温度响应性水凝胶,是一种因响应环境温度变化其体积或其它物理性能改变的智能材料。温度变化是一种普遍存在的环境刺激而且容易施加,因此这类智能材料在生物医学、传感和检测、分离纯化、自动化等领域有诱人的应用前景[1,2]。但是,传统的温度响应性水凝胶的响应速度较低,达到溶胀平衡的时间较长,需要几小时甚至十几个小时。其原因是,在响应温度变化体积收缩时在表面形成了致密的疏水皮层,阻碍内部水分子向外扩散[3]。于是,传统的温度响应性水凝胶在要求响应速度尽可能高的药物可控释放载体、温度传感器、智能阀和智能驱动器等方面的应用,受到了极大的限制。因此,最大限度地提高温度响应性水凝胶的响应速度,是多年来一直受到高度关注的研究课题[4]。Kaneko等[5]最早在温度响应性水凝胶的分子链上接枝亲水性聚合物使其温度响应速度提高,因为致密的疏水皮层中的亲水性聚合物可为水凝胶内部水分子往外扩散提供通道。但是,这种接枝的制备工艺过于繁杂。基于相同的机理,本文作者所在课题组用线性亲水性聚合物(如海藻酸钠)与交联的温度响应性聚合物形成半互穿聚合物网络结构,以提高其响应速度[6]。后来又使用致孔剂使温度响应性水凝胶形成多孔结构,使响应速度进一步提高[7]。其原因是,疏水皮层中的孔道更有利于水分子扩散出来。但是,用这种方法制得的温度响应性水凝胶的机械性能变差,尤其是耐压缩性能。Xia等[8]用表面带活性基团的温度响应性纳米水凝胶为交联剂,制备了具有纳米复合结构的快速温度响应性水凝胶。当环境温度从25℃升高到55℃这种水凝胶达到消溶胀平衡所需时间只有6 min,因为大量的纳米水凝胶更快收缩形成的空隙使水分子更容易扩散出来。同时,这种水凝胶还具有良好的压缩回弹性。为了进一步提高温度响应性水凝胶的响应速度,扩大其应用范围,本文使用切短的温度响应性纳米纤维应用冷冻干燥和热处理等工艺构建超快温度响应性水凝胶。

1 实验方法

1.1 实验用药品

N-异丙基丙烯酰胺(NIPAM,纯度99%)和荧光素异硫氰酸酯标记的葡聚糖(FITC-葡聚糖,分子量10000 g/mol),使用前将NIPAM用体积比为1:1的正己烷/甲苯混合溶剂进行重结晶纯化。N-羟甲基丙烯酰胺(NMA,纯度 98% )、偶氮二异丁腈(AIBN,分析纯)、无水乙醇(分析纯)、正己烷(分析纯)、甲苯(分析纯)等化学药品或化学试剂,使用前未做纯化处理。实验中用到的二次蒸馏水,用自动双重蒸馏水发生器制备。

1.2 PNN纳米纤维的制备

先以共聚单体NIPAM/NMA摩尔比为5:1的配比制备聚(N-异丙基丙烯酰胺-co-N-羟甲基丙烯酰胺)(PNN)共聚物并进行纯化[9],然后将其溶解在乙醇和水的混合溶剂(乙醇与水的体积比为5:1)中配制成浓度为30%(W/V)的纺丝溶液,使用静电纺丝装置制备纳米纤维。纺丝溶液的流速为1.0 mL/h,电压为12 kV,接收距离为15 cm,收集器为接地的铝箔。最后,将制备出的纳米纤维放在110℃烘箱中加热5 h,即得到PNN纳米纤维。

在配制纺丝溶液时加入质量分数为0.2%的FITC-葡聚糖并搅拌溶解,用相同的静电纺丝工艺和热处理制得载药的PNN纳米纤维。

1.3 温度响应性纳米纤维水凝胶的制备

将1.0 g的PNN纳米纤维加入到120 mL叔丁醇中,用高速搅拌机(FJ200-SH型)搅拌将纳米纤维受切短并分散在叔丁醇中。搅拌机的转速为13000 r/min,搅拌时间为5 min。然后将分散液注入具有特定形状的模具中,放在冰箱冷冻室中冷冻6 h,取出后冷冻干燥24 h。最后将冷冻干燥形成的产物放在110℃烘箱中加热2 h,吸水溶胀后即得到温度响应性纳米纤维水凝胶。

1.4 性能表征

以氘代二甲基亚砜为溶剂,用核磁共振波谱 (NMR)仪(Avance-400型,Bruker)测试PNN共聚物的1H NMR谱,以表征其化学结构与组成。用紫外-可见光谱仪(Lambda 35型,Perkin Elmer)测试不同温度下质量浓度约为0.1%的PNN水溶液在500 nm波长处光的透过率,控温精度为±0.01℃,升温速度为0.5℃/min,由透过率与温度的关系曲线的拐点确定PNN的最低临界溶解温度(LCST)。

用扫描电镜(SEM)(S-4800型,Hitachi)观察PNN纳米纤维的形态和表面形貌。将样品喷金处理,用Nano Measurer粒径分析软件随机测量50根纳米纤维的直径并统计它的平均值,计算相对标准偏差。用液氮冷冻未吸水的温度响应性纳米纤维水凝胶,脆断后对断面进行喷金处理,然后用相同的SEM和测量软件观察其内部多孔结构并测量孔洞的平均直径及其相对标准偏差。

表征温度响应性纳米纤维水凝胶在水中的稳定性:将直径为4 cm、厚度为3 mm的圆柱状纳米纤维水凝胶浸泡在去离子水中,用振荡摇床以300 r/min的速度振荡24 h。观察振荡前后纳米纤维水凝胶的外观,然后取出进行冷冻干燥,称量水凝胶振荡前后的重量,计算水凝胶经过振荡后损失的质量百分比。

称量温度响应性纳米纤维水凝胶在干燥状态下的重量(Wdry)和室温下吸水达到溶胀平衡后的重量(Wswolen),其含水量为

纳米纤维水凝胶的温度响应性的表征[8]:在20~50℃范围内用数码相机记录初始厚度为3 mm、直径为4 cm(d0)的圆柱状纳米纤维水凝胶在不同温度水中的直径(d),每次测量前静置平衡1 h。不同温度下水凝胶的体积(V)与20℃的体积(V0)之比为

画出V/V0与温度T之间的关系曲线,根据曲线拐点确定温度响应性纳米纤维水凝胶的体积相转变温度(VPTT)。另外,将圆柱状纳米纤维水凝胶交替浸泡在20℃和55℃水中,用数码相机拍摄水凝胶发生溶胀或消溶胀的视频。从视频中每隔3 s截取图片,以此测量不同时间水凝胶的d,并按照

1.5 体外药物释放实验

将制得的载FITC-葡聚糖的温度响应性纳米纤维水凝胶浸泡在5 mL温度为15℃的PBS缓冲溶液(pH 7.4)中,使其吸水溶胀5 min[10]。然后将水凝胶转移到温度为47℃的PBS缓冲溶液中,停留2 min取出后放入15℃的新鲜PBS缓冲溶液中,如此循环7次。每次水凝胶取出后用紫外-可见光谱仪测定PBS缓冲溶液在493 nm波长处的吸光度,再根据标准曲线得到其中FITC-葡聚糖的浓度,计算出每次FITC-葡聚糖在15℃或47℃温度下从温度响应性纳米纤维水凝胶中释放出来的质量百分比,由此画出FITC-葡聚糖的累积释放曲线。

2 结果和讨论

2.1 温度响应性聚合物PNN的表征

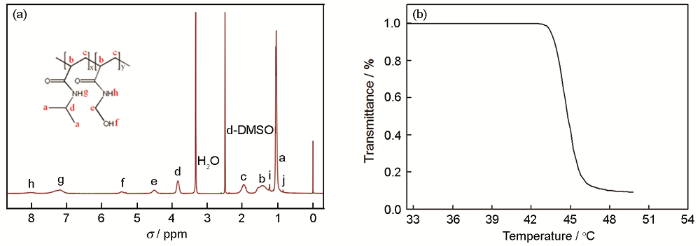

图1a给出了合成的PNN共聚物的1HNMR谱图,谱图中每一个谱峰的归属见图中共聚物结构式上所示。所有的谱峰与共聚物结构中两种重复单元的所有氢原子形成了一一对应的关系,表明合成的聚合物与PNN的结构完全相同。根据谱图中g峰和h峰的相对积分面积计算出PNN共聚物分子链中NIPAM和NMA两种单元的摩尔比为100:22.6,与合成聚合物时使用的两种单体的摩尔比(100:20)基本相同。图1b给出了测得的不同温度下质量浓度约为0.1%的PNN水溶液在500 nm波长处光的透过率与温度的关系曲线。可以看出,当温度低于43℃时PNN水溶液的透光率接近于100%,溶液呈完全透明状态。其原因是,低于此温度时亲水的PNN共聚物完全溶解于水中,分子链处于伸展状态。当温度高于43℃时PNN水溶液的透光率急剧下降,直到大约46℃。其原因是,PNN共聚物由亲水性变为疏水性,相应地分子链由伸展状态变为卷曲状态,形成的疏水性类球状聚合物粒子对光产生了散射[11]。这些结果表明,PNN的相转变温度范围为43~46℃,比PNIPAM均聚物的相转变温度范围宽。其原因是,在温度响应性的聚合物分子链中引入了非温度响应性的NMA单元。画出图1b的微分曲线,曲线峰顶对应的温度为44.6℃,此温度即为PNN的LCST。它比PNIPAM均聚物的LCST(32℃)高,因为在PNN分子链中引入了亲水性重复单元NMA,使PNIPAM的LCST升高[12]。

图1

图1

PNN的1H NMR谱图和质量分数约为0.1%的PNN水溶液的500 nm波长光透过率与温度的关系

Fig.1

1H NMR spectrum of PNN (a) and temperature dependence of light transmittance at the wavelength of 500 nm for the PNN aqueous solution of ca.0.1% (mass fraction) concentration (b)

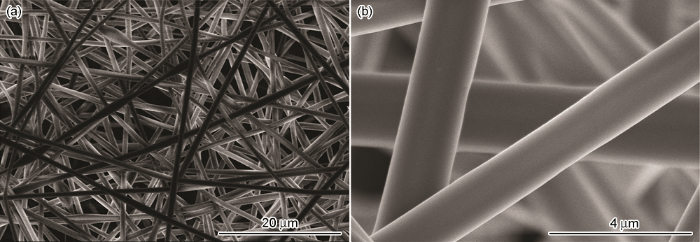

2.2 PNN纳米纤维的形貌

图2

图2

PNN纳米纤维不同放大倍数的SEM照片

Fig.2

SEM images of PNN nanofibers with different magnification times (a) low magnification, (b) high magnification

2.3 温度响应性纳米纤维水凝胶的多孔结构及其形成机理

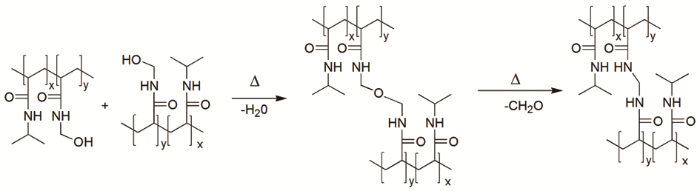

只要改变模具的形状,就可制备出不同形状的温度响应性纳米纤维水凝胶,如图3a所示。这样有利于它的实际应用,例如用作植入人体的药物可控释放载体[13]。图3b给出了纳米纤维水凝胶的不同放大倍数的SEM照片,可见纳米纤维水凝胶由许多的大孔和小孔构成,具有多级多孔结构。用相关软件测量30个大孔或小孔的直径,计算出大孔的平均直径约为19.4 µm,相对标准偏差为19.6%,小孔的平均直径约为2.6 µm,相对标准偏差为20.5%。大孔形成的机理可能是:短纳米纤维的叔丁醇分散液在冷冻过程中叔丁醇发生结晶,晶体的生长使纳米纤维被排斥并聚集,形成叔丁醇晶体相和纳米纤维聚集相。冷冻干燥使叔丁醇晶体升华,形成的空腔即是纳米纤维水凝胶的大孔洞,而聚集的纳米纤维相构成了大孔洞的壁。壁中纳米纤维之间聚集与缠结形成了小孔洞。这种多级多孔结构使纳米纤维水凝胶的水含量高达98.3%。将制得的纳米纤维水凝胶浸入水中,在300 r/min转速下持续振荡24 h前后的外观照片如图3c所示。通过对比可见,振荡前后水凝胶的形状和外观没有变化。称量水凝胶振荡前后烘干后的重量,发现其质量损失仅为0.42%,进一步说明制得的纳米纤维水凝胶在水中具有良好的稳定性。其原因是,形成纳米纤维的聚合物PNN分子侧链上含有反应活性基团—N-羟甲基(N-CH2OH),在110℃热处理过程中该基团之间发生缩合反应[14]

图3

图3

不同形状温度响应性纳米纤维水凝胶的照片、温度响应性纳米纤维水凝胶不同放大倍数的SEM照片、温度响应性纳米纤维水凝胶在300 r/min转速下振荡24 h前后外观照片、传统的温度响应性PNIPAM水凝胶受到刀片压缩前后及其移除后的外观照片以及温度响应性纳米纤维水凝胶受到刀片压缩前后及其移除后的外观照片

Fig. 3

Optical images of temperature responsive nanofibrous hydrogels with various shapes (a), SEM images of temperature responsive nanofibrous hydrogel at various magnification times (b), optical images of temperature responsive nanofibrous hydrogel in water before and after 300 r/min×24 h oscillation (c), optical images of conventional temperature responsive PNIPAM hydrogel before, during and after compression exerted by a blade (d) and optical images of temperature responsive nanofibrous hydrogel before, during and after compression exerted by a blade (e)

于是在纳米纤维内部形成交联结构且在纳米纤维之间发生化学键连接,使纳米纤维水凝胶在水中只吸水溶胀而不溶解。从图3b还可以看出,纳米纤维之间产生了粘结,这是纳米纤维水凝胶具有稳定多级多孔结构的原因。图3d和e分别给出了传统的温度响应性PNIPAM水凝胶和本文制得的纳米纤维水凝胶受到刀片压缩及其前后的外观照片。传统的水凝胶受到刀片压缩后轻易就能切开,因为水凝胶内交联点分布不均匀,受到外力压缩后交联点之间分子量较小的短链优先断裂,使水凝胶韧性很差[15]。而纳米纤维水凝胶受到刀片压缩后再移除,其形状可完全回复,表现出良好的压缩回弹性。如前所述,纳米纤维水凝胶的多级多孔结构受到压缩力后,其中的大孔洞先被挤压产生变形。压缩力进一步增大则聚集和缠结的纳米纤维之间产生滑移,小孔进一步变形以抵消外部压缩力的作用,而不会发生纤维或纤维内部分子链的断裂。

2.4 纳米纤维水凝胶的温度响应性

图4a给出了制得的纳米纤维水凝胶和传统的PNIPAM水凝胶在不同温度水中的V/V0随温度变化的关系曲线。可以看出,当水介质温度从20℃升高到55℃时纳米纤维水凝胶的体积收缩了约70%,而传统的PNIPAM水凝胶只收缩了约40%。这表明,纳米纤维水凝胶比传统的PNIPAM水凝胶具有更显著的温度响应性。其原因是,前者具有明显的多级多孔结构,响应温度变化发生相转变后疏水相互作用使其相互粘贴[16]。这不仅排挤出大孔洞中包含的水,小孔洞中的水也可能排出。从图4a中两条曲线的微分曲线得到纳米纤维水凝胶的VPTT约为39℃,明显高于传统PNIPAM水凝胶的VPTT(约33℃),但是低于其成纤聚合物PNN的LCST。其原因是,在上述热处理过程中PNN分子侧链上亲水性较强的N-羟甲基发生缩合反应形成了亲水性较弱的交联点[10]。将制得的纳米纤维水凝胶交替放入20℃和55℃水中,测出的V/V0与时间的关系如图4b所示。可以看出,纳米纤维水凝胶从20℃水中转移到55℃水中达到消溶胀平衡的时间为34 s,而从55℃水中转移到20℃水中达到溶胀平衡的时间为45 s。而相同形状和体积的PNIPAM水凝胶在相同温度条件下达到消溶胀平衡和溶胀平衡的时间分别为1.2 h和1.5 h。这表明,本文制得的温度响应性纳米纤维水凝胶的响应速度比传统的PNIPAM水凝胶高得很多,也明显高于文献[8]报道的响应速度,属于超快的温度响应性。使纳米纤维水凝胶响应速度超高的原因:其一,纳米纤维的直径非常小,有利于外界刺激的传递[3],即纳米纤维很快达到温度平衡而发生体积相转变;其二,纳米纤维水凝胶具有多级多孔结构,在其发生体积相转变的过程中有利于水分子扩散进入或排出。将纳米纤维水凝胶交替6次浸入20℃和55℃水中,达到溶胀或收缩平衡后测得的V/V0,由图4c所示可以看出,纳米纤维水凝胶响应温度变化发生的体积相转变具有良好的可逆性。

图4

图4

纳米纤维水凝胶和PNIPAM水凝胶的V/V0随温度变化的曲线、纳米纤维水凝胶交替放入20℃和55℃水中测得的V/V0随时间变化的曲线和纳米纤维水凝胶交替6次浸入20℃和55℃水中达到溶胀或收缩平衡后测得的V/V0

Fig.4

Temperature dependent V/V0 of the nanofibrous hydrogel or the PNIPAM hydrogel (a), time dependent V/V0 of the nanofibrous hydrogel immersed alternately in the aqueous medium of 20℃ or 55℃ (b) and the V/V0 of the nanofibrous hydrogel immersed alternately in the aqueous medium of 20℃ or 55℃ for six cycles (c)

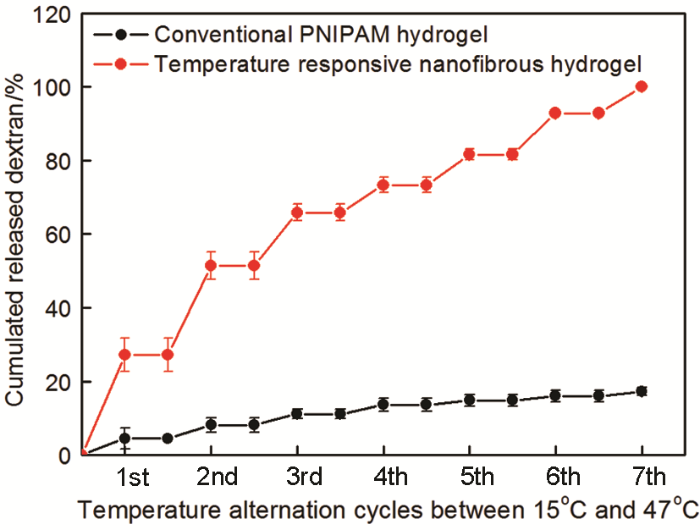

2.5 温度响应性纳米纤维水凝胶用于药物的可控释放

将负载模型药物FITC-葡聚糖的传统PNIPAM水凝胶或温度响应性纳米纤维水凝胶交替浸入温度为15℃和47℃的新鲜PBS缓冲溶液中并停留2 min,测得的药物累积释放曲线如图5所示。可以看到,在15℃传统PNIPAM水凝胶与纳米纤维水凝胶内负载的药物几乎没有释放出来,而在47℃有药物释放出来。其原因是,FITC-葡聚糖是一种亲水的高分子药物,当温度低于水凝胶的VPTT时与水凝胶中亲水的聚合物分子链之间发生缠结或氢键相互作用,难以像亲水的小分子药物一样通过扩散作用释放出来。而当温度高于它的VPTT时聚合物分子链由亲水性变为疏水性,水凝胶发生消溶胀并排除其中的绝大部分水,并将部分解除缠结和氢键作用的FITC-葡聚糖溶解在水中一起释放出来。对比结果表明,第一次响应温度变化刺激后FITC-葡聚糖从温度响应性纳米纤维水凝胶中释放的质量百分比为27.2%,而从传统的PNIPAM水凝胶中释放的仅为4.5%,因为后者在消溶胀过程中形成的致密皮层阻碍了药物的释放。7次温度循环变化后温度响应性纳米纤维水凝胶内FITC-葡聚糖累积释放的质量百分比接近100%,而传统PNIPAM水凝胶的累积释放量还不到20%,表明温度响应性纳米纤维水凝胶具有明显的“开/关”型控制释放药物的能力。

图5

图5

负载FITC-葡聚糖的温度响应性纳米纤维水凝胶和传统的PNIPAM水凝胶响应温度在15~47℃间交替变化释放的药物累积量曲线

Fig.5

Cumulated drug release profiles obtained from FITC-dextran loaded nanofibrous hydrogel and conventional PNIPAM hydrogel in response to alternating change of temperature between 15 and 47℃

3 结论

以NIPAM与NMA形成的PNN共聚物为成纤聚合物,采用静电纺丝工艺制备PNN纳米纤维,然后将其高速搅拌切短并分散在叔丁醇中,再进行冷冻干燥和热处理,可将切短的PNN纳米纤维组装成具有多级多孔结构的纳米纤维水凝胶。这种水凝胶在水中具有良好的稳定性、压缩回弹性和显著的温度响应性,当水介质温度在20~55℃之间交替变化时达到消溶胀平衡所需时间仅为34 s,达到溶胀平衡所需时间为45 s。这种纳米纤维水凝胶具有响应温度变化的“开/关”型控制释放水溶性大分子药物的性能。

参考文献

Stimuli-responsive polymers and their applications

[J].

Thermo-sensitive nanomaterials: recent advance in synthesis and biomedical applications

[J].

Kinetics of discontinuous volume–phase transition of gels

[J].

Smart hydrogels: network design and emerging applications

[J].

Rapid deswelling response of poly (N-isopropylacrylamide) hydrogels by the formation of water release channels using poly (ethylene oxide) graft chains

[J].

Rapid deswelling of sodium alginate/poly (N-isopropylacrylamide) semi-interpenetrating polymer network hydrogels in response to temperature and pH changes

[J].

Preparation of fast temperature responsive porous poly (N-isopropylacrylamide) hydrogels using sodium alginate as pore-making agent in sodium chloride solutions

[J].N-isopropylacrylamide)(PNIPAAm) hydrogels were prepared using sodium alginate(SA) as pore-making agent in aqueous NaCl solutions.The porous structure of the PNIPAAm hydrogels was confirmed by SEM and SAXS,and the results showed that the pores in the hydrogels were interconnected and their pore sizes were increased with the NaCl concentrations used in the polymerization media.Accordingly,the deswelling rates of the porous hydrogels were enhanced with the NaCl concentrations.The water retention ratio of the porous PNIPAAm hydrogel prepared in 0.6 mol/L NaCl aqueous solution was less than 15% within 1 min when the equilibrium-swollen hydrogels at room temperature was transferred into the aqueous medium at 45℃,and the deswelling equilibrium was achieved within 4 min.The porous structure of the PNIPAAm hydrogels may be caused by the micoparticles formed by coil-to-globule transition of sodium alginate chains in the NaCl solution.]]>

在NaCl溶液中以海藻酸钠为致孔剂制备快速温度响应型多孔聚(N-异丙基丙烯酰胺)水凝胶

[J].N-异丙基丙烯酰胺)(PNIPAAm)水凝胶,分别用扫描电镜(SEM)和小角X光散射(SAXS)对PNIPAAm水凝胶的多孔结构进行了表征.结果发现,PNIPAAm水凝胶网络中的孔洞相互贯通,随着反应介质中NaCl浓度的增加,孔洞尺寸逐渐增大,孔洞排列越来越有序.相应地,PNIPAAm水凝胶的消溶胀速率随着反应介质中NaCl浓度的增加而提高.当NaCl浓度为0.6 mol/L时制备的PNIPAAm水凝胶,从室温处于平衡溶胀状态快速转移到45℃水介质中,1 min后凝胶的水保留率不足15%,4 min后消溶胀就达到平衡状态.]]>

Nano-structured smart hydrogels with rapid response and high elasticity

[J].Smart hydrogels, or stimuli-responsive hydrogels, are three-dimensional networks composed of crosslinked hydrophilic polymer chains that are able to dramatically change their volume and other properties in response to environmental stimuli such as temperature, pH and certain chemicals. Rapid and significant response to environmental stimuli and high elasticity are critical for the versatility of such smart hydrogels. Here we report the synthesis of smart hydrogels which are rapidly responsive, highly swellable and stretchable, by constructing a nano-structured architecture with activated nanogels as nano-crosslinkers. The nano-structured smart hydrogels show very significant and rapid stimuli-responsive characteristics, as well as highly elastic properties to sustain high compressions, resist slicing and withstand high level of deformation, such as bending, twisting and extensive stretching. Because of the concurrent rapid and significant stimuli-response and high elasticity, these nano-structured smart hydrogels may expand the scope of hydrogel applications, and provide enhanced performance in their applications.

Fabrication of monodispersed Au@Ag bimetallic nanorod-loaded nanofibrous membrane with fast thermo-responsiveness and its use as a smart free-standing SERS substrate

[J].

Temperature-responsive electrospun nanofibers for ‘on-off’ switchable release of dextran

[J].We propose a new type of 'smart' nanofiber (NF) with dynamically and reversibly tunable properties for the 'on-off' controlled release of the polysaccharide dextran. The fibers are produced by electrospinning copolymers of N-isopropylacrylamide (NIPAAm) and N-hydroxymethylacrylamide (HMAAm). The OH groups of HMAAm are subsequently crosslinked by thermal curing. The copolymers were successfully fabricated into a well-defined nanofibrous structure with a diameter of about 600-700 nm, and the fibers preserved their morphology even after thermal curing. The resulting crosslinked NFs showed rapid and reversible volume changes in aqueous media in response to cycles of temperature alternation. The fibrous morphology was maintained for the crosslinked NFs even after the cycles of temperature alternation, while non-crosslinked NFs collapsed and dispersed quickly in the aqueous solution. Dextran-containing NFs were prepared by electrospinning the copolymers blended with fluorescein isothiocyanate (FITC)-dextran, and the 'on-off' switchable release of FITC-dextran from the crosslinked NFs was observed. Almost all the FITC-dextran was released from the NFs after six heating cycles, whereas only a negligible amount of FITC-dextran was evolved during the cooling process. The reported incorporation of smart properties into NFs takes advantage of their extremely large surface area and porosity and is expected to provide a simple platform for on-off drug delivery.

Stimuli-reponsive polymers and their bioconjugates

[J].

A novel route to prepare pH- and temperature-sensitive nanogels via a semibatch process

[J].A novel method via a semibatch process in the absence of surfactant has been adopted to prepare pH- and temperature-sensitive nanogels. The shape, charge distribution, temperature, and pH-induced volume phase transition behavior of the latexes were investigated by scanning electronic microscopy, zeta potentials, dynamic laser light scattering, and UV/vis spectroscopy. It was found that, in the absence of surfactant, with increasing the amount of AAc from 5 to 20 mol% of N-isopropylacrylamide (NIPAM), the hydrodynamic diameters (D(H)) decrease from 230 to 60 nm. With increasing pH value from 3 to 11, the D(H) values increase slightly, which is different than the dramatic increase seen when using a conventional batch method with a range from 680 to 1700 nm. However, at pH 3, the turbidity curves of these kinds of particles increase dramatically at temperatures between 33 and 37 degrees C, while remaining constant at first and then increasing directly at pH 11. Furthermore, the distribution of carboxylic groups located not only on the interior but also on the exterior of colloidal particles as a result of adoption of the semibatch method, other than simple surface distribution of poly(NIPAM-co-AAc) latexes via the batch method.

Local release of VEGF using fiber mats enables effective transplantation of layered cardiomyocyte sheets

[J].

Multifunctional electrospun nanofibers prepared from poly ((N-isopropylacrylamide)-co-(N-hydroxymethylacrylamide)) and Their Blends with 1,2-Diaminoanthraquinone for NO gas detection

[J].image

Spinks a P W. Progress toward robust polymer hydrogels

[J].In this review we highlight new developments in tough hydrogel materials in terms of their enhanced mechanical performance and their corresponding toughening mechanisms. These mechanically robust hydrogels have been developed over the past 10 years with many now showing mechanical properties comparable with those of natural tissues. By first reviewing the brittleness of conventional synthetic hydrogels, we introduce each new class of tough hydrogel: homogeneous gels, slip-link gels, double-network gels, nanocomposite gels and gels formed using poly-functional crosslinkers. In each case we provide a description of the fracture process that may be occurring. With the exception of double network gels where the enhanced toughness is quite well understood, these descriptions remain to be confirmed. We also introduce material property charts for conventional and tough synthetic hydrogels to illustrate the wide range of mechanical and swelling properties exhibited by these materials and to highlight links between these properties and the network topology. Finally, we provide some suggestions for further work particularly with regard to some unanswered questions and possible avenues for further enhancement of gel toughness.