传统基面织构镁合金板材六方密排的晶体结构,使其在室温下只能激活有限的滑移系,降低了室温强度和成形性能,不利于其在工业领域的应用[1~3]。研究表明,使镁合金板材织构非基面化可提高其成形性能。Tu等[4]进行等径角轧制-连续弯曲-退火(Equal channel angular rolling and continuous bending process with subsequent annealing,ECAR-CB-A)制备的双峰分离非基面织构AZ31镁合金板材具有良好的室温成形性能,其室温杯突值高达7.4 mm。但是,Chen等[5]的研究结果表明,这种双峰分离非基面织构的引入会产生织构软化效应,即AZ31镁合金板材的初始屈服强度仅为73 MPa,比基面织构板材的初始屈服强度162 MPa显著降低约54.94%,严重影响其商业化应用。

目前,作为常规热处理的补充,深冷处理能使镁合金兼具较高的强度和良好的延伸率[6~8]。Mónica等[6]将AZ91镁合金在时效前分别进行T6处理和T6处理+深冷处理,发现深冷处理的样品在时效过程中析出了第二相Mg17Al12。不同样品的拉伸实验结果表明,深冷处理使AZ91镁合金具有相近抗拉强度且使其材料延伸率提高。Qi等[7]将GW83K镁合金分别在室温、-70℃和-196℃进行拉伸实验,结果表明:随着温度的降低强度逐渐提高;而从室温到-70℃延伸率提高,从-70℃到-196℃降低。对其微观组织的观察发现,随着温度的降低{10

1 实验方法

用电火花沿该板材的轧制方向(Rolling direction,RD)切取“狗骨头”状拉伸试样,其标称尺寸为22.5 mm,矩形截面的宽度和厚度分别为6 mm和1.2 mm。

用SANS试验机进行CT样品的室温单轴拉伸实验,拉伸速率为0.001 s-1,重复3次。为了研究单轴拉伸过程中样品微观组织的演化,分别将CT样品单轴拉伸至变形量6%和12%。在6%和12%变形样品标称段的中间位置取样,以观察在相应变形条件下的微观组织。用FEI NOVA 400 Zeiss sigma场发射扫描电子显微镜和FEI Talos F200X场发射透射电子显微镜观察深冷处理后双峰分离非基面织构AZ31镁合金板材单轴拉伸变形前后的微观组织。用文献[14]中的方法制备EBSD样品,变形前后扫描步长分别为0.5 μm和0.3 μm,加速电压为20 keV。TEM样品的制备:先用SiC砂纸将样品磨抛至厚度约为100 μm的薄片,在磨抛过程控制样品的平整度;随后用冲孔仪冲出一个直径为3 mm的圆片,将圆片继续磨抛使其厚度约为30 μm,然后用Gatan 495离子减薄仪将其减薄。

2 实验结果

2.1 样品的初始微观组织和织构

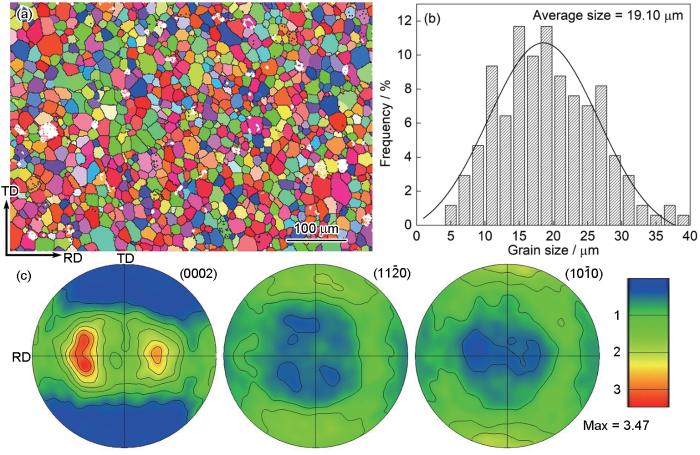

图1给出了CT样品的初始微观组织和织构,图1a给出了该样品的反极图(Inverse pole figure,IPF)。可以看出,CT样品的微观组织由等轴晶粒组成。统计结果表明,CT样品的平均晶粒尺寸为19.10 μm(图1b),与Chen等[5]用ECAR-CB-A工艺制备得的WQ样品的平均晶粒尺寸(14.91 μm)只有微小差别。本文制备的CT样品在520℃退火5 h后进行深冷处理,而WQ样品在300℃退火1 h后水冷。这表明,退火工艺的不同是其微观组织不同的主要原因。图1c给出了CT样品的(0002)、(11

图1

图1

AZ31镁合金板材的初始微观组织和织构

Fig.1

Initial microstructure and texture of fabricated AZ31 Mg alloy sheet (a) inverse pole figure (IPF) (b) statistical analysis of grain size (c) (0002) (11

2.2 单轴拉伸力学行为

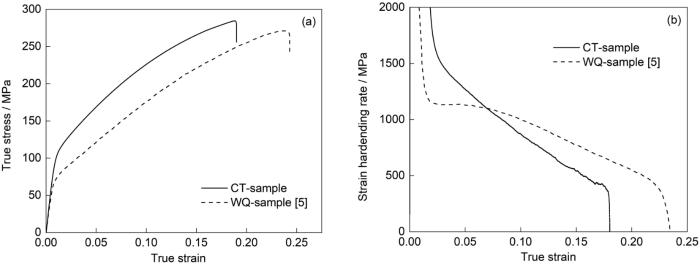

图2给出了CT样品室温单轴拉伸实验得到的真应力-真应变曲线和相应的加工硬化曲线。表1列出了两种样品的初始屈服强度(Yield stress,YS)、最大抗拉强度(Ultimate tensile strength,UTS)、断裂延伸率(Fracture elongation,FE)和屈强比(YS/UTS)。由表1可以看出,与对照组WQ样品相比,CT样品的YS和UTS分别提高了43.8%和5.2%,而FE降低了20.4%。由图2b可以看出,CT样品的加工硬化曲线出现3个明显不同的加工硬化阶段[5],即在塑性变形初始阶段随着真应变的增大应变硬化率急剧降低,对应弹塑性过渡阶段。继续增大真应变,CT样品的应变硬化率比WQ样品的应变硬化率下降得更快。这表明,CT样品和WQ样品在室温单轴拉伸变形过程中激活的位错滑移和变形孪生机制以及两者间的相互作用不同[15,16]。

图2

图2

CT样品和WQ样品的真应力-应变曲线和相应的加工硬化曲线

Fig.2

True stress-strain curves (a) and working hardening curves (b) of CT and WQ samples

表1 CT样品和WQ样品单轴拉伸时的力学性能

Table 1

| Sample | YS / MPa | UTS / MPa | FE / % | YS / UTS |

|---|---|---|---|---|

| CT-sample | 105 | 284 | 19.1 | 0.37 |

| WQ-sample[5] | 73 | 270 | 24 | 0.27 |

2.3 在单轴拉伸过程中微观组织和织构的演化

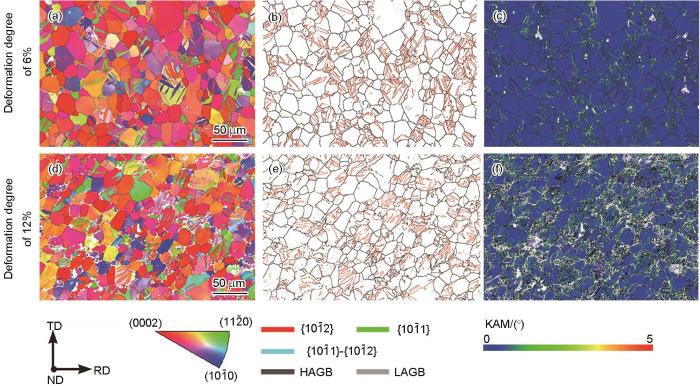

图3给出了CT样品在变形量为6%和12%时的EBSD微观组织。在IPF图(图3a,d)和晶界(Grain boundaries,GBs)图(图3b,e)中,分别用红色、绿色和蓝色表示{10

图3

图3

CT样品的变形量为6%和12%时的微观组织

Fig.3

Microstructure analysis of CT sample at deformation degree of 6% and 12% (a, d) Inverse pole figure (IPF) maps; (b, e) Grain boundaries (GBs) maps; (c, f) Kernel average misorientation (KAM) maps

图4

图4

单轴拉伸过程中CT样品取向差角的分布

Fig.4

Misorientation angle distribution of CT sample during tensile deformation

分析GB图可知,变形程度为6%和12%时的孪晶类型大部分为{10

其中μ为单位(100 nm)长度,b为Burgers矢量的大小。变形量为6%和12%样品的KAM值分别为0.40°和0.65°。这表明,变形12%的样品中GND密度更高。同时,晶界和孪晶界表现出更高的KAM值。这表明,上述位置在塑性变形过程中协调塑性应变的需求更为迫切[17]。

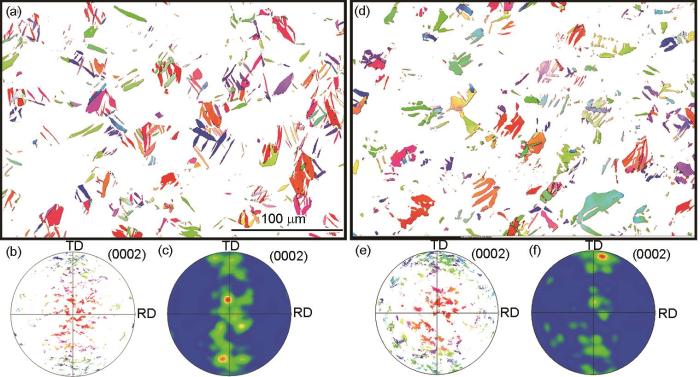

为了研究{10

图5

图5

CT样品的变形量为6%和12%时选取{10

Fig.5

IPF maps and (0002) PF maps of selected {10

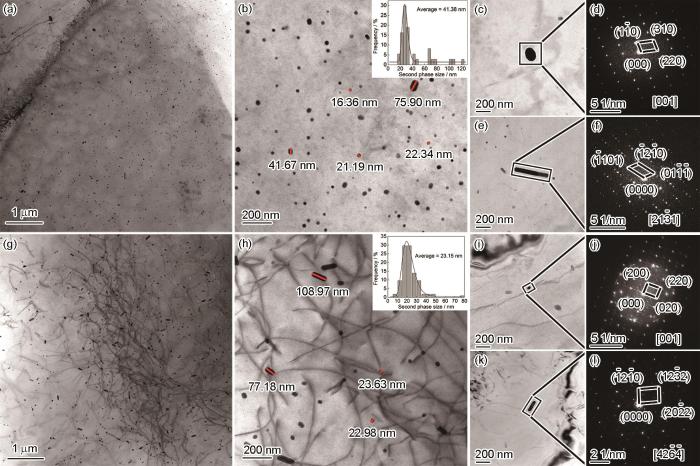

图6给出了CT样品和WQ样品的TEM照片,分为明场(Bright field,BF)像和选区电子衍射(Selected area electron diffraction pattern,SAEDP)像。图6a与g的对比表明,在CT样品中出现了较多的位错,与文献[19]的结果一致。深冷处理使金属材料中的位错密度提高,主要原因是低温使材料的晶格收缩和微应力场增大,使材料发生塑性变形和晶格畸变,最终使位错数量增多[20]。从图6b、h可见,在CT样品和WQ样品中都存在弥散分布的球形、椭球形和棒状纳米析出相。图6d、f、j、l给出了相应析出相的SAEDP图,表明析出相为Mg17Al12 (图6d、j)和Al8Mn5 (图6f、l),与文献[8]的结果一致,即棒状析出物为Al8Mn5相。特别在WQ样品中析出相的形貌大多为球形和椭球型,最大尺寸为77.38 nm,最小尺寸为9.67 nm,平均尺寸为23.15 nm,体积分数为1.45%;CT样品中析出相的形貌大多为椭球形和棒状,最大尺寸为124.43 nm,最小尺寸为15.94 nm,平均尺寸为41.38 nm,体积分数为2.40%。深冷处理使材料的晶格收缩,加速了第二相的析出[21,22]。同时,深冷处理后出现了较多的位错,有利于附近区域溶质原子的富集和析出相的成核[23]。

图6

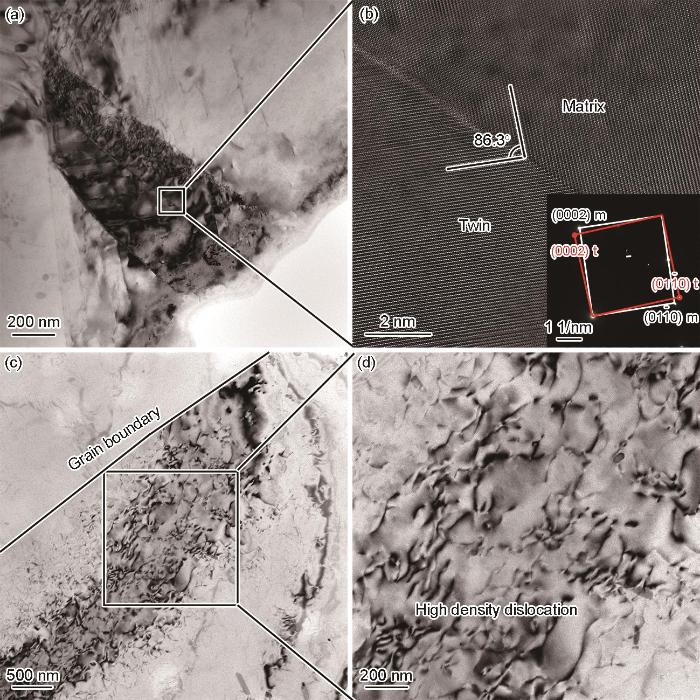

图7给出了CT样品拉伸变形6%的TEM照片,分为明场(BF)像和高分辨(High resolution TEM,HRTEM)像。可以看出,在变形样品中出现了明显的孪晶界面(图7a);同时,在孪晶和孪晶附近的基体中出现了高密度位错,在基体和孪晶中还可见部分直线位错。Gong等[24]观察到与此类似的结果,并推论这些位错可能是基面位错。图7b给出了基体/孪晶界面处的高分辨照片,可见基体与孪晶的取向差角为86.3°。根据基体/孪晶界面处对应的SAEDP图,可进一步确定基体与孪晶之间的取向关系,即基体与孪晶有公共平面{10

图7

图7

CT样品变形量为6%时的TEM照片

Fig.7

TEM micrographs of 6%-deformed CT sample (a, c, d) BF images of different regions (b) HRTEM image of selected region in Fig.7a

3 讨论

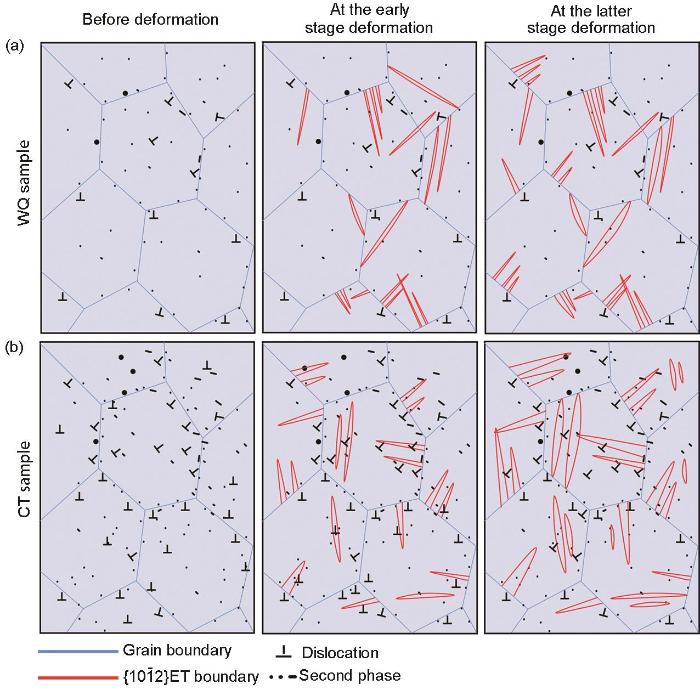

根据上述分析,给出了CT样品和WQ样品室温单轴拉伸变形的变形机制(图8)。在总体上,CT样品和WQ样品的塑性变形机制类似,即在塑性变形的初期,双峰分离非基面织构使AZ31镁合金板材在室温单轴拉伸变形中不仅激活了大量的位错滑移(包含基面<a>位错和非基面<a>位错),还激活了相当数量的{10

图8

图8

在单轴拉伸过程中WQ样品和CT样品的变形机制示意图

Fig.8

Schematic diagram of involved deformation mechanisms during uniaxial tension deformation of WQ (a) and CT (b) samples

与WQ样品相比,CT样品的YS提高43.8%,UTS提高5.2%,主要原因是深冷处理使晶格收缩而产生了高密度位错(图6g)。同时,CT样品的微观组织中尺寸更大、体积分数更高的析出相,在拉伸变形过程中钉轧位错[30]。在变形过程中位错产生应变强化,析出相产生沉淀强化,两者的共同作用使CT样品的强度显著提高。与WQ样品相比,CT样品的FE降低了20.4%。CT样品的拉伸变形激活了更多的{10

4 结论

(1) AZ31镁合金板材的CT样品和WQ样品具有类似的初始晶粒尺寸,都具有双峰分离非基面织构特征。与水冷处理相比,深冷处理不改变AZ31镁合金板材析出相的类型,但是使板材样品析出相的尺寸增大,析出相体积分数和位错密度提高。

(2) WQ样品的YS为73 MPa,UTS为270 MPa,FE为24%,经过深冷处理的CT样品的YS为105 MPa,UTS为284 MPa,FE为19.1%,分别提高43.8%,5.2%和降低20.4%。

(3) AZ31镁合金板材的CT样品和WQ样品的变形机制类似,但是深冷处理在晶界和晶粒内富集了大量位错和析出相,随着塑性应变的增大激活了大量{10

参考文献

Effects of technical factors on formability of AZ31 magnesium alloys

[J].

In this paper, the AZ31 magnesium alloy sheets which have distinct textures and different grain sizes were prepared through different rolling processes, the effects of technological parameters on formability of the magnesium alloy were studied through erichsen test at room temperature. The result show that the strain hardening in the rolling direction of the magnesium sheets which produced in the deformation process can be improvement by increasing the grain size and reducing the basal texture, meanwhile, the elongation and room temperature formability of the magnesium alloy sheets are also improved. The grain size of the magnesium alloy which was prepared by cross shear rolling (the rolling and annealing temperature is 400 ℃, the different rolling speed ratio is 1.5) increases to 20 μm, while the maximum of the (0002) pole figure is only 2, the IE value which is obtained by erichsen experiment is 5.71, the room temperature formability of the magnesium alloy increase significantly.

工艺因素对AZ31镁合金板材室温成形性能的影响

[J].

Current issues in magnesium sheet alloys: Where do we go from here?

[J].

Effect of rolling speeds on texture modification and mechanical properties of the AZ31 sheet by a combination of equal channel angular rolling and continuous bending at high temperature

[J].

Effect of texture types on microstructure evolution and mechanical properties of AZ31 magnesium alloy undergoing uniaxial tension deformation at room temperature

[J].

Deep cryogenic treatment of HPDC AZ91 magnesium alloys prior to aging and its influence on alloy microstructure and mechanical properties

[J].

Enhancing strength-ductility synergy in a Mg-Gd-Y-Zr alloy at sub-zero temperatures via high dislocation density and shearable precipitates

[J].The strength-ductility trade-offdilemma is hard to be evaded in high-strength Mg alloys at sub-zero temperatures, especially in the Mg alloys containing a high volume fraction of precipitates. In this paper, we report an enhanced strength-ductility synergy at sub-zero temperatures in an aged Mg-7.37Gd-3.1Y-0.27Zr alloy. The tensile stress-strain curves at room temperature (RT),-70 °C and-196 °C show that the strength increases monotonically with decreasing temperature, but the elongation increases first from RT to-70 °C then declines from-70 °C to-196 °C. After systematic investigation of the microstructure evolutions at different deformation temperatures via synchrotron X-ray diffraction, electron backscattered diffraction (EBSD) and transmission electron microscopy (TEM), it is found that a high dislocation density with sufficient <c+a> dislocations promotes good tensile ductility at-70 °C, which is attributed to the minimized critical resolved shear stress (CRSS) ratio of non-basal <c+a> to basal <a> dislocations. In ad-dition, more shearable precipitates can further improve the ductility via lengthening the mean free path of dislocation glide. The present work demonstrates that an excellent strength-ductility synergy at sub-zero temperatures can be achieved by introducing a high dislocation density and shearable precipitates in high-strength Mg alloys.

Effects of cryogenic treatment on microstructure and mechanical properties of AZ31 magnesium alloy rolled at different paths

[J].

Effect of post rolling cryogenic treatment on microstructure and mechanical properties of AZ31 magnesium alloy sheet

[J].

轧后深冷处理工艺对 AZ31 镁合金板材组织和力学性能的影响

[J].为了改善传统热轧AZ31镁合金板材的微观组织,提升其综合力学性能,将AZ31镁合金板材经360℃热轧后,采用不同时间液氮浸泡进行深冷处理,研究不同深冷时间处理对热轧AZ31镁合金显微组织和力学性能的影响。结果表明:经深冷处理后,热轧AZ31镁合金中析出第二相,同时合金内部晶粒尺寸得到细化,导致孪晶产生。AZ31镁合金热轧板材经过20 min深冷处理后,综合力学性能得到显著改善,其硬度、屈服强度和极限抗拉强度分别为75.4 HV、182 MPa和278 MPa,较传统热轧分别提高了9.4%、8.3%和14%,此外,随着深冷时间的延长,AZ31镁合金的伸长率逐渐提高,最大伸长率达到14.4%。

Microstructure and strength-ductility balance of pure titanium processed by cryogenic rolling at various rolling reductions

[J].

Effect of cryogenic treatment on B2 nanophase, dislocation and mechanical properties of Al1.4CrFe2Ni2 (BCC) high entropy alloy

[J].

The effects and mechanisms of pre-deformation with low strain on temperature-induced martensitic transformation

[J].Pre-deformation with low strain can effectively control the thermal stability of metastable austenite. Till now, research has mainly focused on the effect of pre-deformation on martensitic transformation at one or more temperatures. However, research is still lacking on the effect of pre-deformation on the temperature at which martensite is formed (Ms), the final martensite content, and the transformational kinetics during continuous cooling. Furthermore, the mechanism underlying how pre-deformation affects martensitic transformation has not been reported. In this work, the influence rule and the corresponding effect of pre-deformation with low strain on martensitic transformation induced by temperature under continuous cooling from 300 K to 4 K was studied with 321 stainless steel samples by using the quasi-in-situ observation technique. The results show that Ms and the final amount of martensite increased under pre-deformation with low strain, and the martensitic transformation during continuous cooling was simultaneously accelerated. The quasi-in-situ observation demonstrated that the slip bands introduced by pre-deformation effectively provided nucleation sites for ε-martensite transformation. Accordingly, the formed ε-martensite increased the number of α'-martensite nucleation sites during continuous cooling, and finally promoted α'-martensite transformation. This builds on the theory proposed by other researchers that the dislocation defects introduced by pre-deformation directly provide the nucleation sites for α'-martensite transformation, and thus, promote martensitic transformation. In addition, by analyzing the nucleation behavior and nucleation priority at slip band defects, it is shown that the nucleation behavior of slip bands introduced by the pre-deformation was similar to that of faulted austenite induced by temperature. However, it is worth noting that the slip bands introduced by pre-deformation had a relatively higher nucleation priority. The crystallography of α'-martensite in the pre-deformed samples was analyzed, and it was found that the slip bands effectively changed the variant selection of α'-martensite so that the texture of α'-martensite was modified. This study advances the existing theory of martensitic transformation and provides theoretical guidance for the proactive control of temperature-induced martensitic transformation.

低应变预变形对变温马氏体相变行为的影响规律及作用机制

[J].以321型不锈钢为实验材料,利用伪原位观察技术研究了300~4 K连续冷却过程中低应变预变形对变温马氏体相变行为的影响规律及作用机制。结果表明,在连续冷却过程中,低应变预变形提高了马氏体相变开始温度和最终的马氏体转变量,同时也加速了整个连续冷却过程中的马氏体相变。通过伪原位观察揭示了预变形引入的滑移带能有效地提供温度诱发ε-马氏体相变的形核质点,促进ε-马氏体转变,进而提高连续冷却过程中α'-马氏体相变的形核质点数量,促进α'-马氏体相变,完善了预变形引入的位错缺陷直接提供α'-马氏体相变的形核质点,促进α'-马氏体相变这一理论。此外,通过对滑移带缺陷的形核行为和形核优先性分析,揭示形变引入的滑移带与温度诱发的缺陷奥氏体具有相同的形核行为,但预变形引入的滑移带具有更高的形核优先性。同时对预变形试样中α'-马氏体的晶体学特征分析发现,滑移带能有效地改变α'-马氏体的变体选择,进而改变α'-马氏体的相变织构。

Influence of bimodal non-basal texture on microstructure characteristics, texture evolution and deformation mechanisms of AZ31 magnesium alloy sheet rolled at liquid-nitrogen temperature

[J].

Role of {10

Simulation of deformation twins and deformation texture in an AZ31 Mg alloy under uniaxial compression

[J].

Effect of twin boundaries on the microstructure and mechanical properties of Inconel 625 alloy

[J].

Investigation on microstructure and mechanical properties of hot-rolled AZ31 Mg alloy with various cryogenic treatments

[J].

Effects of cryogenic treatment on microstructures and mechanical properties of Mg-2Nd-4Zn alloy

[J].

Microstructure and mechanical behavior of Al 7075-T6 subjected to shallow cryogenic treatment

[J].

Influence of cryogenic treatment on room and low temperature tensile behavior of as-cast Mg-10Gd-3Y-0.5Zr magnesium alloy

[J].

Cryogenic treatment of metal-a review

[J].

The development of a W-shaped channel extrusion for fabricating magnesium alloy shells by combining high amplitude shear strain with a shorter process

[J]. J.

In-situ observation of twinning and detwinning in AZ31 alloy

[J].

Dislocation transmutation by tension twinning in magnesium alloy AZ31

[J].

Exceptional improvement in the yield strength of AZ61 magnesium alloy via cryo-stretching and its implications on the grain growth during annealing

[J].

Strengthening mechanisms of semi-coherent boundaries between Al8Mn4Y and the Mg matrix in magnesium alloys

[J].

Evolution of microstructures and mechanical properties of K439B superalloy during long-term aging at 800oC

[J].

K439B铸造高温合金800℃长期时效组织与性能演变

[J].对K439B合金开展800℃、3000 h长期时效,研究合金显微组织及力学性能的演变,分析室温拉伸及815℃、379 MPa持久性能的变形机制。结果表明:热处理态K439B合金中的γ'相呈球状,晶界存在MC及M<sub>23</sub>C<sub>6</sub> 2种碳化物,而枝晶间仅存在MC碳化物。在800℃长期时效过程中,γ'相的粗化遵循Ostwald熟化机制且形貌趋于立方化,γ′相粗化速率为71.7 nm<sup>3</sup>/h;晶界和枝晶间MC碳化物发生退化,M<sub>23</sub>C<sub>6</sub>碳化物析出含量逐渐增加。时效3000 h后晶界γ'相与M<sub>23</sub>C<sub>6</sub>碳化物存在[111] <sub>γ' </sub> //[111] <sub>M</sub>23<sub>C</sub>6、(22¯0) <sub>γ′ </sub> //(22¯0) <sub>M</sub>23<sub>C</sub>6的位向关系。热处理态合金的室温抗拉强度和屈服强度分别为1159.0和911.5 MPa,815℃、379 MPa持久寿命为150.4 h。长期时效后γ'相尺寸增加使得位错的运动方式由以位错在基体中滑移为主向位错切入γ′相为主转变,γ′相中出现了更多的堆垛层错,合金室温拉伸强度和815℃、379 MPa持久寿命均降低。

Effect of pre-strain on tensile mechanical properties of 2195 aluminum-lithium alloy

[J].

预变形对 2195 铝锂合金拉伸力学性能的影响

[J].

The development of a W-shaped channel extrusion for fabricating magnesium alloy shells by combining high amplitude shear strain with a shorter process

[J].

Effects of precipitate shape and orientation on dispersion strengthening in magnesium alloys

[J].