在热处理过程中产生的相转变和显微组织的发展,在很大程度上决定了合金的性能平衡性。因此,适当的热处理工艺是合金能否使用的关键之一。目前,许多的学者研究了亚稳β钛合金在固溶时效处理过程中析出相的演变和拉伸性能。陈强等[15]研究了固溶温度对Ti-3Al-8V-4Mo-4Cr-4Zr-2Nb-2Fe合金组织和拉伸性能的影响,发现固溶处理后合金具有中等水平强度和良好塑性,且在730~830℃间固溶温度越高合金的强度越低而塑性越好;经过固溶+460℃/6 h/AC处理的合金其强度达到1200~1500 MPa,且具有优良的塑性(断裂伸长率6%~10.5%)。但是,α/β固溶时效处理后析出的α相细小且均匀分布使合金的强度明显比β固溶处理的高,差值达300 MPa。Senopati等[16]将Ti-6Mo-6Nb-8Sn合金在900~1100℃(温度间隔100℃)固溶处理45~75 min(时间间隔15 min)后水淬,研究其对力学性能和显微组织的影响,发现固溶处理后的合金具有完全的等轴组织,且在所有的固溶条件下都观察到β相,具有较好的强度,弹性模量低于Ti-6Al-4V合金。Ti-4Mo-6Cr-3Al-2Sn(质量分数,%)合金为一种自主设计的新型亚稳β钛合金,Mo当量为10.6,与当前的商用高强β钛合金(TB6、TB8等)的Mo当量相近。为了确定该新型合金最佳的热处理工艺,本文研究固溶温度对固溶态合金和时效态合金的显微组织和室温拉伸性能的影响。

1 实验方法

将原材零级海绵钛、高纯钼、高纯铬、高纯铝、铝箔和纯锡进行两次真空自耗熔炼,得到直径为120 mm的铸锭。将铸锭在β相区开坯锻造,热轧后得到厚度为5 mm的板材。用金相法测得该合金的相变温度为810±5℃。图1给出了该合金热轧态的显微组织,可见其组织主要由β晶粒组成,因轧制温度高于相变点没有观察到α相。

图1

将在板材上切取的试样分别在700、750、800、850和900℃进行固溶处理,处理0.5 h后水淬(WC),然后进行500℃/4 h的时效处理后空冷(AC)。

使用改进型Kroll's试剂(HF:HNO3:H2O=1:2:10(%,质量分数))对抛光后的固溶态试样进行表面腐蚀,并使用S-3400N型扫描电子显微镜观察固溶态试样的显微组织。在时效态合金上切取直径为3 mm、厚度为0.5 mm的薄片,将其打磨至40 μm厚,用TenuPol-5型电解双喷减薄仪对薄片进行电解减薄(电解液是6%高氯酸+35%正丁醇+59%甲醇(%,质量分数)混合溶液),透光率为80%,电压为19 V,温度为-21℃。用JEM-2100型透射电子显微镜观察时效态合金的析出相。用WDW-200E型电子万能试验机分别对固溶态和时效态合金进行室温拉伸性能测试。

2 结果和讨论

2.1 固溶温度对固溶态合金组织演变的影响

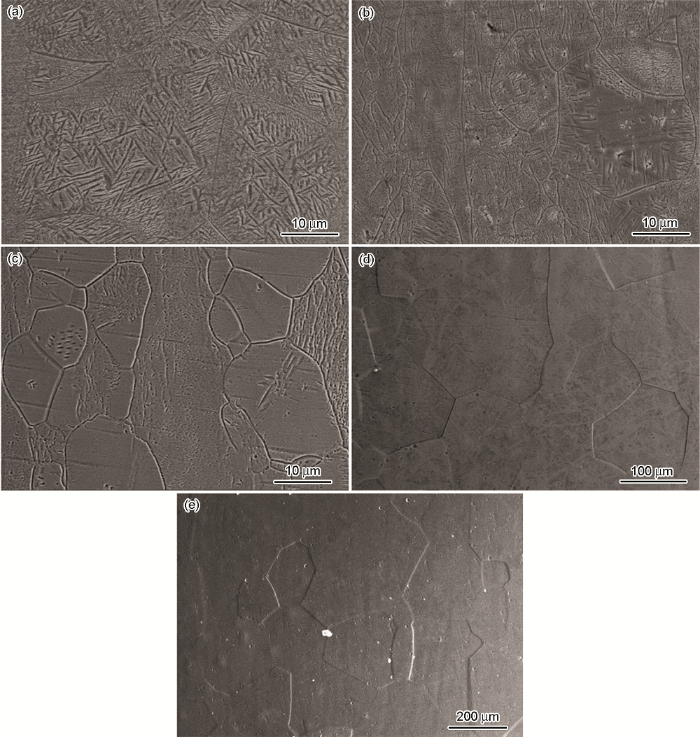

图2给出了合金在不同固溶温度下的显微组织。可以看出,随着固溶温度的初生α相逐渐消失,说明初生α相对固溶温度比较敏感。固溶温度为700℃时大量的初生α相存在于原始β晶粒中且在晶界形成了连续初生α相区域,对晶界的钉扎阻碍了晶粒的长大,晶粒尺寸约为30 μm(图2a);固溶温度为750℃或800℃时晶内还有较多的初生α相,晶界处的初生α相几乎完全消失,为晶粒的长大提供了条件(图2b, c);当固溶温度提高到850℃(高于相变点)时,由于再结晶机制初生α相完全消失,生成了等轴β相,且晶粒明显长大,其尺寸约为120 μm(图2d);固溶温度继续提高到900℃则β晶粒继续长大,其尺寸约为200 μm(图2e)。

图2

图2

在不同温度固溶后合金的SEM组织

Fig.2

SEM microstructure of alloys after solid solution at different temperatures (a) 700℃/0.5 h/WC; (b) 750℃/0.5 h/WC; (c) 800℃/0.5 h/WC; (d) 850℃/0.5 h/WC; (e) 900℃/0.5 h/WC

2.2 固溶温度对固溶态合金拉伸性能的影响

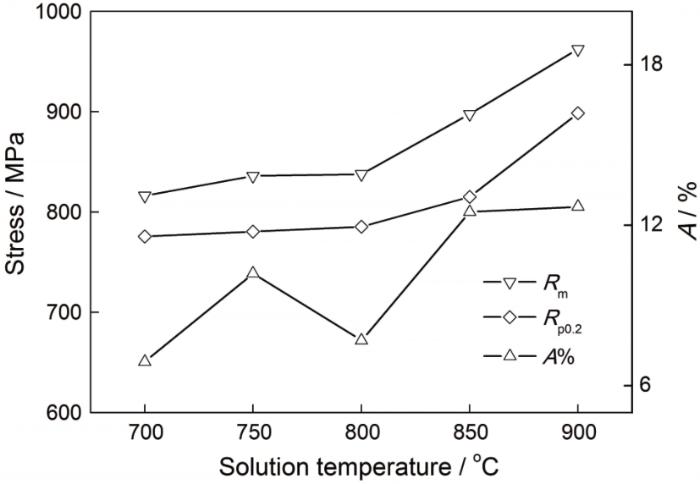

图3给出了Ti-4Mo-6Cr-3Al-2Sn合金在不同固溶温度下的室温拉伸性能。可以看出,随着固溶温度的提高合金的抗拉强度(Rm)和屈服强度(Rp0.2)随之升高;合金的断裂伸长率(A)则先增大固溶温度为800℃时降低,固溶温度高于相变点后继续增大。固溶温度为700℃时晶界处出现大量的连续初生α相,对晶界的钉扎阻碍了晶界的迁移,从而降低了合金的塑性(图2a)。当固溶温度提高到750℃时初生α相的体积分数发生变化,合金的塑性反而提高(图2b)。文献[17]和[18]分别研究了Ti-6Cr-5Mo-5V-4Al合金和TG6合金在不同温度固溶后初生α相对合金拉伸性能的影响,证实初生α相的体积分数在某一范围内变化时可提高β钛合金的塑性。因此可推测,固溶温度为750℃时产生的特定体积分数的初生α相促进了该合金塑性的提高[17,18]。但是,固溶温度进一步提高到800℃时初生α相的数量大幅度减小(图2c),对塑性的影响明显降低。同时,在拉伸变形过程中连续晶界α相的存在使应力集中发生在晶界α相与β相的界面处,使裂纹易于此处萌生和扩展,导致合金的塑性恶化[19]。因此,在800℃固溶处理的合金塑性较差。当固溶温度高于相变点时组织中α相大幅度减少,在拉伸变形过程中bcc结构的β相主导变形机制,使合金具有更好的塑性[20,21]。合金强度的变化可归结为以下原因:(1)随着固溶温度的提高β稳定元素逐渐溶入基体产生一定程度的晶格畸变,从而增大了位错滑移的阻力,使合金的强度提高[22]。(2)固溶温度较高时晶界α相产生不连续区域,已被文献[23]所证实。对于一种亚稳β钛合金Ti-5Al-5Mo-5V-3Cr-1Zr,将其在较高的温度热处理可使连续晶界α相发生“断裂”,形成不连续区域。裂纹穿过这些区域时需要更大的能量,固溶温度越高晶界α相不连续区域越多,合金的强度越高[23]。合金在900℃固溶处理后具有较好强度和塑性匹配,拉伸性能最优:Rm=962.5 MPa,Rp0.2=898.7 MPa,A=12.7%。

图3

图3

在不同温度固溶后合金的拉伸性能

Fig.3

Tensile properties of the alloy after solid solution at different temperatures

2.3 固溶温度对时效态合金组织演变的影响

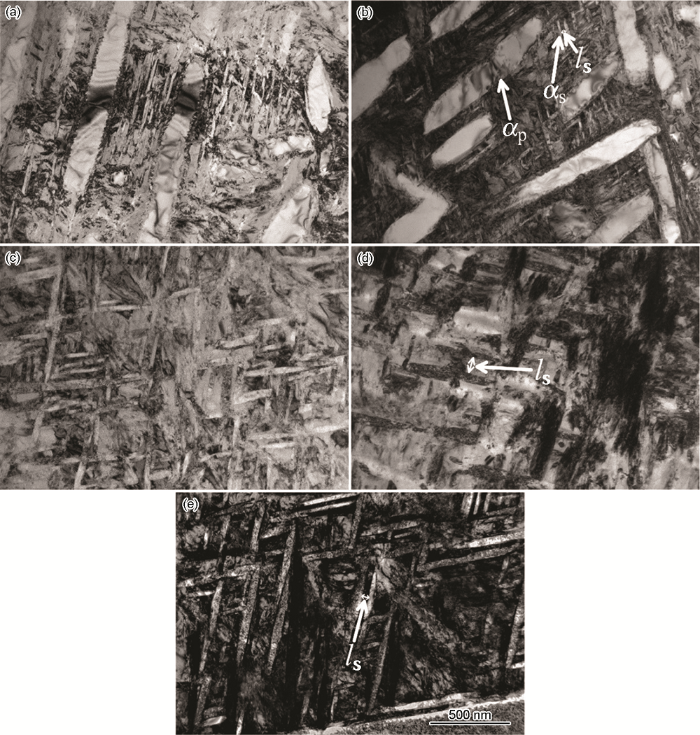

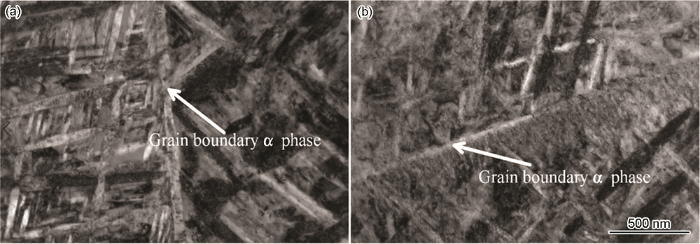

图4给出了合金经不同温度固溶后500℃/4 h时效的TEM照片。可以看出,时效处理后合金晶粒内均有细小且弥散的次生α相析出。固溶温度为750℃时,初生α相的存在使残余β相中的β稳定元素增多,β相的稳定性提高,使在时效过程中析出的次生α相的相变驱动力变小,因此析出的次生α相比较细小,尺寸约为110 nm。这时的固溶温度低于再结晶温度,组织中存在的大量位错等缺陷为次生α相供了更多的位置形核,因此析出的次生α相也更加均匀[24](图4b);随着固溶温度提高到相变点以上初生α相几乎完全消失,β稳定元素逐渐融入基体中,含量减少,导致β相的稳定性降低,使次生α相的相变驱动力变大,生成的次生α相有明显长大[25],尺寸约为550 nm(图4d、e)。

图4

图4

不同固溶温度时效态Ti-4Mo-6Cr-3Al-2Sn合金的TEM像

Fig.4

TEM images of Ti-4Mo-6Cr-3Al-2Sn alloy in aging state at different solid solution temperatures (aging: 500℃/4 h/AC) (a) 700℃/0.5 h/WC; (b) 750℃/0.5 h/WC; (c) 800℃/0.5 h/WC; (d) 850℃/0.5 h/WC; (e) 900℃/0.5 h/WC

2.4 固溶温度对时效态合金拉伸性能的影响

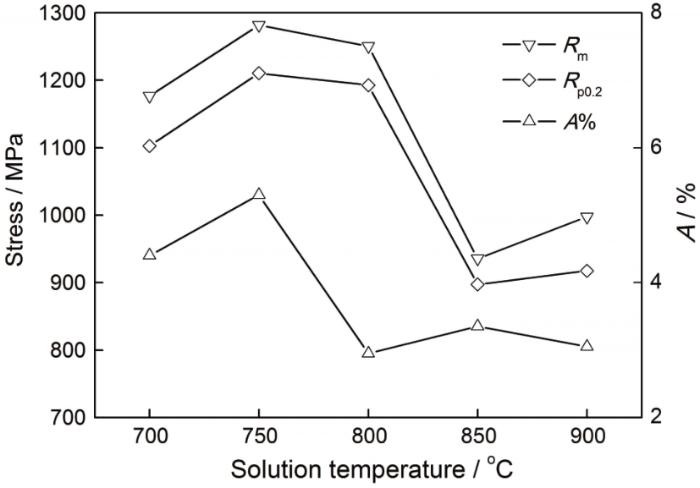

表示,其中σy为合金的屈服强度,lP为初生α相片层间距,lS为次生α相片层间距,KP和KS为“泰勒因子”的常数。固溶温度为750℃时在初生α相间析出了细小的次生α相,这些次生α相片层间平行或者夹角呈60°。不同大小和取向的次生α相相互交错,对位错运动的阻碍在很大程度上提高了合金的抗拉强度[27]。同时,次生α相片层间距很小,尺寸约为41.7 nm。上述公式表明,次生α相片层间距和初生α相片层间距越小合金的屈服强度越高(图4b);当固溶温度提高到相变点以上时初生α相几乎完全消失(图2d、e),合金的屈服强度在很大程度上决定于次生α相的片层间距。固溶温度为850℃时次生α相片层间间距明显变大,尺寸约为146.1 nm,合金具有较低的屈服强度(图4d);当固溶温度提高到900℃时次生α相继续长大,片层间距变小,尺寸约为41.3 nm,合金的屈服强度有所提高(图4e)。

图5

图5

不同固溶温度下时效态合金的拉伸性能

Fig.5

Tensile properties of aged alloys at different solution temperatures (aging: 500℃/4 h/AC)

图6

图6

不同固溶温度下时效态合金晶界处的TEM组织

Fig.6

TEM structure at grain boundaries of aging alloys at different solution temperatures (aging: 500℃/4 h/AC) (a) 700℃/0.5 h/WC; (b) 900℃/0.5 h/WC

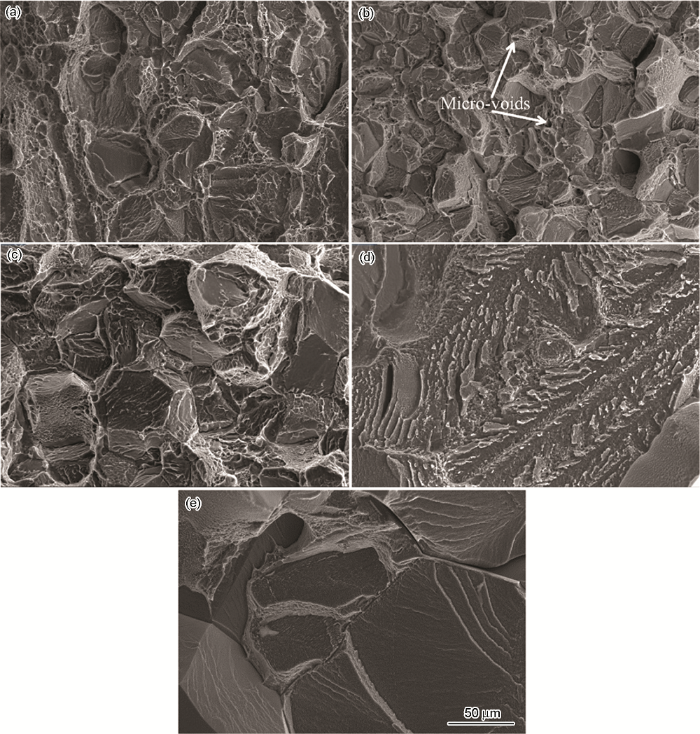

图7

图7

在不同固溶温度下时效态合金的室温拉伸断口

Fig.7

Tensile fracture of aged alloys at room temperature at different solution temperatures (aging: 500℃/4 h/AC) (a) 700℃/0.5 h/WC; (b) 750℃/0.5 h/WC; (c) 800℃/0.5 h/WC; (d) 850℃/0.5 h/WC; (e) 900℃/0.5 h/WC

3 结论

(1) Ti-4Mo-6Cr-3Al-2Sn合金在相变点以下固溶处理后出现大量初生α相,随着固溶温度的提高初生α相逐渐消失;在相变点以上固溶处理时初生α相完全消失,生成等轴β相且其晶粒明显长大。

(2) Ti-4Mo-6Cr-3Al-2Sn合金经不同固溶温度500℃/4 h时效处理后均析出次生α相,随着固溶温度的提高初生α相逐渐消失,β稳定元素逐渐溶入基体,含量减少,导致β相的稳定性降低,使次生α相的相变驱动力变大,析出的次生α相明显长大。所有热处理工艺均生成了连续的晶界α相,弱化了晶界,降低了合金的塑性。

(3) Ti-4Mo-6Cr-3Al-2Sn合金在750℃/30 min+500℃/4 h时效后具有较好的强度和塑性匹配:Rm=1282 MPa,A=4.2%。合金在整个热处理工艺过程中均以脆性断裂为主,与合金较低的塑性相对应。

参考文献

Deformation behavior and microstructure evolution during hot working of a coarse-grained Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy in beta phase field

[J].

Effect of second phase precipitation on martensitic transformation and hardness in highly Ni-rich NiTi alloys

[J].

Development of new β/α″-Ti-Nb-Zr biocompatible coating with low Young's modulus and high toughness for medical applications

[J].

Dynamic transformation of α→β titanium at temperatures below the β-transus in commercially pure titanium

[J].

Effect of C addition on microstructure and mechanical properties of Ti-V-Cr burn resistant titanium alloys

[J].The ingots with 120 mm diameter of burn resistant Ti-alloys with nominal composition of Ti-35V-15Cr, Ti-35V-15Cr-0.075C and Ti-35V-15Cr-0.15C were produced by vacuum arc consumable smelting. These ingots were deformed into bars with 25 mm diameter by sheathed extrusion. The microstructures of the ingots and extruded bars of burn resistant Ti-alloys were investigated. The tensile property, thermal stability and creep properties of the extruded bars of burn resistant Ti-alloys were tested under different conditions. The results show that burn resistant Ti-alloys with C addition have better ductility in tensile test due to refined grain size resulted from the sheathed extrusion process. Carbide can act as a stable sink for dissolved oxygen in the matrix, to improve the tensile ductility of the alloy even after hot exposure. In sum, the moderate C addition can improve the creep properties of burn resistant Ti-alloys.

C含量对Ti-V-Cr系阻燃钛合金微观组织和力学性能的影响

[J].用真空自耗熔炼制备了不同C含量的三种阻燃钛合金铸锭(直径120 mm),其名义成分分别为Ti-35V-15Cr、Ti-35V-15Cr-0.075C和Ti-35V-15Cr-0.15C。将铸锭包套挤压成直径为25 mm的棒材,观察了铸锭和挤压棒材的微观组织,测试并分析了挤压棒材的室温拉伸性能、高温拉伸性能、热稳定性能、高温蠕变以及持久性能。结果表明:添加C使阻燃钛合金热挤压后的晶粒显著细化,使其室温和高温拉伸塑性提高;由于碳化物的吸氧作用,添加C的合金热稳定性能显著提高;添加适量的C可提高阻燃钛合金的高温蠕变和持久性能。

Effects of heat treatment on microstructure, texture and tensile Properties of Ti65 alloy

[J].α-phase and the rolling direction (RD) met at a 70°~90° angle; similar texture could be found in duplex- and lamellar-microstructure, meanwhile a new texture that the c-axis of the α-phase paralleled to RD could be found in the alloy. Room temperature tensile strength of plates with duplex microstructure could be enhanced by the dislocations and sub-structures, while had little effect on tensile properties at high temperature. Texture was found to be the main factor affecting the anisotropy of tensile properties of Ti65 plates, the plate would possess good tensile properties without obvious anisotropy in tensile strength after heat treatment of 980℃/1 h/AC+700℃/4 h/AC.]]>

热处理对Ti65钛合金板材的显微组织、织构及拉伸性能的影响

[J].研究了不同热处理条件下Ti65钛合金板材的显微组织和织构的变化规律,分析了板材织构的类型和热处理影响拉伸强度的机制。结果表明,热处理对板材的显微组织和织构类型具有显著的影响。通过热处理可分别得到具有等轴组织、双态组织或片层组织的板材。等轴组织板材的织构为晶体c轴与板材RD方向呈现70°~90°夹角的B/T型织构,双态组织和片层组织板材的主要织构类型与等轴组织类似,且出现晶体学c轴与RD方向平行的织构。双态组织板材内的位错和亚结构使板材的室温拉伸强度提高,但是对高温拉伸变形的阻碍能力有限。板材中的织构是影响合金力学性能各向异性的主要因素。经980℃/1 h/AC+700℃/4 h/AC热处理后的板材横、纵向拉伸强度的差异最小,且都具有较高的室温拉伸性能和最佳的650℃拉伸性能。

Effect of heat treatment on mechanical properties of Ti-3Al-8V-6Cr-4Mo-4Zr alloy

[J].ω-phases and α-phases result in the increase of hardness and strength of Ti-3Al-8V-6Cr-4Mo-4Zr alloy bars. A lot of dimples exist in the tensile fractures of the hot rolling alloys and heat treatment alloysdemonstrating a typical ductile fracture.]]>

时效处理对Ti-3Al-8V-6Cr-4Mo-4Zr合金力学性能的影响

[J].ω和α析出相共同作用的结果。在合金的热轧态和热处理态的断口都出现了大量的韧窝,表明其为典型的韧性断裂。]]>

Atomic-scale observations of B2→ω-related phases transition in high-Nb containing TiAl alloy

[J].

Evolution mechanisms of the primary α and β phases during α/β deformation of an α/β titanium alloy TC8

[J].

Effect of heat treatment process on microstructure and mechanical properties of titanium alloy Ti6246

[J].α′′ martensite was observed in prior β phase after solution heat treatment followed by water quenching. While a fine transformed β microstructure produced as a result of air cooling. For the air cooling alloy, both the size and volume fraction of the secondary α grain increased with the increasing solution heat temperature in air cooling samples. A “double yield” phenomenon appeared in the engineering stress-strain curves of the water quenching alloy samples. After aging treatment, the strength of water- and air-cooled alloys samples increased but the plasticity decreased. An optimal property in strength and ductility was achieved for the alloysamples after soluted solution treated at 900-920°C and then aged at 595°C.]]>

热处理工艺对Ti6246钛合金组织与力学性能的影响

[J].β单相区及(α+β)两相区固溶后水冷,β相均转化为α′′马氏体和少量亚稳β相。空冷组织中的β相转变为含有少量次生α相的β转变组织,随着热处理温度的提高次生α相的含量逐渐增加,尺寸也逐渐增大。时效后组织中的亚稳相发生分解,析出细小的次生α相。固溶后水冷试样的拉伸曲线上出现“双屈服”现象,且随着固溶温度的提高合金第一屈服点逐渐升高。水淬和空冷合金试样在595℃/8 h时效后其室温拉伸强度提高,延伸率及断面收缩率降低,水淬试样室温拉伸性能的变化更大。固溶后空冷且在595℃时效处理的合金,其室温拉伸性能可达到较好的强塑性匹配。]]>

Effect of long term aging on the fatigue crack propagation in the β titanium alloy Ti17

[J].

Microstructure and mechanical properties of TC21 titanium alloy after heat treatment

[J].

Effect of solution temperature on microstructures and tensile properties of high strength Ti-6Cr-5Mo-5V-4Al alloy

[J].

Precipitation hardening and microstructure evolution of the Ti-7Nb-10Mo alloy during aging

[J].

Effect of solution temperature on microstructure and properties of new type metastable β titanium alloy

[J].

固溶温度对新型亚稳β钛合金组织与性能的影响

[J].

The Effect of solution treatment on microstructure and mechanical properties of Ti-6Mo-6Nb-8Sn alloy

[J].

Effect of solution temperature on microstructures and tensile properties of high strength Ti-6Cr-5Mo-5V-4Al alloy

[J].

The effect of microstructure on tensile properties, deformation mechanisms and fracture models of TG6 high temperature titanium alloy

[J].

Evolution of secondary α phase during aging treatment in novel near β Ti-6Mo-5V-3Al-2Fe alloy

[J].

The effect of thermo-mechanical processing and ageing time on microstructure and mechanical properties of powder metallurgy near β titanium alloys

[J].

ω-Assisted nucleation and growth of α precipitates in the Ti-5Al-5Mo-5V-3Cr-0.5Fe β titanium alloy

[J].AbstractThis paper discusses the structural and compositional changes at the nanometer scale associated with the nucleation and growth of α precipitates in the β titanium alloy Ti-5553 (Ti–5Al–5Mo–5 V–3Cr–0.5Fe) with ω precipitates acting as heterogeneous nucleation sites. The microstructural evolution in this alloy, during β-solutionizing, quenching and aging type heat-treatments, has been investigated by combining results from scanning electron microscopy, orientation imaging microscopy, transmission electron microscopy, high-resolution TEM and three-dimensional atom probe (3DAP) tomography. Athermal ω precipitates form in this alloy on quenching from above the β transus temperature. On isothermal annealing at low temperatures, these ω precipitates coarsen to form chemically ordered ω precipitates, accompanied by the nucleation of the stable α phase. Annealing at higher temperatures leads to dissolution of ω and further growth of α precipitates accompanied by clustering of different α variants in self-accommodating morphologies. 3DAP results indicate that annealing at lower temperatures (∼350 °C) leads to initial nucleation of α precipitates with a non-equilibrium composition, nearly identical to that of the β matrix. Subsequent aging at higher temperatures (∼600 °C) leads to more pronounced partitioning of alloying elements between the two phases. These results indicate that the structural body-centered cubic to hexagonal close-packed transformation and the compositional partitioning of alloying elements occur in sequential steps, resulting in a mixed-mode displacive-diffusional transformation, similar to the bainite transformation in steels.]]>

Effect of microstructure on high cycle fatigue behavior of Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy

[J].

High cycle fatigue behavior of Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy with lamellar microstructure

[J].

Evolution of primary α phase morphology and mechanical properties of a novel high-strength titanium alloy during heat treatment

[J].

Precipitation behavior and tensile property of the stress-aged Ti-10Mo-8V-1Fe-3.5Al alloy

[J].

A low-cost hierarchical nanostructured beta-titanium alloy with high strength

[J].Lightweighting of automobiles by use of novel low-cost, high strength-to-weight ratio structural materials can reduce the consumption of fossil fuels and in turn CO2 emission. Working towards this goal we achieved high strength in a low cost beta-titanium alloy, Ti-1Al-8V-5Fe (Ti185), by hierarchical nanostructure consisting of homogenous distribution of micron-scale and nanoscale alpha-phase precipitates within the beta-phase matrix. The sequence of phase transformation leading to this hierarchical nanostructure is explored using electron microscopy and atom probe tomography. Our results suggest that the high number density of nanoscale alpha-phase precipitates in the beta-phase matrix is due to omega assisted nucleation of alpha resulting in high tensile strength, greater than any current commercial titanium alloy. Thus hierarchical nanostructured Ti185 serves as an excellent candidate for replacing costlier titanium alloys and other structural alloys for cost-effective lightweighting applications.

Effect of aging heat treatment on microstructure and tensile properties of a new β high strength titanium alloy

[J].

Evolution of microstructure and phase composition of Ti-3Al-5Mo-4.5V alloy with varied β phase stability

[J].

Effect of Heat Treatment on microstructure and mechanical properties of Ultra-fine grained Ti-55511 Near β titanium alloy

[J].