极材料、Super P和海藻酸钠。将粘结剂海藻酸钠溶解在去离子水中,再加入混合好的电极材料与导电剂Super P,将其均匀涂布在Cu箔上。将其烘干后冲制成直径为14 mm的电池正极片。以锂片为对电极,在Ar保护气氛的手套箱中装配成2016型扣式电池。使用的隔膜为Celguard2400,电解液为1.3 mol/L LiPF6的EC/DMC(1:1)溶液。

1.3 性能表征

用Bruke D8 ADVANCE X射线衍射仪进行XRD分析;用Hitachi SU8220扫描电镜和FEI Tecnai G2透射电镜分析复合材料的形貌;用Micromeritics ASAP2020分析仪进行N2吸脱附分析和孔径分析;用Thermofisher Escalab 250Xi X射线光电子能谱仪测试XPS谱;在LAND-CT2001A电池测试系统上进行恒电流充放电测试;使用CHI660C型电化学工作站进行EIS与CV分析。

2 结果与讨论

2.1 元素分析与孔径分布

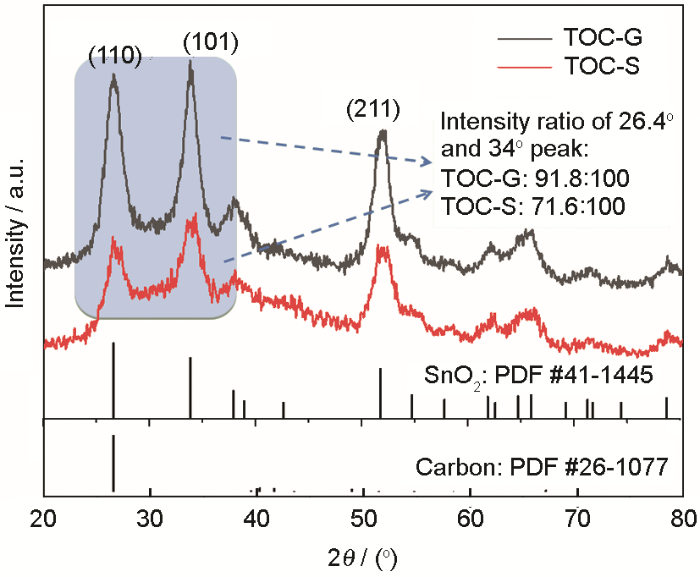

图2给出了两种试样的XRD图谱,可见所有衍射峰与金红石型SnO2完全吻合(PDF #41-1445),属于空间群P42/mnm,a=b=0.4738 nm,c=0.3187 nm,晶胞体积0.716 nm3。两个最强的主峰(26.4°与34.0°)对应SnO2的(110)与(101)晶面,晶面间距分别为0.33 nm与0.26 nm。使用Jade软件分析发现,两主峰的峰强之比分别为91.8:100与71.6:100,其原因是葡萄糖热解炭与淀粉热解炭的结晶程度不同。碳的主要衍射峰位于26.6°,可见TOC-G的XRD图谱上叠加了更强的碳衍射峰,即葡萄糖热解硬炭比淀粉热解硬炭的结晶度和有序度更高,导电性能更好。

图2

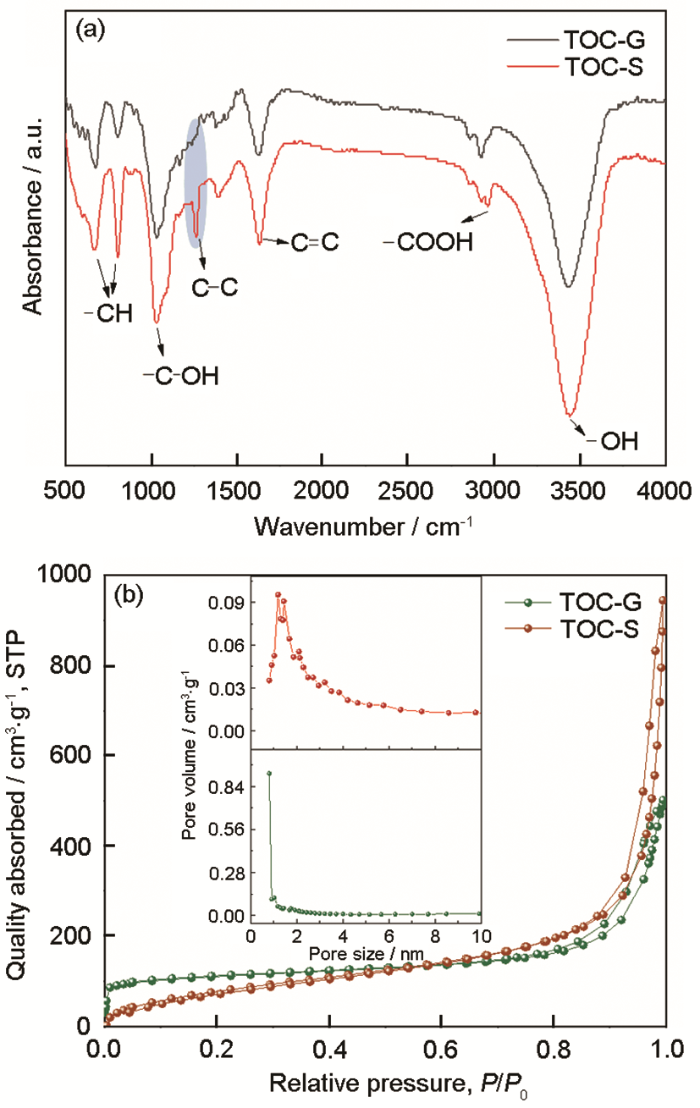

图3a给出了TOC-G与TOC-S的红外光谱,用于分析分子中含有的化学键或官能团信息。1162 cm-1处的尖锐峰对应-C-OH基团中的弹性拉伸,2957与3470 cm-1处的宽峰对应-COOH与-OH基团的振动,这些官能团在电沉积过程中为SnO2纳米颗粒的附着提供缺陷位置[21]。含氧基团将Sn4+氧化为SnO2晶核并在500℃结晶生长为SnO2纳米颗粒,但它与Li+发生不可逆结合而影响复合材料的首次充放电效率。1280和1630 cm-1处的峰为C-C与C=C的拉伸键,分别代表sp3杂化与sp2杂化。红外光谱表明,淀粉热解后形成的炭以sp3键合为主,也有部分炭原子以sp2方式互相键合;而葡萄糖糖热解炭中sp2的比例非常少,表明葡萄糖热解炭的有序程度相对更高,导电性更好。这在两种试样的HRTEM照片中也可看出。

图3

图3

试样的红外光谱(a)、N2吸脱附曲线和孔径分布(b)

Fig.3

FTIR patterns (a), N2 adsorption/desorption curve and pore distribution (b)

图3b给出了TOC-G与TOC-S的N2吸脱附曲线和孔径分布(>10 nm的孔很少,图中没有),两者的比表面积分别为280.3 m2/g和348.0 m2/g。两者的吸脱附曲线均为典型的I型曲线(微孔型),微孔较多的原因是微孔内的强势吸附使低压端靠近Y轴。中压端多为N2在介孔孔道内的冷凝积聚。图中可见中压端的N2吸附量变化不大,说明两种材料中介孔比例都很少,以微孔为主,其中葡萄糖热解炭几乎没有介孔。高压端的上扬程度可用来判断粒径的均匀程度,上扬程度越高则粒径越不均匀。从孔径分布图可以看出,TOC-G的孔类型为直径0.8 nm左右的超微孔,而TOC-S则主要为直径1~2 nm的微孔以及少量的介孔。微孔的数量影响电极材料的平台容量,图6中的充放电曲线也体现了这一点[22]。

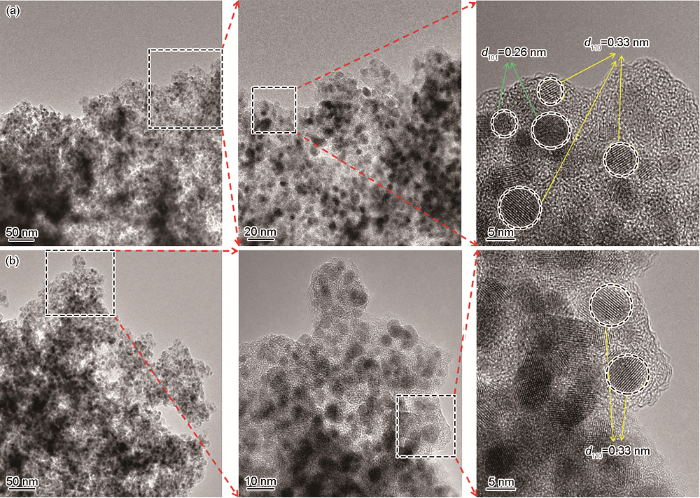

图4

图4

TOC-G(a)和TOC-S(b)的TEM和HRTEM照片

Fig.4

TEM and HRTEM images of TOC-G (a) and TOC-S (b)

图5

图6

图6

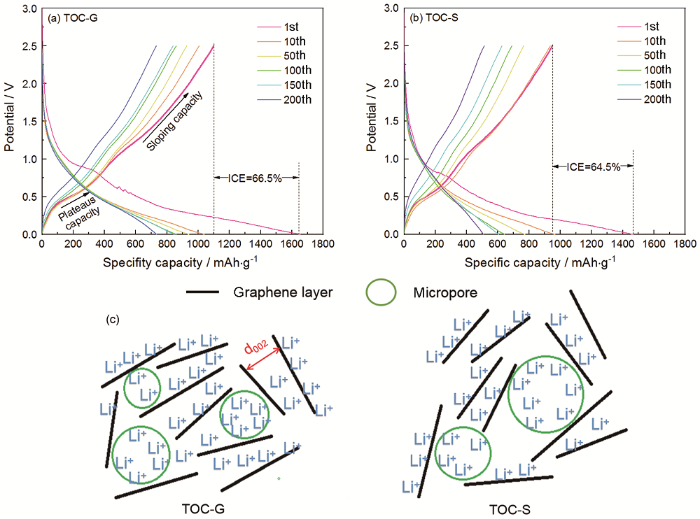

TOC-G 和TOC-S 的充放电曲线以及锂离子在炭基体中的插层和吸附示意图

Fig.6

Charge/discharge curve of TOC-G (a) and TOC-S (b), sketch map of Li+ insertion and absorption in carbon matrix (c)

2.2 微观结构分析

图4给出了复合材料的TEM与HRTEM图谱。可以看出,两种试样均为团絮状结构,SnO2颗粒与热解炭之间没有明确的界限。用DigitalMicrograph透射电镜分析软件分析HRTEM照片,发现主要存在0.26 nm与0.33 nm两种晶面间距,XRD数据表明其对应于SnO2的(101)与(110)晶面。这表明,HRTEM图谱中球形的、直径5 nm左右的颗粒为SnO2纳米点,周围包裹的无定型结构即为炭基体。

两种试样的差别在于TOC-G的SnO2纳米点粒径稍小。5点测量的平均值表明,TOC-G的平均粒径为4.74 nm,TOC-S为5.62 nm。用作锂离子电池负极材料,SnO2具有高容量、低成本的优势,但是它在循环过程中体积膨胀引起的粉化和破碎使其循环性能极差,达不到使用要求。本文使用的糖类前驱体热解产生的炭基体起物理缓冲作用,而且粒径极小的SnO2纳米点具有更高的比表面积,可增加锂/钠离子进入活性物质的途径,缩短锂离子的传输路径,这两者协同作用能调节充放电过程中活性SnO2材料的体积膨胀,从而提高快速充放电能力与循环性能。

2.3 电化学性能分析

以TOC-G和TOC-S为负极装配的CR2016扣式电池其循环性能和倍率性能,如图5a所示。可以看出,200次循环后(电流密度200 mA/g)TOC-G的放电比容量由1099.5 mAh/g降至732.9 mAh/g,TOC-S的放电比容量由948.6 mAh/g降至509 mAh/g,容量保持率分别为66.6%和53.8%。前文的分析表明,以葡萄糖为炭前驱体的TOC-G试样其炭基体的有序化程度更高,SnO2纳米点的粒径更小,因此锂离子在颗粒中的传输更快,SnO2的体积膨胀效应更小,因此具有更好的循环性能。纯SnO2前50次循环容量保持率低于50%,178次循环后容量衰减为零[22]。Zhang等[24]制备的SnO2/石墨烯复合物循环100次后容量保持率约为60%,其他文献的数据略低[25, 27]。试样的倍率性能如图5b所示,可见前10个循环衰减明显,这是固态电解质膜(SEI)的形成以及Li+与含氧基团的不可逆反应造成的。在随后的循环中容量的保持率较好,电流密度达到2 A/g时容量大于400 mAh/g,且TOC-G的容量略高于TOC-S。在此电流密度下一次充放电时间约为10 min,即充放电倍率为12C,已经远高于目前对商用锂离子电池高倍率充放电的要求(5C)。

本文负极材料电化学性能的提高得益于炭材料充当了锚定和分离SnO2纳米粒子的主体,均匀致密的碳基体缓冲了SnO2在锂/脱锂过程中的体积膨胀,促进了电子的传输,稳定了电极结构;其次,SnO2颗粒纳米化使锂离子和电子转移距离较短,Sn/Li2O界面间的互扩散动力学加强,从而提高了电化学反应的可逆性,提高了循环性能。

图6a、b给出了两种试样不同循环次数的充放电曲线,其中加粗线为首次充放电曲线。由于SEI的形成和Li+与含氧基团的不可逆反应,两者的首次库伦效率(ICE)都较低,分别为66.5%与64.5%。首次库伦效率与负极材料的烧结温度相关,烧结温度高于900℃后炭氧键断裂使大量含氧基团消失,使首次库伦效率明显提高[28]。但是温度高于700℃时SnO2被炭还原为单质[29, 30],在充放电过程中体积的膨胀更为严重,因此本文选择的热解温度为500℃。文献[30]表明,在充放电曲线的斜坡区域代表Sn的合金化反应与锂离子在碳层中的插层。插入/脱出电势随着Li+含量的增加而降低,因而形成斜坡;平台区域代表Li+在微孔中的脱嵌过程,低电位平台可以归因于Li+吸附到随机堆积的碳层之间的纳米孔隙中。Li+被吸附到化学势接近其本身的位置从而其电位接近0 V(图6c)。随着循环次数的增加平台容量逐渐变少,尤其是TOC-S第200次循环时平台容量几乎为0。这也是TOC-S的循环性能不如TOC-G的原因。由孔径分布曲线可见,TOC-S的微孔直径大于TOC-G而能吸附更多的Li+。可以推测,孔道深处吸附的Li+会形成团簇,且因传输距离更远而逐渐失去电化学活性,造成容量的损失。

图7给出了两种试样的循环伏安曲线,扫描速率为0.03 mV/s,曲线上不同峰位所代表的电化学反应如图上的标识。在首次CV曲线上,0.6~0.8 V之间的两个明显的阳极峰对应SEI膜的形成和部分不可逆反应(标识①);0 V附近的阳极峰代表Sn与Li+的可逆反应(

图7

图7

TOC-G试样(a)和TOC-S试样(b)的循环伏安曲线(前三次循环和第100次循环)

Fig.7

Cyclic voltammetry curves (the first three cycles and the 100th cycle) (a) TOC-G, (b) TOC-S

3 结论

以糖类有机物葡萄糖和淀粉为炭前驱体,用一种简单方法可合成SnO2@C复合物TOC-G和TOC-S。复合物的微观结构是,SnO2纳米点嵌在团絮状的炭基体上形成了稳定的复合结构。两种复合物的表面均有丰富的微孔,其中TOC-G上的微孔直径小于0.8 nm,TOC-S上的微孔以1~2 nm为主。微孔较大时,锂离子容易在微孔中发生不可逆沉积从而影响循环性能。TOC-G的循环性能略优于TOC-S,200次循环后的容量保持率为66.6%,倍率性能也较好,在2 A/g的大电流密度下其容量约为435 mAh/g。

参考文献

Preparation and electrochemical behavior of mop nanoparticles as anode material for lithium-ion batteries

[J].

MoP纳米粒子锂离子电池负极材料的制备及其电化学性能

[J].用直流电弧等离子体法制备金属钼纳米粉体再使其与赤磷发生固相反应,用两步法制备出磷化钼纳米粒子。使用X射线衍射(XRD)和透射电镜(TEM)等手段表征磷化钼纳米粒子的结构并进行了电化学性能测试。结果表明,MoP纳米粒子呈球状,粒径为20~50 nm;在电流密度为100 mA/g的条件下MoP纳米粒子负极材料的首次放电比容量达到746 mAh/g,50次循环后放电比容量为241.9 mAh/g;电流密度为2000 mA/g时放电比容量为99.90 mAh/g,电流密度恢复到100 mA/g其放电比容量仍然保持247.60 mAh/g。用作锂离子电池的负极材料,MoP纳米粒子具有优异的稳定性和可逆性。

Tin-based amorphous oxide: a high-capacity lithium-ion-storage material

[J].

Large-scale synthesis of SnO2 nanosheets with high lithium storage capacity

[J].In this communication, we successfully synthesized a new SnO(2) nanoarchitecture: extremely thin sheets, with minimum thicknesses of 1.5-3.0 nm. The products were prepared through a facile hydrothermal treatment using tin dichloride as the precursor. Planar or scrolled SnO(2) sheets were carefully examined by transmission electron microscopy. The assemblies of these sheets have a high BET surface area of 180.3 m(2)/g and extraordinarily large pore volume of 1.028 cm(3)/g. They also exhibit a high lithium storage capacity and excellent cyclability due to its nanometer-sized frame and breathable characteristic.

Hierarchical tubular structures constructed by carbon-coated SnO2 nanoplates for highly reversible lithium storage

[J].

In situ observation of the electrochemical lithiation of a single SnO2 nanowire electrode

[J].We report the creation of a nanoscale electrochemical device inside a transmission electron microscope--consisting of a single tin dioxide (SnO(2)) nanowire anode, an ionic liquid electrolyte, and a bulk lithium cobalt dioxide (LiCoO(2)) cathode--and the in situ observation of the lithiation of the SnO(2) nanowire during electrochemical charging. Upon charging, a reaction front propagated progressively along the nanowire, causing the nanowire to swell, elongate, and spiral. The reaction front is a

The preparation of double-void-space SnO2/carbon composite as high-capacity anode materials for lithium-ion batteries

[J].

Reserving interior void space for volume change accommodation: An example of cable-like MWNTs@SnO2@C composite for superior lithium and sodium storage

[J].

Strategy for yolk-shell structured metal oxide-carbon composite powders and their electrochemical properties for lithium-ion batteries

[J].

Flexible anodes with carbonized cotton covered by graphene/SnO2 for advanced lithium-ion batteries

[J].

Synthesis of iron oxide-tin oxide-carbon composite nanobelts and their applications in lithium-ion batteries

[J].

氧化铁-氧化锡-碳复合纳米带的合成及其在锂电池中的应用

[J].

Easy preparation of SnO2@carbon composite nanofibers with improved lithium ion storage properties

[J].

Shell-by-shell synthesis and applications of carbon-coated SnO2 hollow nanospheres in lithium-ion battery

[J].

Cover feature: core-shell structure of SnO2@c/PEDOT: PSS microspheres with dual protection layers for enhanced lithium storage performance (ChemElectroChem 8/2019)

[J].

Honeycomb-like carbon nanoflakes as a host for SnO2 nanoparticles allowing enhanced lithium storage performance

[J].

Composite Nano-materials with 1-D core/shell architecture synthesized in one-pot hydrothemal method and its Li-storage properties

[J].

一步水热法合成CNTs/SnO2@C一维壳核结构复合纳米材料及其锂存储特性研究

[J].

CNTs@SnO2@C coaxial nanocables with highly reversible lithium storage

[J].

Synthesis and electrochemical performance of SnO2/Graphene anode material for lithium ion batteries

[J].

SnO2/石墨烯锂离子电池负极材料的制备及其电化学行为研究

[J].

A SnO2/graphene composite as a high stability electrode for lithium ion batteries

[J].

The “falling cards model” for the structure of microporous carbons

[J].

SnO2 as advanced anode of alkali-ion batteries: inhibiting sn coarsening by crafting robust physical barriers, void boundaries, and heterophase interfaces for superior electrochemical reaction reversibility

[J].

Carbon-confined SnO2-electrodeposited porous carbon nanofiber composite as high-capacity sodium-ion battery anode material

[J].Sodium resources are inexpensive and abundant, and hence, sodium-ion batteries are promising alternative to lithium-ion batteries. However, lower energy density and poor cycling stability of current sodium-ion batteries prevent their practical implementation for future smart power grid and stationary storage applications. Tin oxides (SnO2) can be potentially used as a high-capacity anode material for future sodium-ion batteries, and they have the advantages of high sodium storage capacity, high abundance, and low toxicity. However, SnO2-based anodes still cannot be used in practical sodium-ion batteries because they experience large volume changes during repetitive charge and discharge cycles. Such large volume changes lead to severe pulverization of the active material and loss of electrical contact between the SnO2 and carbon conductor, which in turn result in rapid capacity loss during cycling. Here, we introduce a new amorphous carbon-coated SnO2-electrodeposited porous carbon nanofiber (PCNF@SnO2@C) composite that not only has high sodium storage capability, but also maintains its structural integrity while ongoing repetitive cycles. Electrochemical results revealed that this SnO2-containing nanofiber composite anode had excellent electrochemical performance including high-capacity (374 mAh g(-1)), good capacity retention (82.7%), and large Coulombic efficiency (98.9% after 100th cycle).

A better understanding of the irreversible lithium insertion mechanisms in disordered carbons

[J].

Novel preparation of N-doped SnO2 nanoparticles via laser-assisted pyrolysis: demonstration of exceptional lithium storage properties

[J].

One-pot synthesis of three-dimensional graphene/carbon nanotube/SnO2 hybrid architectures with enhanced lithium storage properties

[J].

Controllable synthesis of monodisperse ultrathin SnO2 nanorods on nitrogen-doped graphene and its ultrahigh lithium storage properties

[J].Monodisperse ultrathin SnO(2) nanorods on nitrogen-doped graphene were firstly synthesized by a facile one-step hydrothermal strategy. The uniformed composites with high nitrogen content and ultrathin SnO(2) nanorods of 2.5-4.0 nm in diameter and 10-15 nm in length show a high reversible specific capacity, superior rate capability and outstanding cycling stability (803 mA h g(-)(1)) as anode materials for lithium ion batteries, owing to the synergistic effect between GS and SnO(2) and nitrogen-doping, which can greatly decrease the energy barrier for Li penetrating the pyridinic defects and improve the electronic structures. This work opens the door to prepare metal oxide/GS-N composites with superior lithium storage properties and engineering of graphene composites for advanced energy storage.

Interface chemistry engineering for stable cycling of reduced go/SnO2 nanocomposites for lithium ion battery

[J].From the whole anode electrode of view, we report in this work a system-level strategy of fabrication of reduced graphene oxide (RGO)/SnO2 composite-based anode for lithium ion battery (LIB) to enhance the capacity and cyclic performance of SnO2-based electrode materials. RGO/SnO2 composite was first coated by a nanothick polydopamine (PD) layer and the PD-coated RGO/SnO2 composite was then cross-linked with poly(acrylic acid) (PAA) that was used as a binder to accomplish a whole anode electrode. The cross-link reaction between PAA and PD produced a robust network in the anode system to stabilize the whole anode during cycling. As a result, the designed anode exhibits an outstanding energy capacity up to 718 mAh/g at current density of 100 mA/g after 200 cycles and a good rate performance of 811, 700, 641, and 512 mAh/g at current density of 100, 250, 500, and 1000 mA/g, respectively. Fourier transform IR spectra confirm the formation of cross-link reaction and the stability of the robust network after long-term cycling. Our results indicate the importance of designing interfaces in anode system on achieving improved performance of electrode of LIBs.

Facile synthesis of SnO2 nanoparticles dispersed nitrogen doped graphene anode material for ultrahigh capacity lithium ion battery applications

[J].

Effect of pyrolysis temperature on lithium storage performance of pyrolitic-PVDF coated hard carbon derived from cellulose

[J].

Preparation of SnO2/carbon composite hollow spheres and their lithium storage properties

[J].

Preparation of spherical Sn/SnO2/porous carbon composite materials as anode material for lithium-ion batteries

[J].

High capacity anode materials for rechargeable sodium-ion batteriess

[J].

N-doped graphene-SnO2 sandwich paper for high‐performance lithium-ion batteries

[J].

Enhanced cyclic performance and lithium storage capacity of SnO2/graphene nanoporous electrodes with three-dimensionally delaminated flexible structure

[J].

Cross-stacked carbon nanotube sheets uniformly loaded with SnO2 nanoparticles: a novel binder-free and high-capacity anode material for lithium-ion batteries

[J].