目前国外已将TA18管材用于制造飞机液压和燃油管路系统,但是有关其制备工艺的文献较少。近年来,中国已经开展了有关TA18管材冷轧变形量和塑性变形行为和性能的研究[7~9]。陈逸等[9]的研究结果表明,在冷轧过程中TA18管材的变形机制为滑移变形,随着变形量的增大滑移方式逐渐由{10

1 实验方法

1.1 TA18管材的冷轧

实验用再结晶退火温度和初始织构相同的中间规格TA18管材的化学成分(质量分数,%)为:Al 2.5~3.5、V 2.0~3.0、Fe 0.11~0.16、O 0.06~0.10,余量为Ti。对TA18管材进行5种Q值分别为1.1、1.4、1.6、1.8和2.0的冷轧,其道次变形量约为60%。

1.2 测试试样晶粒取向和织构

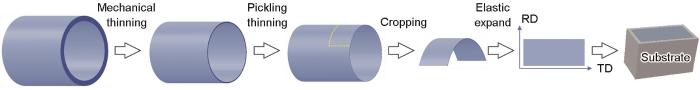

用展平法制备测试晶粒取向和织构的试样,其流程如图1所示。先沿着管材的壁厚方向将其机械减薄至约0.2 mm,减薄时取中层位置;然后将试样置于混合酸液中化学减薄成厚度为0.02~0.04 mm的环形薄片;再将环形薄片裁剪和展平后粘接在衬底上进行机械抛光。展平时薄片失去刚性,因此不影响管材的原有织构;最后,对试样进行氩离子抛光。使用HF + HNO3 + H2O混合酸液(体积分数比为1∶2∶5)进行化学减薄。

图1

用场发射扫描电镜(Zeiss Sigma HD)配套牛津EBSD仪器测试试样的晶粒取向和织构。RD、TD、ND分别代表管材轴向、切向和法向,试样的测试面为RD-TD平面。测试织构时的放大倍数为300倍,步长为1。测试晶粒取向的放大倍数为1000倍,步长0.4。使用HKL Channel 5和Aztec Crystal软件将取向成像图、局部取向差图、极图、取向分布函数(ODF)等信息处理后导出。

1.3 测定滑移系的启动

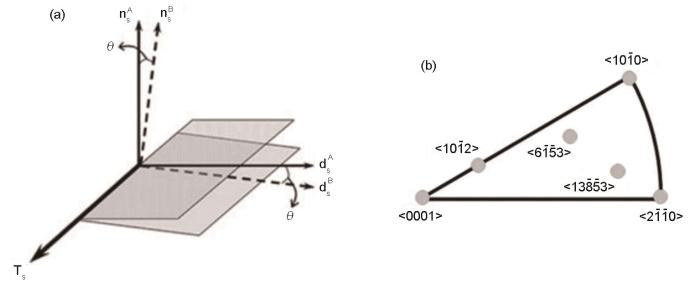

用晶粒内部取向差转轴法(In-Grain Misorientation Axes, IGMA)测定滑移系的启动[16]。晶粒内部取向差转轴法假设:(1) 晶格在滑移变形作用下弯曲;(2) 晶格滑移时绕着Taylor轴弯曲,且晶面围绕Taylor轴旋转。(3) Taylor轴为低指数的晶体学方向,位于滑移面内且与滑移方向垂直。Taylor轴公式为

其中Ts,ns和ds分别为某一滑移系的Taylor轴,滑移面的法向为滑移方向。

基于这些假设,将冷轧变形获得的Taylor轴方向与理想滑移系的Taylor轴方向对比,可得冷轧变形晶粒内主导变形的滑移系。

图2

表1 钛合金中滑移系的Taylor轴分布[16]

Table 1

| Slip system | Number of variants | Taylor axis | Number of Taylor axis variants |

|---|---|---|---|

| {01 | 3 | <0001> | 1 |

| {0001}< | 3 | <0 | 3 |

| {01 | 6 | <0 | 6 |

| {01 | 12 | <13 | 12 |

| {1 | 12 | <6 | 12 |

| {11 | 6 | <1 | 3 |

1.4 对织构的定量描述

钛、锆合金的{0002}、{10

式中N为扫描过的晶粒数目,

2 实验结果

2.1 不同 Q 值冷轧管材的显微组织

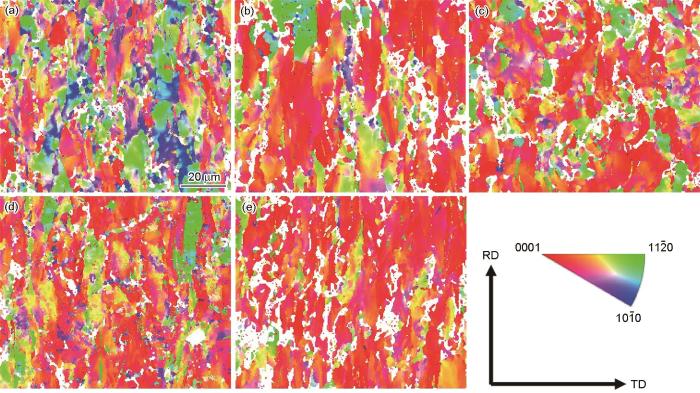

图3~5给出了不同Q值冷轧管材的反极图(IPF)、平均取向差(KAM)以及KAM分布。从图3可以看出,对原始管材进行相同变形量、不同Q值冷轧后,RD-TD平面内的显微组织沿RD方向呈现“河流状”分布,表现出大塑性变形的典型特征。冷轧Q值为1.1时,管材表现为沿RD-TD平面基面织构,IPF图中的晶粒取向分布用红、绿、蓝3种颜色表示,除了<0001>//ND方向,<10

图3

图3

不同Q值冷轧管材的IPF图

Fig.3

IPF map of cold rolled tubes with different Q ratios (a) Q = 1.1, (b) Q = 1.4, (c) Q = 1.6, (d) Q = 1.8, (e) Q = 2.0

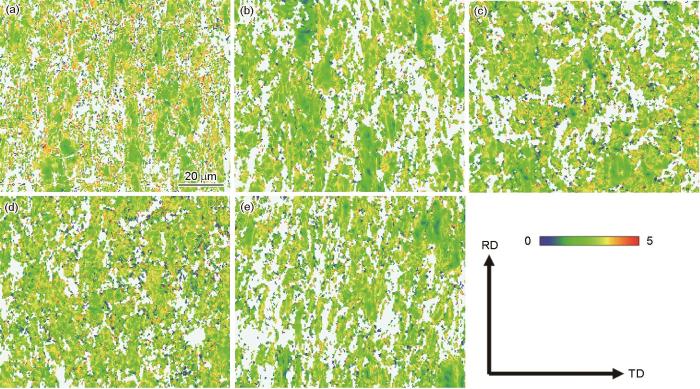

图4

图4

不同Q值冷轧管材的KAM图

Fig.4

KAM map of cold rolled tubes with different Q ratios (a) Q = 1.1, (b) Q = 1.4, (c) Q = 1.6, (d) Q = 1.8, (e) Q = 2.0

图5

图5

不同Q值冷轧管材的KAM分布

Fig.5

KAM distribution of cold rolled tubes with different Q ratios (a) Q = 1.1, (b) Q = 1.4, (c) Q = 1.6, (d) Q = 1.8, (e) Q = 2.0

2.2 不同 Q 值冷轧管材的微观织构

图6给出了不同Q值冷轧管材的{0001}、{10

图6

图6

冷轧管材的{0001}、{10

Fig.6

{0001}、{10

2.3 不同 Q 值冷轧管材的收缩应变比(CSR)

CSR值是变形管材的真周向应变与真径向应变的比值,表征钛、锆等HCP金属的各向异性。因此,TA18管材的CSR值与冷轧Q值和织构的控制有密切的关系。CSR值较小,表示晶粒取向主要沿管材的切向,织构以切向为主,管材的扩口和压扁等工艺性能较好;CSR值较大,表示晶粒取向主要沿管材的径向,织构以径向为主,管材抵抗壁厚方向的变形能力较强,材料的力学性能良好。航空高强级TA18管材的力学性能优异,其CSR值一般为1.3~2.5。图7给出了不同Q值对应的冷轧管材CSR值。Q为1.1~1.4时,CSR为0.75~1.16 (< 1.3),不满足航空TA18管材的CSR指标(1.3~2.5)要求;Q为1.6~2.0时,CSR为1.44~2.0 (> 1.3),满足航空TA18管材CSR指标要求。CSR与Q值之间关系,可表示为拟合方程CSR = -0.775 + 1.389Q。可以看出,Q值与冷轧管材CSR的关系是线性的。随着Q值的增大,CSR值随之线性地增大。其原因是,Q值越大则管材Rw与RD的比值越大,在冷轧变形过程中径向应力增大则晶粒的c轴向径向方向偏移,使管材的径向织构增强。而CSR值表征材料抵抗变形的能力,织构呈径向分布时材料抵抗变形的能力越强,故而CSR值越大。根据CSR与Q值之间的线性关系,为了满足航空TA18管材CSR指标要求,管材冷轧的Q值应该不小于1.49。

图7

3 讨论

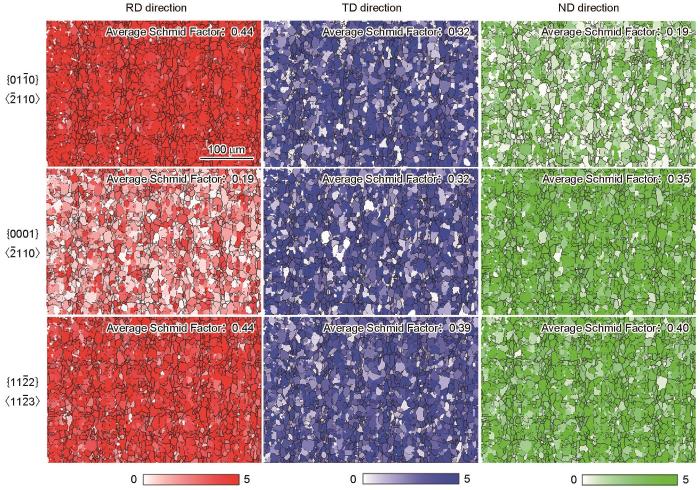

3.1 退火管材的Schmid因子

钛、锆合金管材冷轧时受到三向应力的作用,因此其应力应变行为较为复杂。为了研究管材冷轧变形过程中各滑移系启动的难易程度,统计了与原始管坯冷轧工艺(变形量、Q值)相近的退火管材在RD、TD和ND加载条件下各滑移系的平均Schmid因子(Schmid Factor,SF),如图8所示。在RD方向加载变形时,{01

图8

3.2 不同 Q 值冷轧TA18管材的塑性变形机制

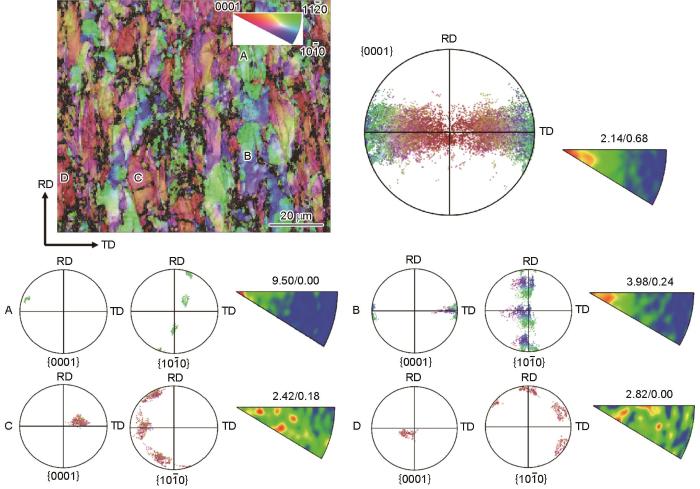

3.2.1 Q = 1.1冷轧管材的IGMA分布

图9给出了Q = 1.1冷轧TA18管材的IGMA分布。从IPF图中全部晶粒的IGMA分布可见,Taylor轴位于<0001>轴附近,IGMA分布较为集中,且密度强度2.14 > 2。这表明,Q = 1.1时冷轧变形以{01

图9

图9

Q = 1.1冷轧管材的IGMA分布

Fig.9

IGMA distribution of cold-rolled tubes with Q = 1.1

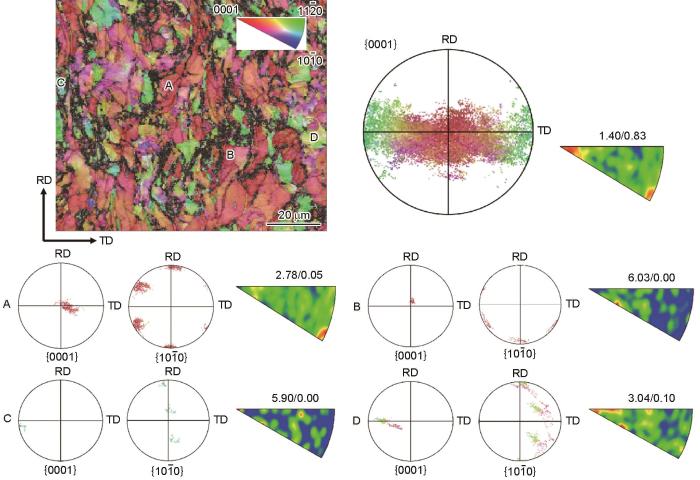

3.2.2 Q = 1.6冷轧管材的IGMA分布

图10给出了Q = 1.6冷轧TA18管材的IGMA分布。从IPF可见,IGMA分布比Q = 1.1时散漫,但是主要分布在<0001>和<0

图10

图10

Q = 1.6冷轧管材的IGMA分布

Fig.10

IGMA distribution of cold-rolled tubes with Q = 1.6

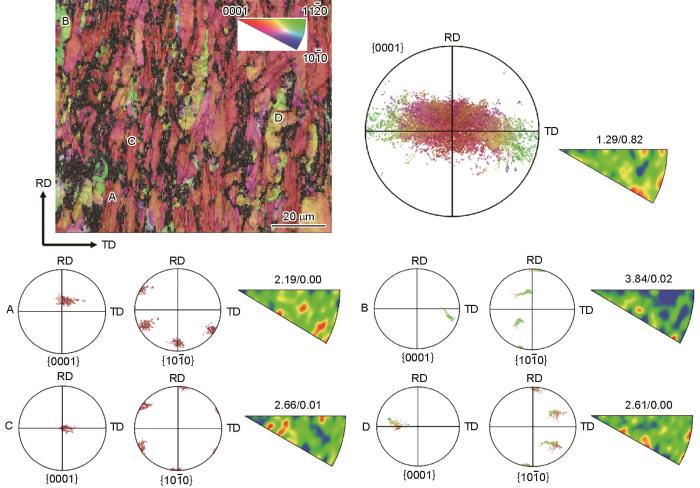

3.2.3 Q = 2.0冷轧管材的IGMA分布

图11给出了Q = 2.0冷轧管材的IGMA分布。从IPF图中全部晶粒的IGMA分布可见,IGMA进一步散漫分布,但是主要分布在<0

图11

图11

Q = 2.0冷轧管材的IGMA分布

Fig.11

IGMA distribution of cold-rolled tubes with Q = 2.0

3.2.4 不同Q值冷轧管材的塑性变形机制

不同Q值冷轧管材的塑性变形机制,列于表2。Q = 1.1时IGMA分布在<0001>轴,主导滑移系为{01

表2 不同Q值冷轧管材的塑性变形机制

Table 2

| Q | Taylor axes | Main slip systems | Slip mechanisms | Kearns factor |

|---|---|---|---|---|

| 1.1 | <0001> | {01 | Prismatic<a> slip | Fn, Ft, Fr |

| 1.4 | <0001> | {01 | Prismatic<a> slip | Fn↑, Ft↓, Fr↑ |

| 1.6 | <0001> and <0 | {01 | Prismatic<a> slip + Pyramidal<c + a>slip | Fn↑, Ft↓, Fr |

| 1.8 | <0001> and <0 | {01 | Prismatic<a> slip + Pyramidal<c + a>slip | Fn↑, Ft↓, Fr |

| 2.0 | <0 | {11 | Pyramidal<c + a>slip | Fn↑, Ft↓, Fr |

3.2.5 不同Q值冷轧TA18管材织构的演变

Bunge提出的HCP金属取向分布函数(ODF)中的Euler角(

晶面(h1k1l1)与(h2k2l2)之间夹角

将不同Q值冷轧TA18管材的峰值Euler角(

表3 TA18管材的主织构组分

Table 3

| Q ratio | Euler ( | Main texture component | Angle with (0002) surface / (°) |

|---|---|---|---|

| 1.1 | (87, 82, 5) | ( | 81 |

| 1.4 | (92, 32, 55) | (11 | 28 |

| 1.6 | (80, 31, 5) | (11 | 28 |

| 1.8 | (81, 25, 5) | (11 | 28 |

| 2.0 | (88, 31, 60) | (11 | 28 |

结合上述不同Q值冷轧管材织构的分布特征,图12给出了不同Q值冷轧管材织构的演变示意图。如图12a所示,冷轧Q值从1.1增大到2.0,{0001}基面切向织构逐渐演变为基面径向织构且呈现出双峰分布特征。反极图中RD方向上由<10

图12

图12

不同Q值冷轧管材的织构演变示意图

Fig.12

Schematic diagram of texture evolution of cold-rolled tubes with different Q ratios (a) texture evolution in basal and RD directions, (b) grain orientation evolution

4 结论

(1) 随着冷轧Q值的增大,TA18管材中晶粒的IGMA分布由<0001>转变为<10

(2) 随着冷轧Q值的增大,TA18管材的<0001>//ND型织构逐渐取代<0001>//TD型织构,使基面径向织构增强。CSR与Q值的拟合方程为CSR = -0.775 + 1.389Q。

(3) 在TA18管材的冷轧过程中,主织构和次织构共同影响其Kearns系数。Q值接近1时晶粒取向以主织构演变为主,Q值增大到1.4则以次织构演变为主。

(4) 冷轧Q值协同影响TA18管材的塑性变形机制和织构演变。Q值较小时冷轧变形以柱面滑移为主,有利于获得基面切向织构;Q值较大时冷轧变形以锥面滑移为主,有利于产生基面径向织构。

参考文献

Residual stress evolution and tailoring of cold pilgered Ti-3Al-2.5V tube

[J].

Texture development of Ti-3Al-2.5V titanium alloy tubes

[J].

Deformation-based joining for high-strength Ti-3Al-2.5V tubular fittings based on internal roller swaging

[J].

Effect of texture on circumferential tensile properties of TA18 titanium alloy tubing

[J].

TA18钛合金管材织构对环向拉伸性能的影响

[J].

An overview on application status and processing technology development of titanium alloy

[J].

钛合金的应用现状及加工技术发展概况

[J].

Crack growth life of Ti-3Al-2.5V tubes under internal impulse pressure

[J].

Rolling process of high-strength TA18 titanium alloy tubes for aviation

[J].

航空用高强TA18钛合金管材的轧制工艺

[J].

Study on processing technology of TA18 titanium tubes for aviation

[J].

航空用TA18管材加工工艺研究

[J].

Investigation of the microstructure and texture of TA18 tubes during cold-rolling process

[J].

冷轧TA18管材变形过程中微观组织及织构

[J].

A miniature physical simulator for pilgering

[J].

Three-dimensional microstructure and texture evolution of Ti35 alloy applied in nuclear industry during plastic deformation at various temperatures

[J].

Evolution of microstructure and texture of a near α titanium alloy during forging bar into disk

[J].

Performance evaluation and control methods of high strength TA18 alloy tube

[J].

高强度TA18合金管材性能评价与控制方法研究

[J].

Texture evolution and controlling of high-strength titanium alloy tube in cold pilgering for properties tailoring

[J].

Effect of ‘Q’ ratio on texture evolution of Ti-3Al-2.5V alloy tube during rolling

[J].

Distribution characteristics of in-grain misorientation axes in cold-rolled commercially pure titanium and their correlation with active slip modes

[J].

On the relationship among `f' texture factors for the principal planes of zirconium, hafnium and titanium alloys

[J].

EBSD analysis of the distribution of in-grain misorientation axes in cold-rolled Zr alloy

[J].

冷轧锆合金晶粒内取向差轴分布规律的EBSD研究

[J].

Evolution of microstructure and texture of pure zirconium during rolling process

[J].

纯锆轧制过程中的组织与织构演变规律

[J].