新型多功能ZnO基压敏陶瓷具有非线性系数高、响应时间快、漏电流小和制造成本低廉等优点,在电子通讯、集成电路等领域得到了广泛的应用[1,2,3,4]。ZnO基压敏陶瓷的非线性伏安特性,可归因于其晶界上背靠背的双肖特基势垒[5,6]。形成肖特基势垒的原因,是晶界受主态对施主载流子的俘获。因此,受主态和施主载流子的来源成为影响ZnO基压敏陶瓷非线性伏安特性的关键因素[7,8]。ZnO晶粒表面过量的吸附氧能引入界面态、降低载流子浓度,从而提高势垒高度和非线性特性[9]。Xiao等[10]研究了WO3掺杂对ZnO基压敏陶瓷电性能的影响,发现Bi2WO6相使材料具有优异的电性能。Zhou [11] 等的研究结果表明,Bi2WO6为Aurivillius相,由交替的钙钛矿状WO42-层和类似萤石的Bi2O22+块体组成[12,13]。基于这种结构,存在氧空位的Bi2WO6具有很高的离子电导率。因此,Bi2WO6可为晶界处吸附氧提供一个氧气传输通道,提高ZnO晶粒表面吸附氧的含量[10],从而提高ZnO基压敏陶瓷的非线性特性。

1 实验方法

实验用化学试剂有:ZnO(99.0%)、Bi2O3 (99.0%)、WO3 (99.0%)、Co2O3 (99.0%)、MnO2 (99.8%)和Sb2O3(99.0%)。先将Bi2O3和WO3按1:1的摩尔比混合,以去离子水为介质球磨8h,在80℃烘干后在马弗炉中750℃煅烧2 h,得到预合成的Bi2WO6添加剂。将Bi2WO6添加剂与按照98 mol % ZnO+0.5 mol % Bi2O3+0.5 mol % Co2O3+0.5 mol % MnO2+0.5 mol % Sb2O3+x% Bi2WO6 (x=0, 1, 3, 5, 7, 9, mass %)的比例混合,然后将混合粉末放在球磨罐中球磨8 h,以去离子水为球磨介质。将球磨后的浆料在80℃烘干后造粒,将其在200 MPa压力下干压成型成直径为10 mm、厚度为1 mm的坯体。将坯体在550℃保温2 h排塑后,以3℃/min的速率升温到950℃,再以100℃/60min的速率升到1050℃保温3 h。将烧成后的陶瓷经打磨、抛光、被银电极,在600℃保温20 min得到接触良好的电极。

用XRD-7000X衍射仪分析样品的物相;用JSM-7610F型扫描电子显微镜观察样品的微观形貌。用Mendeslon线性截距法[15]测量样品的平均晶粒尺寸

非线性系数为

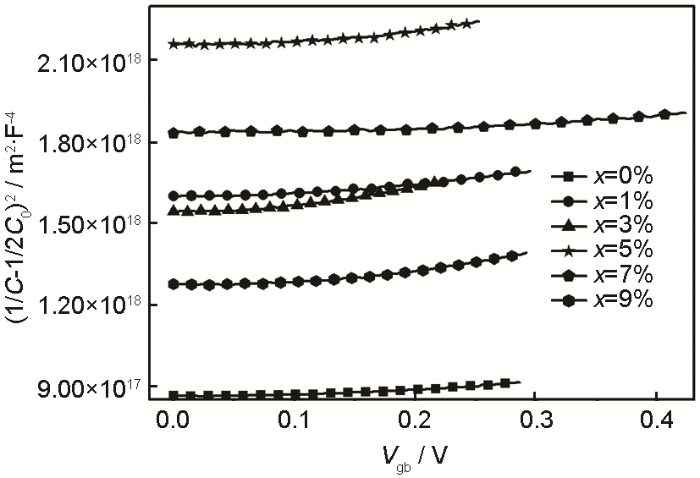

其中d为样品厚度。使用Agilent 4294A型精密阻抗分析仪测量试样在不同偏压下的室温电容(频率为1 kHz),然后绘制出(1/C-1/2C0)2-Vgb关系曲线。晶界势垒高度φb和施主浓度Nd [16]分别为

和

其中b为(1/C-1/2C0)2-Vgb关系曲线的截距,k为(1/C-1/2C0)2-Vgb关系曲线的斜率,s为银电极面积。界面态密度Ns和耗尽层宽度[16]分别为

和

使用Agilent 4294A型精密阻抗分析仪测试压敏陶瓷的室温介电性能,测试频率范围为102~106 Hz。

2 结果和讨论

2.1 物相分析

图1给出了不同Bi2WO6添加量的ZnO基压敏陶瓷的XRD衍射图谱。可以看出,ZnO相(PDF 36-1451)有明显尖锐的衍射峰,是陶瓷的主晶相,第二相的组成包括焦绿石相Bi3Sb3Zn2O14(PDF 52-0114)、尖晶石相Zn7Sb2O12(JCPDS 15-0687)、Bi-rich相、Bi2O3相(JCPDS 51-1161)、Bi2WO6相 (JCPDS 36-0100)、Bi2Mn4O10相(PDF 27-0048)、Co16Bi10O38 相 (PDF 39-1010)和Sb2Co相(PDF 29-0126)。其中Bi2WO6相的出现取决于W6+的含量(质量分数)。如图1所示,当x<5%时,没有检测到关于W6+的相。其原因是,Bi2WO6较少,大部分W6+进入Bi2O3中形成了Bi-rich相[17]。添加量达到5%时,出现了Bi2WO6相。x进一步增加到7%和9%时,Bi2WO6相的峰值增强且出现了新的Bi-rich相衍射峰。这表明,随着Bi2WO6添加量的增加一部分Bi3+和W6+形成了Bi2WO6[13],其余的则溶于Bi2O3中形成了固溶体。另外还可以发现,添加Bi2WO6后焦绿石相Bi3Sb3Zn2O14消失,出现了Bi-rich相且Zn7Sb2O12相峰值增强。其原因可能是,其半径比Bi3+半径小的W6+很容易进入Bi3Sb3Zn2O14晶格而使Bi3Sb3Zn2O14 晶格畸变和稳定性的降低,促进其分解且与ZnO生成Zn7Sb2O12相[17]。当添加量达到5%时Co16Bi10O38相转变为Bi-rich相,表明大部分Co3+进入Bi2O3中形成了固溶体 [18]。

图1

图1

不同Bi2WO6含量样品的XRD图谱

Fig.1

XRD patterns of samples with different Bi2WO6 contents

2.2 微观结构

图2给出了不同Bi2WO6添加量的ZnO基压敏陶瓷的SEM照片,可观察到所有样品中清晰的晶粒和晶界,并发现其微观结构致密。根据图2可计算出样品的平均晶粒尺寸,列于表1。表1表明,随着Bi2WO6添加量的增加平均晶粒尺寸首先从5.86 μm减小到4.42 μm,然后增加到8.46 μm,最后减小到6.22 μm。这表明,Bi2WO6的添加影响了ZnO基压敏陶瓷晶粒的生长。根据对XRD的分析,当Bi2WO6的添加量为1%时,在Bi2WO6的作用下Bi3Sb3Zn2O14分解并与ZnO发生反应生成Zn7Sb2O12。Zn7Sb2O12钉扎在晶界处,阻碍了ZnO晶粒的生长[19],因此晶粒尺寸略微减小。随着Bi2WO6的进一步添加出现了新的Bi-rich相,使Bi-rich液相含量明显提高,对ZnO压敏陶瓷的助烧作用随之提高,使ZnO晶粒的尺寸增大[17]。而当添加量过高(x=9%)时形成过多的Bi2WO6相,在晶界处析出且覆盖在ZnO晶粒上,阻碍了晶粒的生长。这些结果,与XRD的分析吻合。

图2

图2

不同含量Bi2WO6样品的SEM照片

Fig.2

SEM jmages of the samples with different Bi2WO6 contents (a) x=0%, (b) x=1%, (c) x=3%, (d) x=5%, (e) x=7%, (f) x=9%

表1 ZnO基压敏陶瓷的宏观电性能参数

Table 1

| Bi2WO6/% | d/μm | E1 mA/V·mm-1 | Vgb/V | α | JL/μA·cm-2 |

|---|---|---|---|---|---|

| 0 | 5.86 | 291 | 1.71 | 44 | 1.01 |

| 1 | 4.00 | 397 | 1.59 | 37 | 20.64 |

| 3 | 5.39 | 365 | 1.97 | 15 | 41.26 |

| 5 | 5.68 | 312 | 1.77 | 45 | 10.93 |

| 7 | 8.46 | 263 | 2.22 | 53 | 3.50 |

| 9 | 5.83 | 298 | 1.74 | 28 | 11.37 |

2.3 电学性能

2.3.1 宏观电学性能

表1列出了不同Bi2WO6添加量ZnO基压敏陶瓷的电性能参数。可以看出,压敏场强E1 mA先从291 V/mm增加到397 V/mm,然后下降到263 V/mm,最后增加到298 V/mm。根据公式(2),压敏场强E1 mA与平均晶界电压Vgb呈正比,与平均晶粒尺寸成反比,说明E1 mA的变化主要是平均晶粒尺寸的变化引起的,与图2 SEM照片中晶粒尺寸的变化一致。另外,非线性系数α随着添加量的不断增加,先从44减小到15,x=7%时取得最大值53,然后又减小到28。非线性系数主要受晶界势垒高度的影响,结合XRD分析可知,添加量到达7%时W6+溶入Bi2O3生成Bi2WO6相,增加了ZnO晶粒表面的吸附氧含量,提高了界面态密度和晶界势垒高度。但是,当添加量进一步增加到9%时生成了较多的Bi2WO6相和Bi-rich相,其在晶界处析出且覆盖在ZnO晶粒表面,降低了界面态密度和晶界势垒高度,使非线性系数下降。对压敏性能参数的分析表明,x=7%时出现了最大的非线性系数和相对较小的漏电流,说明其为压敏陶瓷的最佳添加量。根据Nahm [20]等的分析,高非线性导致低漏电流的原因是产生了相对较高的隧道电流,而低非线性导致高漏电流的原因是产生了较高的热激发射电流。

图3给出了ZnO基压敏陶瓷的电流-电压曲线,曲线预击穿区与击穿区拐点的尖锐程度代表非线性性能的好坏,拐点越尖锐非线性性能越好,拐点位置对应的x轴坐标值越小说明该组分下的压敏场强越小。从图中可见,添加量为x=7%的压敏陶瓷具有最高的非线性系数和最小的压敏场强。

图3

图3

ZnO基压敏陶瓷的电流-电压(E-J)曲线

Fig.3

current-voltage (E-J) curve of ZnO varistor ceramics

2.3.2 微观电学性能

根据陶瓷在不同偏压下的电容绘制了如图4所示的(1/C-1/2C0)2-Vgb关系曲线,并计算出各样品的晶界势垒高度(φb),施主浓度(Nd),界面态密度(Ns)和耗尽层宽度(t),列于表2。根据公式(4)~(7),晶界势垒高度(φb)分别与施主浓度(Nd)的减小和界面态密度(Ns)平方的增加呈正比。随着添加量的增加晶界势垒高度(φb)首先从4.97 eV下降到3.45 eV,因为施主浓度(Nd)从12.04×1024m-3下降到8.26×1024m-3。当添加量为x=7%时界面态密度(Ns)达到最大,晶界势垒高度(φb)达到极值11.52 eV,与非线性系数α相对应[21]。由于该添加量下出现的Bi2WO6相具有很高的离子电导率,为吸附氧提供了一个氧气传输通道。由于供给和吸附的氧越多在晶界区域形成的陷阱也就越多,因此提高了界面态密度(Ns)的值。随着添加量增加到x=9%,施主浓度(Nd)和界面态密度(Ns)分别减小到5.81×1024m-3和1.32×1017m-2。其原因是,过多的添加导致Bi2WO6相和Bi-rich相增多,使界面态密度和势垒高度降低。对电学性能的参数综合分析表明,添加量为x=7%可以得到电性能较高的ZnO基压敏陶瓷:E1mA=263 V/mm,α=53,JL=3.50 μA/cm2,φb=11.52 eV。

图4

图4

ZnO基压敏陶瓷的(1/C-1/2C0)2-Vgb关系曲线

Fig.4

(1/C-1/2C0)2-Vgb relation curve of ZnO varistor ceramics

表2 ZnO基压敏陶瓷的微观电性能参数

Table 2

| Bi2WO6/% | Nd/1025·m-3 | Ns/1017·m-2 | φb/eV | t/10-8m |

|---|---|---|---|---|

| 0 | 1.204 | 2.37 | 4.97 | 1.97 |

| 1 | 0.83 | 1.64 | 3.45 | 1.98 |

| 3 | 0.82 | 1.51 | 2.94 | 1.84 |

| 5 | 0.80 | 2.24 | 6.67 | 2.8 |

| 7 | 0.59 | 2.52 | 11.52 | 4.3 |

| 9 | 0.58 | 1.32 | 3.18 | 2.27 |

晶界区的缺陷结构和成分分布,是影响ZnO压敏电阻电性能的主要因素[22]。没有添加时第二相主要为Bi-rich相,由于氧空位的存在以及晶格氧的明显迁移,Bi-rich相具有明显的离子电导率,为晶界吸附氧的运输提供了途径。x<7%时,由于Bi2O3具有非常开放的结构,可以容纳不同的杂质离子,因此W6+进入Bi2O3中形成固溶体[23,24,25]。在这个过程中W6+作为施主提高了晶界区域的电子浓度。除了施主效应[14],溶解W6+还降低了氧空位、削弱了氧气的传输和降低了晶界处吸附氧的数量。吸附氧含量的减少,使晶界处作为载流子的电子增多了。晶界捕获电子的能力下降以及电子容易穿过晶界,表明势垒高度的降低,电子穿过势垒所需的电压也随之降低。

当x=7%时,Bi2WO6含量增多使多余的W6+留在晶界处形成了Bi2WO6晶相。Bi2WO6相具有较高的离子电导率,增强了氧转移和吸附氧富集在晶界,从而提高了界面态密度和势垒高度,使ZnO基压敏陶瓷具有良好的非线性性能。

当x>7%时,Bi2WO6过多的添加使Bi2WO6相以及Bi-rich相增多并在晶界处析出,覆盖在ZnO晶粒表面破坏了原始的晶界组分,产生的缺陷和完整晶界的破坏使ZnO晶粒间的肖特基势垒降低,导致非线性系数减小。

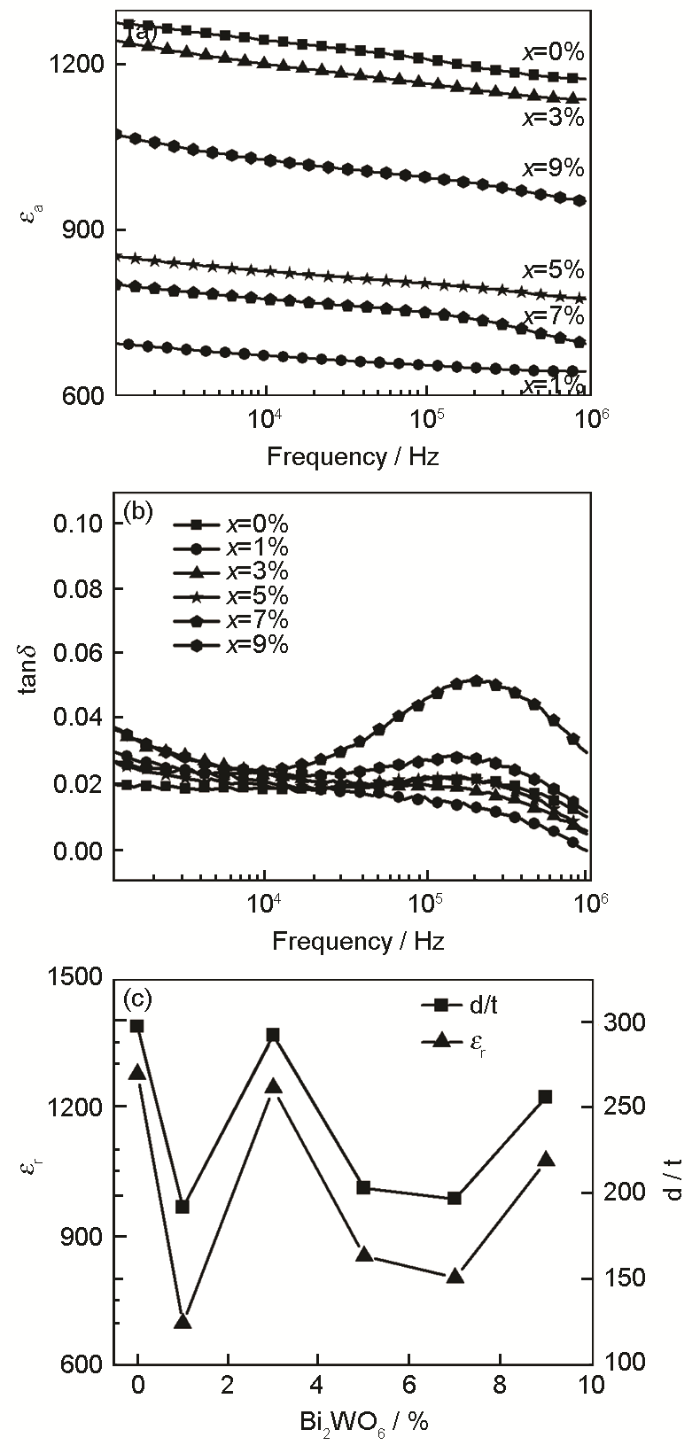

2.4 介电性能

图5给出了样品的室温介电性能与Bi2WO6含量的关系。可以看出,所有样品的介电常数均随着频率的增加而逐渐减小,考虑到电介质的极化,这可能归因于导电载流子的减少[27]。另外还发现,添加Bi2WO6使样品的介电常数εr均减小了。介电常数受晶粒尺寸、耗尽层宽度以及烧结条件的影响,并且与晶粒尺寸成正比,与耗尽层宽度成反比,即εr∝d/t[27]。因此,取1 kHz下各组分的介电常数对比各组分晶粒尺寸与耗尽层宽度t的比值,如图5c所示,随着Bi2WO6含量的提高εr∝d/t,与理论结果一致。另外,当频率提高到105 Hz时添加量为7%的样品介电常数下降速率明显加大,可与图5b中该频率下损耗峰的出现相对应。而其余样品在频率高于105 Hz时下降仍旧缓慢,且损耗峰不明显。介电损耗,主要包括漏电流的焦耳热和电偶极子旋转的摩擦热[28]。当添加量为x=1%时样品的损耗最低,与表1中各样品的漏电流相对比可知,介电损耗的减小主要取决于电偶极子旋转摩擦热的降低。根据总的结果,x=1%的样品具有较低的损耗,陶瓷稳定性较好。

图5

图5

压敏陶瓷的介电性能

Fig.5

Dielectric properties of varistor ceramics (a) change of dielectric constant with frequency, (b) change of dissipation factor with frequency, (c) the relationship between of εr and d/t

3 结论

(1) 添加Bi2WO6能改善ZnO基压敏陶瓷的微观结构,提高非线性特性。添加量为7%的压敏陶瓷综合性能最优异:非线性系数α=53,压敏场强E1 mA=263 V/mm,泄漏电流JL=3.5 μA/cm2。

(2) 添加Bi2WO6可提高ZnO压敏陶瓷晶界处氧的含量,因为Bi2WO6相在晶界处具有较高的离子电导率,增强氧转移并使吸附氧富集在晶界。x=7%时界面态密度提高到Ns=2.52×1017/m2,晶界势垒达到极值φb=11.52 eV。

(3) 添加Bi2WO6对ZnO压敏陶瓷的介电性能有一定的影响。f=1 kHz时介电常数的变化趋势与d/t的比值变化相一致,且x=1%的样品具有较低的损耗,陶瓷稳定性较好。

参考文献

Application of Zinc-Oxide varistors

[J].Double Schottky barriers in ZnO are modified piezotronically by the application of mechanical stresses. New effects such as the enhancement of the potential barrier height and the increase or decrease of the natural barrier asymmetry are presented. Also, an extended model for the piezotronic modification of double Schottky barriers is given.

Mn ion valence change and ZnO varistor ceramics V-I nonlinear character

[J].

Mn离子的价态变化与ZnO压敏陶瓷的V-I非线性

[J].

Soft core phenomenon of ZnO varistors doped with rare-earth oxides

[J].

掺杂稀土氧化物的ZnO-Bi2O3系压敏陶瓷的“软心”

[J].

Theory of conduction in ZnO varistors

[J].

Grain boundary interface electron traps in commercial zinc oxide varistors

[J].

V-I nonlinear and negative temperature coefficient of ZnO/Co2O3 base unit material of sensitive resistance

[J].

ZnO/Co2O3敏感电阻单元材料V-I非线性及NTC效应

[J].

Influence of defects on the electronic structure of zinc oxide surfaces

[J].Zinc oxide (ZnO) is a widely utilized, versatile material implemented in a diverse range of technological applications, particularly in optoelectronic devices, where its inherent transparency, tunable electronic properties, and accessible nanostructures can be combined to confer superior device properties. ZnO is a complex material with a rich and intricate defect chemistry, and its properties can be extremely sensitive to processing methods and conditions; consequently, surface modification of ZnO using both inorganic and organic species has been explored to control and regulate its surface properties, particularly at heterointerfaces in electronic devices. Here, the properties of ZnO are described in detail, particularly its surface chemistry, along with the role of defects in governing its electronic properties, and methods employed to modulate the behavior of as-grown ZnO. An outline is also given on how the native and modified oxide interact with molecular materials. To illustrate the diverse range of surface modification methods and their subsequent influence on electronic properties, a comprehensive review of the modification of ZnO surfaces at molecular interfaces in hybrid photovoltaic (hPV) and organic photovoltaic (OPV) devices is presented. This is a case study rather than a progress report, aiming to highlight the progress made toward controlling and altering the surface properties of ZnO, and to bring attention to the ways in which this may be achieved by using various interfacial modifiers (IMs).

Influence of Bi-Co-O synthetic multi-phase on electrical properties of the ZnO-Bi2O3-MnO2-SiO2 varistors

[J].

Influence of WO3-Doping on the microstructure and electrical properties of ZnO-Bi2O3 varistor ceramics sintered at 950℃

[J].

Defect fluorite superstructures in the Bi2O3-WO3 system

[J].

Detecting different oxygen-ion jump pathways in Bi2WO6 with 1and 2- dimensional 17O MAS NMR spectroscopy

[J].

Electron microscopy analyses and electrical properties of the layered Bi2WO6 phase

[J].

Influences of Ba/Ti ratios on the positive temperature coefficient of resistivity effect of Y-doped BaTiO3-(Bi1/2Na1/2)TiO3 ceramics

[J].

Lineal intercept technique for measuring grain size in two-phase polycrystalline ceramics

[J].

Effect of a Bi-Cr-O synthetic multi-phase on the microstructure and electrical properties of ZnO-Bi2O3 varistor ceramics

[J].

Phase transformation and electrical properties of Bi2O3-based ZnO varistor doped with WO3

[J].

The study on low temperature preparation and properties and Zn-Bi based varistor ceramics

[D].

Zn-Bi系压敏陶瓷的低温制备及性能研究

[D].

High voltage ZnO varistor ceramics doped with Sb2O3, SiO2 and MgO

[J].

Sb2O3, SiO2和MgO 复合掺杂的高梯度氧化锌压敏陶瓷材料

[J].

Microstructure and electrical properties of Y2O3-doped ZnO-Pr6O11-based varistor ceramics

[J].

Microstructures and electrical properties of V2O5-doped ZnO-Bi2O3-Co2O3-MnCO3-TiO2 low voltage varistor ceramics

[J].

V2O5掺杂ZnO-Bi2O3-Co2O3-MnCO3-TiO2低压压敏陶瓷的微结构和电性能

[J].

Effect of antimony oxide stoichiometry on the nonlinearity of Zinc Oxide varistor ceramics

[J].

Oxide ion conducting solid electrolytes based on Bi2O3

[J].

The roles played by Ag and Al dopants in controlling the electrical properties of ZnO varistors

[J].

Influence of SiO2 on electrical properties of the highly nonlinear ZnO-Bi2O3-MnO2 varistors

[J].

Sintering temperature dependence of grain boundary resistivity in a rare-earth-Doped ZnO varistor

[J].

Effect of sintering temperature on varistor properties and aging characteristics of ZnO-V2O5-MnO2 ceramics

[J].