7xxx系铝合金是典型的沉淀强化合金,具有密度小、强度高和优良热塑性等特点,广泛应用在航空航天、汽车以及桥梁等领域。随着对节能减排和轻量化发展的追求,对不同材料间的连接提出了更高的要求。

一些研究表明,焊后热处理可提高FSW接头的力学性能。Chaitanya等[9]研究了不同焊后热处理方式对AA7039搅拌摩擦焊接头组织和力学性能的影响,发现自然时效的焊接头综合力学性能最高,固溶处理的接头力学性能最低。王希靖等[13]对7075铝合金FSW接头进行固溶和时效处理,发现接头各区域的显微硬度明显提高,分布更均匀,接头的强度和伸长率提高。Sivaraj等[14]对AA7075-T651铝合金FSW接头进行人工时效和固溶+人工时效焊后热处理,发现人工时效后焊接头的拉伸性能降低,固溶+人工时效可提高拉伸性能和硬度。本文研究焊后人工时效对7003-7046异种铝合金搅拌摩擦焊接头力学性能的影响。

1 实验方法

1.1 实验用材料和FSW焊接

实验用7003-T4和7046-T4铝合金挤压板材的厚度为3 mm,化学成分列于表1。进行搅拌摩擦焊接时,将7003-T4铝合金板材放置在前进侧,7046-T4铝合金板材置在后退侧,搅拌头的倾斜角为2.5°,压入量为0.3 mm,转速为2000 r/min、焊速为400 mm/min,焊后在空气中自然冷却至室温。

表1 7003和7046铝合金的化学成分

Table 1

| Alloy | Zn | Mg | Cu | Mn | Cr | Zr | Ti | Si | Fe | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 7003 | 5.56 | 0.62 | 0.27 | 0.12 | 0.19 | 0.12 | 0.02 | 0.05 | 0.12 | Bal. |

| 7046 | 6.44 | 1.40 | 0.27 | < 0.01 | < 0.01 | 0.15 | 0.02 | 0.07 | 0.11 | Bal. |

将焊接头试样自然时效60 d后,切取一部分在空气炉中进行人工时效,在120℃保温24 h。将焊后自然时效60 d后的焊接头简称AW接头,将焊后自然时效+人工时效接头简称AA接头。

1.2 组织和性能表征

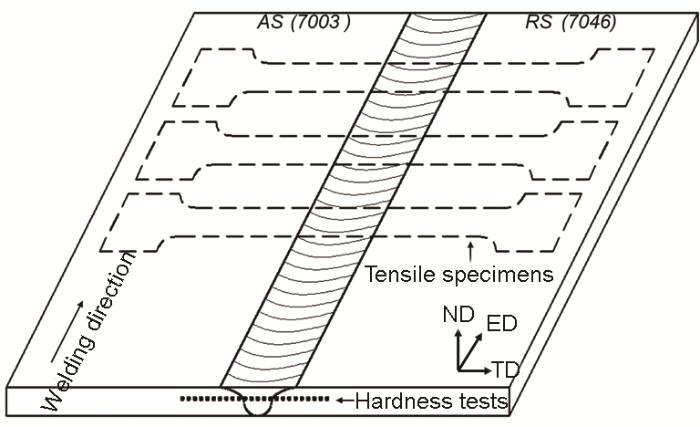

图1

图1

制备FSW接头硬度测试和拉伸用试样的示意图

Fig.1

Schematic of hardness tests and tensile specimens prepared from the FSW joint (ND: normal direction of the base alloy, ED: extrusion direction of the base alloy, TD: transverse direction of the base alloy)

在焊接接头上垂直焊接方向切取金相样品,经Graff试剂(83 mL H2O+16 mL HNO3+1 mL HF+3 g CrO3)浸蚀后用OLYMPUS GX71光学显微镜观察金相组织。将EBSD样品预抛后在10%HClO4+90%C2H5OH溶液中进行电解抛光,用ZEISS EVO MA10型扫描电镜电子背散射模式检测FSW接头不同位置的组织。

从焊接接头的各区域切取试样使用2010V4.4E热分析仪进行DSC测试以分析试样中的沉淀相,用99.99%纯铝做参比样品,升温速率为10℃/min,加热温度范围为室温~500℃。

将TEM试样预减薄至约80 μm并冲成直径为3 mm的圆片。在80%CH3OH+20%HNO3溶液中进行双喷减薄,用液氮冷却,使用Tecnai G2 F20型透射电镜(TEM)观察和分析焊接头不同区域的第二相特征,加速电压为200 kV。

2 结果和分析

2.1 显微组织

图2

图2

7003-7046异种铝合金搅拌摩擦焊接头的宏观形貌

Fig.2

Macrostructure appearance of 7003-7046 dissimilar aluminum alloy FSW joint

图3

图3

母材区ND-TD截面的晶粒取向图

Fig.3

Grain orientation maps in ND -TD section of BM zones (a) position g in Fig.2, (b) position h in Fig.2

图4

图4

AW接头热影响区、热机影响区和母材区的晶粒取向图

Fig.4

Grain orientation maps in ND-TD section of NZ、HAZ and TMAZ zones in AW joint (a) position a in Fig.2, (b) position b in Fig.2, (c) position c in Fig.2, (d) position d in Fig.2, (e) position e in Fig.2, (f) position f in Fig.2

图4a、b给出的图2中a、b位置所对应的NZ区“S”线两侧晶粒组织,都为均匀、细小的等轴晶,晶粒尺寸接近,约为5 μm。NZ区处于焊缝的中心区域,在整个焊接过程中不仅热输入量最大,并且搅拌针的摩擦搅拌作用最为强烈,因此发生了动态再结晶[17,18]。图4c、d分别对应图2中c、d所示位置的组织图,可见晶粒尺寸随着与NZ距离的减小而减小。TMAZ区紧靠NZ区,但的受到的搅拌作用远小于NZ,组织变形程度及流动性相对NZ区较弱,结果是晶粒取向与NZ区明显不同,两者间有清晰的分界线。同时,由于前进侧和后退侧金属流动方向及速度不同,前进侧焊缝组织与母材组织的变形程度差异大[19],使得图4c中前进侧NZ区与TMAZ区分界线较图4d后退侧也更明显。

2.2 透射电镜照片

2.2.1 焊核区

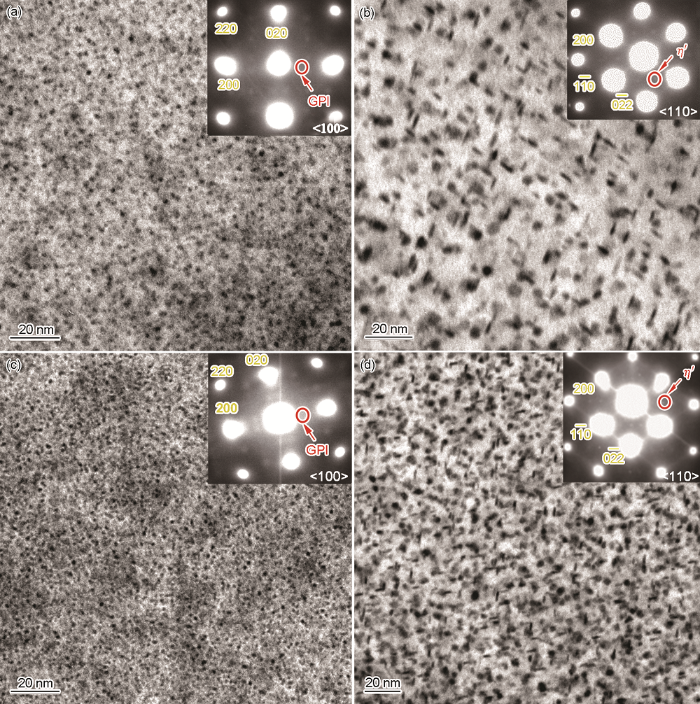

图5给出了S线两侧7003和7046铝合金的TEM明场像照片及其衍射花样(SADP)。在图5a中,自然时效后7003合金一侧NZ区晶内析出相为细小黑灰色点状物,根据<001>Al方向的SADP中{1,(2n+1)/4,0}Al处存在的清晰衍射斑点可知该析出相为GPI区[19];7046合金一侧的NZ区晶内析出相也为GPI区,但是更为密集,如图5c所示。人工时效后NZ区晶内析出相的照片,如图5b和d所示。7003合金一侧NZ区晶内析出相呈现出棒状或针状形貌,尺寸约为4~6 nm;<011>Al方向衍射花样在1/3{220}Al、2/3{220}Al位置有明显斑点,可知为η'相[19];而7046合金一侧NZ区内也析出了η'相,尺寸略小,为3~4 nm,密度更高。

图5

图5

NZ区域人工时效前后的TEM明场像及衍射花样

Fig.5

TEM images and corresponding SADP of NZ zones (a) NZ of AW joint-7003, (b) NZ of AA joint-7003, (c) NZ of AW joint-7046, (d) NZ of AA joint-7046

2.2.2 前进侧区域

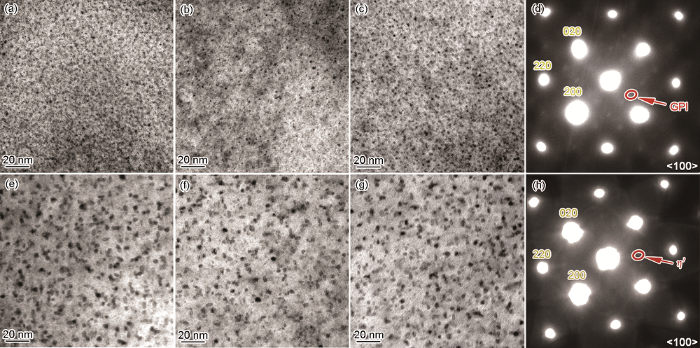

图6

图6

人工时效前后接头前进侧各区域的TEM明场像和典型衍射花样

Fig.6

TEM images and the typical SADP of different zones on AS AW joint: (a) TMAZ, (b) HAZ, (c) BM, (d) SADP of BM, AA joint: (e) TMAZ, (f) HAZ, (g) BM, (h) SADP of BM

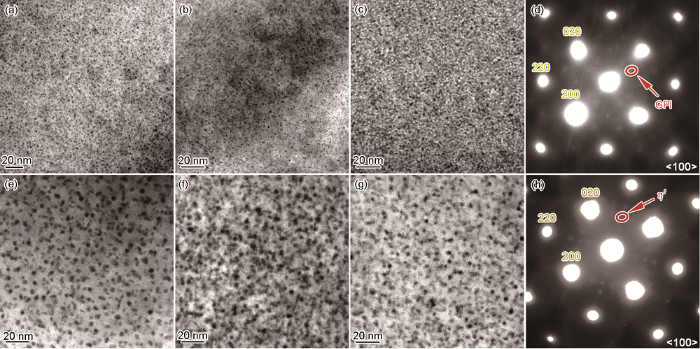

2.2.3 后退侧区域

图7

图7

人工时效前后接头后退侧各区域沿<001>Al方向的TEM明场像和典型衍射花样

Fig.7

TEM images and the typical SADP of different zones on RS AW joint: (a) TMAZ, (b) HAZ, (c) BM, (d) SADP of BM, AA joint: (e) TMAZ, (f) HAZ, (g) BM, (h) SADP of BM

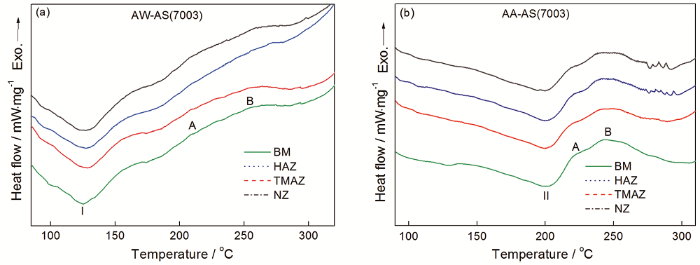

2.3 DSC分析

图8给出了时效前后FSW接头前进侧不同区域的DSC实验结果。DSC曲线的第一个溶解峰与对应区域中的沉淀相有关。峰的面积越大,表示沉淀相的含量越高[20]。对各曲线的第一个溶解峰面积进行统计,结果如表2所示。从图5和图6的TEM实验结果可知,在自然时效后的前进侧各区域均形成了大量的GPI区,因此各区域DSC曲线(图8a)的形状相似。曲线上125℃左右的吸热峰I为GPI区的溶解,根据峰I面积的大小可比较各区域GPI区的含量,如表2所示。BM区峰I的面积最大,GPI区含量最高,NZ、TMAZ区次之,HAZ区峰面积最小,GPI区含量最少,与图5,6中的TEM照片基本一致。在220℃和250℃附近还有两个放热峰A和峰B,两峰明显重叠,温度区间宽,表明生成了η'相、η'相向η相转变以及η相的粗化[21,22]。时效前后焊接头其它区域的DSC曲线也出现了放热峰A和峰B(图8b,图9)。在120℃保温24 h后前进侧各区域的DSC结果如图8b所示。与人工时效前相比,峰I几乎消失,而在200℃左右出现一个吸热峰II。根据图5和图6的结果,这是η'相的溶解峰。BM区峰II的面积最大,表明η'相最多,HAZ区峰面积最小,表明η'相最少。

图8

图8

接头前进侧时效前后不同区域的DSC曲线

Fig.8

DSC curves of AS zones before and after artificial aging (a) AW joint, (b) AA joint

表2 人工时效前后接头各区域析出相反应峰的面积

Table 2

| Zones | Natural aging | Artificial aging | ||

|---|---|---|---|---|

| Area of peak I/J·g-1 | Area of peak II/J·g-1 | |||

| AS (7003) | RS (7046) | AS (7003) | RS (7046) | |

| BM | 12.20±1.47 | 15.82±1.51 | 11.38±2.44 | 14.70±1.87 |

| HAZ | 9.92±1.57 | 13.51±3.13 | 9.14±2.04 | 12.03±0.54 |

| TMAZ | 10.84±1.73 | 15.79±3.48 | 9.72±2.12 | 14.56±0.12 |

| NZ | 11.71±1.79 | 16.95±2.49 | 8.67±1.28 | 15.33±0.95 |

图9

图9

接头后退侧时效前后不同区域的DSC曲线

Fig.9

DSC curves of RS zones before and after artificial aging (a) AW joint, (b) AA joint

图9给出了时效前后接头后退侧不同区域的DSC实验结果。根据图5和图7的实验结果,自然时效后也形成了大量的GPI区,因此图9a中峰I对应的是GPI区的溶解。从表2可见,焊接头后退侧各区域的峰I面积都大于前进侧对应区域,GPI区的含量更高,后退侧中BM区峰I面积最大,表明GPI区的含量最高,NZ区与TMAZ区相近而比BM区略小,HAZ区的面积最小,GPI区含量最少。在120℃保温24 h后的接头后退侧各区域的DSC曲线,如图9b所示。与人工时效前相比,各区域都有吸热峰II,显然为η'相的溶解。由表2可知,NZ区峰II面积最大η'相最多,BM区、TMAZ区η'相含量都比NZ区略少,HAZ区峰面积最小,η'相最少。与人工时效后前进侧各区域(图8b)相比,峰II的面积较大,表明η'相的含量更高。

2.4 硬度分布特征

AW和AA接头硬度分布和各区域近似范围,如图10所示。可以看出,人工时效后接头和两合金母材的硬度都有提高。在焊缝中心线附近,由于7003和7046铝合金成分、组织等的差异,接头硬度曲线分布在NZ区域分成了两部分。对于AW接头,后退侧平均硬度比前进侧高约30HV。前进侧各区域硬度值相差较小,与母材硬度接近,平均硬度约为95HV。后退侧各区域内硬度出现了较小的波动,后退侧NZ区硬度最高,TMAZ、HAZ的大部分区域硬度值比母材高,分布在118~128HV。

图10

图10

AW接头和AA接头的硬度曲线图

Fig.10

Micro-hardness profiles of the AW joint and AA joint

AA接头中后退侧平均硬度与前进侧平均硬度差增大到50HV,硬度分布的不均匀性明显高于AW接头,各区域的硬度都比时效前有所提高。前进侧各区域的硬度都比母材的硬度低,TMAZ和NZ区的硬度分布均匀,约为115HV;而在HAZ区域内,随着距离焊缝中心距离的增大硬度出现了明显的波动,范围为114~124HV。在后退侧,硬度的分布非常不均匀,大部分区域的硬度都比母材的高,小部分与母材相当,分布范围为158~172HV。在总体上,人工时效使接头硬度提高,各区域硬度的分布不均匀性增大。

2.5 拉伸性能

母材和焊接头的拉伸性能,如表3所示。人工时效前7003铝合金母材的抗拉强度和屈服强度分别约为300.3 MPa和179.2 MPa,7046铝合金母材的抗拉强度和屈服强度分别约为406.2 MPa和289.5 MPa,都比7003铝合金母材高近110 MPa,伸长率也比7003母材高约5.2%。FSW接头的抗拉强度和屈服强度分别约为324.5 MPa和203.4 MPa,比7003合金母材的强度高,但低于7046合金母材强度,FSW接头的伸长率比两种合金母材都小,与7003铝合金母材相差约10.2%,与7046铝合金母材相差约4.8%。

表3 人工时效前后母材和FSW接头的室温拉伸性能

Table 3

| Materials conditions | Tensile strength/MPa | Yield strength/MPa | Elongation/% | |

|---|---|---|---|---|

| Natural aging | 7003-BM | 300.3±3.2 | 179.2±3.5 | 23.2±2.3 |

| 7046-BM | 406.2±2.7 | 289.5±1.8 | 17.8±1.7 | |

| 7003-7046-joint | 324.5±1.8 | 203.4±2.7 | 13.0±1.2 | |

| Artificial aging | 7003-BM | 331.4±3.6 | 290.1±3.2 | 16.7±1.6 |

| 7046-BM | 505.7±1.4 | 465.3±2.3 | 11.8±2.4 | |

| 7003-7046-joint | 332.4±4.2 | 264.6±1.6 | 12.8±3.6 |

人工时效后,两母材的强度都有提高,而伸长率减小。7003铝合金母材抗拉强度和屈服强度分别增大了约31.1 MPa和110.9 MPa,伸长率减小约6.2%;7046铝合金母材的抗拉强度和屈服强度分别增大约99.5 MPa和175.8 MPa,伸长率减小约6.0%。FSW接头抗拉强度从324.5 MPa增大到332.4 MPa,变化较小,而屈服强度变化较大,从203.4 MPa增大到264.6 MPa,为时效后7003铝合金母材屈服强度的91.1%,伸长率几乎不变。

3 讨论

从图5,6,7可以看出,7003和7046铝合金搅拌摩擦焊接后再经过60 d的自然时效(属于较低温度下的长时间时效),焊接头中各区域内的析出相都为GPI区,形态为黑灰色点状物,与基体共格,在基体中形成内应力,阻碍位错滑移。根据Srivatsan等的研究[26],变形过程中,粒子尺寸较小时位错直接切过粒子。体积分数越高对位错的阻碍作用更强,强化效果也就越好。合金中Zn、Mg的含量越高GPI区和η'相的析出也更多,而在7046铝合金中Zn、Mg的含量比7003铝合金的高,有利于GPI区的均匀形核和η'相的转化[27],因此AW接头中后退侧GPI区的含量比前进侧的高。因此在焊缝中心线附近,焊接头的硬度分布分成了高低不同的两部分,7046合金侧平均硬度值比7003合金侧硬度大30HV左右(图10)。AW接头前进侧和7003合金母材析出相尺寸和含量接近,硬度相差不多,HAZ,TMAZ区析出相分布不均匀,硬度值有小范围波动。由表2可知,7046合金母材和后退侧NZ区的GPI区含量接近,比HAZ、TMAZ区含量略多,对应硬度值较高。

根据TEM照片(图5,6,7)和DSC实验(表2)结果,对AW接头进行人工时效后接头各区域GPI区转变成η'相,尺寸增大,析出相增多,η'相的强化效果相对GPI区更好[26],硬度值增大,抗拉强度、屈服强度升高,焊接头力学性能增强。7046合金母材一侧各区域的η'相比7003合金母材一侧含量更高,硬度差异进一步增大,两侧平均硬度的差增大到50HV。AA接头前进侧各区域的η'相都比7003合金母材的少,对应的硬度比7003母材的低。7046母材中的析出相为η'相和极少量的GPI区,后退侧各区域的析出相均为η'相,GPI区的强化作用小于η'相,后退侧大部分区域的硬度高于母材,小部分与母材的相当。在焊接过程中,热循环的影响使接头两侧TMAZ、HAZ区域的晶粒尺寸比NZ区的大,析出相较少且分布不均,使硬度比NZ区的略低,硬度分布的波动较大,在HAZ区出现硬度极小值。

4 结论

(1) 在7003-7046异种铝合金FSW接头的焊核区内有一条明显的“S”形分界线。S线两侧均为细小的等轴晶组织,尺寸约为5 μm;热机影响区和热影响区的晶粒尺寸比焊核区的大,热机影响区的组织为再结晶晶粒与回复晶粒混合组成,亚晶粗化使7003侧热影响区的晶粒尺寸减小,7046侧热影响区的晶粒明显粗化。

(2) 7046合金母材的硬度比7003合金母材的高,人工时效前焊接头后退侧的平均硬度比前进侧高约30HV,时效后焊接头各区域的硬度增大,后退侧硬度的增大比前进侧更为显著,与前进侧的平均硬度差增大到50HV,接头的硬度分布更加不均匀。人工时效后,FSW接头的抗拉强度和屈服强度提高,伸长率几乎不变。

参考文献

Microstructure and cyclic deformation behavior of a friction-stir-welded 7075 Al alloy

[J].

Microstructural properties of friction stir welded and post-weld heat-treated 7449 aluminium alloy thick plate

[J].

Microstructure and mechanical properties of 7055 Al alloy sheet friction stir welded joint

[J].

7055铝合金板材搅拌摩擦焊接头的组织与力学性能

[J].

Friction stir welding of high strength aluminum alloys

[J].

Comparison of fatigue properties between friction stir welds and TIG welds for Al alloy

[J].The effect of welding processes friction stir welds (FSW) and (TIG) on fatigue properties of LF2 aluminum welded joints were analyzed and the S-N curve of the welded joints were established. The results show that the fatigue properties of FSW welded joints are better than that of TIG welded joints. Fatigue strength of friction stir welds is determined as 59~65MPa under N=106. Microstructures of joints are comparatively fine grain and narrow HAZ zone in the FSW welds which inhibit the growth of crack and produce high fatigue life compared to that of the TIG welds. Fracture morphologies of TIG welds show that the fatigue fracture occurs from weld defects.

搅拌摩擦与氩弧焊铝合金接头疲劳性能的比较

[J].对比分析了搅拌摩擦和氩弧焊两种工艺方法对铝合金焊接接头疲劳性能的影响,建立了焊接接头的S-N曲线,结果表明:在相同的载荷条件下,搅拌磨擦焊接接头的疲劳性能优于氩弧焊接头。搅拌摩擦焊接头疲劳寿命N=106次的疲劳强度值约为59~65MPa之间。对焊接接头显微组织的分析表明:搅拌摩擦焊接接头具有比氩弧焊接头更为细小的晶粒和狭窄的焊接热影响区,阻碍了滑移带的形成和裂纹的扩展,从而提高了接头的疲劳性能。TIG焊接接头疲劳端口分析显示,焊接缺陷是主要的疲劳裂纹源。

Effect of process parameters on mechanical properties of friction stir welded dissimilar 7075-T651 and 5083-H111 aluminum alloys

[J].

Microstructure and mechanical property of friction stir weld joints of dissimilar Al-alloys 5083 and 6061

[J].Sheets of Al-alloys 5083 and 6061 of 6 mm in thickness were subjected to friction stir welding (FSW) with different welding parameters. The effect of welding parameters on the microstructure and mechanical property of the FSW joints were investigated. Results show that FSW joints with high quality could be produced by controlling welding parameters, and a high joint strength coefficient of 85% was obtained. Dynamic recrystallization took place in the nugget zones (NZs) with fine and equiaxed grains generated, and the grain size increased with the increasing rotation rate; usually the grain size of 5083 Al in the NZ was smaller than that of 6061Al. The heat-affected zones (HAZ) of 6061 Al side were the low hardness zones in all of the FSW joints, and the value of low hardness increased with the increasing rotation rate. It is found that the fracture paths corresponded well with the lowest hardness distribution profiles in the joints and the ultimate tensile strength increased with the increasing of the rotation rate.

5083和6061铝合金异种搅拌摩擦焊接接头的组织和性能

[J].以不同的转速对6 mm厚的5083和6061铝合金进行搅拌摩擦焊接,研究了焊接参数对接头组织和性能的影响。结果表明,控制焊接参数可获得良好的焊接质量,接头强度系数为85%。随着转速的升高5083和6061铝合金的晶粒尺寸都逐渐增大,但是在焊核区内5083铝合金的晶粒尺寸比6061铝合金的小;在6061铝合金一侧的热影响区,随着转速的增加析出相的尺寸和密度都逐渐增大。5组焊接参数的焊接接头的最低硬度区均出现在6061铝合金一侧的热影响区,随着转速的升高接头的最低硬度也逐渐提高;焊接接头均断裂在最低硬度区,且随着转速的升高接头的抗拉强度也逐渐提高。

Friction stir based welding and processing technologies-processes, parameters, microstructures and applications: A review

[J].

Effect of post weld heat treatments on microstructure and mechanical properties of friction stir welded joints of Al-Zn-Mg alloy AA7039

[J].

Effect of welding heat input and post-weld aging time on microstructure and mechanical properties in dissimilar friction stir welded AA7075-AA5086

[J].

Effect of post-weld heat treatment on joint properties of dissimilar friction stir welded 2024-T4 and 7075-T6 aluminum alloys

[J].

Impact of initial temper of base metal on microstructure and mechanical properties of friction stir welded AA 7055 alloy

[J].

Effects of heat treatment after welding on friction stir welding joints of high-strength aluminum alloy

[J].

焊后热处理对高强铝合金搅拌摩擦焊接头的影响

[J].

Effect of post weld heat treatment on tensile properties and microstructure characteristics of friction stir welded armour grade AA7075-T651 aluminium alloy

[J].

Influence of welding speed on zigzag line feature and tensile property of a friction-stir-welded Al-Zn-Mg aluminum alloy

[J].

Microstructural investigation of friction stir welded 7050-T651 aluminium

[J].AbstractThe grain structure, dislocation density and second phase particles in various regions including the dynamically recrystallized zone (DXZ), thermo-mechanically affected zone (TMAZ), and heat affected zone (HAZ) of a friction stir weld aluminum alloy 7050-T651 were investigated and compared with the unaffected base metal. The various regions were studied in detail to better understand the microstructural evolution during friction stir welding (FSW). The microstructural development in each region was a strong function of the local thermo-mechanical cycle experienced during welding. Using the combination of structural characteristics observed in each weld region, a new dynamic recrystallization model has been proposed. The precipitation phenomena in different weld regions are also discussed.]]>

Modelling of 7050 aluminium alloy friction stir welding

[J].

Effect of self-reacting friction stir welding on microstructure and mechanical properties of Mg-Al-Zn alloy joints

[J].

Effect of aging temperature and of retrogression treatment time on the microstructure and mechanical properties of alloy AA 7075

[J].

Influence of quench-induced precipitation on aging behavior of Al-Zn-Mg-Cu alloy

[J].

Precipitate behavior and mechanical properties of enhanced solution treated Al-Zn-Mg-Cu alloy during non-isothermal ageing

[J].

Non-isothermal ageing of an Al-8Zn-2Mg-2Cu alloy for enhanced properties

[J].

Effect of natural aging on quench-induced inhomogeneity of microstructure and hardness in high strength 7055 aluminum alloy

[J].

Precipitation in an Al-Zn-Mg-Cu alloy during isothermal aging: atomic-scale HAADF-STEM investigation

[J].

Investigation of mechanical and corrosion properties of an Al-Zn-Mg-Cu alloy under various ageing conditions and interface analysis of ƞ' precipitate

[J].

Microstructure, tensile deformation and fracture behaviour of aluminium alloy 7055

[J].