硅烷化转化处理,用硅烷水解液与金属表面活性基团发生缩聚反应制备硅烷膜,与传统的化学转化膜技术(如磷化、铬酸盐钝化等)相比,具有操作简单、成本低廉、性能优异、绿色环保等优势[14,15]。但是,甲基活性较高的单硅烷导致膜层渗入水或溶剂介质,影响对金属的防腐性能[16~20]。使用复合硅烷构成具有交联立体结构的高密度复合硅烷膜层,能隔绝空气和腐蚀介质,还能阻止阳极反应防止金属腐蚀[21~24]。王华等[25]在镀锌钢上制备的BTSEPT-VTES双层硅烷膜和硅烷-铈盐复合膜耐蚀性能优于单层硅烷膜。张振海等[26]以KH560和KH602为成膜物质添加无机组分制备出性能优良的无机组分-有机硅烷复合无铬钝化膜。Egli等[27]在电镀锌钢表面制备出3-缩水甘油氧基丙基三甲氧基硅烷(GLYMO)、3-氨基丙基三乙氧基硅烷(AMEO)和3-巯基丙基三甲氧基硅烷(MTMO)三种硅烷薄膜,都有一定的耐腐蚀性能。马启国[28]制备的双硅烷转化膜体系耐蚀性能优异,但是其厚度(> 17 μm)过大。本文以氨基硅烷KH550和环氧基硅烷KH560为主要成膜物,先制备一种贮存稳定性优异的转化液并将其用于制备优异防腐性能的转化膜,研究复合硅烷水解液贮存稳定性优异的原理和转化膜优异耐蚀性能的机制。

1 实验方法

1.1 实验用材料、设备和仪器

实验用材料:硅烷偶联剂KH560,工业级;硅烷偶联剂KH550,工业级;无水乙醇,分析纯;氯化钠,分析纯;去离子水,分析纯;乙酸,分析纯;镀锌板;镀锌螺帽;乳化剂OP-10;硫酸铜,分析纯;有机硅消泡剂,增稠剂。

实验用设备和仪器:101-1A型鼓风干燥机;XL30-FEG型场发射扫描电镜(SEM)并辅以能谱仪(EDS);HDYW-120型盐雾试验箱;PGSTAT302N型电化学工作站。

1.2 复合硅烷转化液和复合硅烷转化膜的制备

复合硅烷转化液的制备:根据硅烷的配比将KH550 0~100 g/L、KH560 0~100 g/L、乙醇50~110 g/L、OP-10 1 g/L、消泡剂0.5 g/L、增稠剂0.7 g/L和去离子水混合搅拌3~5 h并用乙酸将其pH值调节至8,制得复合硅烷水解液。

复合硅烷转化膜的制备:先将镀锌螺帽或镀锌板放在无水乙醇中超声除油,烘干后浸入复合硅烷转化液中30~60 s,取出放入离心筐中离心15~30 s,然后将其先后在80~120 ℃固化10 min,在180~200 ℃固化30 min,得到复合硅烷转化膜。

1.3 复合硅烷转化膜的表征

测试贮存稳定性:将复合硅烷水解液放入样品瓶中,密封后每30 d观察一次流动情况。

转化膜的硫酸铜点滴实验:根据GB 437-1993进行样品的硫酸铜点滴测试。点滴溶液为硫酸铜41 g/L、氯化钠35 g/L和盐酸13 mL/L的混合溶液。测试前用脱脂棉蘸取适量的无水乙醇擦拭转化膜表面,无水乙醇完全挥发后将用滴管吸取硫酸铜溶液点滴在转化膜的表面,记录膜层表面溶液变黑的时间。测试每个试样4个点的变色时间取其平均值。

测试耐腐蚀性能:根据GB/T 10125-2012使用HDYW-120型号中性盐雾(NSS)箱测试样品的耐腐蚀性能,实验温度为(35 ± 2) ℃,腐蚀介质为雾状5%(质量分数)NaCl溶液,pH值为6.5~7.2,采用连续喷雾的方式。

测试转化膜的附着力:用美工刀在转化膜表面划格,深度达到锌层表面,用SCOYCH-600型透明胶带粘贴工作区并用力撕拉,记录漆膜表面剥离面积的比例,参照GB/T 9286-1998对测试结果进行分级。

观察镀锌紧固件表面和截面的形貌:采用XL-30FEG场发射SEM并辅以EDS观察双硅烷转化膜的形貌并进行元素分析。

测试动电位极化曲线:用PGSTAT302N型电化学工作站测试涂层的动电位极化曲线,扫描速率为1 mV/s,使用三电极体系,参比电极为饱和甘汞电极,辅助电极为Pt片,以制备的涂层为研究电极,面积为1 cm2,腐蚀介质为质量分数为3.5%NaCl溶液。

测试傅里叶红外光谱:用NicoletiS50型全反射傅里叶变换红外光谱仪(ATR-FTIR)测试涂层的傅里叶红外光谱,所用的波数范围为4000~400 cm-1,分辨率为0.1 cm-1,扫描次数为130000 s-1,位置精度达0.2 nm。

测试膜层硬度:根据GB/T 6739-2022用QHQ-A型铅笔硬度计测试转化膜的硬度。根据铅笔硬度测试方法测试复合硅烷转化膜涂层的硬度,从低硬度铅笔开始进行划痕测试,每次的速度和力度相同。使用同一硬度的铅笔划出5道直线,划透的直线为0条,硅烷比例为5∶5的硅烷转化膜涂层的硬度为9H。

2 实验结果

2.1 复合硅烷转化液的贮存稳定性

表1 不同硅烷比例转化液在室温储存180 d的稳定性

Table 1

| KH550∶KH560 | State |

|---|---|

| 0∶10 | T |

| 1∶9 | F |

| 2∶8 | F |

| 3∶7 | F |

| 4∶6 | F |

| 5∶5 | T |

| 6∶4 | T |

| 7∶3 | T |

| 8∶2 | T |

| 9∶1 | T |

| 10∶0 | T |

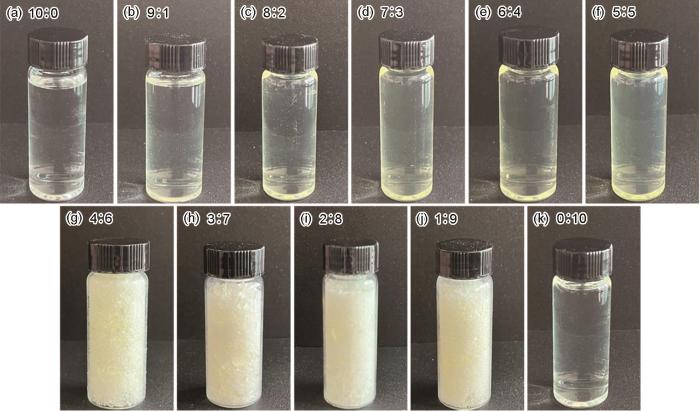

图1

图1

在室温条件下贮存180 d不同硅烷比例的转化液

Fig.1

Conversion solution with different silane proportions was stored at room temperature for 180 d

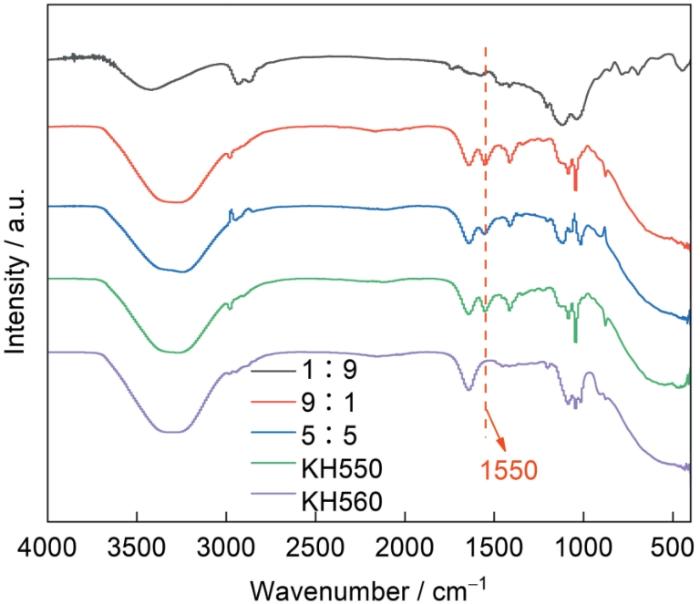

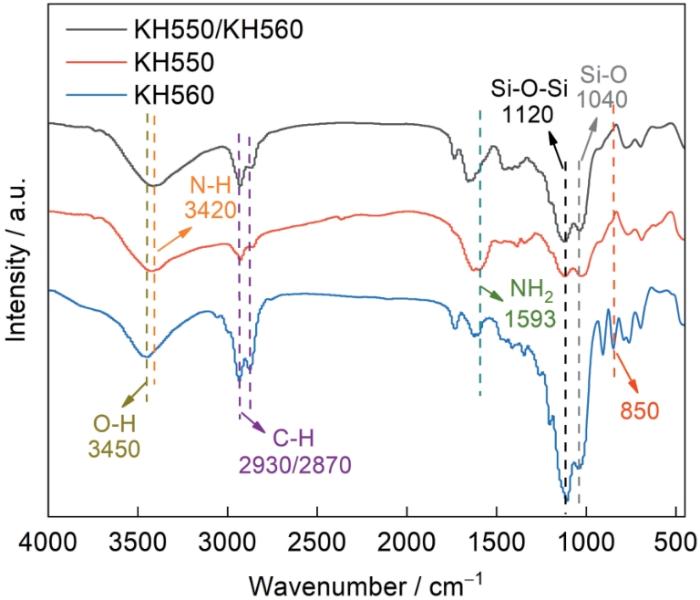

2.2 转化液的红外吸收光谱

为了验证贮存稳定的反应机理,图2给出了不同硅烷比例转化液红外吸收光谱(FTIR)。在1550 cm-1出现了N-H的伸缩振动峰[28],KH550∶KH560 = 1∶9时的光谱未出现明显的特征峰,因为环氧基团的亲核反应使N-H消耗殆尽。KH550添加量较少时体系中氨基-NH2的含量较低,除了单一硅烷水解交联外少量的-NH2在体系中也相当于交联剂,每个-NH2与两个KH560中的环氧基反应形成以氨基为交联点的交联网络结构。这种结构使形成的硅烷体系凝胶中的交联点变多,从而加速了体系的凝胶化;但是添加量较多的KH550使体系中氨基的含量提高和环氧基的含量降低,使与-NH2反应的环氧基团变少。-NH2在其中只能发挥扩链剂的作用无法起交联剂的作用,因此体系中凝胶只有单一硅烷水解交联,使体系的凝胶速度较低,从而保证了转化液的贮存稳定性。

图2

图2

不同硅烷比例转化液红外吸收光谱

Fig.2

Infrared absorption spectra of conversion solution with different silane proportions

2.3 转化膜的耐蚀性能

用硫酸铜滴定可快速检测转化膜的耐蚀性能,镀锌螺帽复合硅烷转化膜的耐蚀性能与硫酸铜液滴变黑的时间成正相关。表2列出不同比例硅烷成膜后硫酸铜点滴实验的结果。可以看出:未经处理的镀锌螺帽硫酸铜点滴开始变黑的平均时间为1.2 s,单一KH560硅烷成膜的硫酸铜液滴开始变黑的平均时间为3.2 s。KH550比例为5∶5时硫酸铜液滴变黑的平均时间为320.3 s,之后随着KH560比例的降低硫酸铜液滴变黑的平均时间逐渐变短。只用KH550成膜时,硫酸铜液滴开始变黑的平均时间仅为9.5 s。这表明,单一硅烷水解固化后形成的转化膜难以形成致密的交联网状结构抵挡腐蚀介质的渗入。结果表明,KH550与KH560的比例为5∶5的转化液处理的镀锌螺帽,其耐腐蚀性能最好。

表2 不同硅烷比例的成膜硫酸铜滴定时间

Table 2

| Sample | pH | Time 1 / s | Time 2 / s | Time 3 / s | Time 4 / s | Average time / s |

|---|---|---|---|---|---|---|

| Pure | - | 1 | 1 | 1 | 2 | 1.3 |

| 0∶10 | 8 | 3 | 4 | 2 | 4 | 3.2 |

| 5∶5 | 8 | 343 | 300 | 320 | 318 | 320.3 |

| 6∶4 | 8 | 270 | 295 | 268 | 280 | 278.3 |

| 7∶3 | 8 | 138 | 160 | 172 | 166 | 159.0 |

| 8∶2 | 8 | 75 | 64 | 95 | 89 | 80.5 |

| 9∶1 | 8 | 66 | 73 | 72 | 80 | 72.8 |

| 10∶0 | 8 | 13 | 10 | 8 | 7 | 9.5 |

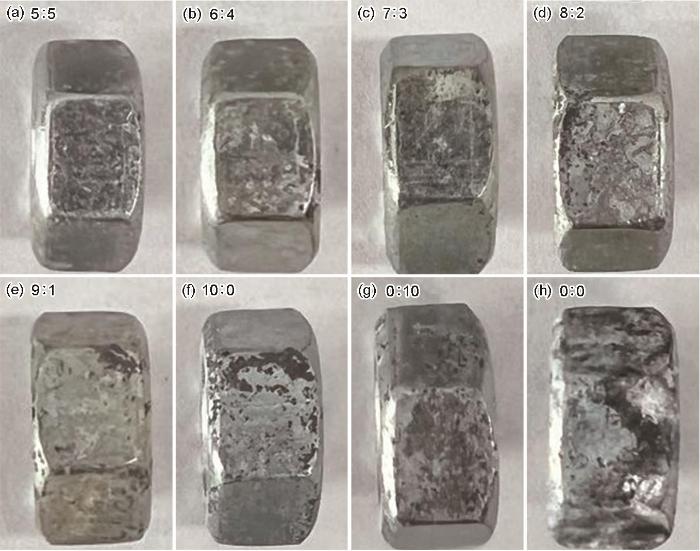

为了进一步表征复合硅烷转化膜的耐蚀性,图3给出了不同比例的复合硅烷(KH550/KH560)转化膜耐中性盐雾实验对比。可以看出,在中性盐雾中72 h空白镀锌螺帽表面严重腐蚀,产生大量的白锈和红锈(图3h),而KH550/KH560比例为5∶5的镀锌螺帽表面没有产生白锈和红锈(图3a)。图3b中的样品表面有少量白锈。图3c~g中的镀锌螺帽腐蚀迹象明显,生成了白锈。这表明,比例为6∶4~9∶1和两种单一硅烷的转化液成膜不均匀,涂层与基材结合不紧密,腐蚀介质的渗入使基材腐蚀。5∶5复合硅烷转化膜的耐腐蚀性能最好。其原因是:在5∶5比例的复合硅烷转化膜制备过程中,以水解后的氨基硅氧烷和环氧基硅氧烷在200 ℃发生开环反应生成的酰胺基团为联结点,进而形成致密的硅氧互联网络结构。这种网络结构,阻止了腐蚀介质对镀锌螺帽的侵蚀。

图3

图3

不同硅烷比例成膜时涂层在5%(质量分数)NaCl中性盐雾中的72 h实验结果

Fig.3

Results of 72 h test of coating with different silane ratio under 5% (mass fraction) NaCl neutral salt spray

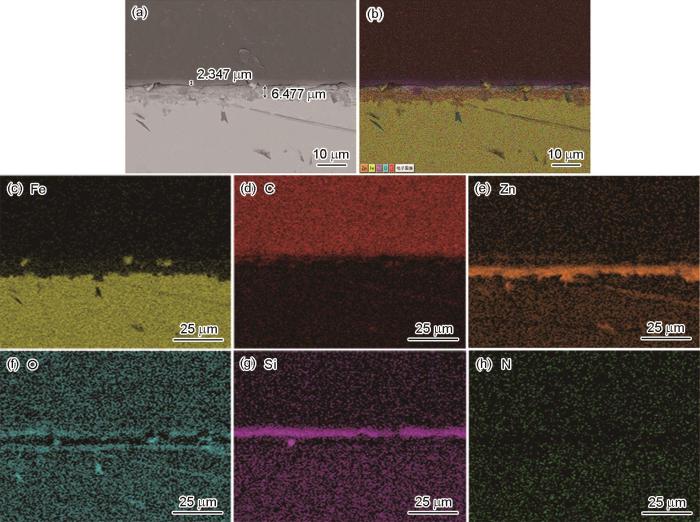

2.4 转化膜的表面形貌和元素表征

图4给出了镀锌紧固件和5∶5硅烷比例表面的形貌。可以看出,硅烷处理前膜层有明显的划痕和坑洞,表面凹凸不平。用转化液处理后膜层表面平整,没有明显的划痕且坑洞减少,分布也比较均匀。这表明,用本方法制备的硅烷转化膜能较好地覆盖基体。

图4

图4

镀锌紧固件和5∶5硅烷比例表面的形貌

Fig.4

Galvanized fasteners (a) and silane ratio 5∶5 (b) surface SEM morphology

图5

图5

硅烷比例为5∶5的转化膜的截面形貌和EDS分层图像

Fig.5

SEM morphology (a, b) and EDS delamination images (c~h) of transformed films with a silane ratio of 5∶5

2.5 转化膜的组成

采用优化的方案在镀锌紧固件表面制备出复合硅烷转化膜,用刀片刮取转化膜烘干后测试红外吸收光谱,结果如图6所示。图中3450 cm-1处的峰对应-OH基团[29],表明复合硅烷膜中有大量的硅醇,其中一部分以Si-OH的形式存在。2930和2870 cm-1处的特征吸收峰分别对应硅烷膜中-CH2和-CH3的C-H键对称和不对称伸缩振动[30,31]。3420 cm-1处的峰对应N-H基团,1593 cm-1处的特征峰对应氨基硅烷-NH2的面内弯曲振动,这是氨基硅烷的特征峰,表明镀锌紧固件表面有KH550转化膜。850 cm-1处的吸收峰对应KH560中的环氧基团[32,33],复合硅烷膜中并没有此环氧基团。1120 cm-1处的吸收峰对应Si-O-Si的伸缩振动区域峰,表明复合硅烷膜中的KH550和KH560硅烷相互之间或者自身发生了交联反应生成了网状结构。1040 cm-1处的特征峰对应Si-O键的伸缩振动,表明硅烷膜在镀锌板上发生了化学反应生成了Si-O键。

图6

FTIR结果表明,复合硅烷之间发生了缩合反应生成Si-O-Si键且形成了交联的网状高分子结构,在镀锌紧固件表面生成了致密的膜,保护镀锌紧固件使其耐腐蚀性能提高。复合硅烷转化膜与镀锌紧固件表面不是单纯的物理吸附或者物理沉积,其中的复合硅烷转化膜与其表面发生化学反应生成了Si-O-Zn键。

2.6 转化膜的硬度和附着力

根据铅笔硬度测试方法测试了复合硅烷转化膜涂层的硬度。结果表明,硅烷比例为5∶5的硅烷转化膜涂层硬度为9H。

图7给出了复合硅烷膜转化膜层的附着力,划格的交叉切割边缘仅有微量的涂层脱落,硅烷转化膜的脱落总面积不大于5%,表明转化膜的附着力为1级。

图7

2.7 复合硅烷转化膜的抗腐蚀性能和防护机理

图8

图8

镀锌板和硅烷比例为5∶5的硅烷转化膜的Tafel极化曲线

Fig.8

Tafel polarization curve of a galvanized sheet with a ratio of 5∶5 silane conversion film

由表3可见,用复合硅烷转化液处理的镀锌板极化电阻增大,腐蚀电流密度减小。与镀锌板相比,复合硅烷转化膜的腐蚀电位(φcorr)正移了44 mV,腐蚀电流密度(jcorr)降低2个数量级,表明膜层阻碍电子转移的能力增强,表面的惰性提高,覆盖在镀锌板表面的复合硅烷转化膜阻挡了腐蚀性物质的渗透,使涂层的耐蚀性更好,提高了镀锌板的防腐性能。盐雾测试结果与电化学极化结果,都表明复合硅烷转化膜中的硅氧烷结构对镀锌板的保护作用比较显著。

表3 镀锌板和硅烷比例为5∶5的转化膜的动电位极化曲线拟合数据

Table 3

| Sample | φcorr / V | jcorr / A·cm-2 | Rp / Ω·cm2 |

|---|---|---|---|

| Galvanized sheet | -1.095 | 6.014 × 10-7 | 8.419 × 103 |

| 5∶5 | -1.051 | 4.229 × 10-9 | 5.443 × 105 |

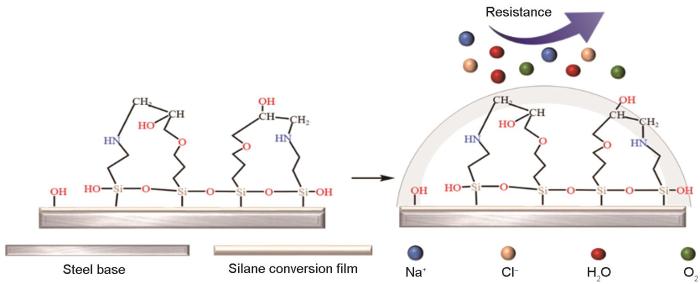

图9

图9

复合硅烷转化膜的防护机理

Fig.9

Protective mechanism diagram of composite silane conversion film

Si-O键(约为460 kJ/mol)的高键能导致复合硅烷膜转化膜的低表面能,隔绝了空气中水分子的H-O键和腐蚀介质,形成了多层次且具有一定三维结构的复合硅烷转化膜。这与电化学极化表征中膜层表面惰性增加,阻碍腐蚀介质渗透相呼应。本文制备的硅烷转化膜既有良好的贮存稳定性,又与基材形成良好的界面结合,具有优异的腐蚀保护作用。

3 结论

(1) 本文制备的复合硅烷体系贮存稳定性优异,KH550与KH560的比例为5∶5~9∶1的硅烷转化液存贮180 d凝胶而无沉淀。

(2) 复合硅烷比例为5∶5的复合转化膜表面致密、平整,没有缺陷。这种复合转化膜具有优异的耐蚀性能,在中性盐雾中72 h表面无锈蚀。

(3) 复合硅烷转化膜具有较低的腐蚀电流密度和较高的极化电阻,使其耐腐蚀性能优异。

参考文献

Overview of corrosion and its control: a critical review

[J].

The cost of corrosion in China

[J].

Preparation of modified aluminum powder coated with SiO2 and its effect on properties of water-based aluminum rich coatings

[J].

SiO2包覆改性铝粉的制备及对水性富铝涂料性能的影响

[J].

Research of preparation and protective performance of Zn-Al alloy coating by low pressure cold spray technology

[D].

低压冷喷涂锌铝合金涂层制备及防护性能研究

[D].

Cold spray coating process for corrosion protection: a review

[J].

Corrosion behavior of Al(Y)-30%Al2O3 coating fabricated by low pressure cold spray technology

[J].

低压冷喷涂制备 Al(Y)-30%Al2O3涂层及其海水腐蚀行为

[J].

Chromium and human health

[J].

铬与人体健康

[J].

Current status, opportunities and challenges in chemical conversion coatings for zinc

[J].

Preparation and corrosion performance of lanthanum nitrate conversion coating on hot- dip galfansteel

[J].

热浸镀Galfan表面镧盐转化膜的生长和耐腐蚀性能的研究

[J].在热浸镀Galfan镀层表面制备了镧盐转化膜, 采用扫描电镜及能谱分析(SEM/EDS)、X射线光电子能谱分析(XPS)、原子力扫描探针显微分析(AFM)研究镧盐转化膜的表面形貌、化学成分和结构。通过中性盐雾试验、电化学极化分析和电化学阻抗研究膜层的耐腐蚀性能, 确定最佳成膜时间。结果表明: 镧盐转化膜成膜不均匀, 优先在晶界或相界等活性区域; 随着处理时间的延长, 膜层的厚度增加; 膜层上存在裂纹, 且裂纹随着处理时间的延长而变宽, 处理时间超过30 min时, 膜层脱落, 耐腐蚀性能降低; 镧盐转化膜由La的氧化物/氢氧化物以及少量的Al和Zn的氧化物/氢氧化物组成。与未经处理的热浸镀Galfan镀层相比, 镧盐转化膜显著减低基体的腐蚀速率, 明显提高其耐腐蚀性能。

Environmental protection chromium free passivation process for new energy power battery cases

[J].

新能源动力电池壳环保无铬钝化工艺

[J].

Corrosion and cathodic disbondment resistance of epoxy coating on zinc phosphate conversioncoatingcontainingNi2+and Co2+

[J].J.

Effect of formulation of silica- based solution on corrosion resistance of silicate coating on hot-dip galvanized steel

[J].

The interaction of phosphate coatings on a carbon steel surface with a sodium nitrite and silicate solution

[J].

A comprehensive review on graphene-based anti-corrosive coatings

[J].Graphene has attracted significant attention for applications in many industrial fields due to its excellent anti-corrosion properties, and a series of satisfactory results have been achieved. In recent years, the scope of research into graphene-based anti-corrosive applications has been extremely diversified and encompasses two aspects: pure graphene coatings and graphene composite coatings. In this study, the application of graphene coatings to metal anti-corrosion is comprehensively reviewed. First, the preparation methods for graphene and pure graphene coatings are described in detail. Second, the corrosion resistance, existing problems, and optimizations of pure graphene coating are presented. Third, methods for improving the dispersibility of graphene, such as chemical modification and surface decoration nanoparticles, are introduced. Next, the corrosion resistance, anti-corrosion mechanism, existing problems, and optimization measures of graphene composite coatings are summarized. Finally, future development directions for graphene anti-corrosive coatings are proposed, and their viability in near-future applications is discussed.

Investigation of the anticorrosion properties of graphene oxide-modified waterborne epoxy coatings for AA6061

[J].

Formation and corrosion resistance of titanium containing conversion film on hot-dip galvanized steel

[J].A Ti containing conversion film on hot-dip galvanized steel was prepared by chemical conversion in titanium sulfate solution. The surface morphology, chemical composition and ingredients of the film were characterized by means of SEM, EDS and XPS. Then the corrosion resistance of the galvanized steel coated with Ti containing conversion film was examined by NSS test, electrochemical polarization and electrochemical impedance spectroscopy (EIS). The results show that the Ti containing conversion film gradually thickens and the Ti content of the film increases with the increasing time in the solution; the film mainly consists of Ti(OH)4/TiO2 and Zn(OH)2/ZnO. In comparison with the blank galvanized steel, the corrosion current density decreases, the polarization resistance and the electrochemical impedance increase significantly for the galvanized steel with Ti containing conversion film on top. The Ti containing conversion films enhance the corrosion resistance significantly, among them a film prepared in the solution for 10 min exhibits the highest corrosion resistance.

热浸镀锌层钛盐转化膜的制备和耐蚀性能

[J].制备了热浸锌层钛盐转化膜, 采用SEM、EDS表征了转化膜的表面形貌、化学成分, 采用XPS技术分析了膜层的组成, 探讨了膜层的生长过程。通过中性盐雾试验、电化学极化分析和电化学阻抗研究了膜层的耐蚀性能。结果表明, 膜层主要由含结晶水的Ti(OH)<sub>4</sub>/TiO<sub>2</sub>和Zn(OH)<sub>2</sub>/ZnO组成, 随着处理时间的增加钛盐转化膜逐渐增厚, 膜层中的Ti含量逐渐增加。与未经处理的热浸镀锌层比较, 转化膜层腐蚀电流密度减小, 极化电阻和电化学阻抗显著增大, 耐蚀性明显增强。

Electrochemical impedance spectroscopy of bis-(triethoxysilypropyl) tetrasulfide on Al 2024-T3 substrates

[J].

Study on green passivation and Corrosion resistance of galvanized sheet

[D].

镀锌板绿色钝化及其耐蚀性能研究

[D].

Effect of the surface modification of zinc powders with organosilanes on the corrosion resistance of a zinc pigmented organic coating

[J].

Fabrication of hollow carbon spheres doped with zinc cations to enhance corrosion protection of organosilane coatings

[J].

Multilayer coatings based on the combination of perfluorinated organosilanes and nickel films for injection moulding tools

[J].

Enhanced corrosion resistance of AA 2024-T3 and hot-dip galvanized steel using a mixture of bis-[triethoxysilylpropyl] tetrasulfide and bis-[trimethoxysilylpropyl]amine

[J].

Environment-friendly and chromium-free passivation of copper and its alloys

[J].

Loison D. Characterization by different analytical techniques of SiO2 and silane thin films deposited on rough hot-dip galvanized steel surfaces

[J].

Galvanized steel surface preparation and properties of the silane film study

[J].

镀锌钢板表面硅烷膜的制备及性能研究

[J].

Composite passivation film of inorganic components and organosilane on hot galvanized sheet Surface

[J].

热镀锌板表面无机组分与有机硅烷复合钝化膜

[J].

Preparation and characterization of silanes films to protect electrogalvanized steel

[J]. J.

Preparation and film forming performance of silane treatment agent for galvanized sheet surface

[D].

镀锌板表面硅烷处理剂的制备及其成膜性能研究

[D].

Preparation of PUF/PANI-CO double-wall microcapsules and anti-corrosion properties of modified water-based epoxy coating

[J].

PUF/PANI-CO双壁微胶囊的制备及改性水性环氧涂层的防腐性能

[J].

Study on Environmental protection silane composite passivation film of galvanized sheet and its corrosion resistance

[D].

镀锌板环保型硅烷复合钝化膜研制及其耐蚀性研究

[D].

Modification of amphiphilic Janus particles with cobalt Phthalocyanine for photocatalytic degradation of dyes at emulsion interface

[J].

钴酞菁修饰两亲性Janus颗粒用于乳液界面光催化染料降解

[J].

Effects of surface modification and heat treatment on the storage and application properties of waterborne zinc-based paint

[J].

Enhanced electromagnetic and microwave absorption properties of carbonyl iron/Ti3 SiC2 /epoxy resin coating

[J].

High mechanical strength superhydrophobic colored sand prepared by a low-temperature strategy

[J].The desert aeolian sand is one of the most abundant resources worldwide, and the utilization of sand with superhydrophobic function has become a heated research field. However, same as other superhydrophobic materials, the abrasion of the surface will lead to the loss of hydrophobic performance. Therefore, we prepared high-performance and mechanically stable superhydrophobic colored sand with a maximum water contact angle of 155° by low-temperature layered chaining technique (80 °C). The technical property of the co-existence of superhydrophobicity and mechanical stability was achieved on the surface of our high mechanical strength superhydrophobic colored sand. The interaction between the grafted particles and water molecules was revealed by molecular adsorption dynamics simulation to investigate the factors that affect hydrophobicity performance. The prepared superhydrophobic colored sand presented stable superhydrophobic performance after 40 min continuous abrasion tests. Moreover, the superhydrophobic sand had excellent chemical stability and liquid impact resistance with the composition stability under 240 °C. This work presents an environment-friendly, and resource-utilization surface modification method on inert materials like sand under a low-temperature condition. It provides framework surfaces like road ground and architectures with high mechanical strength and functional “layer” through a long-term performance and stable method.

Preparation and properties of water-based zinc coating

[J].

水性锌基涂镀涂层的制备及性能研究

[J].

Effect of particle size of silica powder on preparation of silicate conversion film

[J].

二氧化硅粉体粒度对硅酸盐转化膜制备的影响

[J].

Enhancement of anticorrosion property of 304 stainless steel using silane coatings

[J].