Sellars and McTegart [8]提出,可用Arrhenius方程中的正弦-双曲线定律表示材料的流变应力。许多学者修改这个方程以扩大其应用范围[9,10,11],Mandal等[12]和Lin等[13]用应变和应变率补偿的正弦双曲本构方程,分别预测了钛改性奥氏体不锈钢和42CrMo钢的流动应力。吴文祥等[14]为了预测NZ30K合金在热变形过程中的流动应力,基于变形加热的校正数据建立了基于应变补偿的双曲-正弦本构方程。本文进行Ti-62A合金的热压缩试验研究其热变形行为,对实验数据进行多元线性回归拟合研究材料参数与应变量的多项式函数关系,根据应变量对Ti-62A合金热变形行为的影响建立基于应变补偿的Ti-62A合金Arrhenius变形抗力模型。

1 实验方法

表1 Ti-62A钛合金的化学成分

Table 1

| Al | Cr | Mo | Zn | Zr | Si | Fe | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5.25~6.25 | 1.75~2.25 | 1.75~2.25 | 1.75~2.25 | 1.75~2.25 | 0.20~0.27 | ≤0.15 | ≤0.04 | ≤0.03 | ≤0.0125 | ≤0.13 | Bal. |

图1

2 结果和讨论

2.1 Ti-62A 合金的流变行为

图2

图2

在不同变形条件下Ti-62A合金的流变应力曲线

Fig.2

Flow stress curves of Ti-62A alloy under different deformation conditions (a) 0.001 s-1; (b) 0.01 s-1; (c) 0.1 s-1; (d) 1 s-1; (e) 10 s-1

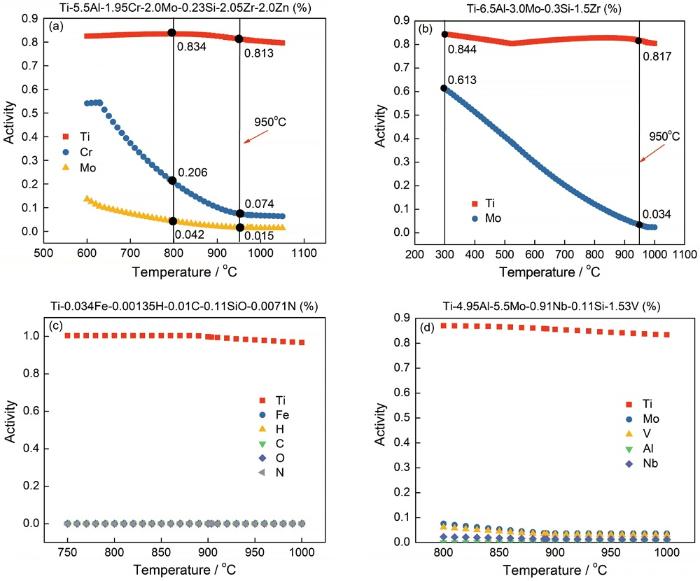

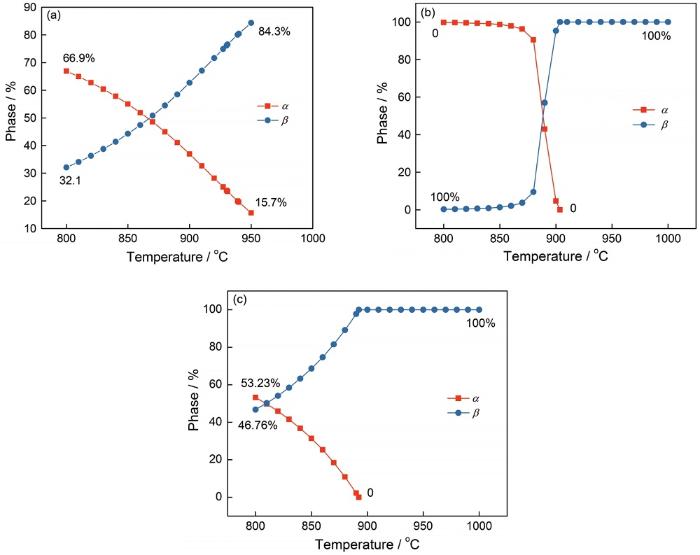

2.2 钛合金在热压缩过程中的动态软化率

无论应变速率多大,Ti-62A合金的动态软化速率都随着变形温度的提高而降低。变形温度较低(800℃)时流变应力曲线大多为动态软化型,而变形温度较高(950℃)时流变应力曲线大多属于动态回复型,中间变形温度(850℃)的流变应力曲线大多属于动态再结晶型,如图2所示。结果表明[15,16,17,18],随着变形温度的提高流变应力曲线表现出的动态软化速率都是降低的。本文根据热力学理论解释这种反常现象。使用JmatPro材料模拟软件分别计算了Ti-62A合金、TC11合金[15]、工业纯钛[19]和TB17合金[23]中关键元素的原子相对活性,结果如图3所示。从图3a可见,温度对Ti-62A合金中Cr和Mo两种元素的原子活性有显著的影响。从800℃升高到950℃,Cr和Mo的原子活性都显著降低。Cr原子的活性从0.206降低到0.074(降幅达到64.1%),Mo的降幅也达到64.3%。温度对TC11合金中Mo元素的原子活性也有显著的影响,从300℃升高到950℃元素Mo的原子活性显著降低(图3b),从0.613降低到0.034(降幅达94.5%)。但是,温度对工业纯钛和TB17合金中各元素的原子活性并没有显著的影响(图3c和3d)。α型钛合金[19,20,21,22]和β型钛合金[23,24]的热加工流变应力曲线都表明,随着加工温度的升高动态软化速率降低。为此,本文使用JmatPro材料模拟软件分别计算了Ti-62A合金、工业纯钛和TB17合金中α和β相的比例(图4)。可以看出,三种合金中β相的含量均随着变形温度的升高而提高。温度由800℃升高到950℃,Ti-62A合金中的β相含量由32.1%提高到84.3%,工业纯钛和β钛合金中β相的比例均已提高到100%。在三种钛合金的高温变形过程中都可能存在形变诱导α相向β相的转变(存在晶体结构有hcp结构向bcc结构的转变),消耗部分变形能使其在较高温度下变形的动态软化率较低。

图3

图3

钛合金中合金元素的活性随温度的变化

Fig.3

Change of alloy element activity with temperature in titanium alloy (a) Ti-62A alloy; (b) TC11 alloy; (c) Commercially pure titanium; (d) TB17 alloy

图4

图4

钛合金中α相和β相的比例随温度的变化

Fig.4

Change of the ratio of α phase and β phase with temperature in titanium alloy (a) Ti-62A alloy; (b) Commercially pure titanium; (c) TB17 alloy

可以推测,α型钛合金和β型钛合金出现动态软化率随变形温度升高而降低的现象和相比例的变化,与β相比例的增大密切相关;但是,α+β双相钛合金的这一现象则可能是主要合金元素Mo、Cr等β稳定元素的原子活性随温度升高逐渐降低与β相比例增大共同作用的结果。这表明,合金元素、相比例和变形温度对Ti-62A合金的热变形行为都有显著的影响。这种合金的α→β相的转变温度约为965℃,即随着变形温度(800~950℃)的提高变形试样中β相的比例增大。上述两种元素在β相(bcc结构)中的活性较低,导致上述反常现象。

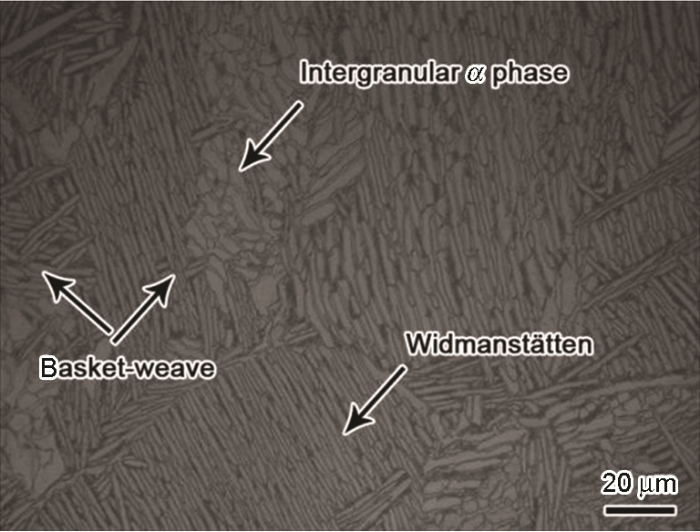

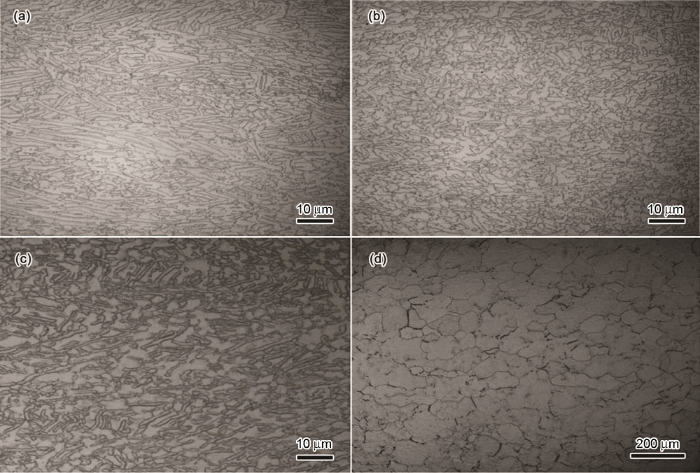

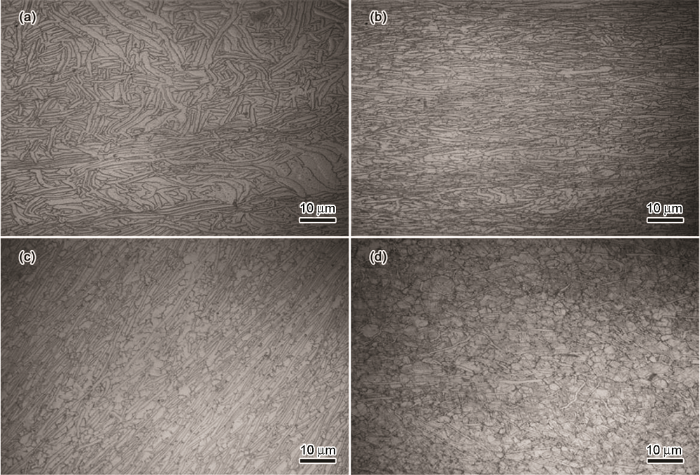

2.3 变形温度对Ti-62A 合金显微组织的影响

图5给出了Ti-62A合金在应变速率为0.001 s-1、不同温度下热压缩变形后的金相照片。变形温度为800℃时,合金的显微组织由片状的初生α相和β转变组织组成(图5a);变形温度为850℃时片状α相的数量减少,β转变组织的尺寸增大(图5b);变形温度为900℃时α相发生了动态再结晶或球化,β相发生再结晶,产生新的等轴β晶粒(图5c);变形温度为950℃时β晶粒完全回复与再结晶,出现粗大的等轴 β晶粒,α相几乎消失(图5d)。可以看出,随着变形温度的升高β晶粒通过晶界迁移粗化,使变形合金中β相的比例增高。这表明,随着变形温度的升高更多的α相向β相转变。这个转变需要能量且随着变形温度的升高Ti-62A中主要合金元素Cr、Mo的活性降低,使流变应力曲线表现出的应变软化速率随着变形温度的升高反而降低。

图5

图5

在应变速率为 0. 001 s-1、不同温度条件下热压缩变形后Ti-62A 合金的显微组织

Fig.5

Microstructure of Ti-62A alloy deformed by hot compression at different temperatures with strain rate of 0.001 s-1 (a) 800℃, (b) 850℃, (c) 900℃, (d) 950℃

图6给出了Ti-62A合金经应变速率为1 s-1、在不同温度热压缩变形后的显微组织照片。与图5中金相相比,尽管应变速率高了3个数量,Ti-62A合金的微观组织仍表现出相同的变化规律。变形温度为800℃时α相与β转变组织都发生了弯曲(图6a);图 6b、6c和6d中的变形分别为经1 s-1和850℃、900℃和950℃热压缩变形,Ti-62A合金的显微组织由片层状的初生α相与β转变组织组成。随着变形温度的升高α相含量降低,β转变组织逐渐增多,且β晶粒尺寸增大(图6b~d)。但是图5d和图6d表明,变形温度同为950℃,应变速率对等轴β相的晶粒尺寸影响显著,前者的晶粒尺寸明显大于后者。从图6d还可以看出,在1 s-1和950℃变形条件下仍有少量的片状α相没有向β相转变。

图6

图6

在应变速率为1 s-1、不同温度条件下变形的Ti-62A合金的显微组织

Fig.6

Microstructure of Ti-62A alloy deformed by hot compression at different temperatures with strain rate of 1 s-1 (a) 800℃, (b) 850℃, (c) 900℃, (d) 950℃

在热变形过程中,温度对Ti-62A合金的热变形组织有显著的影响。随着加工温度的升高,β相比例逐渐增大。由于β相的晶体结构为体心立方结构(bcc),具有较高层错能,而且其中的滑移系比密排六方结构的α相多,容易发生以位错攀移和滑移为机制的动态回复。这使合金中难以储存足够能量使合金发生动态再结晶,即抑制了Ti-62A合金热变形过程中的动态再结晶行为。因此,变形温度较高(950℃)时,流变应力曲线多属于动态回复型。同时,Ti-62A合金中Cr、Mo甚至Ti元素随着变形温度升高活性降低,也阻碍了合金在热变形过程中的动态再结晶。

2.4 基于应变补偿的 Arrhenius 本构模型

式中C、D、E、F为拟合系数。表2给出了Ti-62A合金的常数α,n,Q和ln A的多项式拟合结果。

表2 Ti-62A合金常数拟合参数

Table 2

| α | n | Q | lnA |

|---|---|---|---|

| C0=0.00924 | D0=1.91645 | E0=398.95592 | F0=36.20351 |

| C1=0.01367 | D1=3.79583 | E1=-271.00142 | F1=-21.10215 |

| C2=-0.05939 | D2=-13.6498 | E2=137.81848 | F2=-11.71244 |

| C3=0.14321 | D3=31.05524 | E3=584.16655 | F3=112.84221 |

| C4=-0.1574 | D4=-35.64127 | E4=-1548.1067 | F4=-209.55112 |

| C5=0.06308 | D5=15.75986 | E5=960.56284 | F5=116.99094 |

Ti-62A合金在试验条件范围内任意应变下的流变应力本构方程可表示为

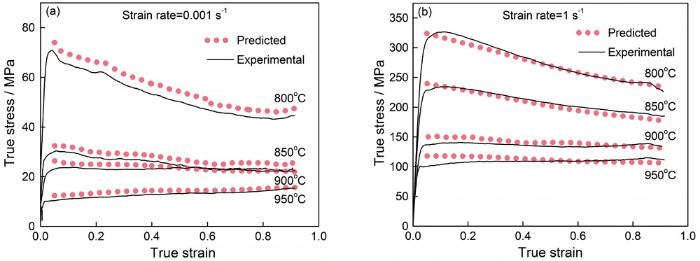

图7

图7

应变补偿的本构方程模拟流变应力曲线与实验流变应力曲线

Fig.7

Comparison of the flow stress curves simulated with strain-compensated constitutive equations and experimental flow stress curves (a) 0.001 s-1; (b) 1 s-1

为了评价基于应变补偿的本构方程对流变应力的预测能力,引入相关系数(R)和平均相对误差(AARE)作为衡量应变补偿本构方程准确性的指标,其表达式为

式中Ei为实验所测的流变应力值(MPa);Pi为由应变补偿本构方程计算的流变应力值(MPa);

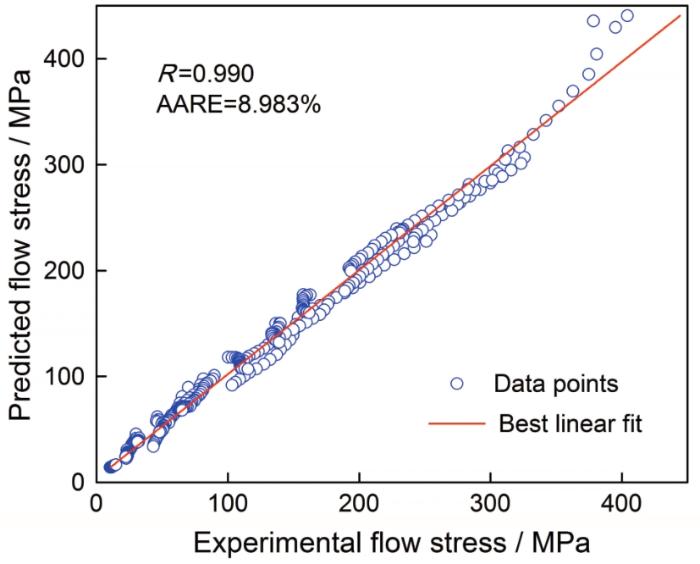

图8给出了Ti-62A合金的应变补偿本构方程的计算值与试验值的相关性对比。误差分析结果表明,使用应变补偿本构方程的计算值与试验值的相关性R为0.990;平均相对误差(AARE)为8.983%。平均相对误差小于10%,表明该模型与试验数据吻合良好。由此可见,本文建立的基于应变补偿的Ti-62A合金流变应力模型能较为准确地描述Ti-62A钛合金在热变形过程中的应力流动变化行为。

图8

图8

Ti-62A合金的应变补偿方程计算值与实测流变应力值的相关性

Fig.8

Correlation between calculated value of strain compensation equation and measured value of flow stress in Ti-62A alloy

3 结论

(1) 在变形温度800~950℃、应变速率0.001~-10 s-1 条件下Ti-62A合金的流变应力对变形温度和应变速率的影响较为敏感,流变应力随着变形温度的降低和应变速率的升高而升高。α钛合金和β钛合金出现动态软化率随着变形温度的升高而降低的现象,与β相比例的增大密切相关;而α+β双相钛合金的这一现象则与主要合金元素的Mo、Cr等β稳定元素随温度升高而逐渐降低、β相比例增大有更大的相关性。从800℃升高到950℃变形试样中β相的比例逐渐增大,Mo、Cr两种元素在β相(bcc结构)中的活性降低。在变形温度范围内Mo和Cr的活性降幅均达到64%,导致变形过程中Ti-62A合金的晶界迁移速度和动态软化速率均随着变形温度的升高而降低,其在较低变形温度(800℃)下的流变应力曲线呈现为动态软化型,在较高变形温度(950℃)下的流变应力曲线反而呈动态回复型。

(2) 变形温度对Ti-62A合金热变形组织的影响显著,变形温度在800~950℃升高合金的中α相由较粗大的片层状发生球化,而且α相的数量逐渐减少;β相由α相片层间的微量比例随着温度的升高逐渐增大,在950℃变形条件下合金的组织完全转变为等轴状的β相。

(3) 考虑应变对材料常数(即α,n,Q和ln A)的影响建立了Ti-62A合金的应变补偿的本构方程,预测应力和实测值之间的相关系数(R)达到0.990,平均相对误差(AARE)为8.983%,表明根据应变补偿本构方程能较好地预测Ti-62A合金的流变应力行为。

参考文献

Change of material selection criterion and development of high damage-tolerant titanium alloy

[J].

选材判据的变化与高损伤容限钛合金的发展

[J].

Research and Application of Typical Aerospace Titanium Alloys

[J].

Effects of cooling rate on the fracture properties of TA15 ELI alloy plates

[J].AbstractThe effects of cooling rate on the mechanical properties and the fatigue crack growth behavior of TA15 ELI alloy plates with different microstructures were investigated at room temperature. The results indicate that the cooling rate (water quench, air cooling, and furnace cooling) has a pronounced influence on the mechanical properties and on the fatigue crack growth, especially for air cooling and furnace cooling. Optical microstructure observation and scanning electron microscopy of tensile fracture surfaces were performed to gain an insight into the mechanism of properties. The dependence of mechanical properties and fatigue crack growth behavior on the cooling rate can be attributed to the α lamellae width and the α colony size, which induce the change in slip length. The microstructure produced by air cooling shows the best damage tolerance behavior when compared with water quench and furnace cooling.]]>

Thermomechanical processing and heat treatment of Ti-6Al-2Sn-2Zr-2Cr-2Mo-Si for structural applications

[J].

Multidisciplinary Design Optimization of a Fighter Aircraft with Damage Tolerance Constraints and a Probabilistic Model of the Fatigue Environment

[D].

Effect of heat treatment process on the mechanical properties of T-Al-Sn-Zr-Mo-Si-X series alloys

[J].

热处理对Ti-Al-Sn-Zr-Mo-Si-X系合金性能的影响

[J].

Mechanical properties and microstucture of an α+β titanium alloy with high strength and fracture toughnes

[J].The Ti-Al-Sn-Zr-Cr-Mo-V-Si (Ti-62A) alloy, an alpha-beta alloy with high strength and fracture toughness, is currently used as an advanced structural material in aerospace and non-aerospace applications. Thermo-mechanical processes can be used to optimize the relationship between its strength and fracture toughness. A Ti-62A alloy bar can be machined through a transus β-forged plus α+β solution treated and aged specimen with a lamellar alpha microstructure. The effects of heat treatment on the mechanical properties were discussed. Heat treatment provided a practical balance of strength, fracture toughness, and fatigue crack growth resistance. A comparison of the Ti-62A alloy with the Ti-62222S alloy under the same thermo-mechanical processing conditions showed that their properties are at the same level.]]>

On the mechanism of hot deformation

[J].

A New Optimization Method of Constitutive Equation for Hot Working Based on Physical Simulation and Numerical Simulation

[C]//

Mathematical modeling for high temperature flow behavior of as-cast Ti-45Al-8.5 Nb-(W, B, Y) alloy

[J].

Modeling and optimization of general constitutive equation of semi-solid thixoforming

[J].

Constitutive equations to predict high temperature flow stress in a Ti-modified austenitic stainless steel

[J].

Constitutive modeling for elevated temperature flow behavior of 42CrMo steel

[J].

Prediction of flow stress of Mg-Nd-Zn-Zr alloy during hot compression

[J].Isothermal hot compression tests were carried out on Mg-3.0Nd-0.2Zn-0.4Zr ( mass fraction, %, NZ30K) alloy using a Gleeble-3500 thermo-simulation machine at temperatures ranging from 350 to 500 C and strain rates from 0.001 to 1 s(-1). A correction of flow stress for deformation heating at a high strain rate was carried out. Based on the corrected data for deformation heating, a hyperbolic sine constitutive equation was established. The constants in the constitutive equation of the hyperbolic sine form were determined as a function of strain. The flow stresses predicted by the developed equation agree well with the experimental results, which confirms that the developed constitutive equations can be used to predict the flow stress of NZ30K alloy during hot deformation.

Investigation of microstructure evolution and thermal deformation behavior of TC11 titanium alloy

[D].

TC11钛合金热变形行为及其组织演变规律的研究

[D].

Hot Deformation Behavior and Processing Map of Titanium Alloy TC21

[D].

TC21钛合金热态变形行为及加工图

[D].

Studies on High Temperature Deformation Mechanics Behavior of Ti-6Al-2Sn Alloy

[D].

Ti-6Al-2Sn钛合金高温变形力学行为研究

[D].

High temperature compression deformation behavior and microstructure evolution of TC4 titanium alloy

[J].

TC4钛合金高温压缩变形行为与组织演变

[J].

Constitutive equation for flow behavior of commercially pure titanium TA2 during hot deformation

[J].

工业纯钛TA2热变形过程的流变行为本构方程

[J].

Hot Deformation Behaviors and Processing Map of TA17 Titanium Alloy

[J].

TA17 钛合金热变形行为及加工图

[J].

Study on hot deformation behavior and processing map of TA15 titanium alloy

[J].

TA15钛合金热变形行为及加工图研究

[J].

Hot deformation behavior of TA15 titanium alloy for aerospace

[J].

航空用TA15钛合金热变形行为研究

[J].

Study on hot deformation behavior and microstructure evolution simulation of TB17 titanium alloy

[D].

TB17钛合金热变形行为及显微组织演变模拟研究

[D].

Study on Hot Deformation Behavior and Processing Map of a New β Titanium Alloy Based on Friction Correction

[D].

基于摩擦修正的新型β钛合金热变形行为与加工图研究

[D].