在实际服役条件下,K4169合金部件经常在拉压、转动或频繁启停等复杂加载工况下工作,其失效的主要形式是疲劳断裂[7,8]。统计结果表明,约60%的航空零件机械失效是疲劳引起的[9]。因此,研究这种合金的疲劳性能是一项极为重要的课题。K4169合金铸件的疏松缩孔、元素偏析以及大尺寸晶粒,使其力学性能严重恶化。为了提高铸件的力学性能,常用的方法是用细晶铸造工艺减小合金的晶粒或在标准热处理前进行热等静压(HIP)处理[10]。目前,已有关于细晶K4169合金在室温和700℃下的低周疲劳行为的研究报导。晶粒细化使合金在室温下的疲劳寿命明显提高,而合金在700℃疲劳寿命的优劣与施加的应变幅有关[2,11]。热等静压处理可消除K4169合金铸件中的显微疏松、减轻元素偏析和促进组织均匀化,在应变比R = -1、应变幅0.4%、加载频率0.2 Hz的条件下,与铸态和标准热处理态合金相比,经热等静压(HIP)+标准热处理(ST)的K4169合金其室温低周疲劳寿命明显提高[12,13]。

式中Δεp/2为塑性应变幅,ε

1 实验方法

实验用K4169合金试棒的化学成分(质量分数,%)为:Cr 19.08,Ni 52.27,Mo 3.16,(Nb + Ta)5.38,Ti 1.02,Al 0.56,C 0.06,Fe余量。对实验用合金试棒进行热等静压、均匀化、固溶和时效处理:1160℃/100 MPa/3 h,炉冷至650℃;AC + 1095℃/1 h,AC + 955℃/1 h,AC + 720℃/8 h,炉冷至620℃ + 620℃/8 h,AC。用试棒机加工低周疲劳试样,其尺寸在图1中给出。

图1

用MTS 370.10型疲劳试验机测试应变控制低周疲劳性能。实验温度为650℃,实验环境为实验室静态空气介质;加载条件为:三角形波,频率0.5 Hz,采用完全反向轴向总应变控制的拉-压加载方式(R = -1)。低周疲劳实验的总应变分别为0.5%、0.6%、0.8%和1.0%,用计算机自动记录实验数据。判定试样失效的条件为:A.试样断裂;B.试样表面出现可检测裂纹。

使用扫描电镜(SEM)观察合金的原始组织、断口形貌和断口纵剖面组织。将SEM样品机械磨抛至表面光亮且无明显划痕,然后用氯化铜腐蚀液(5 g CuCl2 + 100 mL HCl + 100 mL C2H5OH)腐蚀。用酒精将断口样品超声清洗后观察其形貌;用Gemini300扫描电镜对断口纵剖面上的裂纹进行电子背散射衍射(EBSD)分析。将EBSD试样机械磨抛后用VibroMet 2型振动抛光机,再在SiO2悬浮液中振动抛光6 h以去除试样表面的残余应力;使用Talos F200X型场发射透射电子显微镜观察合金变形前后的微观组织结构。TEM样品的制备:沿断口纵向切取厚0.5 mm的薄片,将其机械研磨至厚度约为50 μm,用冲孔仪将样品冲压成直径为3 mm的圆片,用双喷射电抛光设备将圆片样品减薄,双喷液为10%HClO4 + 90%C2H5OH,双喷温度为-25℃,电压为20 V。

2 实验结果

2.1 K4169合金铸棒的组织

图2给出了K4169合金铸棒热处理后的组织形貌。可以看出,合金中有不规则的块状相和针状相(图2a、b)。根据表1中的能谱(EDS)结果和析出相的形状可确定,块状相为富C、Nb、Ti的碳化物(化学式为(Nb,Ti)C),针状相为δ-Ni3Nb。在合金的枝晶间还有粗大的盘片状γ″相(图2c)。晶界上弥散分布的MC相和不连续分布的短棒状δ相,短棒状δ相可能是在热等静压后的缓冷过程中析出的[26]。图2d给出了合金的低倍组织形貌,可见其是树枝晶组织,晶粒的尺寸较大。体心四方结构的纳米级γ″-Ni3Nb颗粒弥散分布在合金基体中(图2e、f)。图2g给出了针状δ-Ni3Nb相的TEM形貌。选区电子衍射(SAED)花样(图2g中的插图)表明,δ-Ni3Nb相与γ-Ni基体的取向关系为(1

图2

图2

K4169合金热处理态的组织特征

Fig.2

Microstructure characteristics of K4169 alloy after heat treatment (a) SEM images showing precipitates (b) BSE images showing precipitates; (c) Coarsening γ″ phase; (d) Low magnification morphology of alloy structure; (e, f) bright- and dark-field TEM images of γ″-Ni3Nb,respectively; (g) TEM images of δ-Ni3Nb (Inset in Fig.2 shows the corresponding SAED pattern)

表1 析出相和基体的能谱 (EDS)

Table 1

| Element (%) | C | Al | Ti | Cr | Fe | Ni | Nb | Mo |

|---|---|---|---|---|---|---|---|---|

| MC | 18.45 | 0.02 | 6.02 | 0.6 | 0.8 | 1.93 | 71.76 | 0.41 |

| δ-Ni3Nb | 4.01 | 0.51 | 1.4 | 14.83 | 14.07 | 49.34 | 12.76 | 3.07 |

| γ-Ni | - | 0.27 | 1.26 | 18.98 | 17.32 | 54.74 | 4.85 | 2.57 |

2.2 循环滞后回线和Masing曲线

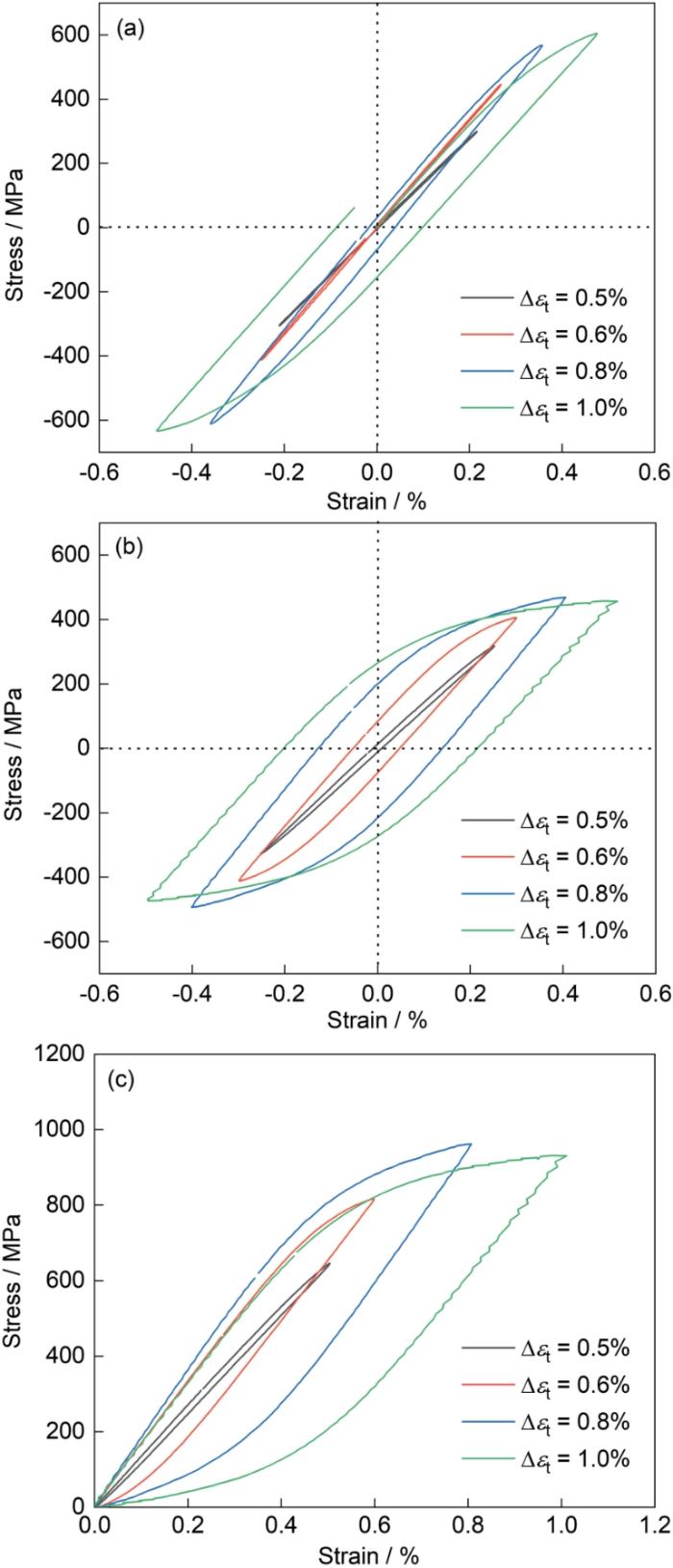

图3a、b分别给出了合金第一周次和半寿命时的循环应力应变滞后回线。可以看出,所有应变的合金其第一周次的滞后回线在拉伸和压缩过程中呈现出亚对称,最大拉应力随着应变的增大逐渐增大。应变为0.5%和0.6%时的滞后回线近似为一条直线,表明合金在第一周次循环过程中几乎只发生弹性变形;应变为0.8%和1.0%时滞后回线是一个未闭合的环,表明合金在循环过程中同时产生弹性变形和塑性变形 [27]。合金半寿命时的循环滞后回线是一个稳定的闭合环,闭合环的面积表示材料在一次循环过程中接收的塑性应变能,表征材料抵抗循环塑性变形的能力[28,29]。可以看出,随着应变的增大闭合环的面积增大,表明合金在循环过程中消耗的塑性应变能越大疲劳寿命越短。

图3

图3

循环滞后回线和Masing曲线

Fig.3

Cyclic hysteresis loops of alloy with the first cycle (a), Cyclic hysteresis loops of alloy with the half-life (b) and Masing curve of alloy (c)

2.3 循环应力响应行为

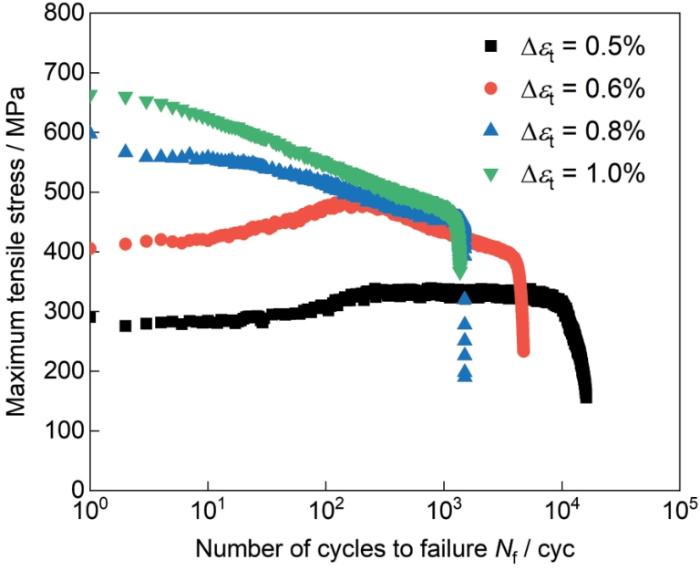

图4给出了合金在不同应变下的循环应力响应曲线。可以看出,合金第一周次的最大拉应力随应变增大而增大,疲劳寿命降低。应变为0.5%时,合金第二周次的最大拉应力相比第一周次下降约12 MPa,随后最大拉应力随着循环周次的增加逐渐增大而出现硬化,循环达到200周次时最大拉应力达到峰值,随后出现循环稳定;应变为0.6%时合金在循环的前200周次内出现循环硬化,随后应力逐渐降低而表现为循环软化;应变为0.8%和1.0%时,合金的最大拉应力随着循环周次的增加逐渐降低,出现连续的循环软化行为直至失效。在所有的应变下,合金在循环最后阶段的最大拉应力均高速降低。这表明,是宏观裂纹的生成和失稳扩展所致[17,18,30]。

图4

为了定量描述合金循环软化/硬化的程度,引入了循环硬化参数[31]

式中σmid-life为循环半寿命时的最大拉应力,σ1为循环第一周次的最大拉应力。图5给出了合金在不同应变下的循环硬化参数D。应变为0.5%时D为很小的正值,表明合金整体上表现出微弱的循环硬化,可归因于循环前2-200周次内产生的硬化行为。应变为0.6%及以上时D为负值,表明合金发生了循环软化,且其软化程度随着应变的增大而提高。

图5

图5

合金在不同应变下的循环硬化参数D

Fig.5

Cyclic hardening parameter D of alloy under different strains

2.4 低周疲劳寿命

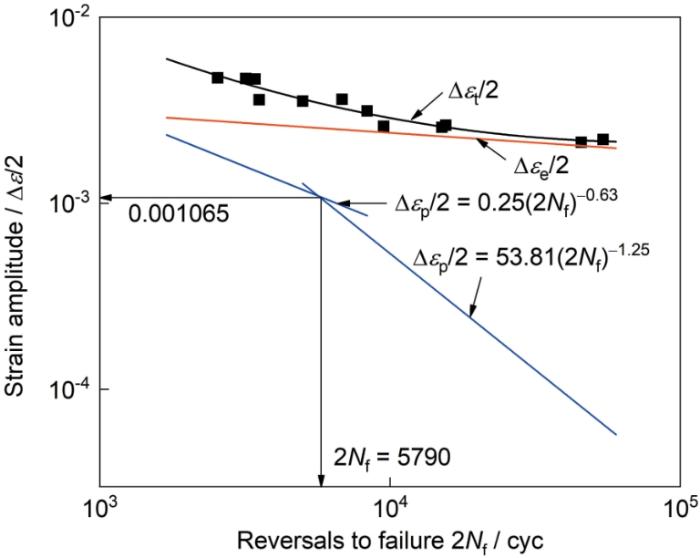

图6给出了这种合金的总应变幅(Δεt/2)、弹性应变幅(Δεe/2)和塑性应变幅(Δεp/2)与疲劳失效反向数(2Nf)的关系曲线。可以看出,总应变幅较小时塑性应变幅很小,随着总应变幅的增大塑性应变幅逐渐增大,但是始终小于其弹性应变幅。Δεp/2-2Nf曲线与Δεe/2-2Nf曲线没有交叉,表明在本文的实验范围内合金的低周疲劳变形集中在弹性变形区,即合金的强度控制了循环过程。IN738LC合金[32]和K416B合金[33]在650℃的弹性应变疲劳在低周疲劳循环过程中也占主导地位。值得注意的是,K4169合金的塑性应变幅(Δεp/2)与疲劳失效反向数(2Nf)的Coffin-Manson方程表现出双线性特征,其形状为“上凸”型结构,较高应变区的疲劳塑性指数c为-0.63,较低应变区c为-1.25,转折点出现在塑性应变幅为0.001065。

图6

图6

应变幅与疲劳失效反向数的关系

Fig.6

Relationship between strain amplitudes (Δε/2) and number of reversals to failure (2Nf)

2.5 断裂行为

2.5.1 断口的形貌

图7

图7

宏观断口的形貌

Fig.7

Macroscopic fracture morphology (a) Δεt = 0.5%; (b) Δεt = 0.6%; (c) Δεt = 1.0%

图8

图8

微观断口的形貌

Fig.8

Microscopic fracture morphology (a, d, g) Δεt = 0.5%; (b, e, h) Δεt = 0.6%; (c, f, i) Δεt = 1.0%; (a~f) Morphology of fatigue propagation zone; (g~i) Morphology of fatigue final rupture

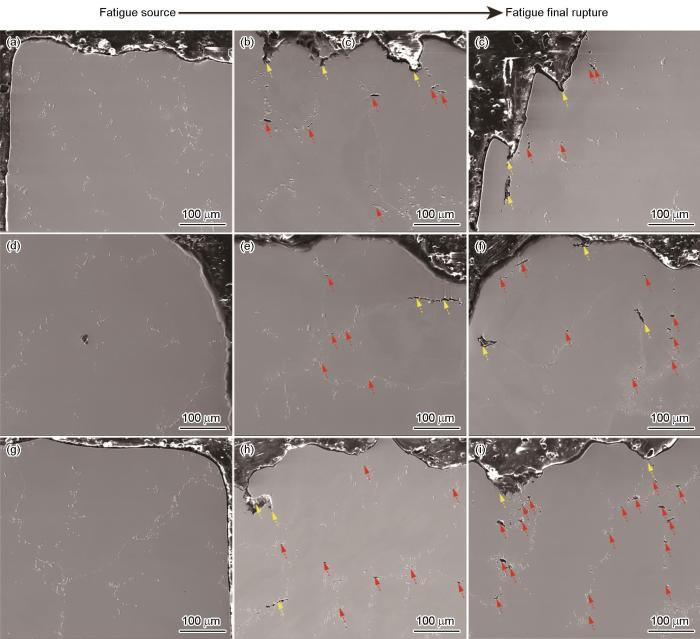

2.5.2 纵剖面的组织

断口附近的纵剖面组织,如图9所示。裂纹源区受到的应力集中较小,因此无论施加应变大小合金组织中的MC相基本上保持原来的形态,且没有出现从断口表面向试样内部扩展的二次裂纹,如图9a,d,g所示。裂纹生成后随着主裂纹不断扩展,能承受施加应力的样品部分逐渐减小,使应力集中逐渐增大。而合金组织中的MC相以及MC相与基体的界面作为变形过程中的应力集中区,裂纹易在这里萌生[37]。在裂纹扩展区可见枝晶间破碎的MC相和在MC相与基体的界面生成的微孔或裂纹(红色箭头标记),从断口处向试样内扩展的二次裂纹或在试样内生成的较大二次裂纹(黄色箭头标记),如图9b,e,h所示。疲劳裂纹扩展的最后阶段类似于拉伸破坏过程,在最终断裂区只有部分样品承受施加的应力,产生了极高的局部应力集中。这表明,在瞬断区有更多破碎的MC相和微孔或裂纹,尤其在应变为1.0%时靠近断口的MC相基本都破裂了,如图9i所示。

图9

图9

断口的纵剖面组织

Fig.9

Fracture longitudinal section organization (a, b, c) Δεt = 0.5%; (d, e, f) Δεt = 0.6%; (g, h, i) Δεt = 1.0%

图10a~c给出了不同应变下试样断口纵剖面上的二次裂纹。可以看出,二次裂纹均萌生在试样表面,并以穿晶模式向试样内扩展,其扩展方向基本上与加载方向垂直。对应变为1.0%的试样断口纵剖面上的二次裂纹进行了EBSD分析,图10d和e分别给出了晶界图和IPF图。可以看出,二次裂纹萌生于试样表面并依次穿过G1、G2、G3三个较大的铸造晶粒。因此,合金在高温下的疲劳裂纹主要以穿晶模式扩展。KAM (Kernel average misorientation)图表示位错密度的大小,用于评估合金变形组织中的应力集中情况[38]。可以看出,在裂纹扩展路径周围和枝晶间的碳化物处产生较高的应力集中,如图10f所示。

图10

图10

断口纵剖面的二次裂纹和EBSD分析

Fig.10

Secondary cracks on the longitudinal section of the fracture with a strain of 0.5%, 0.6%, and 1.0%, respectively (a~c) and the associated EBSD maps of the GB (Grain boundary), IPF and KAM with a strain of 1.0% are shown in (d~f)

3 讨论

3.1 影响循环应力响应行为的因素

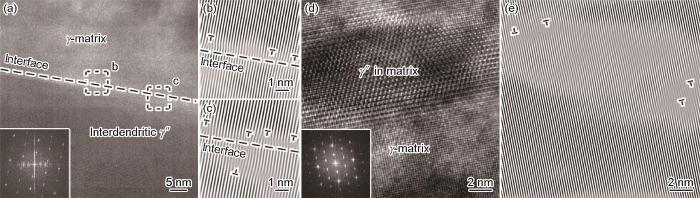

材料的循环应力响应行为与位错的循环运动有关,取决于材料对外部变形的内部阻力。这种阻力,主要来源于其它位错或合金中的析出相对位错运动的钉扎[31]。K4169合金作为一种沉淀强化型铸造高温合金,其初始的循环硬化行为可能与位错在δ相附近的塞积[20]、在滑移带中的累积[18,19]以及γ″/γ′相对位错的钉扎有关[18,20]。而沉淀硬化合金的循环软化行为,则归因于沉淀物的溶解、沉淀物的剪切、沉淀物的粗化、沉淀物的无序化以及不均匀的塑性变形等因素[19,22]。K4169合金在高温低应变条件下循环的前2~200周次内出现循环硬化,在Inconel 718合金高温低周疲劳行为中也出现了这种初始循环硬化,但是只在前几个循环周次内出现[22,39]。与之相比,本文研究的K4169合金其初始硬化期较长。为了揭示K4169合金出现循环硬化行为的原因,对中断试样(Δεt = 0.5%,Nf = 100 cycs)进行了(HR)TEM分析。图11a给出了枝晶间粗大γ″相和γ-基体的HRTEM形貌,可见两者间有清晰的界面,且在界面附近有明显的位错(标记‘T’),如图11b和c所示。这表明,枝晶间的粗大γ″相对位错运动有一定的钉扎。图11d和e分别给出了这种合金基体中细小γ″相的HRTEM图和IFFT图。从IFFT图可以看出,位错存在于γ″相的周围,而在γ″相内部几乎没有位错,表明合金基体中细小的γ″相对位错运动有较强的阻挡能力。由此可见,γ″强化相对位错运动的阻碍使合金在低应变下循环初期出现硬化,且以基体中细小γ″相的作用为主。

图11

图11

中断试样(Δεt = 0.5%,Nf = 100 cycs)的微观变形结构

Fig.11

HRTEM and IFFT image of the specimen with Δεt = 0.5%,Nf = 100 cycs: (a) The HRTEM micrograph of interdendritic γ″ and γ-matrix with the FFT pattern; (b, c) the corresponding inverse FFT images of areas b an c in (a), respectively; (d) The HRTEM micrograph of γ″ in matrix and γ-matrix with the FFT pattern; (e) The corresponding inverse FFT image of (d) (dislocation as marked with ‘T’)

图12

图12

不同应变下断裂试样的微观变形结构

Fig.12

TEM micrographs of fracture specimens under different strains (a) Bright field image with SAED pattern, Δεt = 0.5%;(b) Dark field image, Δεt = 0.5%; (c) Slip bands distribution, Δεt = 0.5%; (d) Bright field image with SAED pattern,Δεt = 1.0%; (e) Dark field image, Δεt = 1.0%; (f) Slip bands distribution, Δεt = 1.0%

3.2 塑性曲线的双线性

大部分材料的塑性应变幅(Δεp/2)与疲劳失效反向数(2Nf)在双对数坐标下的拟合结果为一条直线(单线性),而有些材料表现出双线性C-M关系,即在双对数图中出现两段斜率不同的直线[15,25]。本文研究的K4169合金,在高温下的塑性曲线表现出明显的双线性特征。而对双线性现象的解释,包括变形机制(模式)的转变[15,19,22]、变形均匀性的转变[16,20,21]以及断裂机制的转变[19,25]。为此,观察了不同应变下断裂试样的微观变形结构,如图12所示,合金在低应变(Δεt = 0.5%)和高应变(Δεt = 1.0%)下的微观变形结构中出现明显的滑移带。随着应变的增大滑移带的数量增多和位错密度提高[40],且均未出现变形孪晶,如图12c、f所示。在不同应变的合金的TEM暗场模式下都观察到γ″相被剪切(图12b、e),表明合金在不同应变下的循环变形模式均为位错剪切γ″相和滑移。如上所述,合金在不同应变下的低周疲劳失效均表现为穿晶断裂模式。这表明,导致合金表现出双线性现象的原因可能是变形均匀性的转变,即由低应变下的局部塑性变形转变为高应变下的均匀塑性变形。同时,合金在高温下表现出的非Masing特性也证明其变形均匀性的转变[20]。

4 结论

(1) K4169合金的低周疲劳寿命随着应变的增大逐渐降低,应变为0.5%和0.6%时出现一个初始循环硬化期(2~200周次),随后分别出现循环稳定和循环软化。应变为0.8%和1.0%时,合金表现出连续的循环软化行为。

(2) K4169合金在低应变下循环初期的硬化行为与γ″强化相对位错运动的阻碍有关,而在高应变下的循环软化行为则归因于位错反复剪切γ″相。

(3) K4169合金的塑性应变幅与疲劳失效反向数的Coffin-Manson方程表现出双线性关系,其在高应变和低应变下的循环变形模式均为位错剪切γ″相和滑移,且在不同应变下的疲劳失效均表现为穿晶断裂模式。

参考文献

Influence of heat treatment on the distribution of Ni2Nb and microsegregation in cast Inconel 718 alloy

[J].

Low cycle fatigue behavior of micro-grain casting K4169 superalloy at room temperature

[J].

Effect of Nb content on microstructure and mechanical properties of K4169-type superalloy

[J].

Microstructure evolution of K4169 alloy during cyclic loading

[J].K4169 nickel-based superalloy has been widely used to fabricate high-strength components in aircraft engine. When in service, especially affected by vibration and start-stop process, this alloy is inevitably affected by the external cyclic stress. Therefore, it is of great significance for researchers to understand the microstructure evolution in K4169 while cyclic loading. In the present study, the microstructure evolution of K4169 during cyclic loading has been examined and discussed in detail by using investment casting, cyclic loading and microstructure characterization methods. The cyclic loading test with stress amplitude of 380 MPa was carried out on a pull-push type fatigue machine at room temperature. The dependence of cycle times or fatigue life of specimens with different casting conditions on microporosity content has been discussed. Special emphases have been put on investigating the deformation and fracture characteristics of Laves and δ-Ni3Nb phases under the influence of microporosity. The results show that the cyclic life was mainly dominated by the content of microporosity. The crack initiation occurred mainly near the microporosity of the specimen surface. The specimen with high microporosity content exhibits the characteristic of complete brittle fracture, while the specimen with low microporosity content exhibits obvious transgranular fracture characteristics. In addition, the fracture of Laves phase was not apparently affected by cycle number. At the beginning of cyclic loading, the long-striped Laves phase near the microporosity was easy to crack, which became the sensitive area of crack growth, and extending in the manner of parallel secondary cracks. The δ-Ni3Nb plates near microporosity exhibited two obvious cyclic deformation and fracture characteristics depending on their arrangement (or growth orientation) relative to external loading axis: cracking along length direction (or denoted as branch cracking); and exhibiting slip lines and cracks on the surface of δ-Ni3Nb plates. At the initial stage of cyclic loading, δ-Ni3Nb plates were prone to crack along the length direction, while the surfaces of the δ-Ni3Nb plates far from microporosity appear the characteristics of slipping, bending and fracture in turn with the decrease of microporosity content or increase of cyclic cycles. Edge dislocations have been found within δ-Ni3Nb plates, indicating the transition from screw dislocations to edge dislocations under cyclic loading. Additionally, the twinning deformation of γ-Ni matrix during cyclic loading has been scrutinized through TEM and TKD analyses. The results have been linked to the evolutions of Laves and δ-Ni3Nb phases, i.e., the evolutions were influenced by the increase of strain localization around Laves and δ-Ni3Nb phases.

K4169合金循环加载过程中的微观组织演变

[J].

Effect of nitrogen content on the microstructure and mechanical properties of K4169 alloy

[J].

氮对K4169合金微观组织和力学性能的影响

[J].

Effect of standard heat treatment on the microstructure and mechanical properties of hot isostatically pressed superalloy Inconel 718

[J].

Effect of heat treatment on low cycle fatigue of IN718 superalloy at the elevated temperatures

[J].

Crack growth micro-mechanisms in the IN718 alloy under the combined influence of fatigue, creep and oxidation

[J].

Fatigue failure of aircraft components

[J].

Effects of heat treatment on microstructure and stress rupture properties of K4169 investment castings after hot isostatically pressed treatment

[J].

热处理对热等静压K4169合金组织及高温持久性的影响

[J].

Effect of structure refinement by addition of refiner on LCF properties of cast superalloy K4169

[J].

化学法细化高温合金K4169的低周疲劳性能研究

[J].采用一种新型中间合金复合细化剂,在常规生产工艺条件下对高温合金K4169铸件进行了晶粒细化.测试了常规工艺和细晶铸造工艺两种试样的常温和中温(700℃)条件下的低周疲劳性能.结果表明,这一新型工艺方法能有效细化高温合金K4169晶粒.细晶试样的室温低周疲劳性能有较大的提高,且数据的分散性有所改善;在中温时,疲劳寿命的优劣和疲劳应变幅有关:在小应变幅条件下,细晶仍然有较高的疲劳寿命,在大应变幅条件下,细晶疲劳寿命比粗晶有所降低,但数据的稳定性较好.

Effect of hot isostatic pressing on microstructures and properties of superalloy K4169

[J].

热等静压对K4169高温合金组织与性能的影响

[J].

Crack formation and microstructure-sensitive propagation in low cycle fatigue of a polycrystalline nickel-based superalloy with different heat treatments

[J].

Low-cycle fatigue behavior of Inconel 718 at 298K and 823K

[J].

On the dual slope coffin-manson relationship during low cycle fatigue of ni-base alloy In718

[J].

Temperature-dependent deformation mechanisms of alloy 718 in low-cycle fatigue

[J].

Low-cycle fatigue behavior of Inconel 718 superalloy with different concentrations of boron at room temperature

[J].

Effect of boron on the low-cycle fatigue behavior and deformation structure of Inconel 718 at 650oC

[J].

Fatigue behavior and bilinear coffin-manson plots of ni-based GH4169 alloy with different volume fractions of delta phase

[J].

Low-cycle fatigue behavior of GH4169 superalloy

[J].

GH4169高温合金低周疲劳变形行为研究

[J].

Effect of heat treatment on coffin-manson relationship in lcf of superalloy IN718

[J].

Micromechanism of cyclic plastic deformation of alloy IN718 at 600oC

[J].

A comparative evaluation of low cycle fatigue behavior of conventional and modified Inconel 718

[J].

Effect of hot corrosion on low cycle fatigue behavior of superalloy IN718

[J].

Effect of different heat treatment processes on microstructure and mechanical propertiesof K4169 superalloy

[J].

热处理工艺对K4169高温合金组织和力学性能的影响

[J].对比研究标准热处理(SHT)、热等静压+标准热处理(HIP+SHT)以及热等静压+无均匀化热处理(HIP+HTWH)后K4169合金的组织和力学性能,分析K4169合金HIP后进行无均匀化热处理的可行性,提出了一种适用于热等静压K4169合金的热处理制度。组织研究表明:热等静压处理(1170 ℃/140 MPa/4 h)可以基本消除枝晶间Laves相和δ相;而与HIP+SHT试样相比,无均匀化热处理的试样(HIP+HTWH)晶界上析出了不连续短棒状δ相,但没有对组织的均匀性产生实质影响。力学性能研究表明:相比SHT态,HIP+SHT与HIP+HTWH态合金的室温屈服强度分别提升了73 MPa和91 MPa,持久寿命(704 ℃/448 MPa)分别提升了35%和32%;虽HIP+HTWH态合金的持久寿命和塑性分散度大于HIP+SHT态,但仍能满足AMS5383对K4169合金力学性能的要求。综合考虑工艺成本的降低、生产效率的提高和力学性能的改善等多种因素,可以确定对于K4169合金结构件而言,HIP+HTWH热处理工艺具有实际应用的潜力。

Investigation on low-cycle fatigue behaviors of wrought superalloy GH4742 at room-temperature and 700oC

[J].

Analysis of low cycle fatigue behavior and life prediction model of a new powder superalloy

[J].

一种新型粉末高温合金的低周疲劳行为与寿命预测模型分析

[J].

Low-cycle fatigue of the second generation directionally solidified superalloy

[J].

第二代定向柱晶高温合金低周疲劳行为研究

[J].

Low cycle fatigue behavior of cast nickel base superalloy K52

[J].Low cycle fatigue (LCF) behaviors of cast nickel-base superalloy K52at different temperatures were investigated, and the fatigue parameterswere given by analyzing its cyclic stress-strain curves andstrain-life curves. Cyclic stress response curves show that the alloyexhibited cyclic hardening and softening behaviors at room temperatureand 900℃, respectively. OM and SEM observations indicated that LCF cracksinitiated predominantly on the surface of specimen or at the near-surfacedefects. Once initiated, cracks would propagate perpendicularly to theloading direction and the specimens exhibited transgranular fracture.

铸造镍基高温合金K52的低周疲劳行为

[J].

On the low cycle fatigue behavior of a ni-base superalloy containing high Co and Ti contents

[J].

Effect of microstructural characteristics on the low cycle fatigue behaviors of cast ni-base superalloys

[J].

Low-cycle fatigue behavior of K416B ni-based superalloy at 650oC

[J].

Development of "fractography" and research of fracture micromechanism

[J].

断口学的发展及微观断裂机理研究

[J].

Effect of stress ratio on high cycle fatigue properties in Mg-6Zn-1Mn alloy

[J].

Fracture mechanisms induced by microporosity and precipitates in isothermal fatigue of polycrystalline nickel based superalloy

[J].

Distribution of phosphorus and its effects on precipitation behaviors and tensile properties of IN718C cast superalloy

[J].

Effects of microstructure evolution on the deformation mechanisms and tensile properties of a new ni-base superalloy during aging at 800oC

[J].

Cyclic deformation mechanisms of precipitation-hardened Inconel 718 superalloy

[J].

Low cycle fatigue and high cycle fatigue of K4750 Ni-based superalloy at 600oC: analysis of fracture behavior and deformation mechanism

[J].