冷作模具是生产现代工具的重要装置,广泛应用在汽车制造、航天和电器制造等行业[1~3]。冷作模具钢用于生产冲压、镦锻、挤压等模具[4],表面受到的交变应力、摩擦力和冲击力使其表面过载、磨损和失效[5]。工程上对模具的硬度、韧性和耐磨性等的要求较高,因此必须对模具表面进行改性以提高其性能从而延长其使用寿命。离子渗氮,是一种有效的表面强化方法。将氮原子渗入钢零件的表层并与钢中的某些原子结合生成硬度或强度极高的强化相,从而显著提高其耐磨性[6,7]。赵宝奇等[8]研究发现,低温离子渗氮可降低16Cr3NiWMoVNb齿轮钢的摩擦系数,提高其耐磨性能。Wang等[9]研究表明,在0.1C-3Cr-2W-V轴承钢表面渗氮使其滚动接触疲劳性能显著提高。高玉魁[10]研究发现,在32Cr3MoVA渗氮轴承钢的表面渗氮深度较小时,表面的硬度较低且渗氮层的硬度梯度较大,其表面容易产生应力松弛和剥落而使其接触疲劳性能降低。张道达等[11]研究发现,离子渗氮对20CrMnTi钢的渗氮层组织有显著的影响,复合渗氮工艺可提高渗氮速度和表面的耐磨性能。钟历等[12]研究表明,随着渗氮时间的延长渗氮层的深度和ε相体积分数均增大,渗氮时间达到某一阈值后渗氮层深度的增长速率显著减缓而相组成趋于稳定。

1 实验方法

实验用材料是调质处理后的7Cr7Mo2V2Si钢,调质工艺参数为在1130 ℃固溶、在200 ℃等温盐浴淬火和在500 ℃高温回火。7Cr7Mo2V2Si钢的化学成分(质量分数,%)为: C 0.80, Cr 7.0, V 2.0, Si 1.0, Mn 0.16, Mo 2.0, Fe余量。

将调质处理后的钢材加工成尺寸为20 mm × 20 mm × 10 mm的试样,打磨、抛光、清洗后烘干。将试样在520 ℃进行24 h的离子渗氮,然后在550 ℃真空炉里对渗氮后的试样进行扩散处理,时间分别为10、20和30 h。

使用AL-Y3500型X射线衍射仪(XRD)分析试样的物相,用Co靶,管流为30 mA,管压为30 kV,扫描步长为0.06 (°) / s,测试角度范围为20°~80°。使用BX53M型号光学显微镜、SEM-3100型扫描电子显微镜观察试样的渗氮层截面。用THV-1MDT型显微硬度计测试试样渗氮层截面的硬度,试验力值为3 N,保持时间为15 s,相邻两个硬度点中心相隔0.01 mm。用MMF-10000N型往复式摩擦磨损试验机测试试样的摩擦磨损性能,摩擦载荷为500 N,频率为1 Hz,滑动距离为6 mm,测试时间为30 min;测试前后对试样进行清洗、干燥和称重,以计算摩擦失重量。

2 结果与讨论

2.1 7Cr7Mo2V2Si钢渗氮前后的微观组织

图1

图1

7Cr7Mo2V2Si钢的微观组织

Fig.1

Microstructure of 7Cr7Mo2V2Si Steel (a) after quenching; (b) after tempering

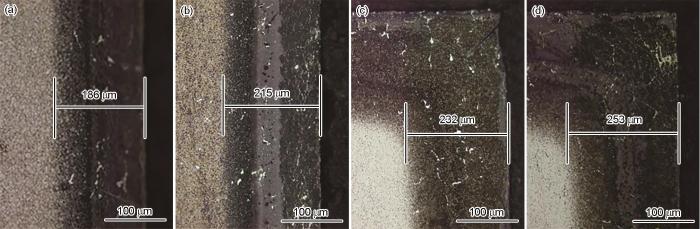

图2给出了7Cr7Mo2V2Si钢离子渗氮后的截面形貌。由图2a可见,在520 ℃渗氮24 h后试样表面渗氮层的厚度约为186 μm;分别将渗氮试样在550 ℃扩散处理10、20和30 h,渗氮层的厚度分别为215、232和253 μm,可见渗氮层深度明显增加(图2b~d)。这表明,随着扩散处理时间的延长渗氮层的厚度逐渐增加,其原因可能是氮原子逐渐向试样中心扩散。根据Fick第一定律,原子在钢中的扩散决定于温度和扩散激活能[17],而扩散激活能与钢晶体中的缺陷密度密切相关;扩散处理时,钢中原子运动的加剧导致出现未被原子占据的空位[18]。这类缺陷使N原子的扩散速度提高,降低了氮化物形核所需的氮势,进而提高了钢表面的化学反应活性,使渗氮层的厚度增加[19]。

图2

图2

7Cr7Mo2V2Si钢经520 ℃ × 24 h离子渗氮并在550 ℃扩散不同时间后渗氮层的厚度

Fig.2

Optical microscope images of 7Cr7Mo2V2Si steel after plasma nitriding at 520 oC for 24 h and diffusion at 550 oC for different time (a) without diffusion treatment; (b) diffusion for 10 h; (c) diffusion for 20 h; (d) diffusion for 30 h

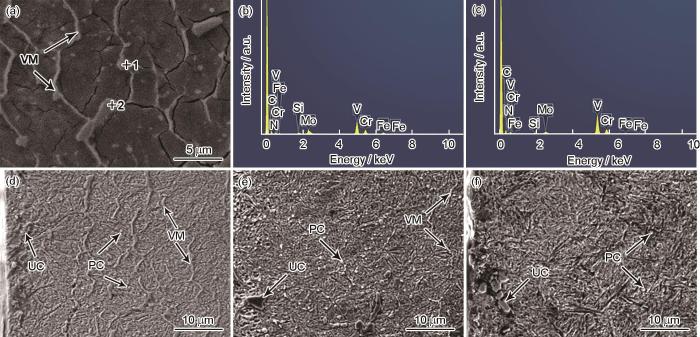

图3给出了7Cr7Mo2V2Si钢在520 ℃离子渗氮并在550 ℃扩散处理不同时间后的形貌和成分分析。由图3a可以看出,渗氮后,7Cr7Mo2V2Si钢渗层中出现了脉状组织(VM) (图3a)。这些脉状组织在原奥氏体晶界处尤为显著,呈连续线状以网状形态分布。能谱分析结果表明,脉状组织的主要化学成分有C、N、Si、V、Cr、Fe和Mo元素(图3b、c)。图3d~f给出了7Cr7Mo2V2Si钢渗氮后分别在550 ℃扩散处理10、20和30 h后的形貌。可以看出,扩散处理后脉状组织显著减少;扩散处理10 h后脉状组织溶解,数量和尺寸明显减小,呈短棒状分布;扩散处理20和30 h后脉状组织显著减少并消失,剩余的不规则形状的碳氮化物弥散发布在钢中;扩散处理后沿晶界析出了较多的碳化物(PC),大块碳化物(UC)随着扩散时间的延长逐渐变小。

图3

图3

7Cr7Mo2V2Si钢经520 ℃ × 24 h离子渗氮并扩散不同时间后渗层的组织

Fig.3

Microstructure of 7Cr7Mo2V2Si steel after plasma nitriding at 520 oC × 24 h and diffusion for different time (a) diffusion for 0 h; (b) energy dispersive spectrum (EDS) analysis of point 1 in Fig.3a; (c) EDS analysis of point 2 in Fig.3a; (d) diffusion for 10 h; (e) diffusion for 20 h; (f) diffusion for 30 h

2.2 7Cr7Mo2V2Si钢离子渗氮并扩散处理后的物相

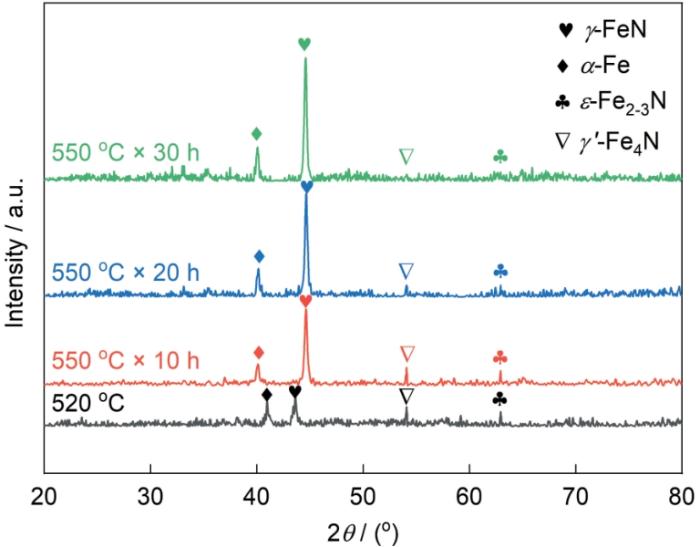

图4给出了7Cr7Mo2V2Si钢在520 ℃离子渗氮24 h然后在550 ℃扩散处理不同时间的XRD谱。可以看出,离子渗氮后的钢中主要有γ-FeN、α-Fe、ε-Fe2-3N和γ′-Fe4N相;扩散处理后7Cr7Mo2V2Si钢谱中出现的主要是α-Fe相、γ-FeN相和ε-Fe2-3N相的衍射峰。经过550 ℃ × 10 h、550 ℃ × 20 h和550 ℃ × 30 h扩散处理后,随着扩散时间的延长γ-FeN峰的强度逐渐提高,ε-Fe2-3N峰的强度降低,γ′-Fe4N峰的强度逐渐消失。其原因是,扩散处理使渗氮试样中的氮化物发生分解,γ相的反应γ′→ε→γ生成了富氮的奥氏体相[20]。扩散处理30 h后α-Fe衍射峰强度最高,表明α-Fe的含量最高。扩散处理后α-Fe的衍射峰向低角度方向偏移,与晶格膨胀和原子间距的增大有关[21]。这有利于增大材料抵抗变形的能力。γ-FeN相的衍射峰向高角度方向偏移,与晶格收缩和原子间距减小有关。这导致原子间的相互作用力减弱,使材料的硬度降低。

图4

图4

7Cr7Mo2V2Si钢经520 ℃ × 24 h离子渗氮并扩散不同时间后的XRD谱

Fig.4

XRD patterns of 7Cr7Mo2V2Si steel after plasma nitriding at 520 oC × 24 h and diffusion at 550 oC for different time

2.3 不同状态7Cr7Mo2V2Si钢截面的硬度

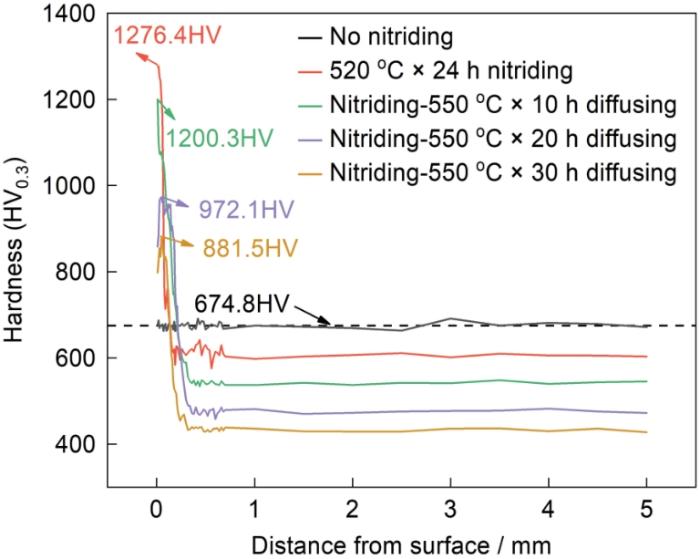

从不同状态7Cr7Mo2V2Si钢截面的表层至中心的硬度,如图5所示。图中的黑色曲线是未渗氮试样的硬度曲线,红色曲线是渗氮试样的硬度曲线,绿色、紫色和黄色曲线分别是渗氮和扩散处理10、20和30 h试样的硬度曲线。可以看出,未渗氮的7Cr7Mo2V2Si钢平均硬度为674.8HV,经520 ℃ × 24 h离子渗氮试样出现在深度为0.03 mm处的硬度峰值为1276.4HV,表面硬度提高了112.88%。经550 ℃ × 10 h扩散后表面硬度的最大值为1200.3HV,经550 ℃ × 20 h扩散后材料表面的最高硬度降为972.1HV,经550 ℃ × 30 h扩散后表面的最高硬度为881.5HV。这表明,表层的硬度随着扩散时间的延长显著降低,但是都高于未渗氮样件表面的硬度。未经过扩散处理试样心部的硬度为674.8HV,而经550 ℃ × 10 h、550 ℃ × 20 h和550 ℃ × 30 h扩散后心部的硬度也明显降低,分别降为541.5HV、475.4HV、432.9HV。

图5

图5

不同状态7Cr7Mo2V2Si钢的硬度梯度

Fig.5

Gradient hardness of nitrided layer in 7Cr7Mo2V2Si steel with different states

2.4 不同状态7Cr7Mo2V2Si钢截面的耐磨性

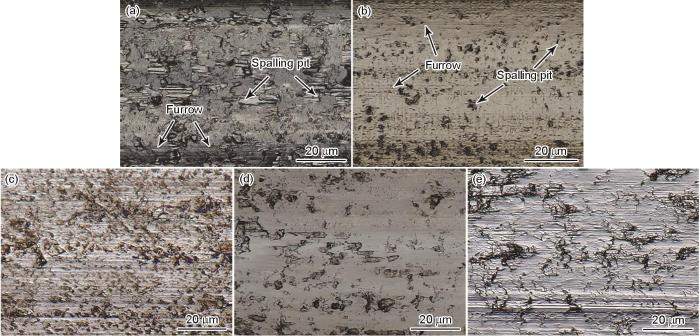

图6

图6

不同状态7Mo2V2Si钢在摩擦磨损测试后表面的形貌

Fig.6

Surface morphology of 7Mo2V2Si steel in different states after friction and wear tests (a) unnitride; (b) nitrided; (c) diffusion treated for 10 h; (d) diffusion treated for 20 h; (e) diffusion treated for 30 h

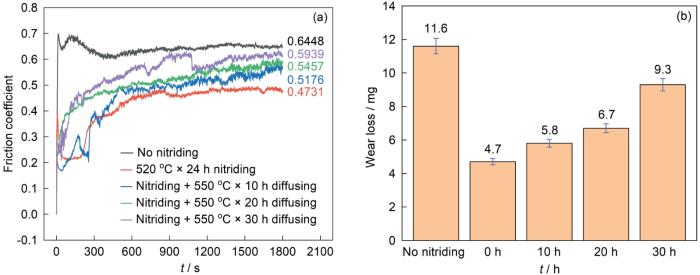

图7给出了不同状态7Cr7Mo2V2Si钢的摩擦系数和磨损失重。图7a表明,未离子渗氮的试样其平均摩擦系数为0.6448。经520 ℃ × 24 h离子渗氮后试样的平均摩擦系数为0.4731,摩擦系数降低了26.64%。离子渗氮后扩散10、20和30 h的试样,其平均摩擦系数分别为0.5176、0.5457和0.5939。这表明,与只经离子渗氮的试样相比,扩散不同时间的试样其平均摩擦系数增加。图7b给出了7Cr7Mo2V2Si钢未经离子渗氮和离子渗氮试样的磨损失重。可以看出未离子渗氮的试样其摩擦磨损失重为11.6 mg。经520 ℃ × 24 h离子渗氮的试样摩擦磨损失重为4.7 mg,降低了59.48%。离子渗氮并扩散处理10、20和30 h的试样,摩擦磨损失重分别为5.8、6.7和9.3 mg。这表明,随着扩散时间的延长磨损量提高,但是低于未渗氮试样的磨损量,即渗氮使7Cr7Mo2V2Si钢的耐磨性能提高。

图7

图7

不同状态7Cr7Mo2V2Si钢的摩擦系数曲线和磨损失重

Fig.7

Friction coefficient curves and wear mass loss of 7Cr7Mo2V2Si steel under different conditions (a) friction coefficient curves; (b) wear mass loss

3 讨论

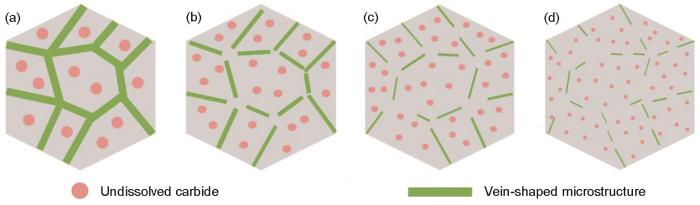

在7Cr7Mo2V2Si钢的渗氮过程中N元素逐渐在α-Fe晶格中累积直至过饱和,随着渗氮的进行N优先在晶界处积聚,并与其他合金元素结合生成稳定的γ'相和合金氮化物[22]。扩散处理促进了氮元素的扩散,使渗氮层的深度增加、改善了表面的积氮并增大了渗氮层与基体间的结合力和提高了渗层的脆性。在550 ℃扩散处理10、20和30 h使7Cr7Mo2V2Si钢渗氮层中的脉状组织减少,如图3所示。图8给出了7Cr7Mo2V2Si钢离子渗氮后在550 ℃扩散处理不同时间脉状组织和碳化物演化的示意图。可以看出,N元素在未经扩散处理的试样的晶界处积聚,形成了粗大的脉状组织(图8a)。随着扩散的进行大块氮化物因N元素的扩散而细化并逐渐溶解在基体中(图8b~d)。

图8

图8

7Cr7Mo2V2Si钢离子渗氮后在550 ℃扩散处理不同时间生成脉状组织和碳化物的演化示意图

Fig.8

Schematic diagram of vein-shaped microstructure and carbide evolution in plasma nitrided 7Cr7Mo2V2Si steel after diffusion treatment at 550 oC for different time (a) 0 h, (b) 10 h, (c) 20 h, (d) 30 h

4 结论

(1) 对7Cr7Mo2V2Si钢进行离子渗氮处理并在550 ℃扩散处理,随着扩散处理时间的延长更多的N原子向心部扩散而使渗氮层深度显著增加,离子渗氮产生的脉状组织由大面积的网状分布特征转变成短棒状,最后消失。

(2) 随着扩散时间的延长7Cr7Mo2V2Si钢渗氮层表面和心部的硬度降低,但是表面硬度仍比未渗氮时高。N原子向其内部扩散生成氮化物产生了适当的硬度梯度。

(3) 离子渗氮后7Cr7Mo2V2Si钢的平均摩擦系数和磨损量显著降低。扩散处理使其平均摩擦系数提高和磨损量提高,但是扩散处理后的耐磨性仍比未渗氮时高。

参考文献

Cold-working die materials and its heat treatment

[J].

冷作模具材料及其热处理

[J].

Development status of continuous casting process for high-carbon and high-alloy tool and die steel

[J].This paper summarizes the reports of latest developments on industrial application of continuous casting technology in high speed steel production abroad. In addition, and summarizes some Chinese enterprises and research institutions have done some research and industrial trial production in this field. It is suggested to increase investment on the research and development of continuous casting technology of high carbon and high alloy steel grades. Compared with the traditional casting, the research shows that continuous casting can reduce the thickness of coarse carbide by 40% and the grain size by 50%,and the carbide pattern is also changed from flat and lamellar to fibrous, which will facilitate the carbide refinement in the subsequent forging and rolling process.Finally,it is proposed that the continuous caster straightening machine,water cooling process,billet cross-section size and finished forging ratio can be optimized. If a breakthrough can be male in current technology of mature arc continous casting machine,it will be condueive to improve the quality of casting billet,and achieue industrial application of high carbon and high alloy die steel casting.

高碳高合金工模具钢连铸工艺发展现状

[J].

New development of research on die steel for die-casting in China

[J].

我国压铸模具钢研究新进展

[J].

Heat treatment microdistortion characteristics and mechanism of SLD-MAGIC cold working die steel

[J].

SLD-MAGIC冷作模具钢的热处理微畸变特性及其机理

[J].

The investigation of wear and corrosion behavior of plasma nitrided DIN 1.2210 cold work tool steel

[J].

Formation of nitrided layers on duplex steel-influence of multiphase substrate

[J].

Effect of ion nitriding process parameters on surface properties of 4Cr5MoSiV steel

[J].

离子渗氮工艺参数对4Cr5MoSiV钢表层组织与性能的影响

[J].

Effect of low temperature ion nitriding on tribological properties of 16Cr3NiWMoVNb gear steel

[J].

低温离子渗氮对16Cr3NiWMoVNb齿轮钢摩擦学性能的影响

[J].

Rolling contact fatigue and wear properties of 0.1C-3Cr-2W-V nitrided steel

[J].

Influence of surface straining on microstructure and mechanical property of 32Cr3MoV steel

[J].

表面形变处理对32Cr3MoVA钢渗氮层组织和性能的影响

[J].

Effect of different ion nitriding process on the nitriding layer of 20CrMnTi steel

[J].

不同的离子渗氮工艺对20CrMnTi钢的渗氮层的影响

[J].

Research on transformation mechanism about ε phase of 40Cr steel ion nitrided layer

[J].

40Cr钢离子渗氮层ε相转变机理研究

[J].

Effect of nitriding temperature on the microstructure of ion nitriding of 24Cr2Ni4MoV steel

[J].

氮化温度对24Cr2Ni4MoV钢离子氮化显微组织的影响

[J].

Effect of surface roughness on microstructure and properties of the nitrided layer of 38CrMoAl steel

[J].

表面粗糙度对38CrMoAl钢渗氮层组织和性能的影响

[J].

Gas nitriding process for 32Cr3MoVE steel

[J].In order to improve its hardness and wear resistance,the nitriding process was studied for the 32Cr3MoVE steel workpiece. The results show that the lower nitriding temperature and the lower nitrogen potential adopted in nitriding process can effectively control the depth of bright white layer,and avoid the production of coarse alloy nitrides,but the nitriding rate is slower. By keeping the nitrogen potential maintaining always around its threshold through certain multi-stage control mode,the nitriding process can ensure the nitriding rate,control the depth of bright white layer,and inhibit the formation of brittle phases as well. Finally,the suitable gas nitriding process by nitrogen potential threshold control for 32Cr3MoVE steel is obtained through process test validation.

32Cr3MoVE钢的气体渗氮工艺

[J].为提高32Cr3MoVE钢工件的硬度和耐磨性,对其渗氮工艺进行了研究。结果表明:渗氮过程中采取较低的渗氮温度及较低的氮势,可以有效控制白亮层深度及避免产生粗大的合金氮化物,但渗氮速度较慢;通过氮势门槛值控制的渗氮方法,在渗氮前期可以适当提高氮势,随着渗氮时间的增加,逐步多段地降低氮势,使实际氮势始终维持在氮势门槛值的附近,此方法在保证渗氮速度的同时,能有效控制32Cr3MoVE钢渗氮后的白亮层深度及抑制脆性相的生成;最后通过工艺试验加以验证,得出适合32Cr3MoVE钢的氮势门槛值控制的气体渗氮热处理工艺。

Effects of nitriding temperature on microstructure and properties of nitriding layer of G13Cr4Mo4Ni4V steel

[J].

渗氮温度对G13Cr4Mo4Ni4V钢渗氮层组织和性能的影响

[J].

Simulation of case depth of cementation steels according to Fick's laws

[J].

Effect of diffusion treatment on structure and hardness of low temperature pack cementation aluminizing coatings

[J].

扩散处理对低温粉末渗铝涂层组织及硬度的影响研究

[J].

Effect of denitriding on property and microstruture of nitrided case of SDHS2 die steel

[J].

退氮处理对SDHS2模具钢渗氮层组织与性能的影响

[J].

Dynamic theory of possible morphological characteristics of austenite nanocrystals formed upon the α-ε-γ transformation in Fe-Ni alloys via deformation and shuffling of {110} α planes

[J].

Effect of vacuum low pressure carburizing on microstructure and properties of austenitic stainless steels 304 and 316L

[J].Surface strengthening of 304 and 316L austenitic stainless steels was processed by using vacuum low pressure carburizing process. The microstructure, phase composition and microhardness distribution of the carburized layers were analyzed by means of optical microscope, scanning electron microscope, Thermo-Calc software, X-ray diffractometer and microhardness tester. The offsets of different diffraction peaks in the carburized layers and the changes in lattice parameters before and after carburizing of the tested steels were calculated. Combined with the effects of molybdenum on carburizing process of the austenitic stainless steels, the differences in the carburized layer thickness, surface hardness and mechanism of carbides precipitation after carburizing of 304 and 316L austenitic stainless steels were compared and studied. The results show that the carburized layers produced by 750 ℃ carburizing for 2.6 h are composed of expanded austenite and Cr<sub>23</sub>C<sub>6</sub> phases, the austenite lattice constant has increased by 1.33% and 1.14% respectively for 304 and 316L stainless steels, and Cr<sub>23</sub>C<sub>6</sub> is mainly precipitated in strip shape on the expanded austenite grain boundaries. The surface hardness of the 304 and 316L stainless steels after carburizing at 750 ℃ for 2.6 h is over 2 times higher than that of substrate.

真空低压渗碳对304与316L奥氏体不锈钢组织和性能的影响

[J].

Tribological properties of nitriding layer of Cr12MoV die steel in different wear stages during service

[J].

Cr12MoV模具钢渗氮层服役过程中不同磨损阶段的摩擦学特性

[J].

Study on effect of holding time in tempering on evolution of microstructures and corrosion resistance of E690 steel for ocean engineering

[J].

回火保温时间对E690海工钢组织演变及耐蚀性影响研究

[J].

Effect of vacuum graded quenching on microstructure and mechanical properties of 8Cr4Mo4V steel

[J].The 8Cr4Mo4V steel for aviation bearing manufacturing was subjected to graded quenching at different temperatures after being vacuum heat-treated. The effect of vacuum graded quenching on microstructure and mechanical properties of 8Cr4Mo4V steel were investigated by scanning electron microscope, XRD, Rockwell hardness tester, impact tester and rotational bending fatigue tester. Results show that the graded quenching 8Cr4Mo4V steel presents a microstructure of lower bainite, martensite/retained austenite and carbides. With the increase of graded quenching temperature, the number of precipitated carbides in the quenched and tempered steel increases, while the amount of retained austenite decreases. When the graded quenching temperature is 580℃, the bainite volume fraction of the quenched steel reaches a maximum of 13.87%, and the residual austenite volume fraction is 28.59%, and then after tempering, the precipitated carbides volume fraction and the Rockwell hardness reach the maximum namely 4.37% and 62.38 HRC respectively, in comparison to other desired graded quenching temperatures. The vacuum graded quenching can improve the comprehensive mechanical properties of 8Cr4Mo4V steel. In other word, the 580℃×10 min vacuum graded quenching treated 8Cr4Mo4V steel presents impact toughness and fatigue limit of rotational bending 23.3% and 110 MPa respectively higher than those of the traditional vacuum quenching treated ones.

真空分级淬火对8Cr4Mo4V钢组织和性能的影响

[J].在真空条件下对航空轴承用8Cr4Mo4V钢进行不同温度的分级淬火并采用扫描电镜观察其微观组织、用XRD谱进行相分析并测试洛氏硬度、冲击性能和旋转弯曲疲劳性能,研究了真空分级淬火对其微观组织和力学性能的影响。结果表明,真空分级淬火后的8Cr4Mo4V钢其微观组织由下贝氏体、马氏体/残余奥氏体和碳化物组成;随着分级淬火温度的提高,淬火和回火态钢中析出碳化物的数量增加,残余奥氏体的含量降低。分级淬火温度为580℃时淬火态钢中贝氏体的含量最高(达到13.87%),残余奥氏体的含量为28.59%。回火后析出碳化物的含量和洛氏硬度均为所有分级温度中的最大值,分别为4.37%和62.38HRC。真空分级淬火能提高8Cr4Mo4V钢的综合力学性能。与未分级真空淬火相比,进行580℃×10 min真空分级淬火的8Cr4Mo4V钢的冲击韧性提高了23.3%,旋转弯曲疲劳极限提高了110 MPa。

Effect of solid solution-and mesothermal phase transition-treatment on microstructure and mechanical property of ball bearing steel 8Cr4Mo4V

[J].

固溶温度对8Cr4Mo4V轴承钢的中温相转变和力学性能的影响

[J].在不同温度对8Cr4Mo4V钢固溶处理后在260℃盐浴中发生相转变而生成贝氏体组织,测定了钢的硬度和冲击韧性。使用扫描电镜、电子探针和光学显微镜等手段观察钢的微观组织,分析了合金元素扩散、贝氏体形核及贝氏体尺寸与固溶温度的关系,研究了固溶处理温度对力学性能的影响。结果表明,在1050℃和1065℃固溶处理后钢中的点状碳化物仍有剩余,阻碍了晶粒的长大;在1095℃和1110℃固溶处理后点状碳化物溶解,晶粒平均尺寸增大。固溶处理促使含Cr和V的碳化物溶解,但对含Mo碳化物的影响较小;高温固溶处理后Mo元素仍然存在于碳化物中,在基体中则较少。高温固溶处理使更多的Cr和V元素溶入基体中,降低了碳元素在基体中的扩散系数和贝氏体形核数目以及贝氏体的最终生成量,使贝氏体的组织粗化;随着固溶温度的提高,钢的硬度提高,而冲击韧性降低。

Effect of nitriding and diffusion time ratio on microstructure and properties of nitrided layer on AISI 316 stainless steel

[J].AISI 316 stainless steel was nitrided by two-stage vacuum nitriding process under different strong nitriding and diffusion time. The microstructure and properties of the nitrided layers were analyzed by means of X-ray diffraction(XRD), scanning electron microscope(SEM), optical microscope(OM), microhardness test and friction and wear test. The results show that after vacuum nitriding for 12 h, the nitrided layer consisting of γ'-Fe<sub>4</sub>N, ε-Fe<sub>2-3</sub>N and CrN phases is formed on the surface of AISI 316 stainless steel. The surface hardness and wear resistance of the nitrided AISI 316 stainless steel are significantly improved compared with those of substrate. Among them, when the nitriding and diffusion time ratio is 1:1(strong nitriding for 6 h and diffusion for 6 h), the thickness of the nitrided layer is about 96 μm, the surface hardness is about 1069 HV0.5, which is 4.5 times of the surface hardness of the substrate, and the wear loss under the load of 20 N is about 1/3 of that of the substrate. When the nitriding and diffusion time ratio is 1:2(strong nitriding for 4 h and diffusion for 8 h), the nitrided layer thickness is about 120 μm, the diffraction peak of ε-Fe<sub>2-3</sub>N phase is enhanced, and the wear loss under the load of 20 N is about 1/30 of that of the substrate. The prolonging of diffusion time can increase the thickness of nitrided layer, improve the surface morphology, and further improve the wear resistance of the AISI 316 stainless steel.

渗扩时间比对AISI 316不锈钢渗氮层组织与性能的影响

[J].

Effect of rare earth addition on microstructure, mechanical property and nitriding performance of a medium carbon steel

[J].Effect of rare earth microalloying on the microstructure and mechanical property of a medium carbon steel have been investigated, focusing on the influence of rare earth on the formed surface layer after nitriding heat treatment. The results indicate that by adding rare earth elements into the test steel: the original inclusions of long strips of MnS and the coarse Al2O3 convert into the small spherical inclusions of complex rare earth sulfur oxide; the ferrite volume content is reduced,while more finer lamellar pearlites are formed; the impact energy increases by 126% and the plasticity increases by 10%. After nitriding heat treatment, it is found that the addition of rare earth elements can significantly improve the surface hardness and nitride case depth, as well as improving the vein-like structure of the nitriding layer.

稀土元素对中碳钢组织、力学性能和渗氮的影响

[J].在一种中碳钢中通过添加微量稀土元素,研究稀土微合金化对钢的微观组织、力学性能以及在渗氮热处理条件下对渗层的影响。结果表明,添加稀土后,长条状的MnS夹杂和粗大块状的Al<sub>2</sub>O<sub>3</sub>转变成小球状的稀土硫氧化物夹杂;铁素体的含量降低,并促进细小片层结构的珠光体形成;冲击性能提升126%以及塑性提高10%;渗氮处理后,添加稀土能显著提高表面硬度和加深有效硬化层深,明显改善表面渗层的脉状组织。