微电子探测用的电磁波使雷达探测和武器装备系统中的电子设备失灵,也可能使飞机操作系统的性能不稳定。因此,使用性能优异的吸波材料使各种装备“隐身”,是目前军事领域的研究热点。吸波材料将电磁波转化为其他形式的能量,从而降低雷达探测的概率[1]。

一些碳材料和导电高分子材料受到了关注,但是其制备工艺复杂和价格较高[2]。一些铁磁性吸收剂(如羰基铁粉)对低频电磁波的吸波性能较好,但是其比重较大和耐温性能较低[3]。一些氧化物基吸波材料的成本低、耐高温和耐腐蚀,得到了广泛的应用[4,5]。离子掺杂使钙钛矿铁氧体的反铁磁性(AFM)与铁磁性(FM)相互转变。但是对其电磁损耗的机理尚不清楚。钙钛矿ABO3,由A位离子半径较大的稀土元素和B位离子半径较小的过渡金属组成。稀土正铁氧体(RFeO3)具有扭曲的钙钛矿结构,六个O2-阴离子形成八面体结构(FeO6),铁离子位于中心,稀土阳离子(R)与十二个O2-与FeO6结构之间的阴离子配位。稀土元素的加入,显著影响RFeO3的结构和磁性[6]。钙钛矿材料的结构受元素离子半径的影响,稳定的钙钛矿结构须满足Goldschmidt容忍度

此式可表征钙钛矿材料结构的对称性和稳定性[7],式中

1 实验方法

1.1 实验用材料和仪器设备

实验用材料(AR):六水合硝酸钇(Y(NO3)3·6H2O),九水合硝酸铁(Fe(NO3)3·9H2O),六水合硝酸镧(La(NO3)2·6H2O),一水合柠檬酸(C6H8O7·H2O)和去离子水。

实验用仪器设备:电子天平(PTT-A+100)、集热式恒温加热磁力搅拌器(DF-101S)、电热鼓风干燥箱(DHG101-1A)、高温烘箱(TDGW-2E)、高温箱式电阻炉(TCW-32B)以及高温智能马弗炉(GXL-05)。

1.2 用溶胶-凝胶法制备Y1-x La x FeO3

用溶胶-凝胶法制备Y1-x La x FeO3 (x = 0,0.1,0.2,0.3,0.4)陶瓷粉末样品的流程,如图1所示。

图1

图1

用溶胶-凝胶法制备Y1-x La x FeO3的工艺流程

Fig.1

Process of preparing Y1-x La x FeO3 by sol-gel method

将实验用原料Y(NO3)3·6H2O、Fe(NO3)3·9H2O、La(NO3)2·6H2O按Y1-x La x FeO3 (x = 0,0.1,0.2,0.3,0.4)的化学计量比配料,具体质量列于表1。将配料混合物溶于45 mL去离子水中,以柠檬酸为螯合剂将柠檬酸与金属硝酸盐按摩尔比1∶1混合。在搅拌条件下将柠檬酸缓慢加入金属硝酸盐溶液中,在100 ℃连续搅拌3 h得到湿凝胶。将湿凝胶在100 ℃的电热鼓风干燥箱中干燥2.5 h,得到干凝胶。将干凝胶在260 ℃高温烘箱(空气气氛)中自蔓延燃烧,得到前驱体。将前驱体研磨成粉末放入900℃高温箱式电阻炉中保温3 h,将得到的试样4.5 g倒入研钵,加入3~4滴PVA溶液研磨至均匀后压片。最后,将压片置于1500 ℃马弗炉在空气气氛中煅烧3 h,得到Y1-x La x FeO3陶瓷片。

表1 样品原料的质量

Table 1

| Sample | Y(NO3)3·6H2O / g | Fe(NO3)3·9H2O / g | La(NO3)2·6H2O / g | C6H8O7·H2O / g |

|---|---|---|---|---|

| x = 0 | 29.8 | 31.3 | 0 | 32.7 |

| x = 0.1 | 26.15 | 30.64 | 3.28 | 31.88 |

| x = 0.2 | 22.67 | 29.89 | 6.41 | 31.09 |

| x = 0.3 | 19.36 | 29.17 | 9.38 | 30.34 |

| x = 0.4 | 16.20 | 28.48 | 12.21 | 29.63 |

1.3 Y1-x La x FeO3 样品的表征

用TESCAN VEGA3型扫描电子显微镜(SEM)观察样品的形貌。用EDS进行元素分析。用Lab-XRD-7000S型X射线衍射仪测试XRD谱,Cu靶,扫描角度范围为20°~80°。扫描速度为10(°)/min。将制备的Y1-x La x FeO3 (x = 0,0.1,0.2,0.3,0.4)陶瓷片用砂纸打磨成长度为22.86 mm、宽度为10.16 mm、厚度为1.90 mm的薄片,用N5225B型网络分析仪(VNA)测试其在8.2~12.4 GHz频率范围的电磁参数,根据传输线理论计算其反射损耗。

2 结果和讨论

2.1 Y1-x La x FeO3 陶瓷材料的组织

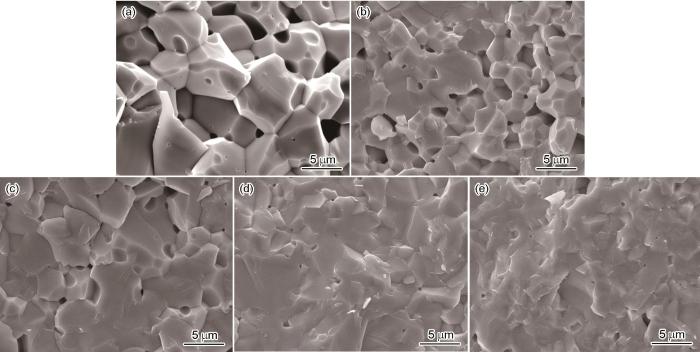

五组Y1-x La x FeO3 (x = 0,0.1,0.2,0.3,0.4)陶瓷片断面的SEM照片,如图2所示。可以看出,五组样品的微观结构相似。所有样品均呈不规则的多面体形貌,没有气孔或裂纹,表明高温煅烧生成的样品微观结构致密。

图2

图2

Y1-x La x FeO3的SEM照片

Fig.2

SEM images of Y1-x La x FeO (a) YFeO3, (b) Y0.9La0.1FeO3, (c) Y0.8La0.2FeO3, (d) Y0.7La0.3FeO3, (e) Y0.6La0.4FeO3

2.2 Y1-x La x FeO3 的相组成

图3给出了Y1-x La x FeO3 (x = 0,0.1,0.2,0.3,0.4)的XRD谱。可以看出,Y1-x La x FeO3具有Pnma空间群的正交晶系结构[15,16]。根据YFeO3标准卡片(PDF#97-008-0866),出现在2θ为26.0°、32.0°、33.1°、33.9°、39.5°、41.6°、42.7°、47.3°、48.9°、53.5°、60.2°、64.5°、69.5°处的特征衍射峰分别对应(111)、(200)、(121)、(002)、(112)、(022)、(131)、(202)、(212)、(311)、(123)、(331)、(242)晶面。谱中没有出现Y2O3、La2O3、Fe2O3和其他次要相的峰,表明反应已完成和YFeO3的晶体结构不随La含量的提高而改变。

图3

图3

Y1-x La x FeO3 (x = 0,0.1,0.2,0.3,0.4)的XRD谱

Fig.3

XRD patterns of Y1-x La x FeO3 (x = 0, 0.1, 0.2, 0.3, 0.4) (a) 20°-80° diffraction pattern, (b) Magnification of 32°-35° diffraction peak

在32°~35°处的放大图,是Y1-x La x FeO3 (x = 0,0.1,0.2,0.3,0.4)的(121)晶面衍射峰。可以看出,随着La含量的提高所有的峰都向左移动。根据Bragg方程2dsinθ = nλ (d为晶面间距,θ为入射角,λ为X射线的波长,n为衍射级数)计算出Y1-x La x FeO3(121)的晶面间距(表2)。可以看出,随着La含量的提高Y1-x La x FeO3陶瓷的晶面间距d(121)增大。其主要原因是,La3+产生的尺寸效应影响了YFeO3的晶格参数,即La3+的半径(0.103 nm)大于Y3+的半径(0.090 nm),使晶格发生了畸变[17]。随着La含量的提高畸变程度随之提高,使衍射峰向低角度方向移动。XRD谱表明,La3+占据了YFeO3晶体结构中Y3+的晶位。

表2 Y1-x La x FeO3 (121)的晶面间距

Table 2

| Y1-x La x FeO3 | x = 0 | x = 0.1 | x = 0.2 | x = 0.3 | x = 0.4 |

|---|---|---|---|---|---|

| 2θ / (°) | 33.68141 | 33.57274 | 33.30108 | 33.25761 | 33.09462 |

| sinθ | 0.28971 | 0.28880 | 0.28653 | 0.28617 | 0.28481 |

| d / nm | 0.265887 | 0.266724 | 0.268837 | 0.269176 | 0.270461 |

2.3 微区内的元素分析

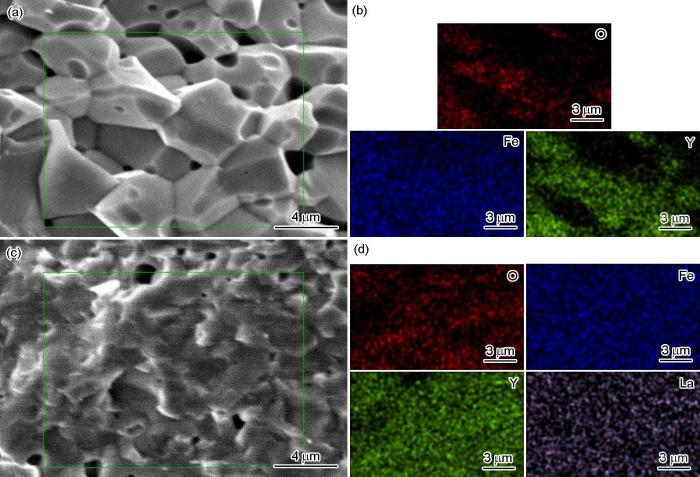

为了比较Y1-x La x FeO3与YFeO3中元素的分布,结合微观形貌用EDS能谱仪对其元素分布进行了定性分析。图4a、b给出了YFeO3的X射线能谱元素分布。图4a给出了YFeO3的SEM照片,图4b给出了图4a中用绿线框标记的区域。不同颜色分别显示了O、Fe、Y各元素的位置,其亮度越高表明元素的含量越高。图4c、d给出了Y0.6La0.4FeO3的元素分布。图4c给出了Y0.6La0.4FeO3的SEM照片,图4d给出了图4c中绿色线框标记的区域,不同的颜色分别显示了元素O、Fe、Y和La的位置。可以看出,O、Fe、Y和La四种元素的分布均匀。这也表明,La3+融入到晶格中,与XRD谱给出的结果一致。

图4

图4

YFeO3、Y0.6La0.4FeO3的SEM照片和YFeO3、Y0.6La0.4FeO3对应的EDS元素分布

Fig.4

SEM images of YFeO3(a), Y0.6La0.4FeO3(c); EDS element distribution map of YFeO3 (b) and Y0.6La0.4FeO3 (d)

2.4 Y1-x La x FeO3 的电磁参数

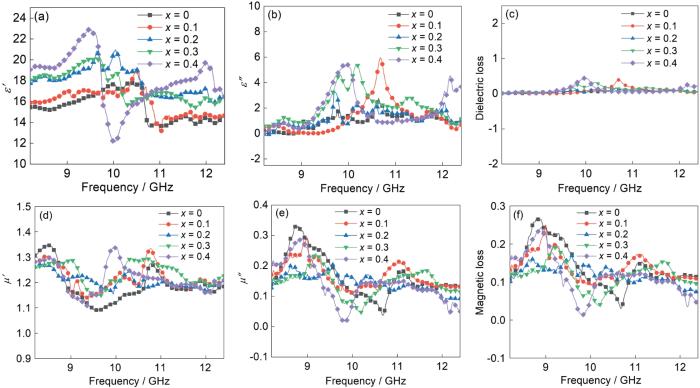

图5给出了Y1-x La x FeO3 (x = 0,0.1,0.2,0.3,0.4)的相对复介电常数的实部、虚部、介电损耗以及相对复磁导率的实部、虚部和磁损耗[18]。从图5a、b可以看出,电磁波的频散效应使ε'在8.2~12.4 GHz范围内呈下降趋势,有利于电磁波吸收[19]。ε'和ε''的增大可能是电子在室温下在Fe3+和Fe2+之间跳跃所致,产生的电子极化增大了导电损耗[20]。其原因是,YFeO3扭曲FeO6八面体结构增强了取向极化,改变化学Fe-O-Fe键角产生了双电荷中心,从而增大了偶极极化(图6g)。同时,掺杂La使氧空位含量的提高进一步增强了偶极极化。但是,在9~11 GHz之间的共振峰随着La掺杂量的向低频移动,从而产生了更高的介电储能和衰减。根据文献[21]的结果,在共振峰的频率附近可能存在良好的吸收特性。此外,La掺杂引起的晶界极化、离子分布不均和内部缺陷使晶粒界面处、缺陷区与完整晶格之间的界面处和掺杂区与未掺杂区之间的界面处出现界面极化。La的掺杂还破坏了YFeO3原有稳定的自旋结构和增强了离子极化[22]。

图5

图5

Y1-x La x FeO3 (x = 0,0.1,0.2,0.3,0.4)的相对复介电常数的实部、虚部、介电损耗以及相对复磁导率的实部、虚部和磁损耗

Fig.5

Real part (ε′) (a), imaginary part (ε′′) (b), dielectric loss and relative complex permeability (c) and real part (μ′) (d), imaginary part (μ′′) (e), magnetic loss (f) of relative complex permittivity of Y1-x La x FeO3 (x = 0, 0.1, 0.2, 0.3, 0.4)

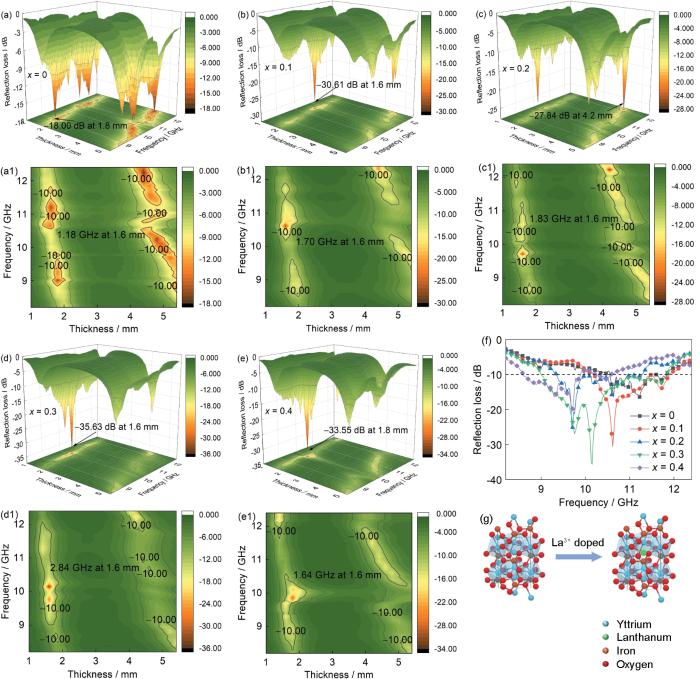

图6

图6

不同厚度的Y1-x La x FeO3的3D、2D反射损耗以及La掺杂YFeO3晶体结构的球棍模型

Fig.6

Reflection loss of Y1-x La x FeO3 at different thicknesses (a, a1) x = 0, (b, b1) x = 0.1, (c, c1) x = 0.2, (d, d1) x = 0.3, (e, e1) x = 0.4, (f) RL value at a thickness of 1.6 mm, (g) Ball rod model of La doped YFeO3 crystal structure

2.5 Y1-x La x FeO3 陶瓷的吸波性能

根据传输线理论计算出各组Y1-x La x FeO3陶瓷样品的反射损耗(RL)

以分析其微波吸收性能[27]。式(

表3 Y1-x La x FeO3 (x = 0,0.1,0.2,0.3,0.4)的反射损耗(RL)参数

Table 3

| Parameter | x = 0 | x = 0.1 | x = 0.2 | x = 0.3 | x = 0.4 |

|---|---|---|---|---|---|

| RLmin / dB | -18.00 | -30.61 | -27.84 | -35.63 | -33.55 |

| Thickness / mm | 1.8 | 1.6 | 4.2 | 1.6 | 1.8 |

| Bandwidth (RL | 1.18 | 1.70 | 1.83 | 2.84 | 1.64 |

| Thickness / mm | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

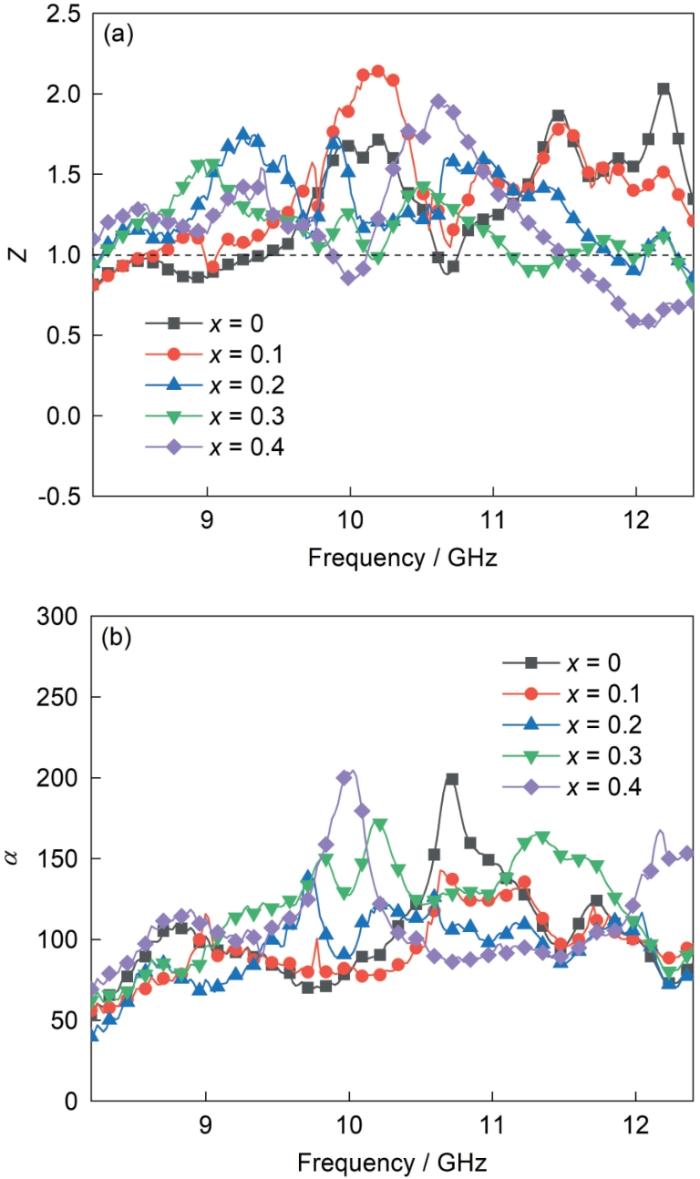

上述结果表明,改变厚度和频率可调节样品的吸收特性。电磁波能较多地进入性能优异的吸收材料,并在其内多次反射和产生热损失,以减少反射和透射。因此,阻抗匹配(Z) [28]

极为重要。衰减常数[29]

图7

图7

Y1-x La x FeO3 (x = 0.1,0.2,0.3,0.4)的阻抗匹配系数(Z)和衰减常数(α)

Fig.7

Impedance matching coefficient (Z) (a) and attenuation constant (b) of Y1-x La x FeO3 (x = 0.1, 0.2, 0.3, 0.4)

2.6 Y1-x La x FeO3 陶瓷的吸波机理

Y1-x La x FeO3的吸波机理:掺杂La产生界面极化,电荷补偿产生离子频繁跳跃使导电损耗增大,La掺杂使FeO6八面体的倾斜度增大,改变了化学Fe-O-Fe键角和产生了双电荷中心,从而增加了偶极极化,Fe-O-Fe超交换效应的增强破坏了稳定的自旋YFeO3的结构,增强了离子极化,La掺杂提高了氧空位的含量和使偶极极化效应增强以及材料内的涡流损耗和弛豫损耗。总之,Y1-x La x FeO3陶瓷良好的阻抗匹配和衰减匹配以及各种损耗机制的协同作用,使其具有优异的微波吸收性能。

3 结论

用溶胶-凝胶法调节La的掺杂量可制备性能优异的Y1-x La x FeO₃ (x = 0.1, 0.2, 0.3, 0.4) 陶瓷吸波材料。La³⁺替代YFeO₃晶体中的Y³⁺,调节La的掺杂量可优化电磁参数,从而提高YFeO₃的电磁波吸收性能,良好的阻抗匹配和衰减常数是提高其吸收性能的关键因素。匹配厚度为1.6 mm时,Y0.7La0.3FeO3在10.15 GHz处的最小反射损耗(RLmin)达到-35.63 dB,EAB为2.84 GHz,几乎覆盖整个X波段。

参考文献

A brief review on various high energy absorbing materials

[J].

The effects of temperature and frequency on the dielectric properties, electromagnetic interference shielding and microwave-absorption of short carbon fiber/silica composites

[J].

Surface structural engineering of carbonyl iron powder for enhancing microwave absorption and anti-oxidation performance

[J].Surface structural engineering is desirable in modifying the surface performance of carbonyl iron powder (CIP) to enhance microwave absorption (MA) and anti-oxidation performance. Herein, the surface shape-dependent CIP absorbers are designed via surface coating with zinc oxide (ZnO) nanoparticles and then a thermal annealing treatment. The morphology of ZnO nanoparticles which can be easily regulated by controlling the annealing temperature ultimately affects the MA performance of CIP coating with ZnO nanoparticles (CIP@ZnO). The core-shell CIP@ZnO particles with cubic cone ZnO nanoparticles exhibit excellent MA performance and thermal stability in comparison to the original CIP. Specifically, the CIP@ZnO annealed at 350 °C (CIP@ZnO-350) samples which have the cubic cone ZnO nanoparticles exhibit a minimum reflection loss (RL<sub>min</sub>) of -55.35 dB at a thickness of 2.1 mm and a maximum effective absorption bandwidth (EAB) of 7.09 GHz at a thickness of 2.0 mm. In addition, the antioxidant property of the CIP@ZnO composite particles is abruptly enhanced, which breaks the restriction of the application of CIP at high temperatures. The superior MA performance of CIP@ZnO particles with cubic cone ZnO nanoparticles comes from the enhancement in surface shape-dependent multiple microwave scattering, interfacial polarization, and electromagnetic-dielectric synergism between ZnO and CIP.

Electrical conductivity, dielectric and microwave absorption properties of graphene nanosheets/magnesia composites

[J].

Influence of A-site doping barium on structure, magnetic and microwave absorption properties of LaFeO3 ceramics powders

[J].

Structural, vibrational and magnetic properties of the orthoferrites LaFeO3 and YFeO3: a comparative study

[J].

Structural, optical and magnetic properties of Sm3+ doped yttrium orthoferrite (YFeO3) obtained by sol-gel synthesis route

[J]. J.

Effect of Gd substitution on the structure and magnetic properties of YFeO3 ceramics

[J].

Effect of Sr doped the YFeO3 rare earth ortho-ferrite on structure, magnetic properties, and microwave absorption performance

[J].Given the remarkable performances of rare earth multiferroic ortho-ferrites with magnetic optical and dielectric properties, the Y1-xSrxFeO3 (x = 0, 0.05, 0.1, 0.15) perovskite structure microwave absorbing ferrite materials was successfully synthesized by Sr2+ ions A-site doping based on sol-gel technology in this paper. The XRD of all samples was refined with FullProf software, which confirmed the formation of the orthogonal perovskite structure (SG: Pnma). The SEM and TEM results display the average particles size of the samples is distributed between 110 and 160 nm. The increase of Sr doping concentration leads to the increase of particles size, which may be related to the growth of preferred orientation and incomplete substitution. The XPS analysis shows that Fe3+ was accompanied by the presence of Fe2+ with the doping of Sr2+ ions and oxygen vacancies increased significantly. The samples change from weak ferromagnetic state to paramagnetic state with the increase of Sr content. The minimum reflection loss (RL) of the Y0.95Sr0.05FeO3 samples at 12.2 GHz reached -30.87 dB with thickness of 2.2 mm, where its effective absorption bandwidth (EAB, RL <=-10 dB) reached 2.4 GHz (11.3-13.7 GHz). Moreover, the EAB of the Y0.85Sr0.15FeO3 samples reached 2.64 GHz, and the corresponding range is 9.0-11.6 GHz (X-band).

Effect of La3+ substitution on the phase transitions, microstructure and electrical properties of Bi1- x La x FeO3 ceramics

[J].

Electron spin resonance study and improved magnetic and dielectric properties of Gd-Ti co-substituted BiFeO3 ceramics

[J].

Control of growth mechanism of electrodeposited nanocrystalline NiFe films

[J].

A novel and facile-to-synthesize three-dimensional honeycomb-like nano-Fe3O4@C composite: electromagnetic wave absorption with wide bandwidth

[J].

Non-linear thermal evolution of the crystal structure and phase transitions of LaFeO3 investigated by high temperature X-ray diffraction

[J].

Determination of the crystal structure of yttrium orthoferrite and refinement of gadolinium orthoferrite

[J].

Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides

[J].

A facile way to enhance microwave absorption properties of rGO and Fe3O4 based composites by multi-layered structure

[J].

Synthesis and characterization of nanosized urchin-like α-Fe2O3 and Fe3O4: microwave electromagnetic and absorbing properties

[J].

Structural, electrical and dielectric properties of yttrium substituted nickel ferrites

[J].

Tunable magnetic and microwave absorption properties of Sm1.5Y0.5Fe17- x Si x and their composites

[J].

Effects of Sr doping on the structure, magnetic properties and microwave absorption properties of LaFeO3 nanoparticles

[J].Lightweight, broadband microwave absorbing materials, with strong absorption capacities, are an urgent demand for practical applications. The microstructural and microwave absorption properties of LaFeO3 samples prepared by a sol-gel method using different amounts of Sr are investigated systematically. X-ray diffraction and Rietveld refinement studies showed that Sr2+ doping can distort the crystal structure of LaFeO3, leading to lattice expansion and spin tilt of the Fe-O-Fe bond angle. The improvement of magnetic properties mainly originates from the synergistic effect of the bond angle spin tilt and crystal structure defects. Oxygen vacancies will be generated due to the fluctuations in the valence state of Fe3+ resulting from the substitution of La3+ by Sr2+ as deduced from the X-ray photoelectron spectroscopy analysis. The generation of oxygen vacancies, electronic hopping and polarization loss may be one of the main reasons for changes in the electromagnetic parameters. The minimum reflection loss (RL) of La1-xSrxFeO3 nanoparticles with the Sr doping of 0.2 can reach approximately -39.3 dB at 10 GHz for the thickness of 2.2 mm, and the effective absorption bandwidth (RL <= -10 dB) can reach approximately 2.56 GHz. In addition, the La1-xSrxFeO3 nanoparticles also can obtain better microwave absorbing performance in the C-band (4-8 GHz) with the minimum RL of -36.8 dB for the matching thickness of 3.0 mm and Sr content of 0.3. Consequently, La1-xSrxFeO3 nanoparticles are promising materials for use in a high-performance and adjustable electromagnetic wave absorber, particularly in C-band and X-band.

High-temperature dielectric properties and microwave absorption abilities of Bi1- x Mg x FeO3 nanoparticles

[J].

Dielectric relaxation and magnetic resonance in microwave absorption performance of Co x Fe3- x O4 (0 ≤ x ≤ 1) nanocrystals

[J].

Effect of aspect ratio on dielectric, magnetic, percolative and microwave absorption properties of magnetite nanoparticles

[J].

Microwave characterization of Co-Ti substituted barium hexagonal ferrites in X-band

[J].

Investigation on the effect of neodymium doping on the magnetic, dielectric and microwave absorption properties of strontium hexaferrite particles in X-band

[J].

Rare earth ions doped polyaniline/cobalt ferrite nanocomposites via a novel coordination- oxidative polymerization-hydrothermal route: preparation and microwave-absorbing properties

[J].

Influence of MnO2 decorated Fe nano cauliflowers on microwave absorption and impedance matching of polyvinylbutyral (PVB) matrix

[J].