骨科植入物须长时间承受应力才能保持稳定,因此其应该具有足够的强度和持久的机械完整性[1]。锌合金具有合适的拉伸强度及降解速率,可用作骨科植入材料[2,3]。锌较低的熔点(419.5 ℃)使其室温抗蠕变性较差。因此,锌及其合金在长期存储或使用时容易变形。Zn-Al基合金[4]、Zn-Cu-Ti[5,6]、轧制Zn-0.15Cu-0.07Ti合金[7]、铸造Zn-8Al-1Cu-(0.01-0.53)Mn[8]、挤压Zn-28.7Al-1.9Cu合金[9]以及压铸Zn-4Al-(0-3Cu)合金[10]都对蠕变较为敏感。Wu等[11]在25 ℃和105 ℃对ZnAl4Cu1Mg (0.04、0.21和0.31)合金进行单轴拉伸蠕变实验,得到的应力指数为6.9~8.0,蠕变激活能为93~104 kJ/mol,表明其蠕变由位错控制。Kallien和Leis[10]研究了压铸Zn-4Al-(0-3Cu)合金在25~85 ℃的蠕变性能,得到的应力指数为4~5,激活能约为94 kJ/mol。在大多数情况下,自扩散控制的位错蠕变是锌及其合金主要的变形机制。

1 实验方法

1.1 Zn-0.45Mn合金的制备

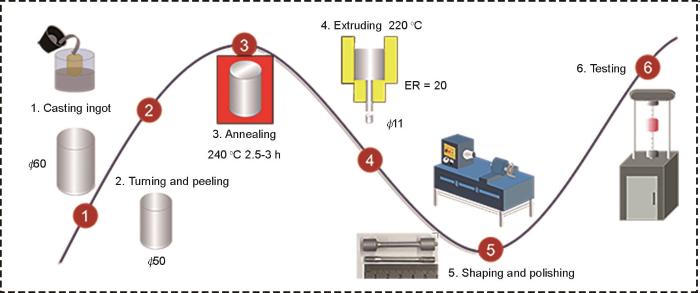

用真空感应炉制备Zn-0.45Mn合金,原料为高纯锌(99.99%)和纯锰(99.99%)。将原料表面打磨,并按Zn-0.45Mn (质量分数,%)的比例称量。为避免混入杂质,熔炼前先用纯锌清洗熔炼炉。熔炼时,将炉温升至650~750 ℃加入Mn和80%的纯锌块,待其完全熔化并均匀搅拌后加入其余20%的纯Zn块。继续搅拌使纯锌充分熔化,保温5 min后捞渣。熔炼时用氩气保护。

使用直径为60 mm的钢模具浇注。先将模具预热至240 ℃,然后将温度为580~620 ℃的金属熔液浇注到模具内,在空气中冷却凝固得到圆柱形铸锭。用机械切削切除铸锭的前端和尾部,除去外皮使其直径为50 mm。将铸锭棒加热至220 ℃,以20∶1的挤压比和0.4 mm/s的速度挤压成直径为11 mm的挤压态Zn-0.45Mn合金。

1.2 合金成分的测试和表征

用电感耦合等离子体发射光谱仪(ICP-OES,Perkin-Elmer Optima 2100)测定合金的成分(质量分数)。将0.2 g的合金粉末溶于6 mL浓盐酸中,置于120 ℃的电板上加热使合金粉末完全溶解,然后使其冷却并加去离子水定容至100 mL、摇匀后与标准液比较以测出其成分。

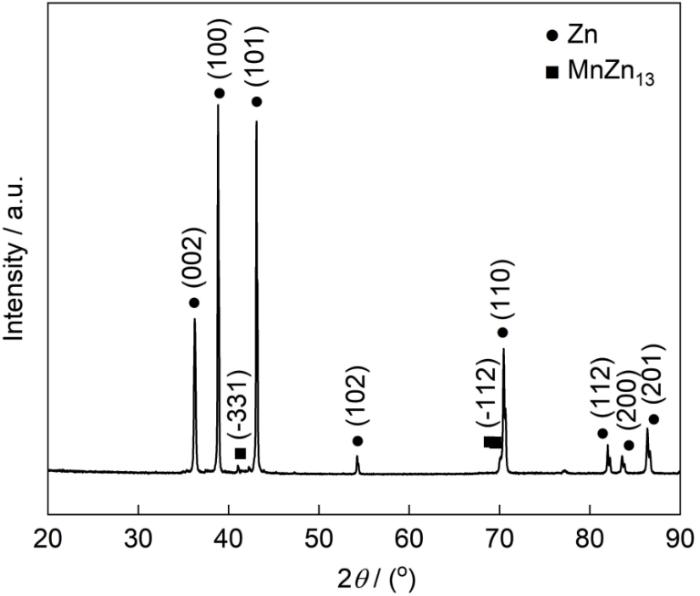

用X射线衍射仪(XRD, D8 Advance Davinci)测定锌合金的XRD谱。采用射线源为Cu Kα靶,扫描范围 10°~90°,扫描速度为0.3 (°)/s,扫描步长为0.02°。使用MDI Jade 6.5软件分析数据以确定合金的物相组成。

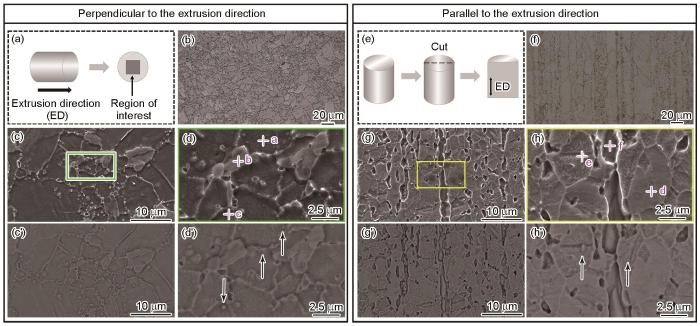

将样品按垂直于挤压方向和平行于挤压方向(ED)切割,逐级打磨抛光后用超声波清洗5 min,烘干后用金相腐蚀液(铬酸)腐蚀约25 s,用金相显微镜(OM,NMM-800RF)和扫描电子显微镜(SEM,FEI Quanta FEG 250)以及扫描电镜自带的背散射电子(BSE)和能谱仪(EDS)表征其微观结构。

1.3 力学性能和蠕变性能的测试

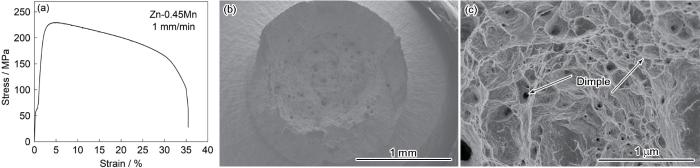

用电子万能实验机(MTS-100 kN)测试合金样品的力学性能。根据ISO 6892-1标准准备长度为11 mm的挤压态样品,并将其加工成标距长度为30 mm、直径为4 mm的拉伸试样。实验在室温下进行,设定十字头速度为1 mm/min。测试每一种试样的三个平行样品,取其结果的平均值。用SEM观察拉伸断口的形貌和微观结构。对比不同样品的断裂模式以分析合金的韧性断裂与脆性断裂。

从挤出的坯料中截取并加工成蠕变测试用样品。将样品表面打磨至光滑,然后用2.5 μm的二氧化硅抛光液手动抛光。根据合金的屈服强度设定蠕变实验的应力,分别为0.2、0.3、0.4、0.5、0.6和0.8 Rp0.2。根据应力-应变曲线确定屈服强度(Rp0.2)为0.2%塑性应变偏移所对应的应力。在机械式持久蠕变实验机(GNCJ-20)上进行恒载荷拉伸蠕变实验,用精度为1 μm的微位移传感器测量蠕变变形。

使用保温套将空气温度的变化控制在± 2 ℃以内,分别在37 ℃、51 ℃和121 ℃进行蠕变实验。蠕变实验至试样失效或在1000 h中断。用SEM表征蠕变实验前后合金样品的微观结构。Zn-0.45Mn合金的制备和力学性能测试的示意图如图1所示。

图1

图1

Zn-0.45Mn合金的制备工艺和性能测试流程

Fig.1

Experimental process flow for preparation and property testing of Zn -0.45Mn alloy

2 实验结果

2.1 Zn-0.45Mn合金的物相和微观组织

用ICP-OES测得的挤压态Zn-0.45Mn合金的实际成分列于表1,测试结果与设计成分基本一致。

表1 Zn-0.45Mn合金的化学成分

Table 1

| Sample | Element / %, mass fraction | |

|---|---|---|

| Zn | Mn | |

| Zn-0.45Mn | Bal. | 0.4511 |

图2给出了Zn-0.45Mn合金的XRD谱。可以看出,这种合金由主相Zn和第二相MnZn13 相组成。图3给出了挤压态Zn-0.45Mn合金在垂直和平行于挤压方向的微观组织形貌,图3a、e分别给出了观察部位的示意图。可以看出,在这两个方向上,合金晶粒的特征不同:垂直于挤压方向的晶粒较为均匀,而平行于挤压方向的晶粒细化有明显的方向性,且部分晶粒较大而具有流变织构。这一组织特征,是由挤压过程中发生动态再结晶和塑性变形诱导的晶粒取向变化所致[17]。从低倍和高倍SEM照片(图3c~d、g~h)可见,晶界清晰且有第二相颗粒,合金具有两种结构:白色颗粒或短棒状、块状结构。其中白色颗粒或短棒状(图3中a、c、e、f点所示)位于晶粒内部。用EDS分析合金的成分,结果列于表2。图3中a、c、e、f点由Zn和Mn元素组成,属于MnZn13相。块状结构(图3中b和d点)由Zn组成,因Zn耐腐蚀位于显微图像中较明亮的区域。

图2

图3

图3

Zn-0.45Mn合金在垂直于和平行于挤压方向的微观组织

Fig.3

Microstructure of Zn-0.45Mn alloy in the perpendicular and parallel to the extrusion direction (a, e) Schematic of the observation locations, (b, f) Optical micrographs of Zn-0.45Mn alloy perpendicular to and parallel to the extrusion direction, with ED indicating the extrusion direction, (c) SEM image perpendicular to the extrusion direction, (d) High magnification image of the green box area in (c), (c'-d') BSE images of (c-d), (g) SEM image parallel to the extrusion direction, (h) High magnification image of the yellow box area in (g), (g'-h') BSE images of (g-h)

表2 在垂直和平行于挤压方向不同位置的EDS分析结果

Table 2

| Point | Element / %, mass fraction | |

|---|---|---|

| Zn K | Mn K | |

| a | 99.30 | 0.70 |

| b | 99.91 | 0.09 |

| c | 99.11 | 0.89 |

| d | 100.00 | 0.00 |

| e | 99.73 | 0.27 |

| f | 98.11 | 1.89 |

这些结果与本文样品的数据相符,确认了Zn-0.45Mn合金中不同相的分布特征。这种分布方式显著影响合金的力学性能,尤其对强度和硬度的影响更大。已有研究表明,Zn基体中Mn元素的适量溶解能提高合金的高温稳定性,且添加扩散活化能(186.12 kJ/mol)较高的Mn可提高合金的抗蠕变性能[8,19]。在ZA-8(Zn-Al-Cu-Mg)合金中添加Mn元素,其稳态蠕变速率随Mn含量的提高而降低,且达到1%应变的时间显著延长,证实Mn是提高合金抗蠕变性能的重要元素[8]。本文实验用Zn-0.45Mn合金的MnZn13相在晶粒内部的稳定分布,可能在一定程度上有类似的作用。强化基体、抑制晶界滑移和位错攀移,可提高合金的高温服役能力和蠕变抗性。

2.2 Zn-0.45Mn 合金的室温拉伸性能

图4a给出了Zn-0.45Mn合金的拉伸应力-应变曲线。根据三组平行样品结果的平均值,计算出这种合金的屈服强度为207.1 MPa,抗拉强度为229.3 MPa,断裂伸长率为27.5%。

图4

图4

Zn-0.45Mn合金的拉伸应力-应变曲线、拉伸断口宏观形貌以及断口中心的放大图

Fig.4

Tensile stress-strain curve (a), macroscopic morphology of tensile fracture (b) and an enlarged view of the center of the fracture in Fig.4b (c)

2.3 在不同温度下的蠕变行为

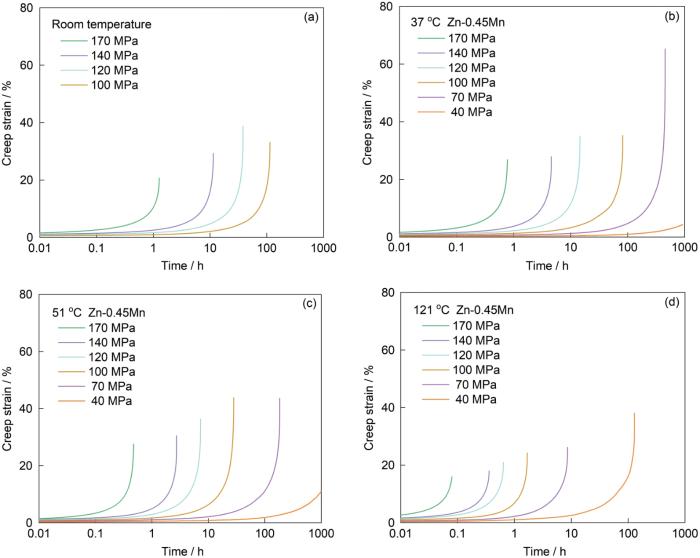

拉伸实验结果表明,Zn-0.45Mn合金的屈服强度为207.1 MPa。蠕变实验选择40、70、100、120、140和170 MPa蠕变应力,以模拟合金在不同负荷下的应力响应。

图5

图5

Zn-0.45Mn 合金在不同温度和应力下的蠕变行为

Fig.5

Creep curves at room temperature (a) and at 37-121 oC (b-d) under various stresses

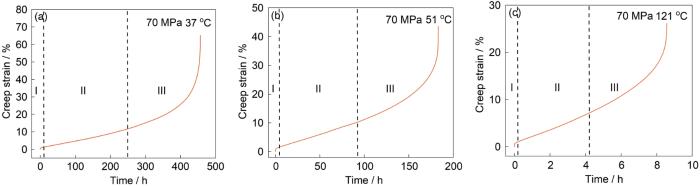

图6

图6

Zn-0.45Mn合金在应力为70 MPa、温度为37~121 oC的蠕变应变随时间的变化

Fig.6

Creep strain versus time curves of Zn-0.45Mn alloy at 70 MPa, 37-121 oC, showing the initial creep stage (Ⅰ), steady state creep stage (Ⅱ) and final creep stage (Ⅲ)

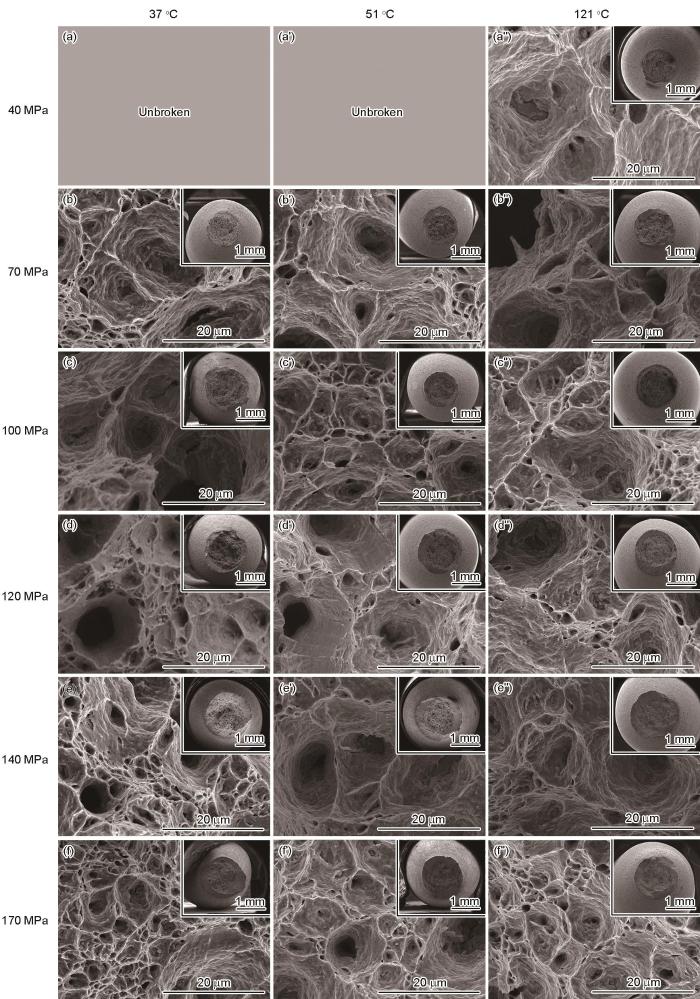

2.4 蠕变断口

图7

图7

Zn-0.45Mn 合金在温度为37 ℃、51 ℃和121 ℃以及各种应力蠕变断裂后的断口形貌

Fig.7

Fracture morphologies of Zn-0.45Mn alloy after creep rupture under various stresses at 37 oC, 51 oC, and 121 oC (No rupture occurred after 1000 h of creep at 37 oC and 51 oC under 40 MPa)

温度也显著影响Zn-0.45Mn合金的蠕变断裂行为。温度为37 ℃,断裂前期的变形主要受韧窝主导。随着实验温度提高到51 ℃,蠕变损伤加剧、微空洞的形核、长大及聚结更加明显。在121 ℃高温条件下样品的平均韧窝直径增大、韧窝数量密度降低和撕裂棱的形貌范围缩小。这些现象表明,较高的温度加速了空洞的扩展,使合金样品较早进入终期蠕变阶段直至断裂。蠕变温度和施加的应力促进了微空隙的长大,使蠕变裂纹沿晶界扩展,最终形成韧窝断裂模式[21]。

实验结果表明,Zn-0.45Mn合金在37 ℃和51 ℃的抗蠕变性能良好,而在121 ℃和高应力下呈现脆性断裂特征。

3 讨论

3.1 蠕变行为

可用Ashby和Dyson[22]提出的蠕变损伤容限参数λ量化蠕变损伤机制,

图8

图8

Zn-0.45Mn 合金在37 ℃、51 ℃和121 ℃的稳态蠕变速率与应力的关系

Fig.8

Relationship between the steady-state creep rate and applied stress for Zn-0.45Mn alloy at 37 oC, 51 oC, and 121 oC

3.2 温度对蠕变的影响

不同温度下的蠕变行为呈现显著的温度依赖性。实验数据表明,在应力相同的条件下随着温度从37 ℃提高到121 ℃,Zn-0.45Mn合金的稳态蠕变速率显著提高(图9),表明温度的提高加速了材料内部的扩散。

图9

图9

Zn-0.45Mn 合金在不同温度的蠕变断裂行为

Fig.9

Creep fracture behavior at different temperatures (a) relationship between fracture time and applied stress, (b) relationship between fracture time and minimum creep rate

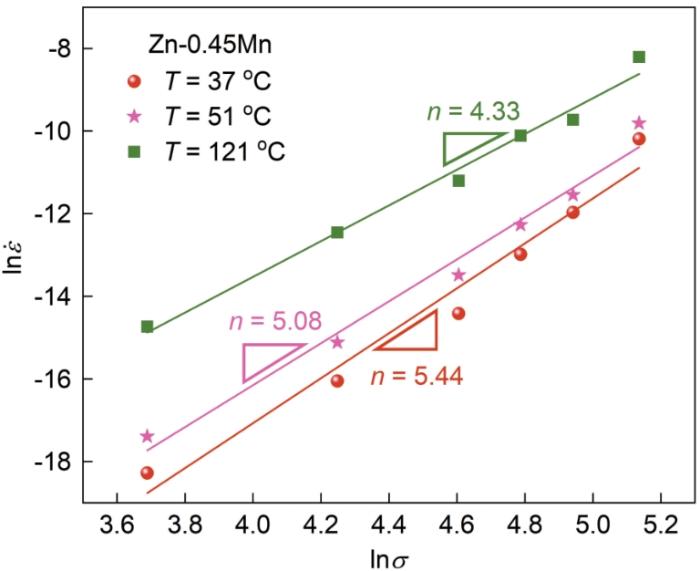

3.3 蠕变机制

Zn-0.45Mn合金的蠕变行为和断裂性能,显著依赖温度和应力。实验结果表明,随着温度的提高和应力的增大,合金的蠕变速率迅速提高和断裂时间显著缩短,表明其在高温高应力条件下抗蠕变性能的明显劣化。蠕变是一种典型的热激活过程,温度达到特定阈值时合金的滑移机制可能转变,显著加速蠕变应变和提高稳态蠕变速率。

合金材料的稳态蠕变速率与外加应力和温度的关系可以用蠕变本构方程

在蠕变过程中温度不变时,

将其微分可得应力指数

对不同温度下Zn-0.45Mn合金的

图10

图10

Zn-0.45Mn 合金在37 ℃、51 ℃和121 ℃的蠕变应力指数n

Fig.10

Creep stress exponent n at 37 oC, 51 oC, and 121 oC

蠕变应力不变时,进行公式变换可得不同应力下稳态蠕变速率的对数与温度的倒数关系(图11a),根据其斜率可计算出蠕变激活能

图11

图11

Zn-0.45Mn合金在不同应力下稳态蠕变速率的对数(

Fig.11

Logarithm of steady state creep rate (

ZnAl4Cu1Mg合金在温度为25 ℃和105 ℃的应力指数和蠕变激活能较高。其应力指数为6.9~8,蠕变激活能为93~104 kJ/mol,与Zn的自扩散激活能(92 kJ/mol)接近[11]。在较低温度区间,Zn-0.3Li和Zn-0.4Li合金[32](23~51 ℃)的蠕变应力指数较低(n ≈ 2.3),激活能为80 kJ/mol,表明晶界滑移可能是其主要的蠕变机制。与其相比,镁合金的蠕变激活能较高,其蠕变变形受到位错攀移与晶界滑移的协同控制[34]。温度为175~225 ℃时,Mg-8.9Gd-1.8Y-0.5Zr-0.2Ag合金[35]的蠕变激活能为95.9 kJ/mol和99.5 kJ/mol,均低于Mg的自扩散激活能(135 kJ/mol),表明蠕变主要由扩散控制的晶界滑移(GBS)主导;当温度提高到225~275 ℃蠕变激活能随之提高到 237.7 kJ/mol和246.3 kJ/mol,对于其它镁合金,其蠕变激活能的升高与沉淀硬化合金的结构变化(如析出或析出相粗化)相关[36,37]。

与晶内位错滑移相比,晶界滑动可能引发局部应力集中,进而加剧微观损伤的累积并促进裂纹扩展。显微观察表明,晶界滑动与位错滑移、晶界迁移和扩散等机制相互作用,共同主导蠕变变形。特别是在高温高应力条件下,晶界滑动的可能性显著提高,从而提高了Zn-0.45Mn合金的蠕变速率。除了晶界滑动,位错攀移也可能是Zn-0.45Mn合金蠕变的重要机制。位错攀移受空位扩散驱动而在晶界区域引发应力松弛,加快了材料的蠕变变形。应力指数的实验结果证实,在高温高应力条件下位错攀移可能占主导,空位扩散使蠕变变形显著加剧。

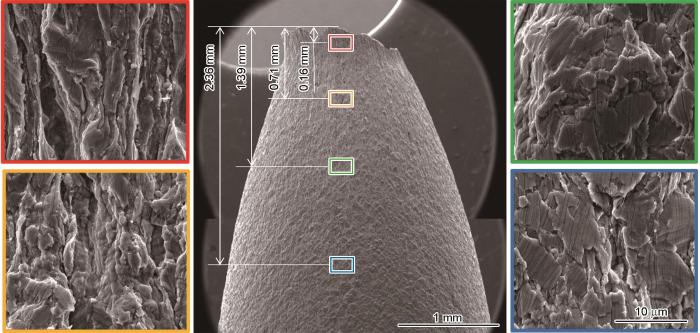

为了验证蠕变机制的主导作用,用SEM观察了Zn-0.45Mn合金在37 ℃、70 MPa应力条件下蠕变断裂样品的微观结构(图12)。结果表明,裂纹扩展表现出明显的区域依赖性:在靠近断口的区域(如颈缩区域,距断口最远端0.16 mm处),晶界滑移和裂纹分叉更明显;而在距离断口较远的区域(距断口最远端2.36 mm处),微观形貌趋于平整,晶界滑移和裂纹扩展减弱。这种区域依赖性表明,随着应力集中效应的减弱,晶界滑动的主导作用降低,进一步证实了晶界滑动在蠕变断裂过程中的关键作用。

图12

图12

Zn-0.45Mn合金在温度为37 ℃、应力为70 MPa条件下蠕变断裂后的纵截面

Fig.12

Longitudinal section of Zn-0.45Mn alloy after creep rupture at 70 MPa and 37 oC

根据Zn-0.45Mn合金的微观组织,其蠕变行为在很大程度上受到显微结构的影响。在晶粒细化过程中粗大晶粒因剧烈塑性变形逐渐破碎,而第二相 MnZn13的均匀分布和晶界钉扎抑制了晶界迁移,从而延缓了蠕变。这种钉扎效应在高温高应力条件下尤为重要,不仅提高了抗蠕变性能还显著影响了蠕变变形模式。同时,晶界滑动和位错滑移、晶界迁移以及扩散相互作用,共同影响了材料的整体蠕变机制。这些显微结构的变化为蠕变断裂行为的理论模型提供了重要支持,揭示了晶界滑动在高温高应力条件下对Zn-0.45Mn合金蠕变变形的主导作用。

4 结论

(1) 在较低的温度即使应力低至屈服强度0.2倍,Zn-0.45Mn合金也发生显著的蠕变变形。Zn-0.45Mn合金的最终断裂模式为韧性断裂。

(2) 随着蠕变应力的增大Zn-0.45Mn合金的蠕变速率和总变形程度显著提高,表明应力是主导其蠕变行为的重要因素,而温度的影响较小。

(3) 在低应力条件下Zn-0.45Mn合金的表观蠕变激活能与Zn的晶界扩散激活能接近,蠕变机制更倾向于晶界滑移。

参考文献

Research progress on biodegradable zinc-based alloys in orthopedics

[J].

可降解锌基合金在骨科领域的研究进展

[J].

Zinc exhibits ideal physiological corrosion behavior for bioabsorbable stents

[J].

Revolutionizing metallic biomaterials

[J].Entering 21st century, the metallic biomaterials are revolutionizing. New kinds of metallic biomaterials represented by biodegradable metals, nacocrystalline metals and alloys, and bulk metallic glasses, had been explored as implantable biomaterials, and correspondingly the nature of metallic biomaterials are shifting from the bio-inert (with stainless steel, Co-based alloys and Ti alloys) to bio-active and multi-biofunctional (anti-bacterial, anti-proliferation, anti-cancer, etc.). The newly-emerging 3D printing technology and thin film technology had been applied to the advancing manufacture and intelligence of the medical devices made of metallic biomaterials. In this paper, the current research status of the revolutionizing metallic biomaterials had been reviewed, and the future research and development tendencies for newly-developed metallic biomaterials towards bio-functionalization, composite and intelligence are also proposed.

处在变革中的医用金属材料

[J].进入21世纪,医用金属材料正在发生变革。以可降解金属、纳米晶金属、大块非晶合金为代表的新型医用金属材料被尝试作为植入材料,材料属性正在从生物惰性向生物活性和生物功能化(抗菌、抗增生、抗肿瘤)方向发展,同时3D打印技术和薄膜技术也在被尝试用于金属植入器械的先进制造以及智能化。本文综合评述了处于变革中的医用金属材料研究现状,展望了新型医用金属材料功能化、复合化、智能化的未来发展趋势。

Creep deformation and microstructural change in extruded Zn-Al based alloy

[J].

Effects of microalloy elements on microstructure and properties of Zn-Cu-Ti alloy

[J].

微量合金元素对Zn-Cu-Ti合金显微组织与性能的影响

[J].

Effect of trace elements Cr and Mg on mechanics and creep properties of Zn-Cu-Ti alloys

[J]

微量元素Cr、Mg对Zn-Cu-Ti合金力学和蠕变性能的影响

[J].采用熔铸、挤压的方法制备了添加Cr、Mg等微量元素的Zn-Cu-Ti系合金, 通过蠕变试验测定了合金的拉伸蠕变性能, 借助SEM、EDS等手段对合金蠕变前后显微组织进行了观察和分析。结果表明: 添加微量元素可降低Zn-Cu-Ti合金常温蠕变速率, 提高合金蠕变抗力。其中添加了Cr元素的Zn-Cu-Ti合金抗拉强度、蠕变性能都有一定的提高;添加了微量元素Mg的Zn-Cu-Ti合金抗拉强度有一定提高, 其蠕变抗力有大幅度提高。Zn-Cu-Ti系合金的常温蠕变机制为位错在晶内的滑移机制, 固溶强化和晶界处的第二相颗粒能提高合金的抗蠕变性能。

Influence of strain rate and heat treatments on tensile and creep properties of Zn-0.15Cu-0.07Ti alloys

[J].The use of Cu and Ti in Zn alloys improves mechanical properties as solid solution and dispersoid particles (grain refiners) may harden the material and reduce creep deformation. This is one of the main design problems for parts made with Zn alloys, even at room temperature. In this work the mechanical behavior of a Zn-Cu-Ti low alloy is presented using tensile tests at different strain rates, as well as creep tests at different loads to obtain the value of the strain rate coefficient m in samples parallel and perpendicular to the rolling direction of the Zn strip. The microstructure of the alloy in its raw state, as well as heat treated at 250°C, is also analyzed, as the banded structure produced by rolling influences the strengthening mechanisms that can be achieved through the treatment parameters.

The effect of manganese on the microstructure and mechanical properties of zinc-aluminium based ZA-8 alloy

[J].

Effect of grain size on the activation energy for plastic deformation near room temperature in a Zn-28.7 pct Al-1.9 pct Cu alloy

[J].

Creep behaviour of eutectic Zn-Al-cu-mg alloys

[J].

Towards revealing key factors in mechanical instability of bioabsorbable Zn-based alloys for intended vascular stenting

[J].Zn-based alloys are recognized as promising bioabsorbable materials for cardiovascular stents, due to their biocompatibility and favorable degradability as compared to Mg. However, both low strength and intrinsic mechanical instability arising from a strong strain rate sensitivity and strain softening behavior make development of Zn alloys challenging for stent applications. In this study, we developed binary Zn-4.0Ag and ternary Zn-4.0Ag-xMn (where x = 0.2-0.6wt%) alloys. An experimental methodology was designed by cold working followed by a thermal treatment on extruded alloys, through which the effects of the grain size and precipitates could be thoroughly investigated. Microstructural observations revealed a significant grain refinement during wire drawing, leading to an ultrafine-grained (UFG) structure with a size of 700 nm and 200 nm for the Zn-4.0Ag and Zn-4.0Ag-0.6Mn, respectively. Mn showed a powerful grain refining effect, as it promoted the dynamic recrystallization. Furthermore, cold working resulted in dynamic precipitation of AgZn particles, distributing throughout the Zn matrix. Such precipitates triggered mechanical degradation through an activation of Zn/AgZn boundary sliding, reducing the tensile strength by 74% and 57% for Zn-4.0Ag and Zn-4.0Ag-0.6Mn, respectively. The observed precipitation softening caused a strong strain rate sensitivity in cold drawn alloys. Short-time annealing significantly mitigated the mechanical instability by reducing the AgZn fraction. The ternary alloy wire showed superior microstructural stability relative to its Mn-free counterpart due to the pinning effect of Mn-rich particles on the grain boundaries. Eventually, a shift of the corrosion regime from localized to more uniform was observed after the heat treatment, mainly due to the dissolution of AgZn precipitates. STATEMENT OF SIGNIFICANCE: Owing to its promising biodegradability, zinc has been recognized as a potential biodegradable material for stenting applications. However, Zn's poor strength alongside intrinsic mechanical instability have propelled researchers to search for Zn alloys with improved mechanical properties. Although extensive researches have been conducted to satisfy the mentioned concerns, no Zn-based alloys with stabilized mechanical properties have yet been reported. In this work, the mechanical properties and stability of the Zn-Ag-based alloys were systematically evaluated as a function of microstructural features. We found that the microstructure design in Zn alloys can be used to find an effective strategy to not only improve the strength and suppress the mechanical instability but also to minimize any damage by augmenting the corrosion uniformity.Copyright © 2020. Published by Elsevier Ltd.

Recent progress of novel biodegradable zinc alloys: from the perspective of strengthening and toughening

[J].

Abnormal effect of Mn addition on the mechanical properties of as-extruded Zn alloys

[J].

Strengthening mechanism and biocompatibility of degradable Zn-Mn alloy with different Mn content

[J].

Bimodal coarse-grained and unimodal ultrafine-grained biodegradable Zn-0.5 Mn alloy: superplastic mechanism and short-term biocompatibility in vivo

[J].

Dynamic recrystallization and its effect on superior plasticity of cold-rolled bioabsorbable zinc-copper alloys

[J].High plasticity of bioabsorbable stents, either cardiac or ureteral, is of great importance in terms of implants’ fabrication and positioning. Zn-Cu constitutes a promising group of materials in terms of feasible deformation since the superplastic effect has been observed in them, yet its origin remains poorly understood. Therefore, it is crucial to inspect the microstructural evolution of processed material to gain an insight into the mechanisms leading to such an extraordinary property. Within the present study, cold-rolled Zn-Cu alloys, i.e., Zn with addition of 1 wt.% and 5 wt.% of Cu, have been extensively investigated using scanning electron microscopy as well as transmission electron microscopy, so as to find out the possible explanation of superior plasticity of the Zn-Cu alloys. It has been stated that the continuous dynamic recrystallization has a tremendous impact on superior plasticity reported for Zn-1Cu alloy processed by rolling to 90% of reduction rate. The effect might be supported by static recrystallization, provoking grain growth and thereby yielding non-homogeneous microstructures. Such heterogeneous microstructure enables better formability since it increases the mean free path for dislocation movement.

Additively manufactured biodegradable Zn-Mn-based implants with an unprecedented balance of strength and ductility

[J].

First-principles calculations of diffusion activation energies for designing anti-self-aging biodegradable zinc alloys

[J].

Fractographic correlations with mechanical properties in ferritic martensitic steels

[J].

Damage accumulation and failure of HSLA-100 steel

[J].

Creep damage mechanics and micromechanisms

[A]. ValluriSR, TaplinDM R, RaoPR, et al.

An empirical relationship between rupture life and minimum creep rate in creep-rupture tests

[J].

Effects of Zn and Cr additions on precipitation and creep behavior of a dilute Al-Zr-Er-Si alloy

[J].

Research on hot working behavior of low-nickel duplex stainless steel 2101

[J].

节Ni型2101双相不锈钢的高温热加工行为研究

[J].采用Gleeble-3800热力模拟试验机在温度为1123~1423 K、应变速率为0.001~10 s<sup>-1</sup>的条件下对2101双相不锈钢进行了热压缩实验,以研究热变形参数对其热加工行为的影响规律。结果表明,相同应变速率下,随温度升高,流变曲线由动态再结晶向动态回复转变。变形速率由0.001 s<sup>-1</sup>增至0.01和0.1 s<sup>-1</sup>提高了动态再结晶温度范围,而1和10 s<sup>-1</sup>的较高应变速率不利于动态再结晶。在应变速率为0.001~0.1s<sup>-1</sup>、变形温度为1253~1323 K时,峰值应力所对应的应变越小,奥氏体动态再结晶越容易发生,有利于等轴状再结晶组织形成。低应变速率下,变形温度升高使奥氏体再结晶晶粒长大,且Zener-Hollomon参数较大时,动态再结晶效果变差与Mn稳定奥氏体能力较Ni弱有关。基于热变形方程计算得到该不锈钢热变形激活能Q=464.49 kJ/mol,略高于2205双相不锈钢,并建立了峰值流变应力本构方程。结合不同变形条件下的应变曲线和显微组织,根据热加工图确定了最佳热加工区域为应变速率在0.001~0.1 s<sup>-1</sup>、变形温度为1220~1350 K,该区域功率耗散系数处于0.40~0.47的较高值,发生了明显奥氏体动态再结晶。

The influence of crystallographic texture on grain boundary sliding during superplastic deformation in Zn–1.1% Al alloy

[J].

Creep behavior and creep mechanism of Mg-Gd-Y-Sm-Zr alloy

[J].

Superplasticity in thin magnesium alloy sheets and deformation mechanism maps for magnesium alloys at elevated temperatures

[J].

Creep deformation mechanisms in coarse-grained solid solution Mg alloys

[J].

Creep-resistant magnesium alloys

[J].

Inhibiting creep in fine-grained Mg-Al alloys through grain boundary stabilization

[J].

Microstructure, mechanical properties and creep behaviour of extruded Zn-xLi (x = 0.1, 0.3 and 0.4) alloys for biodegradable vascular stent applications

[J].

Microstructural evolution during accelerated tensile creep test of ZK60/SiCp composite after KoBo extrusion

[J].In the current study, the creep properties of magnesium alloy reinforced with SiC particles were investigated. For this purpose, ZK60/SiCp composite was produced by the stir casting method following the KoBo extrusion and precipitation hardening processes. The creep tests were performed at 150 °C under 10–110 MPa. The results showed that the stress exponent (n) and the average true activation energy (Q) was changed at high stresses, was found with increasing stress, the creep mechanism changing from grain boundary sliding to dislocation climb. The results of microstructure characterization after the creep test showed that at low stresses, the dynamic recrystallization resulting from twinning induced the GBS mechanism. However, at high stresses, with increasing diffusion rates, conditions are provided for dynamic precipitation and the dislocation climb of the dominant creep mechanism. Examination of the fracture surfaces and the surrounding areas showed that the cavity nucleation in the ternary boundary and surrounding precipitation was the main cause of damage. The evaluation of the samples texture after creep showed that the unreinforced alloy showed a moderately strong fiber texture along the angle of ϕ1 = 0–90°, which was tilted about Φ = 10°. A new strong texture component was observed at (90°, 5°, 0°) for the composite sample, which crept due to minor splitting of the basal pole by ~5° toward RD.

Effect of dislocation-induced aging precipitate bands on creep resistance of Mg-Gd-Y-Zr-Ag alloy

[J].

Microstructures and mechanical properties of Mg-13Gd-1Zn alloy

[J].A ternary alloy with composition of Mg-13Gd-1Zn (%, mass fraction) was prepared by conventional smelting and casting technique. The microstructure and mechanical properties of the as-cast, as-annealed, as-extruded and as-aged (T5) alloy were investigated. The results show that the microstructure of the as-cast alloy consists of α-Mg matrix, (Mg, Zn)3Gd eutectic and a 14H long period staking ordered (14H-LPSO) phase. The significant increase of 14H-LPSO phase after annealing and ageing (T5) treatment in the alloy microstructure indicates that the precipitation of the 14H-LPSO phase occurs in a wide temperature range (200~510oC). The β' and β1 precipitates have also been observed in the alloy after ageing (T5) treatment. Under the combined action of precipitation strengthening and LPSO strengthening, the tensile strength, yield strength and elongation of the alloy are 397 MPa, 197 MPa and 2.56%, respectively. The creep properties of the Mg-13Gd-1Zn alloy are higher than those of the WE54 alloy in the two experimental conditions of 200oC/80 MPa and 200oC/120 MPa.

Mg-13Gd-1Zn合金的组织与力学性能

[J].

Microstructure and creep behavior of a cast Mg-RE alloy

[J].

铸造Mg-RE合金的显微结构及其蠕变行为

[J].

Creep behaviors and stress regions of hybrid reinforced high temperature titanium matrix composite

[J].