BiFeO3的理论饱和自发极化(Ps = 90~100 μC/cm2)和超高的居里温度(Tc = 825 ℃)较高,是制作高温压电器件的理想材料[6~9]。但是,在烧结BiFeO3陶瓷时容易生成第二相,且Bi元素的挥发使漏电流增大。PZT在准同型相界(MPB)区的增强压电特性显著,受此启发在BF基固溶体中生成固溶的第二相并调节组分构建准同型相界(MPB)可提高其电性能。但是,BF-BT基陶瓷中Bi的挥发和Fe2+与Fe3+的热力学竞争使其漏电流增大[10]。Peng等[11]在BiFeO3-BaTiO3中掺入Ga3+阻碍Fe3+向Fe2+的转化并抑制氧空位的生成,从而使漏电流减小。Xun等[12,13]的研究表明,BF-0.30BT陶瓷的室温最大低场压电系数d33为225 pC/N,BF-0.35BT陶瓷的逆压电系数d

1 实验方法

实验用原料:Bi2O3(99.86%)、Fe2O3(99.5%)、BaCO3(99.99%)、TiO2(99%)、Lu2O3(99.9%)、MnO2(99.9%)。用高温固相反应法制备0.67BiFe1 - x Lu x O3-0.33BaTiO3 (BF-BT-xLu,x = 0、0.005、0.008、0.010、0.012、0.015、0.020、0.030)无铅陶瓷。根据其化学计量比计算实验所需原料的质量。

将原料与无水乙醇混合后研磨2 h得到干粉,将其在850 ℃煅烧4 h,升温速率为3 ℃/min。在煅烧后的粉末中加入1%MnO2(摩尔分数),再研磨粉末2 h。将干燥粉末与造粒剂(质量分数为5%的聚乙烯醇,PVA)混合后在研钵中研磨1 h,将其过200目筛网后静置12 h。在10 MPa的压力下将0.25 g粉末压制成直径约为10 mm、厚度约为0.9 mm的圆片。将圆片在600 ℃以1 ℃/min的加热速率退火5 h以去除PVA。最后将其置于Al2O3坩埚中在1000~1030 ℃烧结6 h,得到系列陶瓷片。

为了测试电性能,将陶瓷片抛光使其厚度为0.2~0.3 mm,在其两表面均匀地涂上银浆后在600 ℃烧制20 min去除银浆中的有机溶剂,得到单质银电极。

用X射线衍射分析仪(XRD,XRD-7000)进行物相分析,Cu靶Kα 射线,2θ的范围为20°~70°。用扫描电子显微镜(SEM,JSM-5610)观察陶瓷断面的微观形貌和晶粒尺寸。用X射线能谱仪(EDS,Vario MICRO)测试烧结陶瓷的元素分布。用阻抗分析仪(LCR,TH2828S)测量样品在不同温度、不同频率下的介电常数(εr)和介电损耗(tanδ)。用X射线光电子能谱仪(XPS,Scientific K-Alpha)分析铁离子的价态和氧空位的含量。用铁电分析测试系统测试在1 Hz频率、不同温度下的极化强度-电场强度(P-E)电滞回线以及电流-电场(I-E)曲线、双极和单极电致应变-电场强度(S-E)曲线。

2 结果和讨论

2.1 物相结构和形貌

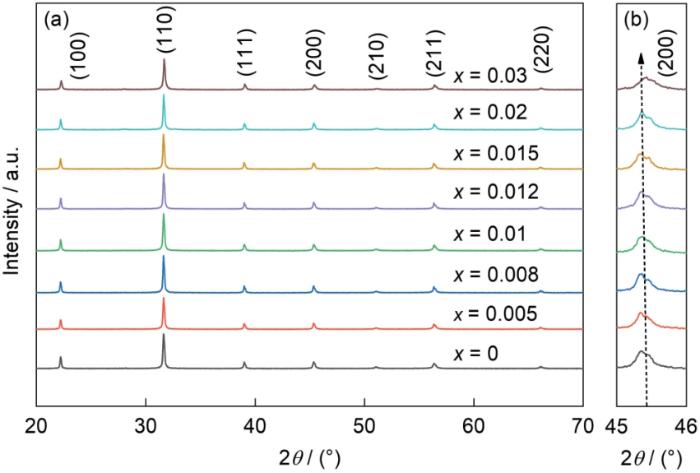

图1

图1

BF-BT-xLu的XRD谱和(200)晶面衍射谱的局部放大谱

Fig.1

XRD patterns of BF-BT-xLu (a) and enlarged pattern of (200) peak (b)

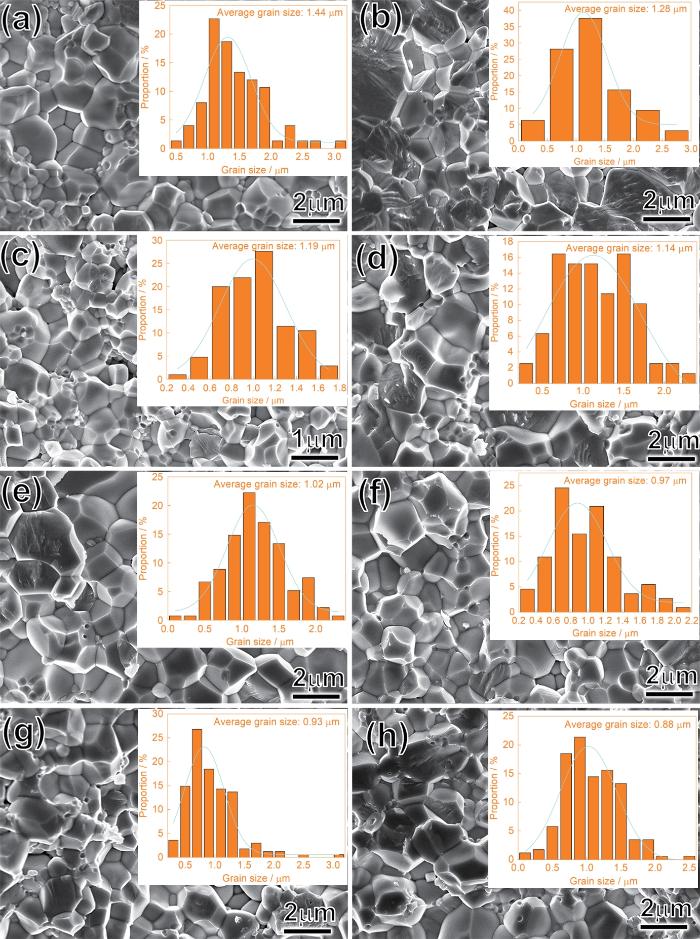

图2给出了BF-BT-xLu陶瓷断面的SEM照片,可见所有样品的微观结构致密且晶界清晰,晶粒大小均匀,没有孔洞,表明陶瓷样品的致密度较高。用线性截距法分析样品的粒径分布得到了BF-BT-xLu陶瓷晶粒尺寸的统计图。可以看出,随着Lu3+浓度的提高BF-BT-xLu的晶粒尺寸从1.44 μm减小到0.88 μm。晶粒减小的原因有二:其一是Lu3+部分取代Fe3+减少了氧空位数,降低了氧离子迁移率和晶粒生长速度;其二是复合的A位离子(Bi3+、Ba2+)的随机分布增大了晶格应变能,抑制了晶粒的生长[20]。图3给出了BF-BT-0.015Lu陶瓷的EDS谱。可以看出,在烧结过程中没有出现组分偏析。

图2

图2

BF-BT-xLu陶瓷的断面SEM照片

(a) x = 0 (b) x = 0.005 (c) x = 0.008 (d) x = 0.010 (e) x = 0.012 (f) x = 0.015 (g) x = 0.020 (h) x = 0.030

Fig.2

Scanning electron microscopy (SEM) images of fractured surfaces for BF-BT-xLu ceramics

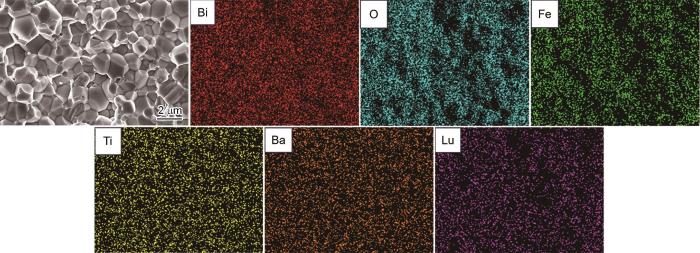

图3

图3

BF-BT-0.015Lu陶瓷的能谱(EDS)的能谱

Fig.3

Energy dispersive spectroscopy (EDS) of BF-BT-0.015Lu

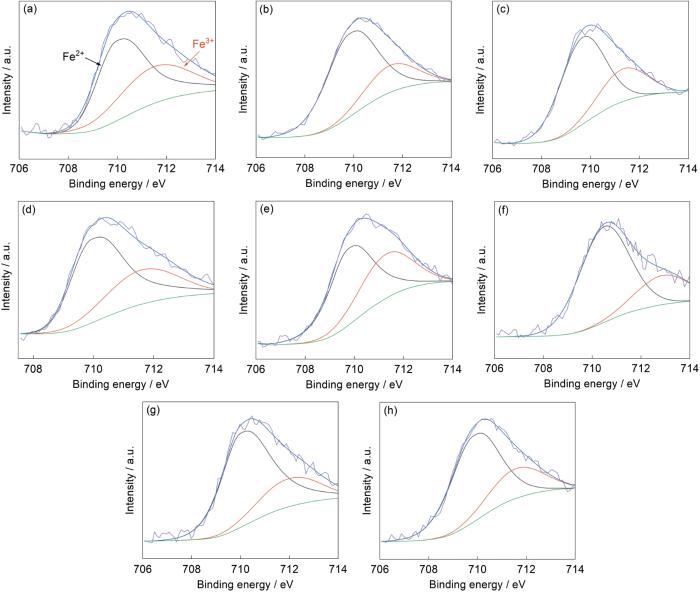

BiFeO3基铁电陶瓷中Fe2+和Fe3+的相对含量以及氧空位的产生是热力学竞争和电荷补偿的结果,是影响BF-BT-xLu陶瓷漏电流和电学性能的关键因素。图4a~h给出了BF-BT-xLu (x = 0、0.005、0.008、0.010、0.012、0.015、0.020、0.030)陶瓷样品中铁离子的价态变化。根据XPS谱研究了Lu3+掺杂对样品中铁元素的2p电子能级价态的影响。通过高斯拟合铁元素氧化态的Fe 2p3/2谱,可见Fe 2p3/2峰的形状不对称,表明不同组分的陶瓷样品中Fe2+和Fe3+共存。709 eV处的峰与Fe2+键的结合能有关,711.3 eV处的峰源于Fe3+,峰的面积表征Fe2+/Fe3+的相对含量[21]。x = 0、0.005、0.008、0.010、0.012,0.015、0.020、0.030对应的Fe2+/Fe3+比值分别为1∶0.61、1∶0.53、1∶0.49、1∶0.5、1∶0.21、1∶0.33、1∶0.54、1∶0.68,表明调整Lu3+的含量可控制Fe3+到Fe2+的转化。分析该比值的变化可确定,掺杂适量的Lu3+可阻碍Fe3+向Fe2+的转变,从而降低BF-BT-xLu样品中的漏电流。

图4

图4

BF-BT-xLu陶瓷Fe2+/Fe3+峰位的XPS谱

Fig.4

XPS spectra of BF-BT-xLu ceramics Fe2+/Fe3+ ions peak positions (a) x = 0; (b) x = 0.005; (c) x = 0.008; (d) x = 0.010; (e) x = 0.012; (f) x = 0.015; (g) x = 0.020; (h) x = 0.030

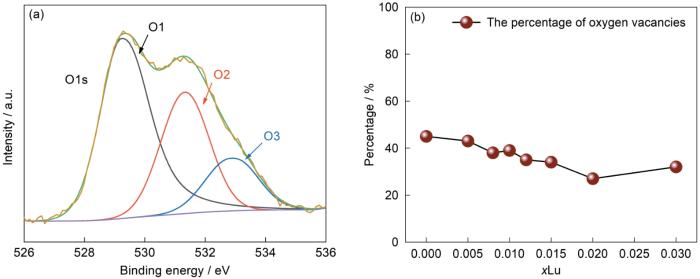

为了进一步探索氧空位含量的变化,用XPS法分析了氧空位。根据284.6 eV的C 1s峰校准了所有的光谱,根据高斯拟合记录了O 1s的不对称峰(图5)。该峰可拟合成三个峰,分别对应晶格固有的O2-、氧空位、和表面吸附的氧,分别记作O1、O2和O3。结合能(约531 eV)较高的主要成分为氧空位,结合能(约529 eV)较低的峰为钙钛矿晶格固有的O2-[22~26]。在x = 0、0.005、0.008、0.010、0.012、0.015、0.020、0.030的BF-BT-xLu样品中,氧空位/(氧空位 + O2- + 吸附氧)的值分别为0.45、0.43、0.38、0.39、0.35、0.34、0.27和0.32。Bi2O3的挥发使材料产生缺陷,缺陷钉住材料中的畴壁,Lu3+与缺陷结合形成缺陷偶极子,限制氧空位的移动。这证实了,适量的Lu3+进入BF晶格能降低氧空位的浓度和抑制Fe2+的生成。

图5

图5

BF-BT-0.02Lu陶瓷O 1s的XPS谱和BF-BT-xLu陶瓷中氧空位的占比

Fig.5

XPS spectrum of BF-BT-0.02Lu ceramics O 1s (a) and proportion of oxygen vacancy in BF-BT-xLu ceramics (b)

2.2 BF-BT-0.015Lu陶瓷的介电性能

图6a、b分别给出了BF-BT-0.015Lu陶瓷在频率为100 Hz~100 kHz时的介电常数(ε')和介电损耗(tanδ)随温度的变化。图中介电温谱出现一个介电异常(对应温度为Tm),表明发生了从铁电相到顺电相的转变。同时,随着Lu3+的掺入介电峰不但宽化,而且最大介电常数温度(Tm)随着频率的提高而移向高温方向,表明各组分都具有频率色散特性。这充分说明,随着Lu3+的加入BF-BT-xLu陶瓷从普通铁电体转变为弛豫铁电体。产生弛豫行为的原因,可能是在B位引入Lu3+打破了铁电长程有序,形成了极性纳米区(PNRs)[27,28]。图中在Tm右侧出现的介电异常,可能是热激活缺陷引起的。热激活缺陷在短范围内运动或跳跃,近似于偶极子的重定向过程,导致介电异常和巨大的介电损耗。从图6b可见,介电损耗从常温到Tm比较低,温度高于Tm后急剧增大[29~31]。

图6

图6

BF-BT-0.015Lu陶瓷在不同频率下介电常数图和介电损耗图随温度的变化

Fig.6

Temperature dependence of dielectric constant (ε') (a) and dielectric loss (tanδ) (b) of BF-BT-0.015Lu

2.3 BF-BT-xLu陶瓷的铁电和压电性能

图7a给出了BF-BT-xLu (x = 0、0.005、0.008、0.010、0.012、0.015、0.020、0.030)陶瓷在电场强度位80 kV/cm、频率为1 Hz条件下的室温电滞回线(P-E曲线)。可以看出,所有的回线都是饱和对称的且其角锋利,表明烧结陶瓷的电滞回线完美和电阻率较高。在高强度电场中,可观察到无漏特性。纯BF-BT具有典型铁电体的P-E电滞回线,剩余极化(Pr) = 26.47 μC/cm2,矫顽场(Ec) = 30.45 kV/cm。掺杂Lu3+改性使BF-BT-0.015Lu的Pr提高到28.66 μC/cm2,表明Lu3+掺杂可提高其铁电性能。其原因是,Lu3+的加入使晶格发生扭曲,产生的阳离子无序和Bi3+偏离其初始位置生成了极性纳米区和非永久性周期性弛豫畴[32]。图7b给出了样品的Pr和Ec与Lu3+含量的关系。可以看出,随着Lu3+含量的提高Ec从30.45 kV/cm下降到24.15 kV/cm,在x = 0.010时Pr从26.54 μC/cm2上升到28.12 μC/cm2,在x = 0.030时下降到24.15 μC/cm2。这表明,掺杂适量的Lu3+使陶瓷的极化增强和Ec降低,使其性能软化,有助于极化翻转和提高铁电性能。但是,过量的Lu3+在一定程度上使其铁电性降低,因为较大的陶瓷晶粒有利于畴的运动[33~35]。x = 0.030陶瓷的晶粒太小,阻碍畴的运动而使铁电性能降低。图7c给出了BF-BT-xLu陶瓷的J-E开关电流曲线,可见所有成分的陶瓷都出现一个电流密度峰,对应铁电畴的大量翻转,因此电流密度峰处的电场对应于P-E电滞曲线中的Ec。x = 0.030陶瓷的电流密度峰越来越钝化,表明其铁电性能降低。

图7

图7

BF-BT-xLu压电陶瓷在80 kV/cm下的室温电滞回线、Pr-Ec关系、J-E关系以及双极应变

Fig.7

P-E hysteresis loops for BF-BT-xLu ceramics (a); the variations of Pr and Ec with the content of Lu3+ (b); J-E curves of BF-BT-xLu ceramics at room temperature (c); bipolar strains of BF-BT-xLu ceramics (d) in 80 kV/cm at room temperature

图8a~d给出了BF-BT-xLu陶瓷(x = 0、0.005、0.012和0.030)在80 kV/cm电场中随温度变化的P-E电滞回线。可以看出,所有的P-E电滞回线都表现出典型的铁电体特征。值得注意的是,随着温度的提高P-E电滞回线的矫顽场降低,剩余极化增大。x = 0.012的陶瓷其Ec在25~100 ℃从27.34 kV/cm下降到24.16 kV/cm,Pr从26 μC/cm2上升到43.52 μC/cm2。其原因是,温度的升高在一定程度上有利于电畴的翻转,但是点缺陷也变得活跃,使漏电流增大和剩余极化假性升高[37]。尤其是温度高于100 ℃后有足够的热能解离缺陷偶极子,从而产生漏电流并使电滞回线变“胖”。图8b、d表明,当温度高于100 ℃时,漏电流的增大使电滞回线的顶部出现明显的突起。图8e、f给出了BF-BT-xLu (x = 0.012、0.030)在25~125 ℃应变的变化。可以看出,在125 ℃应变为0.4% (最大值),d

图8

图8

BF-BT-xLu陶瓷在不同温度下的P-E回线和双极应变

Fig.8

P-E loop of BF-BT-xLu ceramics measured and bipolar strain of BF-BT-xLu ceramics at variable temperature (a) x = 0; (b) x = 0.005; (c, e) x = 0.012; (d, f) x = 0.030

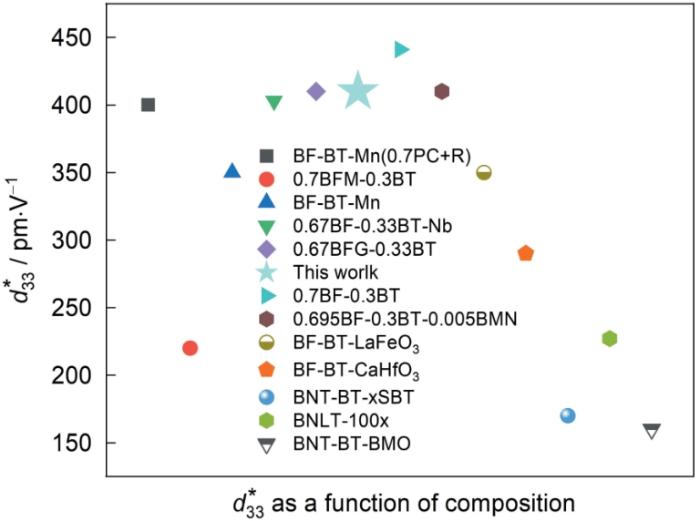

图9

图9

BF-BT-0.010Lu陶瓷与其它BF-BT基陶瓷d

Fig.9

Comparison of d

3 结论

用传统的高温固相合成法可制备致密的纯钙钛矿结构0.67BF-0.33BT-xLu无铅压电陶瓷。适当的Lu3+掺杂降低了Fe2+的比例,可减小材料的漏电流和软化晶格,有利于提高极化翻转和铁电性能,但是过量的Lu3+使其铁电性能降低。BF-BT-0.010Lu的正应变Spos可达0.328%,高场应变常数d

参考文献

A new impedance measurement system for PZT-based structural health monitoring

[J].

Preparation, structural and dielectric properties of nanocomposite Al2O3/BaTiO3 for multilayer ceramic capacitors applications

[J].

Ultrahigh strain in PZ-PT-BNT piezoelectric ceramic

[J].

Microstructure and ferroelectric properties of Nb2O5-modified BiFeO3-BaTiO3 lead-free ceramics for energy storage

[J].

Dielectric and piezoelectric characteristics of lead-free Bi0.5(Na0.84K0.16)0.5TiO3 ceramics substituted with Sr

[J].

First principle study of band gap nature, spontaneous polarization, hyperfine field and electric field gradient of desirable multiferroic bismuth ferrite (BiFeO3)

[J].

Microstructure, ferroelectric and piezoelectric properties of Bi0.5K0.5TiO3-modified BiFeO3-BaTiO3 lead-free ceramics with high curie temperature

[J].

Thermally stable electrostrain in BiFeO3-BaTiO3-based high temperature lead-free piezoceramics

[J].

Conductive property of BiFeO3-BaTiO3 ferroelectric ceramics with high curie temperature

[J].

Progress in engineering high strain lead-free piezoelectric ceramics

[J].

High curie temperature BiFeO3-BaTiO3 lead-free piezoelectric ceramics: Ga3+ doping and enhanced insulation properties

[J].

Lead-free BiFeO3-BaTiO3 ceramics with high curie temperature: Fine compositional tuning across the phase boundary for high piezoelectric charge and strain coefficients

[J].

Enhanced resistance in Bi(Fe1 - x Sc x )O3-0.3BaTiO3 lead-free piezoelectric ceramics: Facile analysis and reduction of oxygen vacancy

[J].

High electrostrain with high curie temperature in BiFeO3-BaTiO3-based ceramics

[J].

Large electric field-induced strain and excellent photoluminescence properties of Pr-modified 0.94Bi0.5Na0.5TiO3-0.06BaTiO3 lead-free ferroelectric ceramics

[J].

Ultrahigh piezoelectricity in ferroelectric ceramics by design

[J].Piezoelectric materials, which respond mechanically to applied electric field and vice versa, are essential for electromechanical transducers. Previous theoretical analyses have shown that high piezoelectricity in perovskite oxides is associated with a flat thermodynamic energy landscape connecting two or more ferroelectric phases. Here, guided by phenomenological theories and phase-field simulations, we propose an alternative design strategy to commonly used morphotropic phase boundaries to further flatten the energy landscape, by judiciously introducing local structural heterogeneity to manipulate interfacial energies (that is, extra interaction energies, such as electrostatic and elastic energies associated with the interfaces). To validate this, we synthesize rare-earth-doped Pb(Mg1/3Nb2/3)O-3-PbTiO3 (PMN-PT), as rare-earth dopants tend to change the local structure of Pb-based perovskite ferroelectrics. We achieve ultrahigh piezoelectric coefficients d(33) of up to 1,500 pC N-1 and dielectric permittivity epsilon(33)/epsilon(0) above 13,000 in a Sm-doped PMN-PT ceramic with a Curie temperature of 89 degrees C. Our research provides a new paradigm for designing material properties through engineering local structural heterogeneity, expected to benefit a wide range of functional materials.

Simultaneously achieving high energy storage density and efficiency under low electric field in BiFeO3-based lead-free relaxor ferroelectric ceramics

[J].

Competitive mechanism of temperature-dependent electrical properties in BiFeO3-BaTiO3 ferroelectrics controlled by domain evolution

[J].

Grain size effects in Mn-modified 0.67BiFeO3-0.33BaTiO3 ceramics

[J].

Realizing excellent energy storage performance and fatigue endurance in Sr0.7Sm0.2TiO3 modified 0.67BiFeO3-0.33BaTiO3 lead-free relaxor ceramics

[J].

Reduction inhibition of Fe3+ ions in mn-doped 0.7BiFeO3-0.3BaTiO3 ceramics by direct reaction sintering

[J].

Critical roles of Mn-ions in enhancing the insulation, piezoelectricity and multiferroicity of BiFeO3-based lead-free high temperature ceramics

[J].

Giant electromechanical response in layered ferroelectrics enabled by asymmetric ferroelastic switching

[J].

Enhanced electromechanical properties of SrTiO3-BiFeO3-BaTiO3 ceramics via relaxor behavior and phase boundary design

[J].

Phase structure and electrical properties of BiFeO3-BaTiO3 ceramics near the morphotropic phase boundary

[J].

Role of trivalent acceptors and pentavalent donors in colossal permittivity of titanium dioxide ceramics

[J].

Dielectric, ferroelectric, and piezoelectric properties of Bi(Ni1/2Ti1/2)O3-modified BiFeO3- BaTiO3 Ceramics with high curie temperature

[J].

Simultaneously enhanced energy storage density and efficiency in novel BiFeO3-based lead-free ceramic capacitors

[J].

Optimized energy storage performance in BF-BT-based lead-free ferroelectric ceramics with local compositional fluctuation

[J].

Energy storage properties of bismuth ferrite based ternary relaxor ferroelectric ceramics through a viscous polymer process

[J].

Effect of Er3+ doping on the properties of Bi3Ti1.5W0.5O9-Bi4Ti3O12 symbiotic lead-free piezoelectric ceramics

[J].

Er3+掺杂对Bi3Ti1.5W0.5O9-Bi4Ti3O12共生无铅压电陶瓷性能的影响

[J].用传统固相法制备了Bi<sub>7-</sub><sub>x</sub> Er <sub>x</sub> Ti<sub>4.5</sub>W<sub>0.5</sub>O<sub>21</sub>(BTW-BIT-xEr<sup>3+</sup>,x=0.05、0.10、0.15、0.25、0.35)共生铋层结构无铅压电陶瓷,用BTW-BIT-xEr<sup>3+</sup>的XRD和SEM表征其相结构和形貌,研究了Er<sup>3+</sup>掺杂对其上转换发光性能和电学性能的影响。结果表明:在这种陶瓷中生成了铋层状结构的单一晶相。在980 nm光波激发下所有组分的上转换荧光谱中都能清晰地观察到两个绿光和一个红光发射峰,峰的中心分别位于532 nm、548 nm和660 nm处。改变掺杂Er<sup>3+</sup>离子浓度可调节其强度比。根据BTW-BIT-0.15Er<sup>3+</sup>样品在532 nm和548 nm绿光的光强比拟合了290~440 K的温度灵敏度,结果表明440 K处的灵敏度最大为0.0023 K<sup>-1</sup>。Er<sup>3+</sup>离子替代BTW-BIT-xEr<sup>3+</sup>伪钙钛矿层的Bi<sup>3+</sup>使氧空位浓度的降低,降低了高温介电损耗,提高了激活能和压电常数。BTW-BIT-0.15Er<sup>3+</sup>陶瓷的综合电学性能最优,分别为d<sub>33</sub>=14 pC/N、T<sub>c</sub>=697℃,tanδ=0.53%、Q<sub>m</sub>=2055。这种陶瓷材料具有最优的发光性能和良好的热稳定性。

High recoverable energy storage density in nominal (0.67-x)BiFeO3-0.33BaTiO3-xBaBi2Nb2O9 lead-free composite ceramics

[J].

Investigation of nonstoichiometric Fe on the ferroelectric properties of BiFeO3-based piezoelectric ceramics

[J].

Enhanced piezoelectric and ferroelectric properties of BiFeO3-BaTiO3 lead-free ceramics by optimizing the sintering temperature and dwell time

[J].

Effects of Ga content on the structure and electrical performances of 0.69BiFe1 - x Ga x O3-0.31BaTiO3 lead-free ceramics

[J].

Role of bi chemical pressure on electrical properties of BiFeO3-BaTiO3-based ceramics

[J].

High remanent polarization and temperature-insensitive ferroelectric remanent polarization in BiFeO3-based lead-free perovskite

[J].BiFeO3 is the only known single-phase multiferroic material above room temperature, and it has excellent properties. Therefore, BiFeO3-based materials have been extensively investigated. However, its applications have been hindered by temperature sensitivity. Herein, we report a temperature-stable ferroelectric material, 0.675BiFeO(3)-0.3BaTiO(3)-0.025LaFeO(3)-x mol% MnO2 (x = 0-4.0), prepared by a solid-state reaction. The temperature stability of remanent polarization was regulated by changing the doping amount of MnO2 and sintering temperature. The temperature stability has been greatly improved by a slight increase of MnO2 content and sintering temperature. Samples with larger grain size showed not only improved ferroelectric properties, but also excellent temperature stability. Moreover, these samples with excellent temperature stability have small leakage current variation at high temperature and high electric field, which demonstrates the enhanced temperature stability from a new perspective. The sample with a composition of x = 1.0 sintered at 1050 degrees C has outstanding temperature stability, with remanent polarization variation less than 7% of its room temperature value in the temperature range of 25-155 degrees C. The effects of MnO2 doping on strain, ferroelectric and leakage current properties were also studied. All samples with MnO2 doping had lower strain, remanent polarization and leakage current density than those of the undoped ones.

Lead-free high performance Bi(Zn0.5Ti0.5)O3-modified BiFeO3-BaTiO3 piezoceramics

[J].

Understanding the strain mechanisms in BiFeO3-BaTiO3 piezoelectric ceramics near the morphotropic phase boundary

[J].

Enhanced piezoelectric properties in coarse-grained 0.7Bi(Fe0.9985Mn0.0015)O3-0.3BaTiO3 ceramics

[J].

Piezoelectric properties of mechanochemically processed 0.67BiFeO3-0.33BaTiO3 ceramics

[J].

Donor multiple effects on the ferroelectric and piezoelectric performance of lead-free BiFeO3-BaTiO3 ceramics

[J].

High-performance lead-free piezoceramics with high curie temperatures

[J].Lee, Myang Hwan; Kim, Da Jeong; Park, Jin Su; Song, Tae Kwon; Kim, Myong-Ho Changwon Natl Univ, Sch Mat Sci & Engn, Chang Won 641773, Gyeongnam, South Korea. Kim, Sang Wook; Kim, Won-Jeong Changwon Natl Univ, Dept Phys, Chang Won 641773, Gyeongnam, South Korea. Do, Dalhyun Keimyung Univ, Dept Adv Mat Engn, Daegu 704701, South Korea. Jeong, Il-Kyoung Pusan Natl Univ, Dept Phys Educ, Busan 609735, South Korea.

Enhanced electrical properties of (Zn, Mn)-modified BiFeO3-BaTiO3 lead-free ceramics prepared via sol-gel method and two-step sintering

[J].

High strain (0.4%) Bi(Mg2/3Nb1/3)O3‐BaTiO3‐BiFeO3 lead‐free piezoelectric ceramics and multilayers

[J].

Enhanced ferroelectric, magnetic and magnetoelectric properties of multiferroic BiFeO3-BaTiO3-LaFeO3 ceramics

[J].

Improved piezoelectric performance via orientation regulation in novel BNT-BT-SBT thin film

[J].