1 实验方法

1.1 实验用原料

实验用原料都是分析纯:异佛尔酮二异氰酸酯(IPDI),聚四氢呋喃二醇(PTMG,Mn ≈ 1 000),1,4-丁二醇(BDO),三羟甲基丙烷(TMP),二月硅酸二丁基锡(DBTDL),碳酸二甲酯(DMC),邻苯二甲酸二辛酯(DOP),二氯甲烷(DCM),丙酮,双三氟甲基磺酰亚胺锂(LiTFSI),聚碳酸丙烯酯(PPC),丁二腈(SN),铝箔(Al,厚度d = 0.2 mm)。

1.2 CPUEEs的制备

用预聚体法制备CPUEEs并在室温下固化成型:设定预聚体异氰酸酯的含量NCO为8%,扩链系数为0.9,扩链交联剂为TMP和BDO。

预聚体电解质的合成:将PTMG加入配有搅拌器、温度计、真空系统和电加热套的三口烧瓶中,在100 ℃~110 ℃真空脱水1 h。将其降温到30 ℃~50 ℃加入IPDI,待自然升温停止后缓慢加热到70 ℃~80 ℃,保温反应2 h后得到预聚体。取样分析NCO基的含量。当NCO的含量达到设定值时在室温下在该预聚体中加入溶解在极性溶剂DMC中的锂盐LiTFSI,搅拌90 min后密封静置3~6 h备用。

PPC-LiTFS I的制备:在溶于DCM的PPC中添加溶于DMC中的LiTFSI,充分搅拌后静置备用。SN-LiTFSI的制备:将SN与LiTFSI混合后静置24 h,高浓度锂盐的加入使原来的蜡状SN呈现流动态,加入丙酮充分搅拌后静置备用。CPUEEs的制备:在上述制备好的预聚体电解质中按照一定比例加入PPC-LiTFSI或PPC-LiTFSI、SN-LiTFSI,在40 ℃搅拌1 h得到复合预聚体电解质。将扩链剂BDO、交联剂TMP在100 ℃~110 ℃下真空脱水1 h后再加入适量的催化剂DBTDL,均匀混合后将其加入复合预聚体电解质中,然后快速搅拌2~4 min。观察其温度的变化并记录,然后尽快地将其放入抽真空装置中脱泡30~90 s。把制备好的混合物尽快浇注在涂有脱膜剂的聚四氟乙烯模具中(CPUEEs厚度为0.8 mm),将其在室温固化7~10 d。CPUEEs的组成列于表1。

表1 CPUEEs的组成

Table 1

| Sample | nTMP / nBDO | PPC-LiTFSI / % | SN-LiTFSI / % |

|---|---|---|---|

| CPUEE1 | 0.25∶0.65 | 0 | 0 |

| CPUEE2 | 0.25∶0.65 | 10 | 0 |

| CPUEE3 | 0.25∶0.65 | 10 | 15 |

1.3 热引导动态场阳极的键合[15]

设计热引导动态场阳极键合,使用由高渐低递减的动态电场将表面处理后经过热引导预连接的样品在较低的温度和较低的压力下进行键合,制备出适于耐热性较差、高电场容易击穿的聚合物材料。实验步骤为:

待键合基片表面清洗后,分别用丙酮、无水乙醇和去离子水将Al箔清洗后干燥,用棉棒蘸取丙酮清洗制备出的CPUEEs表面,再将其分别置于无水乙醇和去离子水中超声清洗。

表面活化处理:对CPUEEs的待键合表面进行反应性气体低温等离子体表面处理5~10 min以提高表面亲水性和引入含氧官能团;将Al箔浸于温度为30 ℃~50 ℃的标准RCA溶液(标准RCA常用于半导体硅片的去氧化膜清洗,溶液配比为NH4OH∶H2O2∶H2O = 4∶1∶6)中10~20 min,使其表面有一定数量的氢氧基团。

热引导预连接:将CPUEEs置于温度为80 ℃~110 ℃的真空干燥箱中预热处理3~5 min使聚合物材料整体足够柔顺和表面易于贴合。将Al箔在100~130 ℃的真空干燥箱中预热,使其温度略高于CPUEEs表面的温度。将预热处理的CPUEEs和Al箔立即进行层叠贴合并在0.05~0.15 MPa的恒定压力下保持5~10 min,卸载压力后进行静电键合。

动态场静电键合:将预连接的CPUEEs和Al箔置于静电键合设备中,设定温度为55 ℃、载荷为0.05 MPa、电场强度为0.65 kV,然后接通电源开始键合。电流在短时间内上升到峰值后随即降低,当电流的下降明显减慢或者电流下降出现停滞时立即调低键合电压,调幅为初设值的1/2~1/4;当电流降速再次明显降低或电流下降再次出现停滞时继续调低键合电压,调幅为上一次稳定值的1/2~1/4,重复此步骤,直到电流值稳定在较小的数值。CPUEEs与Al箔在热引导动态场阳极键合连接后,将其标记为CPUEEs-Al。

1.4 性能表征

在室温下用布鲁克D8 Advance衍射仪测试样品的XRD谱,2θ扫描范围为5°~80°,扫描速度为5 (°)/min。用Q2000型示差扫描量热仪进行示差扫描量热分析(DSC),测试温度范围为-90~300 ℃。用STA449F3同步热重分析仪进行热重分析(TGA),测试温度范围为25~610 ℃。用交流阻抗技术测量阴极材料的电导率,CPUEEs的厚度为0.3 cm,将其裁成3 cm × 1 cm的长方形,夹在两片不锈钢之间组装成不锈钢/CPUEEs/不锈钢阻塞电极,用Autolab/PG STAT302电化学工作站测试,测试温度为55 ℃。

用LYRA 3 XMH扫描电子显微镜观察CPUEEs表面的形貌和TPUEEs-Al阳极键合连接界面的微观形貌。按国家标准GB/T528-2009标准测试用CMT6503型微机控制电子万能试验机测定键合界面的拉伸强度,键合后的CPUEEs-Al的截面为7 mm ×7 mm的正方形。

2 结果和讨论

2.1 CPUEEs阴极材料的表面形貌

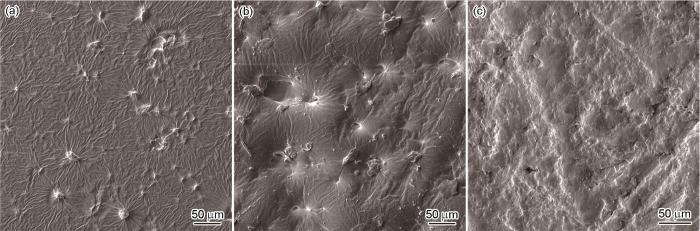

图1

图1

CPUEEs阴极材料的SEM照片

Fig.1

SEM images of surface of CPUEEs (a) CPUEE1, (b) CPUEE2, (c) CPUEE3

2.2 复合材料CPUEEs的结晶能力

图2给出了CPUEEs阴极材料的XRD谱。可以看出,所有样品均在谱中位于2θ ≈ 22°附近出现一个较宽的衍射峰。单一漫射峰表明其为非晶嵌段,这是聚氨酯基体软硬段的非晶玻璃态中因氢键化作用而有序排列的硬段区域[17~19]。这表明,复合材料的结晶能力较弱,存在微晶等近程有序结构和无定形结构。CPUEE1、CPUEE2、CPUEE3的衍射峰强度依次减弱,宽度增加。PPC为非晶态聚合物,与PU基体的共混改性能增加聚合物的非晶区,降低基体的结晶度。具有高盐溶解性的SN作为增塑剂加入到基体中,打乱了聚合物中链段的规则排布,使聚合物内部的运动更自由,原有的结晶区域向无定型区域转化,PPC和SN的共同作用使CPUEE3的结晶性最弱。

图2

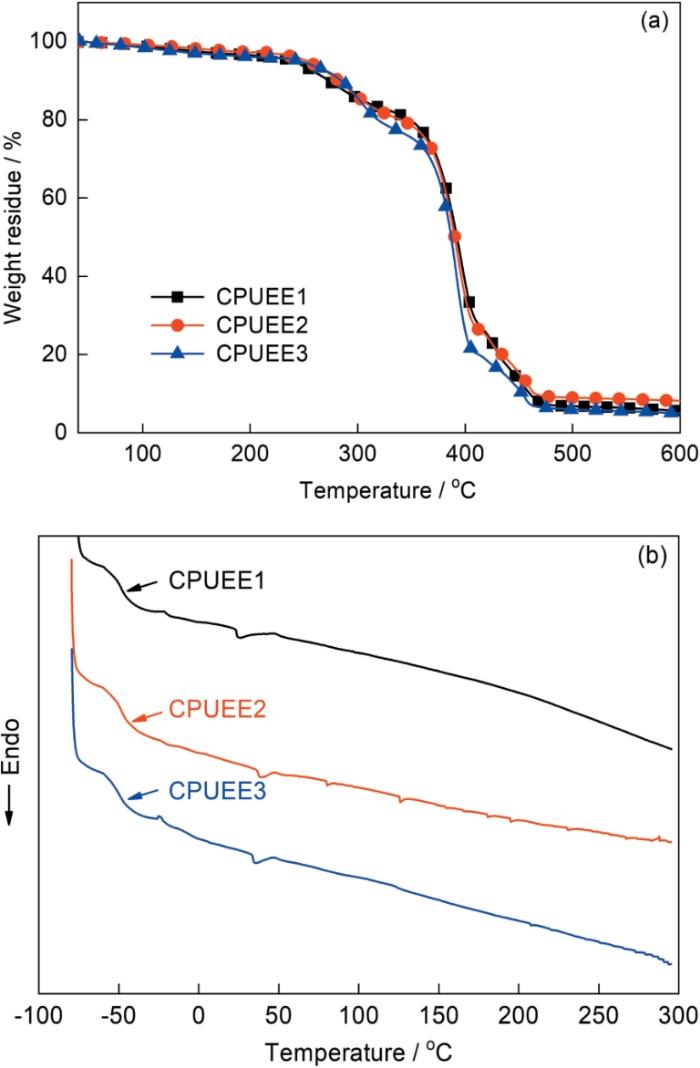

2.3 CPUEEs的热性能

材料的耐热性影响其应用范围,聚合物阴极材料在较宽的温度范围内的性能稳定性对阳极键合至关重要。聚氨酯的硬段先发生热分解,在高温下短时间内软段不会很快氧化和降解。这表明,硬段的耐热性影响复合弹性体的热稳定性[20~23]。可用5%热分解温度评价CPUEEs的热稳定性。图3a给出了CPUEEs的TGA曲线,5%热分解温度列于表2。可以看出,所有样品的Td, 5%均高于200 ℃,表明所制备的CPUEEs热稳定性都满足阳极键合要求。PPC的主链上极性较大的C═O增大了分子间作用力和分子的刚性,并且PU中的―NH与PPC的C═O生成了大量的氢键,使聚合物体系间的结合更加紧密,因此共混PPC改性的CPUEE2热稳定性最高。有增塑作用的SN加入后分散在聚氨酯基体中,SN与LiTFSI和聚氨酯硬段的相互作用使硬段的有序排列和聚集状态减弱,使更多的硬段溶于软段相中,硬段耐热性的降低使复合弹性体的热稳定性降低(CPUEE3)。

图3

表2 CPUEEs的热性能和离子导电率

Table 2

| Sample | Tg / oC | Td, 5% / oC | Rb / Ω(55 oC) | σ / S·cm-1(55 oC) |

|---|---|---|---|---|

| CPUEE1 | -48.07 | 235 | 292 | 3.4 × 10-4 |

| CPUEE2 | -48.31 | 254 | 240 | 4.2 × 10-4 |

| CPUEE3 | -49.65 | 227 | 154 | 6.5 × 10-4 |

图3b给出了CPUEEs的DSC曲线,其玻璃化转变温度Tg列于表2。在低于玻璃化转变温度Tg的温度,高聚物非晶部分的分子运动基本冻结[24],使复合弹性体中锂离子的迁移失去了原动力;在玻璃化转变温度以上的温度分子热运动活跃,热容量增大。这表明,玻璃化转变温度Tg是衡量聚合物电解质的重要指标。CPUEEs的Tg均低于-45 ℃,表明CPUEEs的分子链段均具有良好的低温柔顺性。PPC具有较高的介电常数、较低的玻璃化转变温度和无定形结构,使PPC和PU共混后材料的结晶度降低,无定形相的比例提高。另外,PPC主链上的醚键容易使链段绕醚键发生内旋转,从而使链段的柔性提高和CPUEE2的Tg比CPUEE1的低。SN作为增塑剂加入复合弹性体体系中,促进了LiTFSI的解离和提高了弹性体的柔韧性。SN与聚氨酯硬段的相互作用降低了硬段间的氢键化作用和使硬段的无序性提高。硬段对软段运动的限制性降低使复合弹性体分子的自由体积增大,因此CPUEE3的Tg最低。

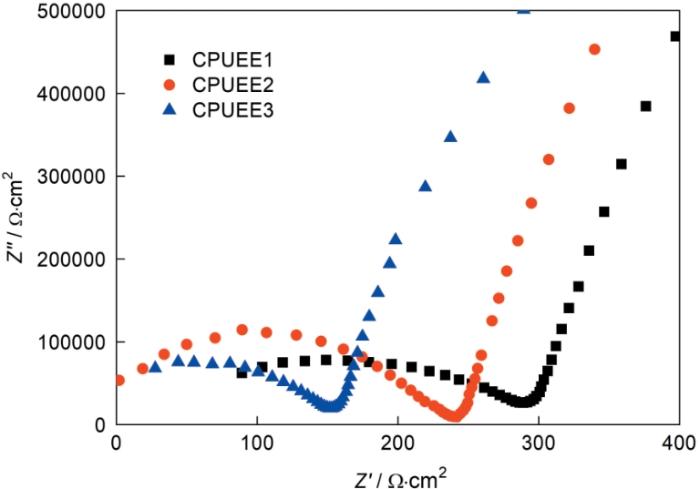

2.4 离子导电性

图4给出了CPUEEs在55 ℃时的交流阻抗谱,CPUEEs的离子导电率σ列于表2。可以看出,在键合温度范围内所有样品的离子导电率均符合键合要求,经PPC共混改性、PPC和SN共混改性后的复合弹性体离子其导电率依次增大。聚氨酯分子链段富集的羰基、醚基等极性基团可溶解锂盐并和锂离子产生配位作用,特别是由聚醚多元醇构成软段的聚氨酯具有良好的柔顺性,软段的热运动可促进锂离子的迁移[25,26]。与碳酸盐增塑剂具有相似结构的PPC与锂盐有良好的相容性,PPC聚合物链醚键的氧原子与锂离子的相互作用能促进锂离子转移;锂离子传输的主要通道,在聚合物的无定形区域及能垒较低的相界面。PPC混入聚氨酯基体中形成许多微相区和微界面,在一定程度上强化了锂离子传输的通道,使CPUEE2的离子导电率高于CPUEE1。在CPUEE3中,SN具有优异的溶盐能力和独特的间扭式/反式异构化结构。SN打乱了聚氨酯基体链段长程有序结构,使复合弹性体的无序性提高、结晶性降低和无定形相的比例提高,因此离子导电率提高;另外,SN对基体材料有增容作用,增强了分子链段的运动能力,也有利于导电率的提高。

图4

图4

CPUEEs在55 ℃的交流阻抗谱

Fig.4

Electrochemical impedance spectroscopy (EIS) of CPUEEs at 55 ℃

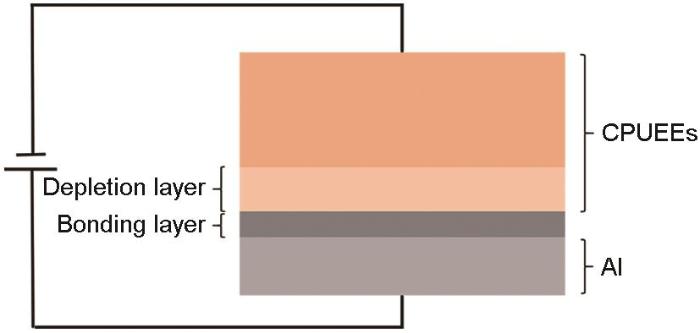

2.5 键合性能

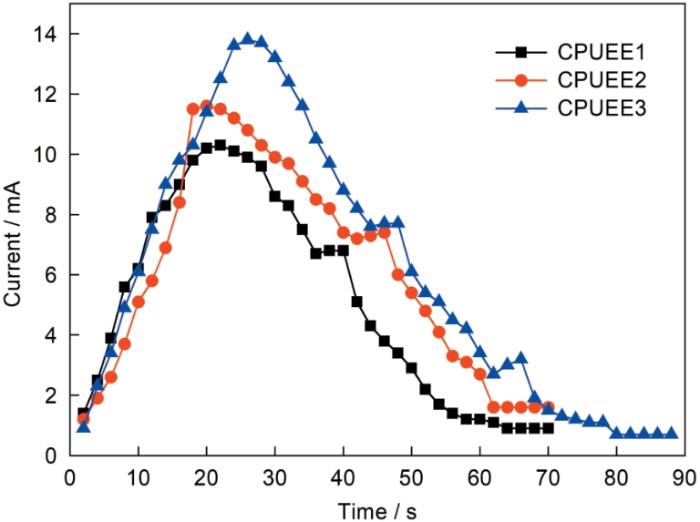

电场、温度场和压力场的共同作用使阴极材料中的碱金属离子迁移形成强大的界面静电场吸引力,使界面间紧密贴合,阳极材料和阴极材料元素相互扩散生成新键合连接层而产生了永久连接(图5)[27~29]。图6给出了CPUEEs-Al阳极键合时间-电流特性曲线,峰值电流和键合时间列于表3。可以看出,阳极键合开始时,电场、热场和压力场耦合作用使溶解在CPUEEs基体中的锂离子借助高分子链段的柔性运动跨越能垒,锂离子与分子链极性基团间的络合、解络合行为使离子迁移与扩散,在电场作用下锂离子的定向运动产生电流。图6表明,阳极键合开始后在很短时间内(15~30 s)键合电流达到峰值,随后逐渐降低,直到稳定到最低值键合结束。电流的变化,是阳极键合微观过程最直接的反应[30~32]。键合的起始阶段电场均匀分布在CPUEEs上,强电场的作用使锂离子快速向阴极迁移并富集在阴极区,在键合界面处形成阳离子耗尽层,该过程伴随着电流的迅速增大。随着阳离子耗尽层宽度的增大大部分电压作用在耗尽层,多数锂离子完成迁移后电流开始下降,锂离子由瞬时高密度迁移转向低密度稳态迁移。随着耗尽层宽度达到最大外加电场全部集中在耗尽层,离子迁移基本完成,电流稳定在最低值。键合界面发生化学反应生成中间键合层,使键合电流先快速增加到达峰值再缓慢下降。PPC、SN的加入使基体材料的结晶度降低,无定形相比例提高。锂离子迁移通道富集在无定形相中,使锂离子的动力学通道增多;另外,SN的增塑作用使分子链段的柔顺性增强和离子的迁移活化能降低。其结果是,CPUEE3的峰值电流最大,CPUEE2其次。从图6还可见,键合电流下降时较为缓慢并出现水平甚至略微上升现,接着继续降低。其原因是,当电流下降停滞时复合材料极可能被动态梯度电场击穿。为了延长键合时间和使键合反应更加充分,须及时降低电压使键合继续进行和使电流随之下降。样品中CPUEE3的键合时间最长。

图5

图6

图6

CPUEEs-Al静电键合的时间-电流曲线

Fig.6

Time-Current curves of CPUEEs-Al by electrostatic bonding

表3 CPUEEs-Al的阳极键合峰值电流、键合时间和界面强度

Table 3

| Sample | Peak current / mA | Bonding time / s | Max load / N | S/ mm2 | Tensile strength / MPa |

|---|---|---|---|---|---|

| CPUEE1-Al | 10.3 | 63 | 29.54 | 50.24 | 0.58 |

| CPUEE2-Al | 11.6 | 61 | 38.13 | 50.24 | 0.76 |

| CPUEE3-Al | 13.7 | 80 | 57.92 | 50.24 | 1.15 |

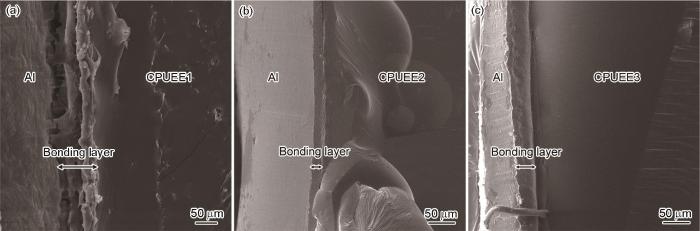

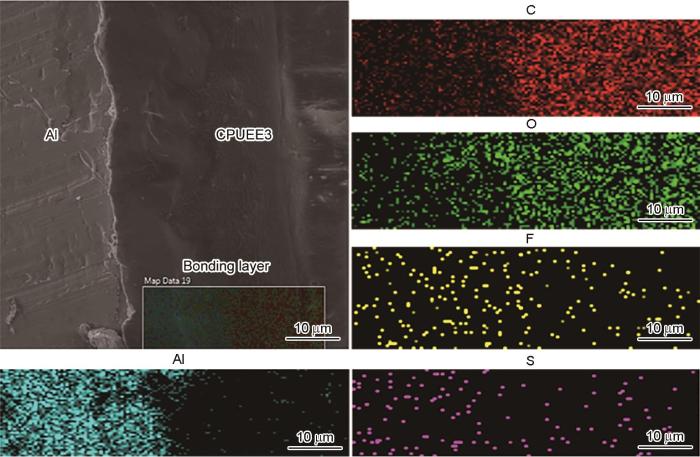

阳极键合固态连接的关键,在于在界面处生成了由氧化层构成的键合层。根据键合层的形貌和分布状态,可评判阳极键合的质量[33-36]。图7给出了CPUEEs-Al键合界面SEM照片,可见CPUEEs-Al键合界面中间的键合层。CPUEE1-Al的键合层最宽,但是又裂纹和孔洞等缺陷;CPUEE2-Al和CPUEE3-Al的键合层分布均匀、致密,形态良好,并且CPUEE3-Al键合层的宽度明显比CPUEE2-Al的大。图8给出了CPUEE3-Al键合界面的EDS图,可见Al、S、O、C和F元素在键合界面发生了相互扩散。S和F是LiTFSI的组成元素,在界面扩散较为均匀;O和C是聚合物基体和LiTFSI的组成元素,其向阳极Al扩散且浓度呈梯度分布;在CPUEE3侧,还可见少量的Al元素。各元素在电场能、热场能以及化学能的作用下克服自身的势垒定向扩散,生成了键合层。CPUEEs-Al阳极键合界面的拉伸性能列于表3。可以看出,CPUEE1-Al、CPUEE2-Al、CPUEE3-Al的键合拉伸强度依次增大,CPUEE3-Al的键合强度达到1.15 MPa。

图7

图7

CPUEEs-Al键合界面的SEM照片

Fig.7

SEM images of bonding interface of CPUEEs-Al

(a) CPUEE1-Al, (b) CPUEE2-Al, (c) CPUEE3-Al

图8

图8

CPUEE3-Al阳极键合界面的EDS图

Fig.8

EDS mapping of the bonded interface of Al sheet to CPUEE3

3 结论

(1) 三种不同结构的阳极键合阴极材料CPUEEs的性能优异,其分子链段都具有良好的低温柔顺性,在键合温度(55 ℃) CPUEE3的离子导电率最高。

(2) 热引导动态场阳极键合,可实现CPUEEs与Al的阳极键合连接,在CPUEEs-Al键合界面有中间键合层,其中CPUEE3-Al的键合层均匀、致密、形态良好且宽度较大。

参考文献

Emulating learning behavior in a flexible device with self-formed Ag dewetted nanostructure as active element

[J].

Unveiling innovative design of customizable adhesive flexible devices from self-healing ionogels with robust adhesion and sustainability

[J].

High stretchable and self-adhesive dual networks ionic gels and flexible devices application

[J].

A Review of Manufacturing Methods for Flexible Devices and Energy Storage Devices

[J].

Nano-copper enhanced flexible device for simultaneous measurement of human respiratory and electro-cardiac activities

[J].

Triboelectric nanogenerator-based anodic bonding of silicon to glass with an intermediate aluminum layer

[J].

Ultra-low temperature anodic bonding of silicon and glass based on nano-gap dielectric barrier discharge

[J].

Ultra-low temperature anodic bonding of silicon and borosilicate glass

[J].

Investigation on the effects of low-temperature anodic bonding and its reliability for MEMS packaging using destructive and non-destructive techniques

[J].

Anodic bonding of titanium alloy with bioactive glass

[J].

Synthesis and characterization of electrolyte substrate materials based on hyperbranched polyurethane elastomers for anodic bonding

[J].

Conductive polyurethane elastomer electrolyte (PUEE) materials for anodic bonding

[J].Polyurethane elastomer electrolyte (PUEE) represents a promising class of polymer solid electrolytes for the preparation and packaging of flexible devices by anodic bonding. In this work, PUEEs were designed and prepared a pre-polymerization method and cured at room temperature using polypropylene glycol (PPG), toluene-2,4-diisocyanate (TDI) and 1,4-butanediol (BDO) in the presence of varying amounts of lithium bis(trifluoromethanesulphonyl)imide (LiTFSI). All PUEEs exhibited high thermal stability and conductivity, with the highest ionic conductivity of 9.6 × 10 S cm for PUEE6 (= 1) at 55 °C. The results showed that LiTFSI was dissolved completely in the polyurethane matrix, and the complexing reactions occurred between the lithium ions and the polar groups of polyurethane. After that, the prepared PUEE and the Al sheet were successfully joined by the anodic bonding process. The microstructures of the bonded interface between PUEE and the Al sheet with a clear intermediate bonding layer could be observed in the cross-section scanning electron microscopy (SEM) images, and the elements in each layer were also detected by energy dispersive spectroscopy (EDS), which indicated that the PUEE and the Al sheet were bonded together. The maximum tensile strength for bonded PUEE6/Al was up to 0.45 MPa. All these results demonstrated that the prepared PUEE material would be a promising candidate for the preparation and packaging of flexible devices by anodic bonding.This journal is © The Royal Society of Chemistry.

TMP-based hyperbranched polyurethane elastomer (HBPUE) packaging material applied to anodic bonding

[J].

Flexible anodic bonding for the bonding between elastomer and metal

[J].

Anodic bonding applied to flexible packaging using elastomer composites

[J].

应用于弹性体复合材料柔性封装的阳极键合

[J].

Batch fabrication of electrospun PAN/PU composite separators for safe lithium-ion batteries

[J].

Self-healing polyurethane elastomer with ultra-high mechanical strength and enhanced thermal mechanical properties

[J].

An efficient phenylaminecarbazole-based three-dimensional hole-transporting materials for high-stability perovskite solar cells

[J].

The choice of noble electrolyte for symmetric polyurethane-graphene composite supercapacitors

[J].

Ladder-type poly(3,4-ethylenedioxythiophene)-poly(ethyleneglycol)-polyurethane supramolecular network for gel polymer electrolyte

[J].

Fluorene-containing polyhedral oligomericsilsesquioxanes modified hyperbranched polymer for white light-emitting diodes with ultra-high color rendering index of 96

[J].

Synthesis and characterisation of polyurethane elastomers with semi-products obtained from polyurethane recycling

[J].

Epoxy resin-modified thermo-reversible polyurethane with high strength, toughness, and self-healing performance

[J].An epoxy resin modified thermo-reversible polyurethane with self-healing ability was manufactured successfully by introducing E51 epoxy resin into Diels-Alder reaction-based thermo-reversible polyurethane. The tensile strength, Young's modulus, impact toughness and Shore hardness of the thermo-reversible polyurethane were significantly enhanced, while the elongation at break of which was remained at a relatively high level after epoxy resin was introduced. The 20% epoxy resin-modified thermo-reversible polyurethane material presents high mechanical properties such as strength, toughness and hardness, as well as excellent self-healing characteristic. If damages such as cracks and crevices have been accidently emerged on the epoxy resin modified thermal reversible polyurethane, such damaged spots can be recovered through a post heat treatment by either 130℃×20 min or 60℃×24 h. Moreover, such repair may be allowed to repeat several times for the same location after being subjected to repeatedly damages. It is believed that the enhancement of mechanical performance of the epoxy resin modified thermal reversible polyurethane may be ascribed to the so called "forced mutual dissolution" and "synergistic effect", resulted from the interpenetrating polymer network structure formed through entanglement of the rigid phase of epoxy and the elastic polyurethane phase of polyurethane. Meanwhile, the repeatable self-healing of the epoxy resin modified thermal reversible polyurethane may be due to the synergistic effect of the thermo-reversible Diels-Alder reaction and the thermal movement of molecular chains.

兼具高强度、高韧性和自修复性能的环氧树脂改性热可逆聚氨酯

[J].将E51环氧树脂引入基于Diels-Alder反应的热可逆聚氨酯,制备出环氧树脂改性热可逆自修复聚氨酯材料。引入环氧树脂,可提高改性热可逆聚氨酯的拉伸强度、杨氏模量、冲击韧性和邵氏硬度且保持较高的断裂伸长率。添加20%的环氧树脂制备的环氧树脂改性热可逆聚氨酯材料兼具优异的强度、韧性、硬度等力学性能和良好自修复性能。当环氧树脂改性热可逆聚氨酯出现裂纹裂缝等损伤后,在130℃处理20 min及60℃处理24 h便可修复损伤,并可实现同一部位多次损伤的重复自修复。力学性能提高的原因,是刚性环氧树脂相与聚氨酯弹性相相互缠结形成互穿聚合物网络结构产生的“强迫互溶”和“协同效应”;而多次重复自修复则归因于热可逆Diels-Alder反应和分子链热运动的协同作用。

Fabrication of polyurethane elastomer/hindered phenol composites with tunable damping property

[J].

Improving nanoparticle dispersion and polymer crystallinity in polyvinylidene fluoride/POSS coatings using tetrahydrofuran as co-solvent

[J].

Polycarbonate-based polyurethane as a polymer electrolyte matrix for all-solid-state lithium batteries

[J].

Effect of rare earth oxide CeO2 on the anodic bonding performance of PEG-based MEMS encapsulation materials

[J].

Physicochemical processes in alkaline glass with anodic bonding of glass and silicon

[J].

Shorting out bonding method for multi-stack anodic bonding and its application in wafer-level packaging

[J].

Modeling of anodic bonding with SiO2 dielectric as interlayer

[J].

Self-encapsulated DC MEMS switch using recessed cantilever beam and anodic bonding between silicon and glass

[J].

Hermetic sealing of MEMS including lateral feed throughs and room-temperature anodic bonding

[J].

Wafer-level self-packaging design and fabrication of mems capacitive pressure sensors

[J].

Plasma-activated high-strength non-isothermal anodic bonding for efficient fabrication of the micro atomic vapor cells

[J].

The microfabricated alkali vapor cell with high hermeticity for chip-scale atomic clock

[J].

Triboelectric nanogenerator-based anodic bonding of silicon to glass with an intermediate aluminum layer

[J].