根据Cr/Ni伪二元相图,基于铬镍当量比Creq/Nieq奥氏体不锈钢的凝固可分为4种模式,依次为A模式(<1.25):L→L+γ→γ,AF模式(1.25~1.48):L→L+γ→L+γ+(δ+γ)共晶→γ+δ,FA模式(1.48~1.95):L→L+δ→L+δ+(δ+γ)包晶,共晶→γ+δ,以及F模式(>1.95):L→L+δ→δ→γ+δ。冷却速度,是影响300系奥氏体不锈钢凝固行为的一个重要因素[5]。在快冷条件下一些奥氏体不锈钢的凝固由初始铁素体模式变为初始奥氏体,其热裂敏感性随之提高[6,7,8,9]。氮的加入也使奥氏体不锈钢的凝固从初始铁素体模式变为初始奥氏体,并促进铁素体转变位置处的热裂[10,11,12,13]。关于奥氏体不锈钢快速凝固微观组织和热裂已经进行了很多研究,但是尚未完全了解凝固行为变化对热裂敏感性的影响[9]。

1 实验方法

表1 301L板材的化学成分

Table 1

| C | Si | Mn | Ni | Cr | N |

|---|---|---|---|---|---|

| 0.022 | 0.32 | 1.26 | 7.32 | 17.71 | 0.13 |

表2 301L板材的力学性能

Table 2

| Plate | R0.2/MPa | Rm/MPa | δ/% |

|---|---|---|---|

| 301L-DLT | 365 | 740 | 53 |

| 301L-ST | 435 | 790 | 52 |

| 301L-MT | 524 | 880 | 37 |

| 301L-HT | 700 | 950 | 28 |

根据WRC-1992相组分图计算出301L的铬镍当量比Creq/Nieq为1.66,因此301L以FA模式凝固,铁素体含量约为4%(体积分数)。

焊接板材不开坡口,焊前将板材端面打磨后用丙酮清洗。使用Trudisk4002固体激光器进行激光焊接,光纤直径为0.5 mm,焊接功率为2.5 kW、焊接速度为1.5 m/min、离焦量为0 mm,保护Ar气0º侧吹,流量为30 L/min。

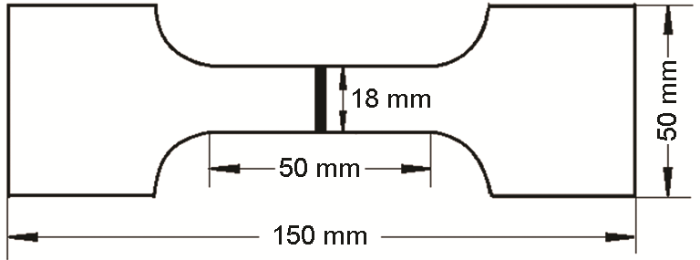

用线切割将焊件加工成拉伸试样(图1),根据ISO 6892:1998标准在MTS材料试验机上进行拉伸实验,拉伸速度为4 mm/min。

图1

用扫描电镜和光学显微镜分析激光焊缝凝固组织,用EDS分析焊缝组织的杂质偏析,用Fischer FMP30铁磁仪测定焊缝的铁素体含量,用HXZ-1000显微硬度计测定接头硬度分布,载荷100 g,加载时间15 s。

2 实验结果

2.1 焊缝的凝固组织

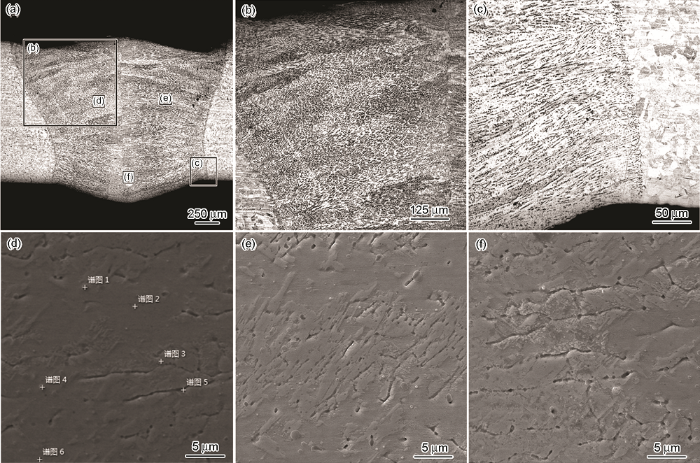

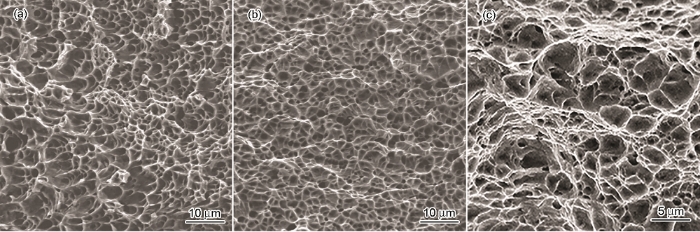

图2给出了激光焊接接头的凝固组织,各局部区域微观组织的位置在焊缝整体图图2a中标出。从图2a~c可以看出,焊缝中柱状晶的凝固从熔合区两侧的板材边界起始,垂直熔合线向焊缝内生长,最终在中心线相遇。这种凝固行为使焊缝内没有中心等轴晶粒区。焊缝组织为奥氏体和枝状铁素体,焊缝底部的铁素体枝晶间距比顶部的小,底部的铁素体分布比顶部的更均匀,一次铁素体枝晶臂的平均间距约为17.5 μm。焊缝整体没有热裂纹和其它凝固缺陷,最终凝固的柱状晶接合线附近也没可见杂质,但是焊缝的顶部局部凹陷,焊缝底部的中心明显下沉。图2d~f给出了焊缝中部和底部不同区域的SEM高倍显微组织,可见铁素体呈板条状、骨架状和蠕虫状,板条铁素体束的宽度约为14 μm。铁素体的形态表明,301L激光焊缝以初始铁素体FA模式凝固,焊缝中平均铁素体量约为5.7%(体积分数)。在焊缝中心最后凝固区域的高倍组织中未见夹杂物和析出相,根据一次铁素体枝晶臂间距可推测焊缝金属熔池冷却速度约为90~100℃/s[18]。焊接热影响区的奥氏体发生了再结晶,晶粒尺寸为20~50 μm,部分晶粒明显长大。

图2

图2

激光焊接接头的显微组织

Fig.2

Microstructure of laser butt welded joint (a) overall view of welded joint; (b) optical micrograph of upper weld; (c) optical micrograph of weld bottom; (d) SEM micrograph of middle weld center; (e) lathy ferrite bunch in SEM micrograph; (f) SEM micrograph of bottom weld center

2.2 激光焊接接头的拉伸性能和断裂行为

图3给出了4种强度301L冷轧板激光焊接接头的硬度分布。可以看出,焊缝的硬度为208~241HV,平均硬度为218HV,与301L-DLT板材的硬度相近,比301L-ST、301L-MT和301L-HT冷轧板的低;三种高强度冷轧板焊接热影响区的硬度明显较低,从焊缝边缘至冷轧母材原始硬度的距离约0.5 mm。

图3

图3

不同强度激光焊接301L冷轧板的显微硬度分布

Fig.3

Microhardness profiles of laser welded 301L cold-rolled plates with different strengths

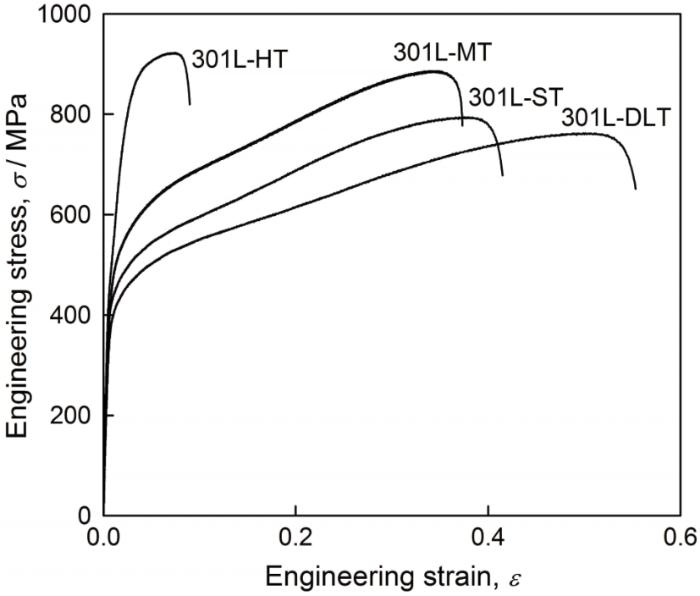

图4

图4

不同强度激光焊接301L冷轧板的拉伸曲线

Fig.4

Tensile curves of laser welded 301L cold-rolled plates with different strengths

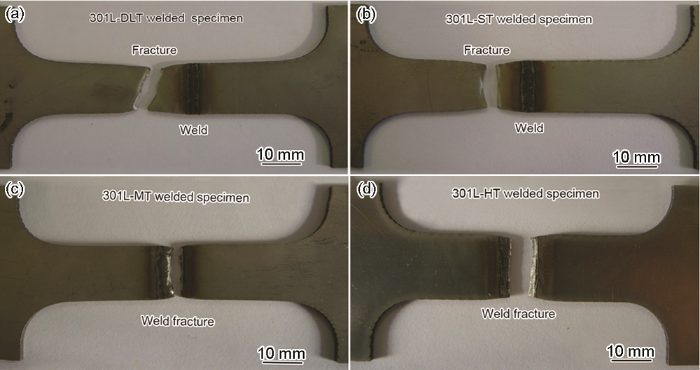

图5给出了4种强度冷轧板激光焊接试样的拉伸断裂位置。可以看出:301L-DLT和301L-ST激光焊件的断裂位置在焊缝附近;301L-MT和301L-HT焊件的断裂位置在焊缝内,焊缝的断裂位置与焊缝顶部的凹陷位置吻合。图5还表明,301L-DLT和301L-ST拉伸试样的板材与焊缝基本上保持等截面同步变形,试样的标距发生均匀伸长和截面减小,断裂位置在板材内。这表明,两试样的拉应力尚未达到激光焊缝的断裂强度。301L-MT和301L-HT两试样断口附近的焊缝和热影响区的局部截面明显小于标距内其它部位的板材,尤其是301L-HT全硬化冷轧板试样。这表明,在焊缝及其附近区域发生了非均匀集中塑性变形,两试样的拉伸应力达到了焊缝金属的断裂强度。

图5

图5

激光对焊的4种强度301L冷轧板的拉伸断裂位置

Fig.5

Tensile fracture positions of laser butt welded 301L cold-rolled plates with four grade strengths (a) 301L-DLT, (b) 301L-ST, (c) 301L-MT, (d) 301L-HT

301L-HT板激光焊件的延伸率较低,因为板材与焊缝的硬度相差悬殊。在拉伸过程中塑性变形集中在硬度较低的焊缝及热影响区,焊接试样标距内301L-HT板的长度和截面的变化很小。301L-ST激光焊件的断裂位置不在硬度较低的焊缝,可能与试样切割损伤有关。断裂起始于两侧板材切割部位,断裂面的变形不均匀,这也是激光焊件的延伸率和断裂强度较低的原因。

图6

图6

激光焊缝和冷轧板材的断口形貌

Fig.6

Fracture morphologies of upper laser weld (a), bottom laser weld (b) and 301L-DLT plate (c)

3 讨论

在快冷条件下301L冷轧板激光焊接金属并不像与其铬镍当量比相近的304不锈钢由初始铁素体凝固模式变为初始奥氏体[3,9],而是仍以初始铁素体FA模式凝固,并且焊缝内的铁素体量较多。对301L不锈钢激光焊接和MIG焊接微观组织的对比也证明,301L焊缝金属的凝固模式对冷却条件不敏感[15,16]。初始铁素体对热裂有重要的抑制作用,能钉扎凝固晶界增大热裂纹的扩展阻力[13]。301L焊接金属的这种快冷凝固模式,可能与其低铬、镍成分组合有关。虽然添加了奥氏体稳定元素氮,常温下其奥氏体的稳定性仍远低于304不锈钢[14]。根据高斯光束沿传播方向的线能量分布规律,焊缝熔池顶部的能量输入大于底部,即焊缝熔池顶部的温度高于底部[20]。当熔池温度降至1400 ~ 1450℃初始铁素体凝固温度区间时,焊缝顶部周围板材温度的升高和导热率的较低使顶部的冷却速度低于焊缝底部,并且顶部熔池中心和边缘的过冷度差大于底部[21,22],因此焊缝底部的柱状晶比顶部更细、方向更一致,凝固组织的铁素体分布更均匀。焊缝中没有中心等轴晶粒区,说明焊缝金属凝固主要通过两侧的固体母材散热,焊缝纵向散热对熔池金属凝固的影响不明显。

上述结果表明,301L亚稳态不锈钢具有优异的激光加工成型性能,其初始铁素体模式凝固的激光焊缝组织保证了焊件在外载荷作用下断口内没有低延性断裂区,焊接金属的断裂强度高达886 MPa和921 MPa,远高于铬镍当量比相近的以初始奥氏体模式凝固焊接金属的断裂强度。

4 结论

(1) 301L激光焊缝以初始铁素体FA模式凝固,热裂敏感性低;焊缝柱状晶垂直熔合线向内生长在中心线相遇,没有中心等轴晶粒区。焊缝组织为奥氏体和铁素体,铁素体呈板条状、骨架状和蠕虫状,一次铁素体枝晶臂平均间距约17.5 μm,平均铁素体量5.7%体积分数。焊缝中最后凝固的中心柱状晶接合线附近没有杂质,焊缝整体没有热裂纹和析出相。

(2) 激光焊缝的硬度为208~241HV,与301L-DLT板材的硬度接近,低于301L-ST、301L-MT和301L-HT冷轧板硬度。301L-DLT和301L-ST板焊接试样的拉伸断裂位置在母材内,301L-MT和301L-HT板焊接试样的断裂位置在焊缝内,激光焊缝金属的断裂强度为886 MPa和921 MPa。

(3) 301L-HT板激光焊件的塑性低于标准规定的最低值0.2,其余三种强度冷轧板激光焊接试样的拉伸性能都达到JIS G 4305标准中相应强度冷轧301L板材的力学性能。

参考文献

Cracking behavior and mechanical properties of austenitic stainless steel parts produced by laser metal deposition

[J].

Microstructure evolution of 316L stainless steel during laser rapid forming

[J].crystallographic orientation leaning to, even parallel to the deposition direction. There also exist a thin layer in which the dendrites grow along the laser scaning direction at the top of the LRF sample. Clad layer bandings were found in the samples; however, the continuity of the growth of the columnar dendrites was not upset. The growth morphology of primary dendrites can be predicted by the microstructure selection models based on the maximum interface temperature criterion. The formation of the clad layer bandings and the epitaxial growth characteristic during LRF are also explained by the criteria for planar interface instability and dendritic growth theory and the columnar to equiaxed transition model. There shows an reasonable agreement between the theoretic analysis and the experimental results.]]>

激光快速成形过程中316L不锈钢显微组织的演变

[J].对316L不锈钢在激光快速成形过程中的凝固行为和组织形成进行了系统考察,发现,成形件呈现全奥氏体结构,其组织主要由从基体连续外延生长的细长列状枝晶组成,并显示较强的晶体取向性,其(100)晶向基本平行沉积方向,仅在顶部出现了一薄层转向枝晶层,而在成形件中出现的层带结构并未影响不同熔覆沉积层之间组织生长和取向的连续性,并采用最高界面生长温度判据对激光快速成形中的相形成规律进行了分析,并结合平界面稳定性分析,枝晶生长理论和我们所发展的列状晶/等轴晶转变模型对成形件中的层带形成,外延列状晶生长特性进行了较为系统的研究,并与实验结果得到了合理的吻合。

Weldability, microstructure and mechanical properties of laser-welded selective laser melted 304 stainless steel joints

[J].

The dependence of crack properties on the Cr/Ni equivalent ratio in AISI 304L austenitic stainless steel weld metals

[J].

Small-scale resistance spot welding of austenitic stainless steels

[J].

Investigation on effect of welding parameters on solidification cracking of austenitic stainless steel 314

[J].

Study on microstructure and mechanical properties of 304 stainless steel joints by TIG, laser and laser-TIG hybrid welding

[J].AbstractThis paper investigated the microstructure and mechanical properties of 304 stainless steel joints by tungsten inert gas (TIG) welding, laser welding and laser-TIG hybrid welding. The X-ray diffraction was used to analyze the phase composition, while the microscopy was conducted to study the microstructure characters of joints. Finally, tensile tests were performed and the fracture surfaces were analyzed. The results showed that the joint by laser welding had highest tensile strength and smallest dendrite size in all joints, while the joint by TIG welding had lowest tensile strength, biggest dendrite size. Furthermore, transition zone and heat affected zone can be observed in the joint of TIG welding. The fractograph observation showed that the TIG welding joint existed as cup–cone shaped fracture, while the laser welding and hybrid welding joints existed as pure-shear fracture. The laser welding and hybrid welding are suitable for welding 304 stainless steel owing to their high welding speed and excellent mechanical properties.]]>

Solidification behavior and cracking susceptibility of pulsed-laser welds in austenitic stainless steels

[J].

Influences of alloying elements and solidification modes on the nitrogen content of nitrogenous stainless steel

[J].

合金元素及凝固模式对含氮不锈钢氮含量的影响

[J].

Effect of nitrogen addition on microstructure and fusion zone cracking in type 316L stainless steel weld metals

[J].

Effect of nitrogen on solidification mode and microstructure of 316L stainless steel

[J].

氮对316L不锈钢焊缝凝固模式和组织的影响

[J].

Evaluation of hot cracking nitrogen-bearing and fully austenitic stainless steel weldments

[J].

Effect of strain rate on strain induced α'-martensite transformation and mechanical response of austenitic stainless steels

[J].-4 s-1 (slow strain rate) and 2×10-2 s-1 (fast strain rate). The mechanism and volume fraction of strain induced α'--martensite transformation were investigated by using TEM, SEM and XRD. The amount of strain induced α'--martensite in EN1.4318 is much higher than that in EN1.4301 when both steels are deformed at the same strain rate. Adiabatic heating caused by the fast strain obviously decreases the α'--martensite transformation rate and work hardening rate in cold rolled EN1.4318 steel. The amount of α'--martensite and transformation rate for both steels are reduced during uniform deformation compared with those at slow strain rate, this behavior is more significant in cold rolled steels than that in annealed ones. For the more stable EN1.4301 with low saturated amount of α'--martensite (<0.3, volume fraction), rapidly plastic instability and tremendous reduction of uniform elongation are due to the small hardening effect at fast strain. In contrast, for EN1.4318 with low stacking fault energy and rather high saturated amount of α'--martensite, the tensile strength is significant decreased with increasing saturated amount of α'--martensite when deformation at fast strain. The strain rate sensitivity of EN1.4318 is much higher than that of EN1.4301.]]>

应变速率对奥氏体不锈钢应变诱发α'-马氏体转变和力学行为的影响

[J].-4 s-1(慢速拉伸)和2×10-2 s-1(快速拉伸) 2种应变速率对EN1.4318 (AISI301L)和EN1.4301(AISI304)冷轧和退火态奥氏体不锈钢板试样(厚度为2 mm)进行了拉伸实验, 用TEM, SEM以及XRD分析应变诱发 α'--马氏体转变机制和转变量. 结果表明, 相同应变速率拉伸时, EN1.4318钢的α'--马氏体转变量远远高于EN1.4301钢; 快速拉伸可明显抑制冷轧EN1.4318钢中α'--马氏体的转变速率, 降低硬化率. 在均匀变形阶段, 2种钢中α'--马氏体的转变速率和转变量比慢速拉伸时有不同程度地下降, 而且冷轧比退火态更显著. 奥氏体稳定性较高的EN1.4301钢, 常温拉伸 α'--马氏体转变饱和值低于0.3(体积分数), 增强效果小, 快速拉伸导致较快发生塑性失稳和均匀延伸率大幅降低; 而对于层错能低、α'--马氏体饱和值很高的EN1.4318钢, 快速拉伸则使抗拉强度大幅降低, 而且下降的幅度随α'--马氏体饱和值增加而增大; EN1.4318钢的应变速率敏感性远大于EN1.4301钢.]]>

Contrasting study on quality of SUS301L-HT jointsin fiber laser welding and MIG welding

[J].

SUS301L-HT不锈钢激光焊接与MIG焊接对比试验研究

[J].

Mircostructure and performance of CO2-MIG hybrid welding of SUS301L stainless steel

[J].

SUS301L不锈钢CO2激光-MIG复合焊接头组织性能研究

[J].

Effects of different welding processes on microstructure and mechanical properties of SUS301L-MT stainless steel joints

[J].

不同焊接工艺对SUS301L-MT不锈钢接头组织和力学性能的影响

[J].

Solidification microstructure of laser welded stainless steels

[A].

Effect of cooling rate on the solidification process of austenitic stainless steel by in-situ observation

[J].

冷却速率对奥氏体不锈钢凝固过程影响的原位观察

[J].

Numerical simulation of transient temperature field during laser keyhole welding of 304 stainless steel sheet

[J].AbstractA three-dimensional transient numerical model was developed to study the temperature field and molten pool shape during continuous laser keyhole welding. The volume-of-fluid (VOF) method was employed to track free surfaces. Melting and evaporation enthalpy, recoil pressure, surface tension, and energy loss due to evaporating materials were considered in this model. The enthalpy-porosity technique was employed to account for the latent heat during melting and solidification. Temperature fields and weld pool shape were calculated using FLUENT software. The calculated weld dimensions agreed reasonable well with the experimental results. The effectiveness of the developed computational procedure had been confirmed.]]>

Equivalent heat source approach in a 3D transient heat transfer simulation of full-penetration high power laser beam welding of thick metal plates

[J].

Modeling of temperature field and pool formation during linear laser welding of DP1000 steel

[J].

High temperature behavior of Ni-base weld metal: Part II-Insight into the mechanism for ductility dip cracking

[J].

An investigation of ductility-dip cracking in nickel-based weld metals-Part III

[J].

Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel

[J].

Influences of pulse laser parameters on properties of AISI316L stainless steel thin-walled part by laser material deposition

[J].

Effects of Laser Shock Processing on Mechanical Properties of Laser Welded ANSI 304 Stainless Steel Joint

[J].