为了满足高能量吸收性能的需求,以晶格结构或金属泡沫为夹芯填充到增强结构(金属板/管)中可制备三明治结构的多孔材料[11~13]。夹芯结构与金属增强体结构之间的相互作用使复合结构的力学性能优于单一材料的性能之和,称为交互效应[14]。但是,金属板/管与金属夹芯之间有限的接触面积限制了多孔复合材料力学性能的提高;同时,三明治结构多孔复合材料中的单一组成在三维空间上的不连续以及复合材料在压缩方向上的各向异性,使其在多方向撞击等复杂工况下的应用存在局限性。设计制备在三维空间内组成相各自连续的结构—双连续互穿相复合材料(Bi-continuous interpenetrating phase composite)是提高其能量吸收性能的有效策略。这种结构不仅能防止裂纹沿着阻力最小的路径传播,即在较弱的基体相内传播,还能在最大程度上保留各组成相的性能优势[15~17]。因此,由有序和无序多孔金属构成的互穿相复合材料能实现强度和能量吸收的最佳结合。

目前对金属基多孔复合材料的研究集中于三明治结构,对合金板/管的研究也局限于厚度的调整。本文结合熔体发泡和渗流铸造制备双连续互穿多孔复合材料(BIPC),研究并比较每种单一多孔结构和双连续互穿多孔复合材料的力学性能。在此基础上对这种复合结构进行T6热处理,研究热处理对其力学性能的影响。

1 实验方法

1.1 试样的制备和热处理

用间接增材制造的方式制备特征单元框架:用3D打印设备打印出有序框架结构的反结构砂型,随后将熔融的ZL111合金以渗流铸造的方式在675 ℃浇注进入预制反结构砂型中,待铸锭凝固后将其置于400 ℃的热处理炉中保温2 h后去除砂型,得到有序多孔结构。用线切割加工出特征单元的立方体框架用于性能对比。ZL111框架尺寸为11 mm × 11 mm × 11 mm。

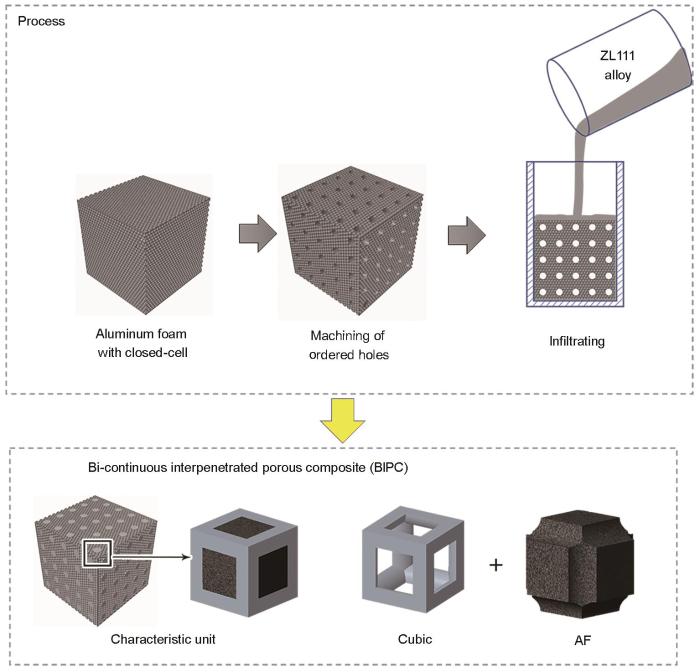

双连续互穿多孔复合材料(BIPCs)的制备工艺流程如图1所示。先用熔体发泡法制备闭孔泡沫铝(AF)。在坩埚中将纯铝(纯度99.99%)熔化并加热到740 ℃,然后向熔体中加入质量分数(下同)为5%的钙并搅拌使其均匀分布;待熔体冷却至685 ℃加入0.05%的TiH2。开启搅拌桨以1200 rad/min的速度搅拌熔体90 s,然后使熔体在685 ℃保温120 s;最后从熔炼炉中取出坩埚空冷至室温(25 ℃)。用线切割将得到的泡沫铝锭加工成尺寸为60 mm × 60 mm × 60 mm的立方块;在块体上加工出直径为6 mm的通孔,每组平行面上有25个孔;在675 ℃熔化ZL111 合金并浇注进立方体泡沫铝的预加工孔中,凝固后即得双连续互穿多孔复合材料。制备的BIPC密度为1.77 g/cm3。ZL111合金的成分:9.78% Si,1.51% Cu、0.51% Mg,0.20% Mn,0.16% Ti,其余为Al。泡沫铝的密度为0.67 g/cm3,ZL111合金的密度为2.68 g/cm3。用线切割从复合结构特征单元取样,如图1所示。特征单元由框架和泡沫铝组成,其尺寸为11 mm × 11 mm × 11 mm。

图1

图1

双连续互穿复合多孔材料的制备过程和特征单元构成的示意

Fig.1

Schematic representation of the preparation process of the Bi-continuous interpenetrating porous composite and the components of the characteristic units

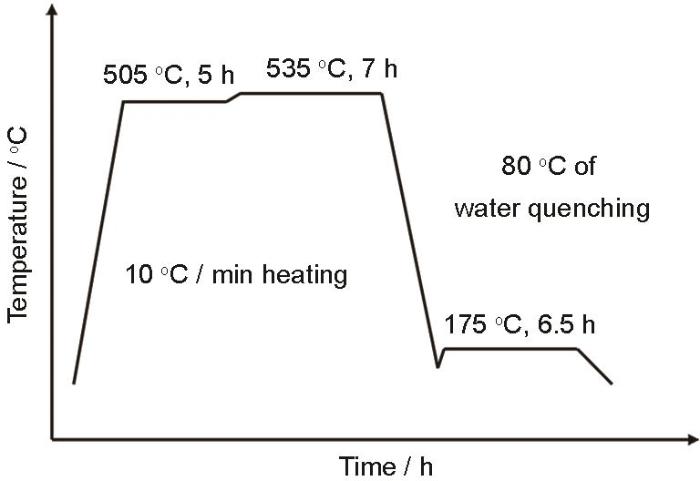

对制备出的特征单元进行T6热处理,分为固溶处理和时效处理,如图2所示。固溶处理:在室温下以10 ℃/min的速度加热至505 ℃保温5 h,随后在535 ℃下保温7 h,将试样取出并在80 ℃的热水中进行淬火。时效处理:将样品在175 ℃保温6.5 h。

图2

1.2 组织和性能表征

用微米级X射线显微镜(μ-CT, Zeiss 610 Versa)分析复合材料内部结构的完整性;用Instron电子万能材料实验机(5982型,100 kN)测试材料的力学性能,设置压缩应变率为10-3,为保证实验数据的准确性每组试样进行三次实验,按照ISO 13314标准获取压缩性能指标;用扫描电镜(SEM, IT800-SHL)和配套的能谱仪(EDS, Oxford UltimMax40)分析热处理前后的微观组织形貌和界面处的元素分布;用X射线衍射仪(XRD, D8 ADVANCE)分析材料的物相组成。

2 结果和讨论

2.1 复合和热处理对结构完整性的影响

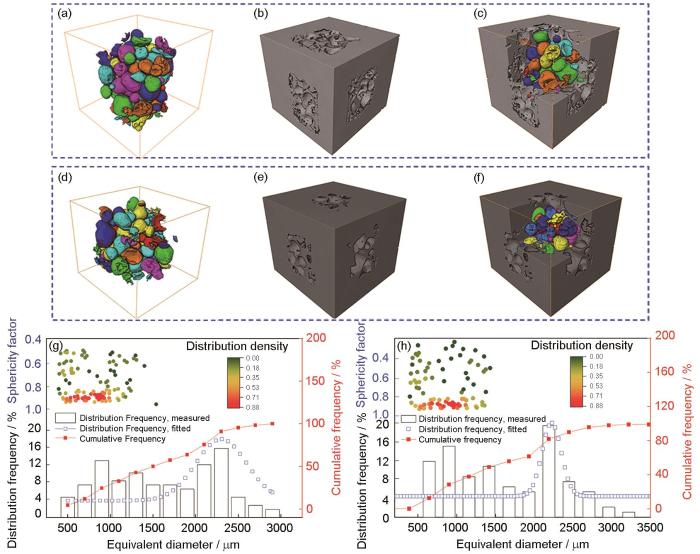

图3

图3

热处理前后特征单元结构和内部气孔结构参数及其形貌

Fig.3

Structural and internal pores structural parameters of the characteristic unit before and after heat treatment

(a) shows the morphology of the pores in the characteristic unit before heat treatment, (b) shows the three-dimensional reconstruction of the characteristic unit, and (c) shows the co-presentation of the pores and the reconstruction, (d) shows the morphology of the pores in the characteristic unit after heat treatment, (e) shows the three-dimensional reconstruction of the characteristic unit after heat treatment, and (f) shows the co-presentation of the pores and the reconstruction after heat treatment, (g) and (h) show the distribution of the size of the pores in the characteristic unit before and after heat treatment and the sphericity respectively

2.2 多孔金属材料的力学性能

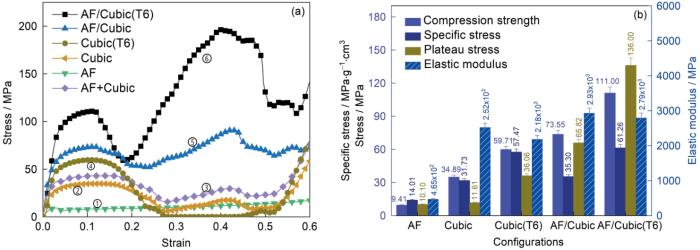

图4a给出了特征单元单一构成(立方框架与泡沫铝)、特征单元以及T6热处理后的应力应变曲线。可以看出,所有的结构都具有多孔金属的典型压缩特征,即线弹性阶段、应力平台阶段以及致密化阶段。图中的曲线①是泡沫铝的应力应变曲线。由于本文制备的泡沫铝密度较高,其压缩强度(9.41 MPa)略高于传统泡沫铝,致密化应变约为0.5;泡沫铝在整个压缩过程中都发生了稳定的变形,从开始到致密化阶段都没有出现显著的应力波动。曲线②是有序框架的应力应变曲线,可见其压缩强度比泡沫铝更高;曲线②在应变为0.18和0.42时应力明显下降,前者是结构中的纵向支柱被压断所致,而后者是结构的整体性失效所致。曲线④是有序框架热处理后的应力随应变的变化。可以看到,T6热处理使有序结构的压缩强度显著提高,从而提高了结构的抗压缩变形性能。曲线③是有序结构框架和泡沫铝应力应变曲线的叠加,曲线⑤是特征单元的应力应变曲线。可以看出,特征单元的力学性能显著高于单一构成的力学性能叠加的总和 (提高了66%)。这些结果,与结构中的界面约束和单一构成在压缩过程中的相互作用有关;曲线⑤在0.12应变和0.42应变分别出现两个明显的应力下降,表明特征单元分别发生了支柱断裂和整体结构性破坏。曲线⑥是特征单元进行T6热处理后的应力应变曲线,可见也出现了两个明显的应力下降,且其发生应变点与热处理前的相同。这表明,热处理不改变复合结构的失效应变点。

图4

图4

构型及其组成的力学性能

Fig.4

Mechanical properties of configurations and their components (a) stress-strain curves; (b) corresponding mechanical property indexes

图4b给出了图4a中相应的力学性能指标。根据ISO 13314标准,压缩强度是曲线出现第一次应力下降前的应力峰值,平台应力是应力平台对应的0.2应变间隔应力的算术平均值,弹性模量是线弹性阶段曲线的斜率,比强度是材料的压缩强度与密度的比值。由图4b可见,泡沫铝的相应力学性能指标最低,其压缩强度为9.41 MPa,比强度为14 MPa·g-1·cm3,平台应力为10.10 MPa,弹性模量为465 MPa;立方体框架的压缩强度较大,其比强度是泡沫铝的2.26倍。框架是特征单元中的单一构成,所以其平台应力较低,只略比泡沫铝的高。框架T6热处理后的各项力学性能指标均比热处理前提高,只是其弹性模量略有下降。互穿多孔复合材料的力学性能优异,其压缩强度为73.55 MPa,比强度为35.30 MPa·g-1·cm3,分别是泡沫铝的7.82和2.52倍;同时,复合材料的平台应力明显提高,是泡沫铝的6.52倍,是单一构成性能加和的304%,其弹性模量比单一框架结构的略高,表现出优异的综合力学性能。T6热处理后特征单元结构的压缩强度为111 MPa,比热处理前提高了51%,其比强度、平台应力也大幅度提高。但是,热处理使复合结构的弹性模量略有降低,与ZL111合金中的共晶硅形貌有关。

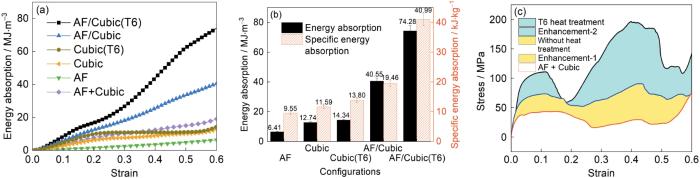

式中σ为应力,εd为致密化应变,ρ为试样的密度。随着应变的增大所有结构的能量吸收都随之提高,如图5a所示。泡沫铝的能量吸收性能最低,有序结构框架的能量吸收性能略比泡沫铝的高;T6热处理使框架结构的能量吸收性能略有提高。特征单元的能量吸收显著提高,在0.2应变后更加显著;T6热处理后的特征单元其能量吸收性能最好,在0.25应变后比热处理前大幅度提高。图5b给出了不同结构的总能量吸收和比能量吸收。可以看出,单一构成(如泡沫铝、立方结构框架)的能量吸收和比能量吸收较低,结构的复合(AF/Cubic)使其比能量吸收远高于单一构成。其原因是,复合结构中的结构组件在压缩过程中相互约束,使其能量吸收产生了1 + 1 > 2的效应。结合图5c可见,T6热处理后试样的能量吸收提高了83%,比能量吸收提高了111%。

图5

图5

构型及其组成的能量吸收性能

Fig.5

Energy absorption of configurations and their components (a) energy absorption-strain curves, (b) energy absorption and specific energy absorption of specimens, (c) enhancement of mechanical properties by composite reinforcement and heat treatment enhancement effects

2.3 微观组织对压缩性能的影响

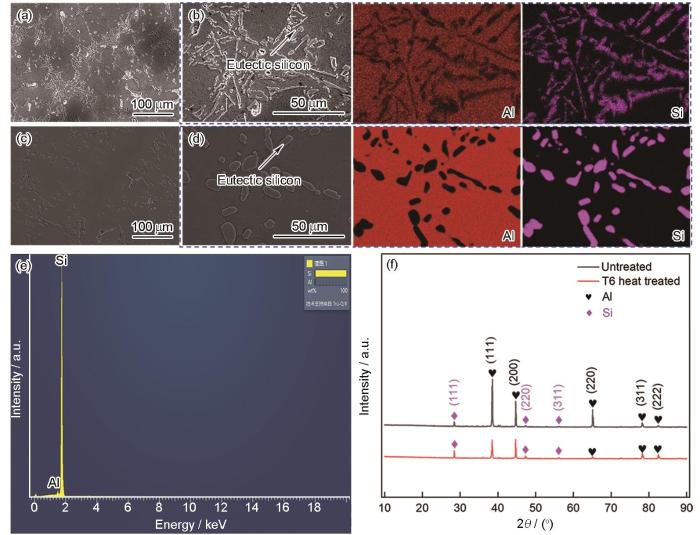

复合结构是泡沫铝与ZL111合金的固-液结合,而热处理并不影响纯金属(泡沫铝)的微观组织,因此只分析了ZL111合金的微观组织。图6a给出了热处理前ZL111合金的微观组织,图6b给出了图6a的放大和元素分布。热处理前的共晶硅呈现片层状分布,与传统ZL111合金的微观组织相同。图6c给出了热处理后ZL111合金的微观组织,图6d给出了相应的放大图和元素分布。结果表明,热处理使共晶硅由片层状向球状转变,使结构的脆性降低和韧性提高,对应弹性模量的下降和压缩强度的提高。结合EDS元素分析(图6e)和XRD谱(图6f)可知,ZL111合金中没有新相生成。根据文献[21],ZL111合金在T6热处理后出现少量Al2Cu相,在一定程度上使其强度提高。但是,由于其尺寸较小在SEM下不易发现。

图6

图6

T6热处理前后ZL111合金中的微观组织和物相

Fig.6

Microstructure morphology and phase in ZL111 alloy before and after T6 heat treatment

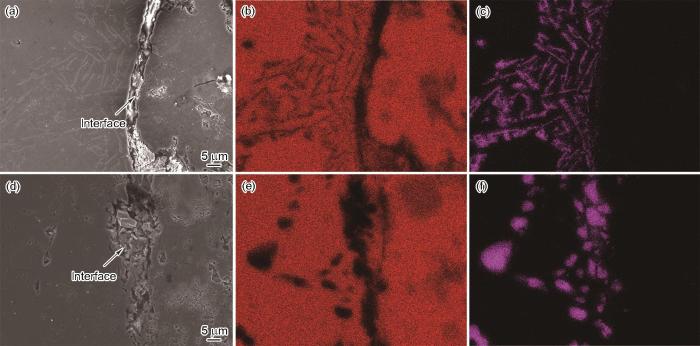

ZL111合金与泡沫铝间的界面结合对复合材料的力学性能的影响很大,用扫描电镜分析了热处理前后ZL111合金/泡沫铝界面的微观形貌和元素分布。热处理前泡沫铝与ZL111合金之间有缝隙。根据Al,Si元素在界面的分布,ZL111合金与泡沫铝之间形成了机械结合和部分点位冶金结合的界面(图7a~c)。在渗流铸造过程中高温ZL111合金液使部分泡沫铝孔壁熔化,在随后的冷却过程中凝固形成冶金结合,未熔化的泡沫铝孔壁与ZL111合金形成机械结合。冶金结合位点的强度较高,能传递应力而使复合多孔金属的抗变形性能提高,从而使其能量吸收性能较高;机械结合界面为复合结构提供变形空间,有利于应力的耗散[22]。混合形式的界面结合使复合结构在变形过程中的抗变形能力优异,和显著提高其能量吸收性能,如图4所示。从图7d~f可见,热处理后的界面依然是机械结合和冶金结合的混合界面。与热处理前不同的是,热处理后的界面出现了球化的共晶硅。这表明,热处理提高了界面冶金结合位点的强度和材料的抗变形性能。

图7

图7

T6热处理前后ZL111/泡沫铝界面的形貌和元素分布

Fig.7

Morphology and element distribution of ZL111/AF interface before and after T6 heat treatment

综上所述,结构的复合使材料的力学性能显著提高,其原因可归因为:(1)混合界面(机械结合和冶金结合界面)能高效传递应力和提高结构的抗变形性能;(2)在压缩过程中不同结构间相互约束使复合结构的压缩强度显著提高;(3)结构中单一结构间的相互约束使其达到应力峰值后的应力降减小,从而出现较高的应力平台,而结构间的增强效应使复合结构的应力平台保持在较高的水平。最后,复合结构的压缩强度较高,应力平台较长以及平台应力较高。T6热处理后结构的增强表现为:界面的冶金结合位点增强,抗变形能力更高;ZL111合金材料结构中的微观组织由片层状共晶硅向球状转变,其压缩强度较高;同时,立方结构的抗变形能力使其在应力平台阶段充分地与泡沫铝互相约束,从而提高了复合结构的平台应力,如图4所示。T6热处理使微观组织中析出Al2Cu,使结构的压缩强度提高。

3 结论

(1)双连续互穿铝基多孔复合材料中有序多孔金属与无序泡沫铝的复合使其综合力学性能优异,较高的压缩强度、较大的平台应力以及较长的应力平台阶段使其能量吸收性能提高。

(2)T6热处理使ZL111合金材料结构的微观组织由片层状的共晶硅向球状转变,微观组织中析出Al2Cu提高了结构的压缩强度并增大了结构的平台应力,使复合结构的能量吸收性能提高。

(3)互穿多孔复合材料保留了单一构成的优势而使其能量吸收性能优异,进行适当的热处理可提高其综合力学性能。

参考文献

A novel method of indirect rapid prototyping to fabricate the ordered porous aluminum with controllable dimension variation and their properties

[J].

Relationship among pore wall thickness, porosity and average pore size of aluminum foam

[J].

泡沫铝孔壁厚度、孔隙率和平均孔径之间的关系

[J].

Effect of structure design on compressive properties and energy absorption behavior of ordered porous aluminum prepared by rapid casting

[J].

Properties and applications of additively manufactured metallic cellular materials: A review

[J].

SLM lattice structures: Properties, performance, applications and challenges

[J].

Preparation of complex shaped aluminum foam by a novel casting-foaming method

[J].

Quasi-static compressive behavior of the ex-situ aluminum-alloy foam-filled tubes under elevated temperature conditions

[J].

Architected cellular materials: A review on their mechanical properties towards fatigue-tolerant design and fabrication

[J].

Development of AlMg35-TiH2 composite foaming agent and fabrication of small pore size aluminium foams

[J].

Stability of pore structure of ZL102 Al-alloy foam prepared by secondary foaming method

[J].SiC / ZL102 Al-alloy composite foam was prepared via secondary foaming process in the temperature range of 660oC~700oC, by taking the prepared SiC/ZL102 Al-alloy composites with addition of appropriate foaming agent and various SiC amount as precursors. The influence of viscosity of melt composites on the stability of ZL102 Al-alloy foam was studied by revealing the relation between the SiC content with the density of precursor, the variation of porosity, pore number, average pore size and pore wall thickness of the prepared ZL102 Al-alloy foams at different temperatures. The acquired foams were characterized by means of EDS, SEM and super deep field microscope. The results show that with the increasing SiC content the density of the precursors is increased, whilst, the density, precursor with 6wt.%SiC is the highest. The suitable secondary foaming temperature is 680oC. With the increasing foaming temperature, the average pore size and pore wall thickness of low viscosity Al-alloy foam decrease, while the average pore size of high viscosity Al-alloy foam increases and the pore wall thickness decreases. The high viscosity Al-alloy foam has stable pore structure and higher porosity.

用二次发泡法制备SiC/Al复合泡沫铝孔结构的稳定性

[J].用二次发泡法制备不同SiC含量的SiC/Al复合泡沫铝前驱体,再将其在660℃~700℃发泡制备出SiC/Al复合泡沫铝,用EDS、SEM和超景深显微镜等手段对其表征,研究了SiC含量对前驱体致密度的影响、对在不同温度制备的ZL102复合泡沫铝合金的孔隙率、孔数、平均孔径和孔壁厚度的变化,以及黏度对其孔结构稳定性的影响及其机制。结果表明,提高SiC含量可提高前驱体的致密度。680℃是较为适宜的二次发泡温度。随着发泡温度的提高低黏度泡沫铝的平均孔径和孔壁厚度减小,而高黏度泡沫铝的平均孔径增大、孔壁厚度减小。高黏度泡沫铝的孔结构稳定,其孔隙率更高。

Efficient energy absorption of functionally-graded metallic foam-filled tubes under impact loading

[J].The deformation behavior and crashworthiness of functionally-graded foam-filled tubes (FGFTs) under drop-weight impact loading were investigated. Closed cell aluminum, A356 alloy and zinc foams fabricated by the liquid state processing were used as axial grading fillers for the manufacture of single-layer and multilayer structures with different configurations. The results indicate that the deformation of multilayer foam filled tubes initiates from the low-strength components, and then propagates in the high-strength components through the gradual increment of stress. The use of more A356 alloy and aluminum foam layers provides greater specific energy absorption (SEA) for the graded structures, whereas the high-strength zinc foam has no positive effect on the crash performance. The progressive collapse of graded structures consisting of the aluminum and A356 alloy foams occurs in a symmetric mode under quasi-static and drop-weight impact conditions. However, the zinc foam causes a combination of symmetric and extension modes as well as greater localized deformation under dynamic loading and greater local rupture in quasi-static loading condition. The Al-A356 foam-filled tubes with a combination of the highest SEA (10 J/g) and the lowest initial peak stress (sigma(max) of 10.2 MPa) are considered as the best lightweight crashworthy structures.

Dynamic response of sandwich tubes with continuously density-graded aluminum foam cores under internal explosion load

[J].

Compressive strength and energy absorption of sandwich panels with aluminum foam-filled corrugated cores

[J].

Crushing energy absorption mechanisms of the composite-metal-foam hybrid tubes under axial and oblique loads

[J].

轴向和斜向加载下复合材料-金属-泡沫混杂管件的压溃吸能机制

[J].

3D printed Mg-NiTi interpenetrating-phase composites with high strength, damping capacity, and energy absorption efficiency

[J].

Nanoarchitected metal/ceramic interpenetrating phase composites

[J].

Bi-continuous interpenetrated porous composite integrating the high strength and long plateau stress stage prepared by an in situ method

[J].

Compression performances of integral-forming aluminum foam sandwich

[J].

Processing, compression response and finite element modeling of syntactic foam based interpenetrating phase composite (IPC)

[J].

Metallic microlattice and epoxy interpenetrating phase composites: Experimental and simulation studies on superior mechanical properties and their mechanisms

[J].

Effects of TiB2 content and T6 heat treatment on microstructure and hardness of in-situ TiB2/ZL111 composites

[J].

TiB2含量及T6热处理对原位TiB2/ZL111复合材料显微组织和硬度的影响

[J].

Recent advances and future trends in processing methods and characterization technologies of aluminum foam composite structures: A review

[J].