Tribological properties of different-sized black phosphorus nanosheets as water-based lubrication additives for steel/titanium alloy wear contact

2

2022

... 钛合金的比强度高、抗腐蚀性强和耐高温性能优异,可用于制造航空薄壁部件[1].在可切削加工钛制薄壁部件的高速切削过程中易发生“颤振”和“弯曲”,产生的切削热使刀具变形、切削刃断裂、切屑粘附或刀具磨损失控[2].同时,在切削过程中工件与刀具之间较大的摩擦力严重影响工件表面的质量和降低刀具的寿命.使用切削液能润滑、冷却工件和切削刀具并降低切削过程中的温度、切削载荷、延长刀具寿命和提高工件表面的质量[1,3~5]. ...

... [1,3~5]. ...

A novel bionic micro-textured tool with the function of directional cutting-fluid transport for cutting titanium alloy

1

2023

... 钛合金的比强度高、抗腐蚀性强和耐高温性能优异,可用于制造航空薄壁部件[1].在可切削加工钛制薄壁部件的高速切削过程中易发生“颤振”和“弯曲”,产生的切削热使刀具变形、切削刃断裂、切屑粘附或刀具磨损失控[2].同时,在切削过程中工件与刀具之间较大的摩擦力严重影响工件表面的质量和降低刀具的寿命.使用切削液能润滑、冷却工件和切削刀具并降低切削过程中的温度、切削载荷、延长刀具寿命和提高工件表面的质量[1,3~5]. ...

Experimental investigation of eco-friendly cryogenic minimum quantity lubrication (CMQL) strategy in machining of Ti-6Al-4V thin-wall part

1

2022

... 钛合金的比强度高、抗腐蚀性强和耐高温性能优异,可用于制造航空薄壁部件[1].在可切削加工钛制薄壁部件的高速切削过程中易发生“颤振”和“弯曲”,产生的切削热使刀具变形、切削刃断裂、切屑粘附或刀具磨损失控[2].同时,在切削过程中工件与刀具之间较大的摩擦力严重影响工件表面的质量和降低刀具的寿命.使用切削液能润滑、冷却工件和切削刀具并降低切削过程中的温度、切削载荷、延长刀具寿命和提高工件表面的质量[1,3~5]. ...

Cellulose nanocrystals as sustainable additives in water-based cutting fluids

0

2022

Study on friction and wear of Cellulose Nanocrystal (CNC) nanoparticle as lubricating additive in engine oil

1

2019

... 钛合金的比强度高、抗腐蚀性强和耐高温性能优异,可用于制造航空薄壁部件[1].在可切削加工钛制薄壁部件的高速切削过程中易发生“颤振”和“弯曲”,产生的切削热使刀具变形、切削刃断裂、切屑粘附或刀具磨损失控[2].同时,在切削过程中工件与刀具之间较大的摩擦力严重影响工件表面的质量和降低刀具的寿命.使用切削液能润滑、冷却工件和切削刀具并降低切削过程中的温度、切削载荷、延长刀具寿命和提高工件表面的质量[1,3~5]. ...

Problems and perspectives of titanium alloy lubrication in cutting process

2

2022

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... [6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

钛合金切削润滑研究现状与发展趋势

2

2022

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... [6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Tribological properties of quaternary ammonium salt polymeric ionic liquids as water-based lubricant additive

1

2022

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

季铵盐聚离子液体作为水基润滑添加剂的摩擦学性能研究

1

2022

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Towards superior lubricity and anticorrosion performances of proton-type ionic liquids additives for water-based lubricating fluids

2

2020

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... [8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

A molecular dynamics study on the synergistic lubrication mechanisms of graphene/water-based lubricant systems

1

2022

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Evaluation of vegetable and mineral oil-in-water emulsion cutting fluids in turning AISI 4340 steel with coated carbide tools

1

2014

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Research progress of graphene as additive of water-based lubricants

1

2021

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

石墨烯基水润滑添加剂研究进展

1

2021

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Friction and wear characteristics of chemically modified mahua (madhuca indica) oil based lubricant with SiO2 nanoparticles as additives

1

2022

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

2D black phosphorus dotted with silver nanoparticles: An excellent lubricant additive for tribological application

1

2020

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Tribological investigation of MoS2 coatings deposited on the laser textured surface

1

2012

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Friction behavior and structural evolution of hexagonal boron nitride: A relation to environmental molecules Containing- OH functional group

1

2022

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

In-situ exfoliated graphene for high-performance water-based lubricants

3

2016

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... 基于上述结果和对磨损表面的分析,提出了F-BNNSs12的润滑机理.与h-BNNSs相比,F-BNNSs12作为水基润滑添加剂使摩擦系数和磨损率大幅度降低.h-BNNSs作为水基润滑剂时,由于其在摩擦微区内发生团聚和较低的硬度与断裂韧性,在外力长时间作用下容易发生破损、断裂,使润滑效果降低[16,22,47].F-BNNSs12作为水基润滑添加剂时,纳米片上较大的负电荷使层间的极性相互作用减弱,与h-BNNSs相比更小的剪切力就能使片层间发生相对滑动,从而使摩擦力更小.图6也表明,F-BNNSs12不相称的纳米棒-纳米片结构在摩擦过程中呈现出滚动摩擦.同时,F-BNNSs12还能填充磨损表面的凹槽使摩擦副之间的接触面积减小.这些因素,都有助于实现良好的润滑性能[16,21,45,54].同时,在外力的作用下F-BNNSs12逐渐沉积在摩擦副的表面,在边界润滑状态下摩擦副的表面形成了一层稳定且不连续的润滑膜,减少了钛合金/钢接触点而使摩擦和磨损降低[55]. ...

... [16,21,45,54].同时,在外力的作用下F-BNNSs12逐渐沉积在摩擦副的表面,在边界润滑状态下摩擦副的表面形成了一层稳定且不连续的润滑膜,减少了钛合金/钢接触点而使摩擦和磨损降低[55]. ...

Black phosphorus-graphene oxide hybrid nanomaterials toward advanced lubricating properties under water

2

2019

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... 图5给出了样品的TEM图像、选定区域电子衍射(SAED图像)以及粒径统计.图5a、b分别给出了不同区域F-BNNS12的TEM照片,可见纳米片边缘明显的卷曲结构.图5d给出了图5a白色边框内样品的放大示意图,可见卷曲结构且因弯曲较大形成了纳米棒结构[40].图5c中的SAED图表现出典型h-BN的6倍对称特征,表明得到的F-BNNSs在球磨过程中结晶良好,没有发生损伤[17].图5e给出了图5d中红框区域内的高分辨TEM照片,可见十个晶面的间距为2.189 nm,一个晶面间距大约为0.22 nm,对应于F-BNNSs12的(001)平面,与原始的h-BNNSs相同.对F-BNNSs12粒度分析(图5g、h)结果表明,最小直径为46.41 nm,最大直径为191.15 nm,平均直径为91.78 nm,大部分纳米片的直径集中在40~120 nm. ...

Tribological behaviours of black phosphorus/MoS2 composites as water‐based lubrication additives

1

2021

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Friction and wear properties of a nanoscale ionic liquid-like GO@ SiO2 hybrid as a water-based lubricant additive

1

2022

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Mechanisms of friction and wear reduction by h-BN nanosheet and spherical W nanoparticle additives to base oil: Experimental study and molecular dynamics simulation

1

2020

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Ball milling of hexagonal boron nitride microflakes in ammonia fluoride solution gives fluorinated nanosheets that serve as effective water-dispersible lubricant additives

3

2019

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... 图2a给出了h-BNNSs和F-BNNSs(F-BNNSs8、F-BNNSs12和F-BNNSs16)在20°~80°的完整XRD谱,可见所有样品的出峰位置一致,衍射角度(2θ)均为26.6°、41.5°和54.9°.图2b给出了h-BNNSs和F-BNNSs在(002)晶面的局部放大XRD谱,用以进一步分析2θ为26.6°处峰的结构.根据Bragg方程(2dsinθ = λ),XRD峰的衍射角(θ)随着纳米片层间间距(d)的变化而变化.X射线的波长为0.15406、2θ为26.6°,根据Bragg方程计算出h-BNNSs的平面间距大约为0.33 nm.B-F和N-F的键长分别为0.131 nm和0.138 nm,小于h-BNNSs的平面间距,因此(002)晶面并没有偏移[42].图2c给出了h-BNNSs、F-BNNSs8、F-BNNSs12和F-BNNSs16的FTIR光谱.h-BNNSs在780 cm-1和1362 cm-1处的峰可归因于B-N-B弯曲和B-N伸缩振动[43].F-BNNSs12和F-BNNSs16在1080 cm-1和1253 cm-1处的特征峰,对应B-F振动[21].没有发现N-F键振动的原因是,B-N-B平面外弯曲振动重叠[44].F-BNNSs8并没有B-F和N-F的特征峰出现,其原因可能是NH4F的使用较少,嫁接在h-BNNSs的表面上F原子含量较低. ...

... 基于上述结果和对磨损表面的分析,提出了F-BNNSs12的润滑机理.与h-BNNSs相比,F-BNNSs12作为水基润滑添加剂使摩擦系数和磨损率大幅度降低.h-BNNSs作为水基润滑剂时,由于其在摩擦微区内发生团聚和较低的硬度与断裂韧性,在外力长时间作用下容易发生破损、断裂,使润滑效果降低[16,22,47].F-BNNSs12作为水基润滑添加剂时,纳米片上较大的负电荷使层间的极性相互作用减弱,与h-BNNSs相比更小的剪切力就能使片层间发生相对滑动,从而使摩擦力更小.图6也表明,F-BNNSs12不相称的纳米棒-纳米片结构在摩擦过程中呈现出滚动摩擦.同时,F-BNNSs12还能填充磨损表面的凹槽使摩擦副之间的接触面积减小.这些因素,都有助于实现良好的润滑性能[16,21,45,54].同时,在外力的作用下F-BNNSs12逐渐沉积在摩擦副的表面,在边界润滑状态下摩擦副的表面形成了一层稳定且不连续的润滑膜,减少了钛合金/钢接触点而使摩擦和磨损降低[55]. ...

Evaluation of hexagonal boron nitride nano-sheets as a lubricant additive in water

3

2013

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... [22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... 基于上述结果和对磨损表面的分析,提出了F-BNNSs12的润滑机理.与h-BNNSs相比,F-BNNSs12作为水基润滑添加剂使摩擦系数和磨损率大幅度降低.h-BNNSs作为水基润滑剂时,由于其在摩擦微区内发生团聚和较低的硬度与断裂韧性,在外力长时间作用下容易发生破损、断裂,使润滑效果降低[16,22,47].F-BNNSs12作为水基润滑添加剂时,纳米片上较大的负电荷使层间的极性相互作用减弱,与h-BNNSs相比更小的剪切力就能使片层间发生相对滑动,从而使摩擦力更小.图6也表明,F-BNNSs12不相称的纳米棒-纳米片结构在摩擦过程中呈现出滚动摩擦.同时,F-BNNSs12还能填充磨损表面的凹槽使摩擦副之间的接触面积减小.这些因素,都有助于实现良好的润滑性能[16,21,45,54].同时,在外力的作用下F-BNNSs12逐渐沉积在摩擦副的表面,在边界润滑状态下摩擦副的表面形成了一层稳定且不连续的润滑膜,减少了钛合金/钢接触点而使摩擦和磨损降低[55]. ...

Study on the preparation and tribological properties of BN@C-OA nano-additive lubricants

2

2021

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

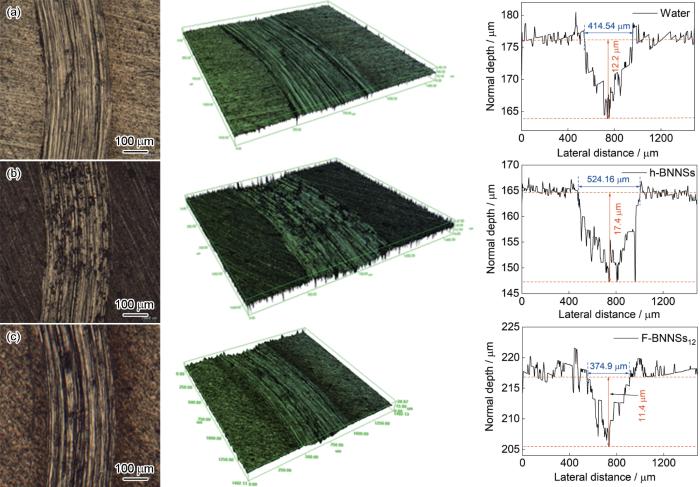

... 图11给出了用纯水与浓度都为0.1 mg/mL的h-BNNSs和F-BNNSs12水基润滑后的磨损轨道、三维轮廓图像和对应的二维高度轮廓曲线.图11c给出了F-BNNSs12水基润滑后TC4盘的磨损轨道和三维轮廓图像,可见其表面比用纯水与h-BNNSs润滑(图11a、b)更平整光滑,也得到了二维高度轮廓曲线的进一步验证.纯水、h-BNNSs与F-BNNSs12的磨损轨道宽度分别为414.5 μm、524.15 μm、374.9 μm,磨损深度分别为12.2 μm、17.4 μm、11.4 μm.定量计算结果表明,对应的磨损率分别为4.5 × 10-6 mm3·N-1·m-1、9.2 × 10-6 mm3·N-1·m-1、3.9 × 10-6 mm3·N-1·m-1.h-BNNSs比纯水与F-BNNSs水基润滑的磨损量较大,其原因是h-BN的硬度(莫氏硬度为2)和断裂韧性(1.09 ± 0.01 MPa·m1/2)较低[51].同时,硼原子与氮原子的电负性不同,使h-BNNSs的片层之间除了有极弱的范德华力还有极强的极性,抑制了层间滑移和降低了h-BNNSs作为润滑添加剂的性能[23,24].F-BNNSs12的磨损轨道的磨损率最低,因为F-BNNSs12优异的抗裂能力使层状的平面结构免受平面内刚度和外应力的破坏,并使层间在外力的作用下相对滑动(起减磨润滑作用),与前文的实验验证结果一致[52]. ...

In-situ growth of amorphous carbon on sucrose-assisted exfoliated boron nitride nanosheets: Exceptional water dispersibility and lubrication performance

3

2022

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... [24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... 图11给出了用纯水与浓度都为0.1 mg/mL的h-BNNSs和F-BNNSs12水基润滑后的磨损轨道、三维轮廓图像和对应的二维高度轮廓曲线.图11c给出了F-BNNSs12水基润滑后TC4盘的磨损轨道和三维轮廓图像,可见其表面比用纯水与h-BNNSs润滑(图11a、b)更平整光滑,也得到了二维高度轮廓曲线的进一步验证.纯水、h-BNNSs与F-BNNSs12的磨损轨道宽度分别为414.5 μm、524.15 μm、374.9 μm,磨损深度分别为12.2 μm、17.4 μm、11.4 μm.定量计算结果表明,对应的磨损率分别为4.5 × 10-6 mm3·N-1·m-1、9.2 × 10-6 mm3·N-1·m-1、3.9 × 10-6 mm3·N-1·m-1.h-BNNSs比纯水与F-BNNSs水基润滑的磨损量较大,其原因是h-BN的硬度(莫氏硬度为2)和断裂韧性(1.09 ± 0.01 MPa·m1/2)较低[51].同时,硼原子与氮原子的电负性不同,使h-BNNSs的片层之间除了有极弱的范德华力还有极强的极性,抑制了层间滑移和降低了h-BNNSs作为润滑添加剂的性能[23,24].F-BNNSs12的磨损轨道的磨损率最低,因为F-BNNSs12优异的抗裂能力使层状的平面结构免受平面内刚度和外应力的破坏,并使层间在外力的作用下相对滑动(起减磨润滑作用),与前文的实验验证结果一致[52]. ...

Tribological behaviour of modified jatropha oil by mixing hexagonal boron nitride nanoparticles as a bio-based lubricant for machining processes

1

2017

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Few-atomic-layered hexagonal boron nitride: CVD growth, characterization, and applications

1

2017

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Controlling catalyst bulk reservoir effects for monolayer hexagonal boron nitride CVD

1

2016

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Exfoliation of hexagonal boron nitride by molten hydroxides

1

2013

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Atomic resolution imaging and topography of boron nitride sheets produced by chemical exfoliation

1

2010

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Surface modification of hexagonal boron nitride nanomaterials: a review

2

2018

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... ,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Fluorinating hexagonal boron nitride into diamond-like nanofilms with tunable band gap and ferromagnetism

2

2011

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... F-BNNSs是由恒温磁力搅拌与球磨辅助氟化与剥离制备的.在第一个制备过程中,氟化铵的高温分解有利于氟化h-BNNSs.N原子与B原子的电荷性不同,使其更倾向于与B原子结合,如图6所示.边缘的B原子嫁接了更多的F原子,且掺杂F原子使h-BNNSs表面弯曲[31,38].随后在球磨过程中纳米片发生了剥离,使F原子有更多的嫁接位点,促进h-BNNSs的氟化形成了纳米棒结构[45]. ...

Oxidation of a two-dimensional hexagonal boron nitride monolayer: a first-principles study

0

2012

Effect of fluorine content on structure and tribological properties of diamond-like carbon films

1

2013

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

氟含量对类金刚石薄膜结构及摩擦学性能的影响

1

2013

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Excellent electrical conductivity of the exfoliated and fluorinated hexagonal boron nitride nanosheets

3

2013

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

... 在外部负载作用下,球-盘接触点处是椭圆接触区[34].相应的赫兹接触应力(p)为 ...

... 图12a、b分别给出了在10 N和50 mm/s条件下使用1 mg/mL F-BNNSs12水基润滑剂的TC4圆盘磨损表面的拉曼谱和检测位置.图12a表明,拉曼检测位置在磨痕的中间,保证了检测结果准确性.从拉曼谱可见,表面出现了大面积的暗斑,可能产生了不连续的润滑膜.在拉曼光谱(图12b)的1366 cm-1处出现一个F-BNNSs12特征峰,表明磨损表面残留有润滑剂[45].为了进一步证明存在化学反应膜并得到其化学成分,进行了XPS分析 (图12c~g).图12c给出了用1 mg/mL F-BNNSs12水基润滑后TC4盘磨损疤痕的全谱,检测到F 1s、O 1s、Ti 2p、N 1s、C 1s和B 1s.图12d表明,位于188.5 eV和190.4 eV处的B 1s峰主要以B-N和B-F的形式存在;还检测了F 1s XPS谱(图12f),证明摩擦实验后残留的润滑剂紧密结合在磨损处的表面.N 1s位于396.6 eV和399.5 eV处的峰对应N-B和Ti-N,但是没有检测到N-F键,可能是F原子与B原子很大的电负性差异使其更倾向于彼此结合,而不是与N原子结合,摩擦实验后N-F键的量更少[34];Ti 2p XPS谱中396.6 eV和399.5 eV处出现了双峰.结合图7b的EDS分析结果,在磨损痕迹处聚集了大量的N、B、F元素,证明大部分磨损痕迹都有残留的润滑剂.根据前述对磨痕的分析,磨损痕迹处有润滑剂的残留,在一定的力和滑动的作用下润滑剂与TC4盘发生了化学反应,在磨损表面生成了由F-BNNSs和TiN组成的不连续润滑薄膜.生成不连续润滑膜的原因,可能是TC4金属盘表面不十分平整,每个接触点受力的不同使有的位置没有产生润滑膜.本文的研究结果表明,磨损表面形成的润滑膜是降低钛合金/钢接触点的摩擦和磨损的关键. ...

Reduction of interlayer friction between bilayer hexagonal boron nitride nanosheets induced by electron redistribution

0

2019

Preservation of the frictional properties of h-BN under chemical modification in the presence of a commensurate Ni (1 1 1) substrate

1

2019

... 钛合金切削液,分为油基切削液和水基切削液[6].传统的油基切削液可减少刀具的磨损,但是其冷却性能较差和不易降解[7].因此,研发高效和环保的钛合金切削液极为迫切.水资源储量丰富和绿色环保,因此可在摩擦过程中提供流体动力膜,但是其单独作为润滑剂时润滑性能和成膜能力较低[6,8,9].将添加剂加到水中生成的水基润滑剂,能减摩和提高耐磨性能[8,10],尤其是将纳米材料作为润滑添加剂其润滑性能更为优异.目前作为润滑相的纳米材料,有石墨烯[11],二氧化硅[12],黑磷[13],二硫化钼[14]和六方氮化硼[15]等.Liang[16]等研究了原位剥离石墨烯作为水基润滑添加剂的摩擦学行为.结果表明,石墨烯具有良好的分散稳定性和减磨耐磨性能,其在5~15N载荷下的摩擦系数为0.05~0.2.Guo[17]等用自组装法制备黑磷-氧化石墨烯纳米复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,在5N负载下几乎实现了超滑状态.Wang[18]等用自组装法制备黑磷/二硫化钼复合材料,研究了其作为水基润滑添加剂的摩擦学特性.结果表明,黑磷与二硫化钼的质量比为1∶4时润滑效果最佳,摩擦系数为0.2272.Liang[19]等制备出一种GO@ SiO2纳米离子液体,使用球-盘摩擦机进行了室温摩擦实验.结果表明,载荷为15N、浓度为4%时减磨耐磨效果最佳,摩擦系数约为0.3.但是,虽然以上这几类纳米润滑材料的润滑效果较好,但是使用成本较高.h-BN是一种典型的二维材料,与石墨的晶体结构和晶格参数相似,具有优于石墨的良好的热稳定性、优异的机械强度和润滑性能[20].同时,h-BN具有良好的生物相容性、优良的电绝缘和高化学稳定性,是水基润滑添加剂的理想候选材料[21].Cho等[22]发现,向水中加入h-BN能提高耐磨性能和降低摩擦系数.但是,h-BN纳米片具有化学惰性和较高的表面能,其在润滑介质中的分散性较差且在滑动过程中易发生团聚,使其润滑性能降低[22,23].同时,硼原子和氮原子的电负性不同,使h-BN的片层之间产生了极强的极性,能抑制层间的滑移,使h-BN作为润滑添加剂的减摩和抗磨性能降低[24,25].用电化学剥离[26]、化学气相沉积[27]、液体超声处理[28]、化学反应[29]和水热法[30]等方法将块状h-BN剥离,可制备出单层或多层氮化硼纳米片(BNNS).但是,这些方法的生产条件苛刻、生产率较低、成本较高和产生环境污染.特别是剥离的BNNS生成很少的官能团,且在润滑介质中的分散稳定性较差而产生团聚,严重降低其减摩作用[24,30].表面功能化(例如氟化和氧化),是改变和监测二维材料的力学和物理性能的有效方法[31~33].氟化物修饰能降低h-BN的表面极性和抑制其在溶剂中的团聚,掺杂到h-BNNSs上的原子可使电子再分配,从而减少其层间摩擦.鉴于此,本文以氟化铵(NH4F)作为氟源用恒温磁力搅拌和高能球磨工艺制备F-BNNSs[34~36],研究其作为水基添加剂的摩擦学性能. ...

Ultralow concentration of graphene oxide nanosheets as oil-based lubricant additives

1

2019

... E′为有效弹性模量[37],W位施加的载荷,R为球半径.E1 (TC4-113 GPa)和E2 (GCr15-207 GPa)分别为摩擦副的弹性模量,μ1 (TC4 0.34)和μ2 (GCr15 0.30)分别为摩擦副的泊松比.于是可计算出最大赫兹接触应力为1.3~1.6 GPa. ...

Tribological behavior of black phosphorus nanosheets as water-based lubrication additives

3

2022

... V为磨损体积,N为球上施加的载荷,S为滑动距离[38],l为磨损轨迹的深度,r为球的半径,d为磨损直径. ...

... F-BNNSs是由恒温磁力搅拌与球磨辅助氟化与剥离制备的.在第一个制备过程中,氟化铵的高温分解有利于氟化h-BNNSs.N原子与B原子的电荷性不同,使其更倾向于与B原子结合,如图6所示.边缘的B原子嫁接了更多的F原子,且掺杂F原子使h-BNNSs表面弯曲[31,38].随后在球磨过程中纳米片发生了剥离,使F原子有更多的嫁接位点,促进h-BNNSs的氟化形成了纳米棒结构[45]. ...

... 计算理论最小薄膜厚度和比率.式中U = ηV/E′R,G = αE′,W = F/E′R2,R (3 mm)为GCr15球的半径,V (50 mm/s)为线速度,η为润滑油粘度,α为粘度压力系数为,E′ (164 GPa)为有限弹性模量,F (10 N)为应用载荷,k ≈ 1为椭圆参数.σ1 (2.850 μm)与σ2 (4.424 μm)分别为上摩擦副球与下摩擦副TC4盘的粗糙度[38].其中σ1 (2.850 μm)和σ2 (4.424 μm)分别为上摩擦副球与下摩擦副TC4盘的粗糙度.计算结果表明,hmin约为12.9 nm,λ约为0.25,小于1,表明润滑状态处于边界润滑.在边界润滑状态下,上下摩擦副之间产生一层极薄的润滑膜,有助于实现良好的润滑性能.法向载荷的不断增大和摩擦时间的延长,使润滑薄膜的完整性受到破坏,但是F-BNNSs12提供了更多的接触位点,避免了上下摩擦副之间较多的接触和实现了自身优异的润滑性能,从而产生了优良的减磨耐磨作用[53]. ...

Sequentially bridged biomimetic graphene-based coating via covalent bonding with an effective anti-corrosion/wear protection for Mg alloy

1

2021

... r为GCr15小球的半径,h为TC4盘的磨损深度,N为施加的载荷,S为滑动距离[39,40]. ...

Evaluation of the wear and abrasion resistance of hard coatings by ball-on-three-disk test methods—A case study

2

2013

... r为GCr15小球的半径,h为TC4盘的磨损深度,N为施加的载荷,S为滑动距离[39,40]. ...

... 图5给出了样品的TEM图像、选定区域电子衍射(SAED图像)以及粒径统计.图5a、b分别给出了不同区域F-BNNS12的TEM照片,可见纳米片边缘明显的卷曲结构.图5d给出了图5a白色边框内样品的放大示意图,可见卷曲结构且因弯曲较大形成了纳米棒结构[40].图5c中的SAED图表现出典型h-BN的6倍对称特征,表明得到的F-BNNSs在球磨过程中结晶良好,没有发生损伤[17].图5e给出了图5d中红框区域内的高分辨TEM照片,可见十个晶面的间距为2.189 nm,一个晶面间距大约为0.22 nm,对应于F-BNNSs12的(001)平面,与原始的h-BNNSs相同.对F-BNNSs12粒度分析(图5g、h)结果表明,最小直径为46.41 nm,最大直径为191.15 nm,平均直径为91.78 nm,大部分纳米片的直径集中在40~120 nm. ...

A novel mechano-chemical synthesis route for fluorination of hexagonal boron nitride nanos-heets

1

2019

... 制备F-BNNSs时,因NH4F的分解温度为168℃,设定磁力搅拌温度为170℃[41].h-BNNSs的化学惰性很强和稳定性较高,因此很难将小分子和杂原子共价接枝到h-BNNSs上.以NH4F作为氟源,F与B原子的结合能约为-4.17 eV.结合能较低有利于F原子的吸附,并且NH+和F-在剥离和氟化BNNSs中起关键作用[42]. ...

One‐step exfoliation and fluorination of boron nitride nanosheets and a study of their magnetic properties

2

2014

... 制备F-BNNSs时,因NH4F的分解温度为168℃,设定磁力搅拌温度为170℃[41].h-BNNSs的化学惰性很强和稳定性较高,因此很难将小分子和杂原子共价接枝到h-BNNSs上.以NH4F作为氟源,F与B原子的结合能约为-4.17 eV.结合能较低有利于F原子的吸附,并且NH+和F-在剥离和氟化BNNSs中起关键作用[42]. ...

... 图2a给出了h-BNNSs和F-BNNSs(F-BNNSs8、F-BNNSs12和F-BNNSs16)在20°~80°的完整XRD谱,可见所有样品的出峰位置一致,衍射角度(2θ)均为26.6°、41.5°和54.9°.图2b给出了h-BNNSs和F-BNNSs在(002)晶面的局部放大XRD谱,用以进一步分析2θ为26.6°处峰的结构.根据Bragg方程(2dsinθ = λ),XRD峰的衍射角(θ)随着纳米片层间间距(d)的变化而变化.X射线的波长为0.15406、2θ为26.6°,根据Bragg方程计算出h-BNNSs的平面间距大约为0.33 nm.B-F和N-F的键长分别为0.131 nm和0.138 nm,小于h-BNNSs的平面间距,因此(002)晶面并没有偏移[42].图2c给出了h-BNNSs、F-BNNSs8、F-BNNSs12和F-BNNSs16的FTIR光谱.h-BNNSs在780 cm-1和1362 cm-1处的峰可归因于B-N-B弯曲和B-N伸缩振动[43].F-BNNSs12和F-BNNSs16在1080 cm-1和1253 cm-1处的特征峰,对应B-F振动[21].没有发现N-F键振动的原因是,B-N-B平面外弯曲振动重叠[44].F-BNNSs8并没有B-F和N-F的特征峰出现,其原因可能是NH4F的使用较少,嫁接在h-BNNSs的表面上F原子含量较低. ...

Functionalized boron nitride porous solids

1

2015

... 图2a给出了h-BNNSs和F-BNNSs(F-BNNSs8、F-BNNSs12和F-BNNSs16)在20°~80°的完整XRD谱,可见所有样品的出峰位置一致,衍射角度(2θ)均为26.6°、41.5°和54.9°.图2b给出了h-BNNSs和F-BNNSs在(002)晶面的局部放大XRD谱,用以进一步分析2θ为26.6°处峰的结构.根据Bragg方程(2dsinθ = λ),XRD峰的衍射角(θ)随着纳米片层间间距(d)的变化而变化.X射线的波长为0.15406、2θ为26.6°,根据Bragg方程计算出h-BNNSs的平面间距大约为0.33 nm.B-F和N-F的键长分别为0.131 nm和0.138 nm,小于h-BNNSs的平面间距,因此(002)晶面并没有偏移[42].图2c给出了h-BNNSs、F-BNNSs8、F-BNNSs12和F-BNNSs16的FTIR光谱.h-BNNSs在780 cm-1和1362 cm-1处的峰可归因于B-N-B弯曲和B-N伸缩振动[43].F-BNNSs12和F-BNNSs16在1080 cm-1和1253 cm-1处的特征峰,对应B-F振动[21].没有发现N-F键振动的原因是,B-N-B平面外弯曲振动重叠[44].F-BNNSs8并没有B-F和N-F的特征峰出现,其原因可能是NH4F的使用较少,嫁接在h-BNNSs的表面上F原子含量较低. ...

Fluorinated h-BN as a magnetic semiconductor

1

2017

... 图2a给出了h-BNNSs和F-BNNSs(F-BNNSs8、F-BNNSs12和F-BNNSs16)在20°~80°的完整XRD谱,可见所有样品的出峰位置一致,衍射角度(2θ)均为26.6°、41.5°和54.9°.图2b给出了h-BNNSs和F-BNNSs在(002)晶面的局部放大XRD谱,用以进一步分析2θ为26.6°处峰的结构.根据Bragg方程(2dsinθ = λ),XRD峰的衍射角(θ)随着纳米片层间间距(d)的变化而变化.X射线的波长为0.15406、2θ为26.6°,根据Bragg方程计算出h-BNNSs的平面间距大约为0.33 nm.B-F和N-F的键长分别为0.131 nm和0.138 nm,小于h-BNNSs的平面间距,因此(002)晶面并没有偏移[42].图2c给出了h-BNNSs、F-BNNSs8、F-BNNSs12和F-BNNSs16的FTIR光谱.h-BNNSs在780 cm-1和1362 cm-1处的峰可归因于B-N-B弯曲和B-N伸缩振动[43].F-BNNSs12和F-BNNSs16在1080 cm-1和1253 cm-1处的特征峰,对应B-F振动[21].没有发现N-F键振动的原因是,B-N-B平面外弯曲振动重叠[44].F-BNNSs8并没有B-F和N-F的特征峰出现,其原因可能是NH4F的使用较少,嫁接在h-BNNSs的表面上F原子含量较低. ...

Controllable preparation of fluorinated boron nitride nanosheets for excellent tribological behaviors

3

2022

... F-BNNSs是由恒温磁力搅拌与球磨辅助氟化与剥离制备的.在第一个制备过程中,氟化铵的高温分解有利于氟化h-BNNSs.N原子与B原子的电荷性不同,使其更倾向于与B原子结合,如图6所示.边缘的B原子嫁接了更多的F原子,且掺杂F原子使h-BNNSs表面弯曲[31,38].随后在球磨过程中纳米片发生了剥离,使F原子有更多的嫁接位点,促进h-BNNSs的氟化形成了纳米棒结构[45]. ...

... 图12a、b分别给出了在10 N和50 mm/s条件下使用1 mg/mL F-BNNSs12水基润滑剂的TC4圆盘磨损表面的拉曼谱和检测位置.图12a表明,拉曼检测位置在磨痕的中间,保证了检测结果准确性.从拉曼谱可见,表面出现了大面积的暗斑,可能产生了不连续的润滑膜.在拉曼光谱(图12b)的1366 cm-1处出现一个F-BNNSs12特征峰,表明磨损表面残留有润滑剂[45].为了进一步证明存在化学反应膜并得到其化学成分,进行了XPS分析 (图12c~g).图12c给出了用1 mg/mL F-BNNSs12水基润滑后TC4盘磨损疤痕的全谱,检测到F 1s、O 1s、Ti 2p、N 1s、C 1s和B 1s.图12d表明,位于188.5 eV和190.4 eV处的B 1s峰主要以B-N和B-F的形式存在;还检测了F 1s XPS谱(图12f),证明摩擦实验后残留的润滑剂紧密结合在磨损处的表面.N 1s位于396.6 eV和399.5 eV处的峰对应N-B和Ti-N,但是没有检测到N-F键,可能是F原子与B原子很大的电负性差异使其更倾向于彼此结合,而不是与N原子结合,摩擦实验后N-F键的量更少[34];Ti 2p XPS谱中396.6 eV和399.5 eV处出现了双峰.结合图7b的EDS分析结果,在磨损痕迹处聚集了大量的N、B、F元素,证明大部分磨损痕迹都有残留的润滑剂.根据前述对磨痕的分析,磨损痕迹处有润滑剂的残留,在一定的力和滑动的作用下润滑剂与TC4盘发生了化学反应,在磨损表面生成了由F-BNNSs和TiN组成的不连续润滑薄膜.生成不连续润滑膜的原因,可能是TC4金属盘表面不十分平整,每个接触点受力的不同使有的位置没有产生润滑膜.本文的研究结果表明,磨损表面形成的润滑膜是降低钛合金/钢接触点的摩擦和磨损的关键. ...

... 基于上述结果和对磨损表面的分析,提出了F-BNNSs12的润滑机理.与h-BNNSs相比,F-BNNSs12作为水基润滑添加剂使摩擦系数和磨损率大幅度降低.h-BNNSs作为水基润滑剂时,由于其在摩擦微区内发生团聚和较低的硬度与断裂韧性,在外力长时间作用下容易发生破损、断裂,使润滑效果降低[16,22,47].F-BNNSs12作为水基润滑添加剂时,纳米片上较大的负电荷使层间的极性相互作用减弱,与h-BNNSs相比更小的剪切力就能使片层间发生相对滑动,从而使摩擦力更小.图6也表明,F-BNNSs12不相称的纳米棒-纳米片结构在摩擦过程中呈现出滚动摩擦.同时,F-BNNSs12还能填充磨损表面的凹槽使摩擦副之间的接触面积减小.这些因素,都有助于实现良好的润滑性能[16,21,45,54].同时,在外力的作用下F-BNNSs12逐渐沉积在摩擦副的表面,在边界润滑状态下摩擦副的表面形成了一层稳定且不连续的润滑膜,减少了钛合金/钢接触点而使摩擦和磨损降低[55]. ...

Friction and wear properties of ZrO2/SiO2 composite nanoparticles

1

2011

... 润滑液在金属基体表面的铺展能力越强,其润湿性能越好.因此,纳米粒子的润湿性是度量纳米流体稳定性的关键.图7给出了F-BNNSs的Zeta电位和接触角测试结果.纳米颗粒之间的团聚可用Zeta电位值表征(图7a),绝对值越大意味着纳米颗粒分散得越均匀[46,47].F-BNNSs8、F-BNNSs12和F-BNNSs16的电位绝对值分别为13.1 mV、19.6 mV和37.0 mV,均大于h-BNNSs的绝对电位值.F-BNNSs的静电排斥性比h-BNNSs更强,从而分散性更好,随着NH4F使用量的增多分散性提高.图7b~f给出了纯水、h-BNNSs和F-BNNSs的接触角测试结果.可以看出,纯水与TC4盘的接触角为47.523°,向水溶液中加入少量的h-BNNSs接触角即增大为48.531°,表明其在TC4盘的表面铺展性不好.氟化改性的h-BNNSs,随着NH4F使用量的增多F-BNNSs与TC4盘的接触角逐渐减小,F-BNNSs16的接触角最小为36.613°.以上分析均表明,F-BNNSs润滑添加剂具有良好的分散稳定性和润湿性,并且氟化程度越高分散性和润湿性越好. ...

Preparation and tribological behavior of nano-BP/TiO2 lubrication additives

2

2021

... 润滑液在金属基体表面的铺展能力越强,其润湿性能越好.因此,纳米粒子的润湿性是度量纳米流体稳定性的关键.图7给出了F-BNNSs的Zeta电位和接触角测试结果.纳米颗粒之间的团聚可用Zeta电位值表征(图7a),绝对值越大意味着纳米颗粒分散得越均匀[46,47].F-BNNSs8、F-BNNSs12和F-BNNSs16的电位绝对值分别为13.1 mV、19.6 mV和37.0 mV,均大于h-BNNSs的绝对电位值.F-BNNSs的静电排斥性比h-BNNSs更强,从而分散性更好,随着NH4F使用量的增多分散性提高.图7b~f给出了纯水、h-BNNSs和F-BNNSs的接触角测试结果.可以看出,纯水与TC4盘的接触角为47.523°,向水溶液中加入少量的h-BNNSs接触角即增大为48.531°,表明其在TC4盘的表面铺展性不好.氟化改性的h-BNNSs,随着NH4F使用量的增多F-BNNSs与TC4盘的接触角逐渐减小,F-BNNSs16的接触角最小为36.613°.以上分析均表明,F-BNNSs润滑添加剂具有良好的分散稳定性和润湿性,并且氟化程度越高分散性和润湿性越好. ...

... 基于上述结果和对磨损表面的分析,提出了F-BNNSs12的润滑机理.与h-BNNSs相比,F-BNNSs12作为水基润滑添加剂使摩擦系数和磨损率大幅度降低.h-BNNSs作为水基润滑剂时,由于其在摩擦微区内发生团聚和较低的硬度与断裂韧性,在外力长时间作用下容易发生破损、断裂,使润滑效果降低[16,22,47].F-BNNSs12作为水基润滑添加剂时,纳米片上较大的负电荷使层间的极性相互作用减弱,与h-BNNSs相比更小的剪切力就能使片层间发生相对滑动,从而使摩擦力更小.图6也表明,F-BNNSs12不相称的纳米棒-纳米片结构在摩擦过程中呈现出滚动摩擦.同时,F-BNNSs12还能填充磨损表面的凹槽使摩擦副之间的接触面积减小.这些因素,都有助于实现良好的润滑性能[16,21,45,54].同时,在外力的作用下F-BNNSs12逐渐沉积在摩擦副的表面,在边界润滑状态下摩擦副的表面形成了一层稳定且不连续的润滑膜,减少了钛合金/钢接触点而使摩擦和磨损降低[55]. ...

BP/TiO2复合纳米润滑添加剂的制备及摩擦学行为研究

2

2021

... 润滑液在金属基体表面的铺展能力越强,其润湿性能越好.因此,纳米粒子的润湿性是度量纳米流体稳定性的关键.图7给出了F-BNNSs的Zeta电位和接触角测试结果.纳米颗粒之间的团聚可用Zeta电位值表征(图7a),绝对值越大意味着纳米颗粒分散得越均匀[46,47].F-BNNSs8、F-BNNSs12和F-BNNSs16的电位绝对值分别为13.1 mV、19.6 mV和37.0 mV,均大于h-BNNSs的绝对电位值.F-BNNSs的静电排斥性比h-BNNSs更强,从而分散性更好,随着NH4F使用量的增多分散性提高.图7b~f给出了纯水、h-BNNSs和F-BNNSs的接触角测试结果.可以看出,纯水与TC4盘的接触角为47.523°,向水溶液中加入少量的h-BNNSs接触角即增大为48.531°,表明其在TC4盘的表面铺展性不好.氟化改性的h-BNNSs,随着NH4F使用量的增多F-BNNSs与TC4盘的接触角逐渐减小,F-BNNSs16的接触角最小为36.613°.以上分析均表明,F-BNNSs润滑添加剂具有良好的分散稳定性和润湿性,并且氟化程度越高分散性和润湿性越好. ...

... 基于上述结果和对磨损表面的分析,提出了F-BNNSs12的润滑机理.与h-BNNSs相比,F-BNNSs12作为水基润滑添加剂使摩擦系数和磨损率大幅度降低.h-BNNSs作为水基润滑剂时,由于其在摩擦微区内发生团聚和较低的硬度与断裂韧性,在外力长时间作用下容易发生破损、断裂,使润滑效果降低[16,22,47].F-BNNSs12作为水基润滑添加剂时,纳米片上较大的负电荷使层间的极性相互作用减弱,与h-BNNSs相比更小的剪切力就能使片层间发生相对滑动,从而使摩擦力更小.图6也表明,F-BNNSs12不相称的纳米棒-纳米片结构在摩擦过程中呈现出滚动摩擦.同时,F-BNNSs12还能填充磨损表面的凹槽使摩擦副之间的接触面积减小.这些因素,都有助于实现良好的润滑性能[16,21,45,54].同时,在外力的作用下F-BNNSs12逐渐沉积在摩擦副的表面,在边界润滑状态下摩擦副的表面形成了一层稳定且不连续的润滑膜,减少了钛合金/钢接触点而使摩擦和磨损降低[55]. ...

Reduction of interfacial friction in commensurate graphene/h-BN heterostructures by surface functionalization

1

2016

... 图8a、b给出了载荷为10 N、线速度为50 mm/s条件下h-BNNSs和不同氟化效果的F-BNNSS(F-BNNSs8、F-BNNSs12、F-BNNSs16)的摩擦曲线和磨损率.图8a表明,添加了h-BNNSs的水基润滑剂的摩擦系数最大,平均摩擦系数可达0.3135.h-BNNSs在水中的分散性最差,h-BNNSs的纳米片之间发生了团聚,且其润湿性较差使摩擦系数比较大.添加少量的F-BNNSs作为润滑剂,使摩擦系数显著降低.F-BNNSs8作为水基润滑添加剂,摩擦曲线在开始100 s内的磨合阶段摩擦系数较高,经过一段时间后饱和摩擦系数趋于平缓稳定,平均摩擦系数为0.1512,表明其润滑性能良好.以F-BNNS16作为润滑添加剂,摩擦系数随时间呈现缓慢的下降趋势且波动较小,相应的平均摩擦系数为0.2177.F-BNNSs12作为水基润滑添加剂时摩擦系数最低,摩擦曲线的变化趋势与F-BNNSs8相似,但是磨合阶段较短,摩擦系数略低.F-BNNSs12的平均摩擦系数为0.1435,比h-BNNSs水基润滑平均摩擦系数降低55%.虽然F-BNNSs16片层表面嫁接了更多的F原子,但是其摩擦系数在0.2附近波动.其原因是,随着F原子掺杂的进一步增加分子层之间的滑动变化缓慢[48].图8b给出了h-BNNSs和F-BNNSs作为水基添加剂的GCr15磨损率.可以看出,随着氟化强度的增强磨损率逐渐降低,最小的磨损率为1.41 × 10-6 mm3·N-1·m-1,比h-BNNSs的磨损率降低了75%.这表明,h-BNNSs表面接枝氟原子,减小了摩擦力且具有一定的抗磨损能力. ...

Size effects of SiO2 nanoparticles as oil additives on tribology of lubricant

1

2010

... 图8c给出了不同质量的F-BNNSs12分散在水溶液中得到浓度分别为0.5 mg/mL、1 mg/mL、1.5 mg/mL、2 mg/mL的水基润滑剂的摩擦曲线,并且在载荷为10 N和线速度为50 mm/s的条件下验证上述4种浓度润滑剂的摩擦学性能.结果表明,F-BNNSs12的浓度为1 mg/mL、1.5 mg/mL时摩擦系数均低于0.2,浓度为1 mg/mL时平均摩擦系数为0.1435.浓度过低时难以形成连续的润滑膜,浓度过高时纳米片在摩擦副接触微区容易发生团聚,使摩擦系数过大[49,50].图8d给出了纯水和1 mg/mL F-BNNSs12在8 N、10 N、12 N和15 N负载下的平均摩擦系数.可以看出,在负载为8~15 N时纯水的平均摩擦系数均高于添加浓度为1 mg/mL的F-BNNSs12平均摩擦系数.随着载荷的增大添加1 mg/mL F-BNNSs12水基润滑剂的平均摩擦系数呈现先减小后增大的变化趋势,载荷为10 N和20 N时平均摩擦系数分别达到最小和最大.调整h-BNNSs与NH4F的质量比、浓度和载荷,发现最佳氟化样品为F-BNNSs12,最佳浓度和载荷分别为1 mg/mL、10 N. ...

The elastohydrodynamic lubrication of heavily loaded contacts

1

1977

... 图8c给出了不同质量的F-BNNSs12分散在水溶液中得到浓度分别为0.5 mg/mL、1 mg/mL、1.5 mg/mL、2 mg/mL的水基润滑剂的摩擦曲线,并且在载荷为10 N和线速度为50 mm/s的条件下验证上述4种浓度润滑剂的摩擦学性能.结果表明,F-BNNSs12的浓度为1 mg/mL、1.5 mg/mL时摩擦系数均低于0.2,浓度为1 mg/mL时平均摩擦系数为0.1435.浓度过低时难以形成连续的润滑膜,浓度过高时纳米片在摩擦副接触微区容易发生团聚,使摩擦系数过大[49,50].图8d给出了纯水和1 mg/mL F-BNNSs12在8 N、10 N、12 N和15 N负载下的平均摩擦系数.可以看出,在负载为8~15 N时纯水的平均摩擦系数均高于添加浓度为1 mg/mL的F-BNNSs12平均摩擦系数.随着载荷的增大添加1 mg/mL F-BNNSs12水基润滑剂的平均摩擦系数呈现先减小后增大的变化趋势,载荷为10 N和20 N时平均摩擦系数分别达到最小和最大.调整h-BNNSs与NH4F的质量比、浓度和载荷,发现最佳氟化样品为F-BNNSs12,最佳浓度和载荷分别为1 mg/mL、10 N. ...

Rich activated edges of hexagonal boron nitride flakes in-situ triggered by nickel nanoparticles to achieve efficient reduction of friction and wear

1

2022

... 图11给出了用纯水与浓度都为0.1 mg/mL的h-BNNSs和F-BNNSs12水基润滑后的磨损轨道、三维轮廓图像和对应的二维高度轮廓曲线.图11c给出了F-BNNSs12水基润滑后TC4盘的磨损轨道和三维轮廓图像,可见其表面比用纯水与h-BNNSs润滑(图11a、b)更平整光滑,也得到了二维高度轮廓曲线的进一步验证.纯水、h-BNNSs与F-BNNSs12的磨损轨道宽度分别为414.5 μm、524.15 μm、374.9 μm,磨损深度分别为12.2 μm、17.4 μm、11.4 μm.定量计算结果表明,对应的磨损率分别为4.5 × 10-6 mm3·N-1·m-1、9.2 × 10-6 mm3·N-1·m-1、3.9 × 10-6 mm3·N-1·m-1.h-BNNSs比纯水与F-BNNSs水基润滑的磨损量较大,其原因是h-BN的硬度(莫氏硬度为2)和断裂韧性(1.09 ± 0.01 MPa·m1/2)较低[51].同时,硼原子与氮原子的电负性不同,使h-BNNSs的片层之间除了有极弱的范德华力还有极强的极性,抑制了层间滑移和降低了h-BNNSs作为润滑添加剂的性能[23,24].F-BNNSs12的磨损轨道的磨损率最低,因为F-BNNSs12优异的抗裂能力使层状的平面结构免受平面内刚度和外应力的破坏,并使层间在外力的作用下相对滑动(起减磨润滑作用),与前文的实验验证结果一致[52]. ...

Toward excellent tribological performance as oil-based lubricant additive: particular tribological behavior of fluorinated graphene

1

2018

... 图11给出了用纯水与浓度都为0.1 mg/mL的h-BNNSs和F-BNNSs12水基润滑后的磨损轨道、三维轮廓图像和对应的二维高度轮廓曲线.图11c给出了F-BNNSs12水基润滑后TC4盘的磨损轨道和三维轮廓图像,可见其表面比用纯水与h-BNNSs润滑(图11a、b)更平整光滑,也得到了二维高度轮廓曲线的进一步验证.纯水、h-BNNSs与F-BNNSs12的磨损轨道宽度分别为414.5 μm、524.15 μm、374.9 μm,磨损深度分别为12.2 μm、17.4 μm、11.4 μm.定量计算结果表明,对应的磨损率分别为4.5 × 10-6 mm3·N-1·m-1、9.2 × 10-6 mm3·N-1·m-1、3.9 × 10-6 mm3·N-1·m-1.h-BNNSs比纯水与F-BNNSs水基润滑的磨损量较大,其原因是h-BN的硬度(莫氏硬度为2)和断裂韧性(1.09 ± 0.01 MPa·m1/2)较低[51].同时,硼原子与氮原子的电负性不同,使h-BNNSs的片层之间除了有极弱的范德华力还有极强的极性,抑制了层间滑移和降低了h-BNNSs作为润滑添加剂的性能[23,24].F-BNNSs12的磨损轨道的磨损率最低,因为F-BNNSs12优异的抗裂能力使层状的平面结构免受平面内刚度和外应力的破坏,并使层间在外力的作用下相对滑动(起减磨润滑作用),与前文的实验验证结果一致[52]. ...

Performance of CrN coatings under boundary lubrication

1

2016

... 计算理论最小薄膜厚度和比率.式中U = ηV/E′R,G = αE′,W = F/E′R2,R (3 mm)为GCr15球的半径,V (50 mm/s)为线速度,η为润滑油粘度,α为粘度压力系数为,E′ (164 GPa)为有限弹性模量,F (10 N)为应用载荷,k ≈ 1为椭圆参数.σ1 (2.850 μm)与σ2 (4.424 μm)分别为上摩擦副球与下摩擦副TC4盘的粗糙度[38].其中σ1 (2.850 μm)和σ2 (4.424 μm)分别为上摩擦副球与下摩擦副TC4盘的粗糙度.计算结果表明,hmin约为12.9 nm,λ约为0.25,小于1,表明润滑状态处于边界润滑.在边界润滑状态下,上下摩擦副之间产生一层极薄的润滑膜,有助于实现良好的润滑性能.法向载荷的不断增大和摩擦时间的延长,使润滑薄膜的完整性受到破坏,但是F-BNNSs12提供了更多的接触位点,避免了上下摩擦副之间较多的接触和实现了自身优异的润滑性能,从而产生了优良的减磨耐磨作用[53]. ...

Tribological properties of graphene in PAO base oil

1

2019

... 基于上述结果和对磨损表面的分析,提出了F-BNNSs12的润滑机理.与h-BNNSs相比,F-BNNSs12作为水基润滑添加剂使摩擦系数和磨损率大幅度降低.h-BNNSs作为水基润滑剂时,由于其在摩擦微区内发生团聚和较低的硬度与断裂韧性,在外力长时间作用下容易发生破损、断裂,使润滑效果降低[16,22,47].F-BNNSs12作为水基润滑添加剂时,纳米片上较大的负电荷使层间的极性相互作用减弱,与h-BNNSs相比更小的剪切力就能使片层间发生相对滑动,从而使摩擦力更小.图6也表明,F-BNNSs12不相称的纳米棒-纳米片结构在摩擦过程中呈现出滚动摩擦.同时,F-BNNSs12还能填充磨损表面的凹槽使摩擦副之间的接触面积减小.这些因素,都有助于实现良好的润滑性能[16,21,45,54].同时,在外力的作用下F-BNNSs12逐渐沉积在摩擦副的表面,在边界润滑状态下摩擦副的表面形成了一层稳定且不连续的润滑膜,减少了钛合金/钢接触点而使摩擦和磨损降低[55]. ...

石墨烯在PAO基础油中的摩擦学性能

1

2019

... 基于上述结果和对磨损表面的分析,提出了F-BNNSs12的润滑机理.与h-BNNSs相比,F-BNNSs12作为水基润滑添加剂使摩擦系数和磨损率大幅度降低.h-BNNSs作为水基润滑剂时,由于其在摩擦微区内发生团聚和较低的硬度与断裂韧性,在外力长时间作用下容易发生破损、断裂,使润滑效果降低[16,22,47].F-BNNSs12作为水基润滑添加剂时,纳米片上较大的负电荷使层间的极性相互作用减弱,与h-BNNSs相比更小的剪切力就能使片层间发生相对滑动,从而使摩擦力更小.图6也表明,F-BNNSs12不相称的纳米棒-纳米片结构在摩擦过程中呈现出滚动摩擦.同时,F-BNNSs12还能填充磨损表面的凹槽使摩擦副之间的接触面积减小.这些因素,都有助于实现良好的润滑性能[16,21,45,54].同时,在外力的作用下F-BNNSs12逐渐沉积在摩擦副的表面,在边界润滑状态下摩擦副的表面形成了一层稳定且不连续的润滑膜,减少了钛合金/钢接触点而使摩擦和磨损降低[55]. ...

Functionalised h‐BN as an effective lubricant additive in PAO oil for MoN coating sliding against Si3N4 ball

1

2021

... 基于上述结果和对磨损表面的分析,提出了F-BNNSs12的润滑机理.与h-BNNSs相比,F-BNNSs12作为水基润滑添加剂使摩擦系数和磨损率大幅度降低.h-BNNSs作为水基润滑剂时,由于其在摩擦微区内发生团聚和较低的硬度与断裂韧性,在外力长时间作用下容易发生破损、断裂,使润滑效果降低[16,22,47].F-BNNSs12作为水基润滑添加剂时,纳米片上较大的负电荷使层间的极性相互作用减弱,与h-BNNSs相比更小的剪切力就能使片层间发生相对滑动,从而使摩擦力更小.图6也表明,F-BNNSs12不相称的纳米棒-纳米片结构在摩擦过程中呈现出滚动摩擦.同时,F-BNNSs12还能填充磨损表面的凹槽使摩擦副之间的接触面积减小.这些因素,都有助于实现良好的润滑性能[16,21,45,54].同时,在外力的作用下F-BNNSs12逐渐沉积在摩擦副的表面,在边界润滑状态下摩擦副的表面形成了一层稳定且不连续的润滑膜,减少了钛合金/钢接触点而使摩擦和磨损降低[55]. ...