主要的减摩抗磨涂层有:氮化物涂层(CrN[6,11]、TiN[12,13]、CrAlN[14]、AlTiN[15]等)、碳化物涂层(CrC[16]、TiC[17]等)、碳基涂层(a-C[18,19]、GLC[20]、ta-C[21,22]等)以及其他涂层(CKS[23]、GDC[24]等)。CrN涂层是一种典型的氮化物涂层,具有优异的耐磨性以及抗腐蚀和抗氧化性,广泛用于材料的表面处理[25]。但是,CrN涂层的硬度和摩擦系数比较高,没有自润滑性能[20],容易产生拉缸现象而影响发动机的燃油效率转换。对于CrC类碳化物涂层[26],利用其中的高热稳定性金属相或金属碳化物纳米晶掺杂相降低内部的石墨化程度,并可通过与润滑油之间的摩擦化学反应降低摩擦系数,具有优异的硬度、韧性、稳定性与减磨耐磨性。但是,CrC类碳化物涂层摩擦时生成的硬质碳化物、氧化物颗粒产生严重的磨粒磨损。非晶碳涂层的黏附磨损和化学稳定性较低,在润滑条件下摩擦系数也比较低,但是其较高的内应力限制了薄膜的厚度,使其负载能力较小[27]。

在金属氮化物中引入C元素,使部分金属碳化物纳米晶与非晶碳嵌入氮化物结构中,可构造多相复合涂层[28,29]。Lin等[10]用等离子体增强磁控溅射技术制备的内部结构致密的TiSiCN涂层,主要由TiC x N y 纳米晶和TiSiCN非晶相构成。在摩擦磨损测试中TiSiCN涂层表现出优异的低摩擦磨损性,但是Si元素对涂层结构和性能的影响还需要进一步研究。Xu等[30]用中频磁控溅射制备的CrCN涂层,主要由CrN相、Cr3C7相与无定形碳构成。但是中频磁控溅射的效率较低,制备的CrCN涂层厚度只有2 μm,使其负载能力和结合力较差。特别是,关于能应用于材料表面的多相复合涂层研究较少[31~35]。鉴于此,本文用多弧离子镀技术制备CrN:a-C多相复合涂层,改变C2H2的流量控制碳含量以调控涂层的微观结构和摩擦学性能。

1 实验方法

1.1 涂层的制备

实验用基体选用铸铁和316不锈钢(尺寸为30 mm × 20 mm × 2 mm)[36],铸铁基体用于检验涂层在复杂圆弧面表面的生长结构和均匀性,316不锈钢基体用于考察涂层在润滑缺失的干摩擦状态以及油润滑状态条件下的摩擦学性能。预先对铸铁表面进行渗氮处理以提高其强度。同时,打磨和抛光316不锈钢的表面使其光滑达到镜面反光的状态。将铸铁和316不锈钢先后置于丙酮和乙醇中进行超声清洗,以去除表面的油污和杂质。将清洗好的铸铁和316样块擦干后备用。

氮源和碳源是氮气和乙炔。在氮气和乙炔的混合气体环境下,对分成三组的九块高纯铬靶(直径为63 mm,厚度为32 mm,纯度99.95%)施加电流使其产生多弧溅射,混合等离子体到达铸铁和316不锈钢的表面进行沉积。装夹铸铁和316样片时使镀膜面与靶面平行以确保膜层生长均匀。镀膜前,先对铸铁与316样品预加热到250℃,然后使用Ar+刻蚀铸铁和样片以去除表面的污染物。在镀膜件表面沉积10 min生成Cr过渡层,以提高膜基间的结合力。在偏压为20 V、电弧电流为60 A的条件下制备CrN:a-C多相复合涂层。改变C2H2的流量以调节涂层中的C含量,在沉积的前十分钟内C2H2的流量由5 sccm分别均匀升到40 sccm、80 sccm和120 sccm,分别将在此条件下制备的三组涂层记为CrN:a-C#40、CrN:a-C#80、CrN:a-C#120。

1.2 组织结构和性能表征

用D8 ADVANCE DAVINCI X射线衍射仪(XRD)检测和分析CrN:a-C多相复合涂层的组织结构。用Renishaw inVia Reflex型共聚焦显微拉曼光谱仪(Raman)分析涂层的化学键,使用的激光器波段为532 nm。用FEI Quanta FEG 250场发射扫描电镜热场(FE-SEM)测量铸铁表面CrN:a-C多相复合涂层的厚度,并用其自带的能谱仪(EDS)定性分析涂层的元素组成和半定量分析元素的含量,同时表征316基底表面的CrN:a-C多相复合涂层表面的形貌。用CSM Revetest划痕测试系统表征样品的膜基结合力,载荷为1~100 N,加载速率为19.8 N/min,总划痕长度为5 mm。用HV-1000S 显微维氏硬度计测量涂层的硬度,载荷为200 gf,载荷保持时间为10 s。在涂层表面随机选择不同的位置进行多次测量取其结果的平均值,采集压痕照片的镜头其放大倍数为40。用UMT-3多功能高温摩擦磨损试验机在大气和5W-30润滑油环境下采用往复式模式测试CrN:a-C多相复合涂层表面耐磨损性能,对磨件是直径为3 mm的Al2O3球,载荷为10 N,频率为5 Hz,时间为30 min,磨痕长度为5 mm。用SEM表征何分析磨痕的形貌。用UP-Lambda 3D光学轮廓仪测量磨痕的轮廓,磨损率为

式中V为磨损体积,F为载荷,L为总移动路径长度,A为磨痕的横截面孔面积,d为磨痕长度。

2 结果和讨论

2.1 CrN:a-C多相复合涂层的组织和成分

2.1.1 涂层的晶相组织

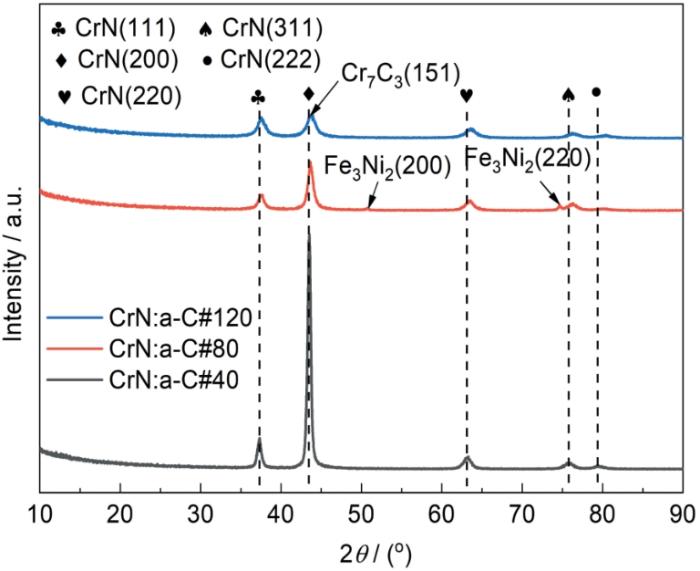

图1给出了乙炔流量不同的CrN:a-C多相复合涂层的XRD谱。可以看出,在37.5°、43.6°、63.3°、76.0°和80.1°处出现了明显的特征峰,分别对应CrN的(111)、(200)、(220)、(311)和(222)晶面[20];(151)峰标定为Cr7C3的一个晶面[30],表明该涂层同时存在CrN和Cr7C3的晶体结构。可以看出,随着C2H2流量的提高,(200)衍射峰的强度急剧降低。其原因可能是,涂层中生成的大量非晶碳抑制了(200)晶面的生长。还可以发现,随着C2H2流量的提高,衍射峰的峰位向高角度轻微偏移,可能与涂层中的残余应力有关。在CrN:a-C#80涂层的XRD谱中,50.8°和74.7°处出现两个小峰,源于Fe3Ni2的(200)和(220)晶面,是316不锈钢基底的衍射峰[28]。

图1

图1

CrN:a-C多相复合涂层的XRD谱

Fig.1

XRD pattern of CrN:aC multiphase composite coating

2.1.2 涂层内非晶碳的分布

图2

2.2 涂层的断面形貌和元素组成

在已镀膜的铸铁横截面方向施加外力使其发生脆性断裂并将产生的断面置于扫描电镜下,观察到的断面形貌如图3所示。可以看出,涂层的厚度为26 ± 2 μm。从断面处可观察到CrN:a-C多相复合涂层主要由柱状晶结构组成,在CrN:a-C多相复合涂层与基底之间有一层薄薄白亮的Cr过渡层。随着C2H2流量的提高,柱状生长结构逐渐粗大,微孔和缺陷增多,致密性降低,断裂面变得不平整。这可能与涂层内无定型碳的增多有关。

图3

图3

铸铁横截面的形貌

Fig.3

Cross-sectional morphologies of piston rings (a) CrN:aC#40, (b) CrN:aC#80, (c) CrN:aC#120

对涂层上半层区域的元素组成进行半定量分析,可知Cr元素的含量从41.23% (原子分数)逐渐降至36.32%。并且即随着C2H2流量的增大,C的相对含量不断提高,说明成功地实现了C元素的掺入与调控。

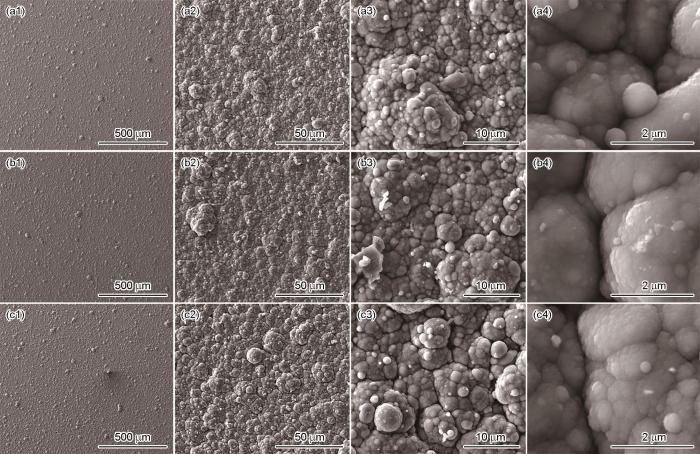

2.3 316不锈钢表面CrN:a-C多相复合涂层的形貌

图4

图4

316不锈钢表面CrN:a-C多相复合涂层的形貌

Fig.4

Morphologies of CrN:aC multiphase composite coating on the surface of 316 (a) CrN:aC#40, (b) CrN:aC#80, (c) CrN:aC#120

2.4 膜基间结合力的变化

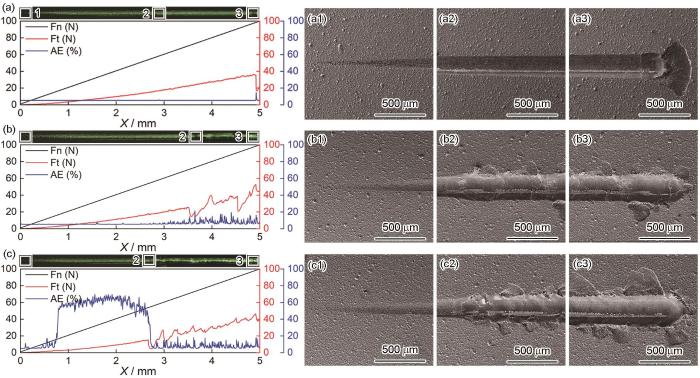

图5给出了膜基间结合力的测试结果。在划痕曲线图中,Fn为实时载荷,Ft为压头与样品之间的摩擦力,AE为测试时的声信号,用于判断涂层的破损程度。涂层出现初始裂纹时的载荷,称为临界载荷Lc1;涂层出现崩落时的载荷,称为临界载荷Lc2。声学信号的变化、划痕的光学照片以及SEM形貌表明,涂层具有优异的附着力。但是,涂层的初始裂纹不易观察到,因此考察了样品的临界载荷Lc2。结果表明:随着碳含量的提高临界载荷Lc2逐渐降低,其数值依次约为98 N、71 N和54 N。从SEM形貌可见,涂层崩落的面积逐渐增大。其原因可能是,涂层内非晶碳含量的提高使涂层内的缺陷增多,进行划痕测试时裂纹沿缺陷扩展而发生崩落。同时,涂层的膜基间的结合力与残余应力相关。由此可以推测,随着碳含量的提高涂层内的残余应力增大,使涂层的崩落情况明显不同。涂层与基体的结合力随碳含量的提高逐渐减小,但是Lc2数值均大于54 N,表明与基体间的结合良好。

图5

图5

316表面CrN:a-C多相复合涂层划痕的测试曲线和SEM形貌

Fig.5

Scratch test curves and scratch SEM morpographies of CrN: a-C multiphase composite coating on the surface of 316 (a) CrN:aC#40, (b) CrN:aC#80, (c) CrN:aC#120

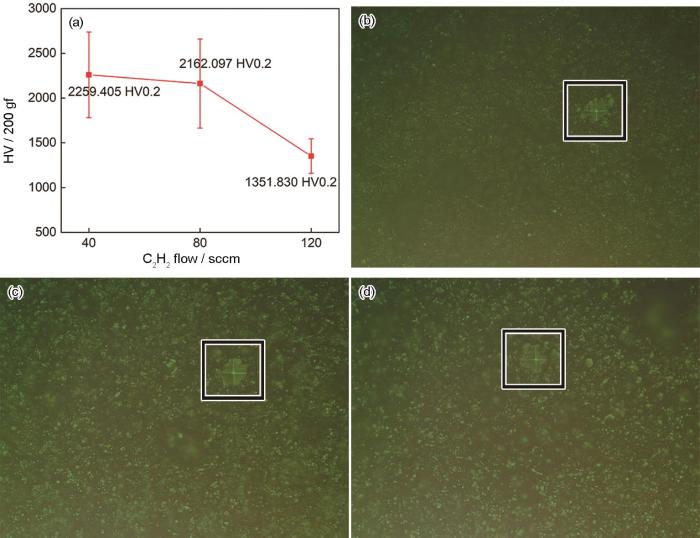

2.5 涂层的维氏硬度

图6给出了碳含量不同的CrN:a-C多相复合涂层维氏硬度的变化以及压痕形貌。可以看出,随着碳含量的提高,涂层的维氏硬度逐渐降低,可能是涂层内部结构疏松所致。光学照片表明涂层的表面不均匀,粗糙度较高,使硬度测量值的误差较大。结合划痕测试可见,碳含量的提高使CrN:a-C多相复合涂层的机械性能降低。碳含量超过26.8%的涂层,其机械性能显著降低。其原因是,过高的碳含量导致生成大量的无定形碳,降低了涂层中硬质氮化物相的含量,使涂层的内聚力降低,从而使膜基间的结合力和硬度降低。

图6

图6

316表面CrN:a-C多相复合涂层的硬度曲线和压痕的光学显微照片

Fig.6

Hardness curve (a) of CrN:aC multiphase composite coating on 316 surface and optical micrograph of indentation (b) CrN:aC#40, (c) CrN:aC#80, (d) CrN:aC#120

2.6 不同环境下涂层的摩擦学性能

图7给出了以316不锈钢为基底的CrN:a-C多相复合涂层在大气环境下的摩擦磨损性能。图7a中的摩擦曲线表明,在摩擦的初始阶段摩擦系数骤升,其原因是粗糙表面与磨球之间产生了机械互锁。随着摩擦测试的进行,摩擦系数很快到达较稳定的磨合阶段。不同碳含量的CrN:a-C多相复合涂层其摩擦系数都出较高,是其表面较为粗糙所致。CrN:a-C#120的摩擦曲线全程远低于另外两组,其原因可能是在摩擦的初始阶段过高含量的碳良好地润滑了摩擦接触界面。界面润滑作用的增强降低了摩擦接触界面之间的滑动阻力,摩擦接触界面之间的剪切作用的降低也使涂层的磨损率有所降低。图7b给出了平均摩擦系数和磨损率。可以看出,随着乙炔含量的提高,摩擦系数和磨损率都先提高后降低。

图7

图7

大气环境下的摩擦曲线和摩擦平均系数与磨损率

Fig.7

Friction curves (a), average coefficient of friction and wear rate (b) in atmospheric environment

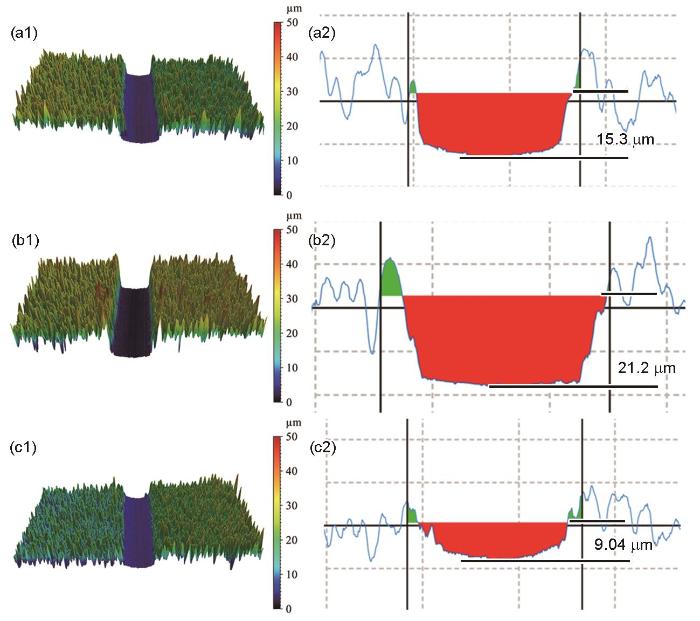

图8给出了用3D光学轮廓仪进行白光干涉成像形成的磨痕3D轮廓和磨痕横截面的轮廓曲线。可以看出,粗糙表面受到了磨损,样品CrN:a-C#80的磨损最严重。从轮廓曲线可见,CrN:a-C#80涂层的磨痕最深且最宽,CrN:a-C#120涂层的磨损最小。图中的红色区域是产生磨损的横截面孔面积,用来计算磨损率。

图8

图8

大气环境下磨痕的3D轮廓形貌以及磨痕截面曲线

Fig.8

3D profile of wear scars (1) and cross-sectional curves of wear scars (2) in the atmospheric environment (a) CrN:aC#40, (b) CrN:aC#80, (c) CrN:aC#120

图9给出了不同倍率下的磨痕形貌。可以看出,磨痕表面呈现出典型的磨粒磨损特征。磨痕的宽度先大后小,与3D光学轮廓仪的测试结果一致。观察磨痕内的细节可见,涂层没有磨穿,表面的大颗粒被挤压削平,其形貌表现出差异。磨痕处的凹坑先变多后变少,在摩擦测试过程中影响摩擦系数的准确性。在摩擦副相对运动时较多得到凹坑使接触面处产生较大的波动。这个结果,与摩擦系数的变化规律一致。同时,在CrN:a-C#120的磨痕内出现了大量垂直于磨痕轨迹的条状磨屑。这些磨屑在摩擦副之间类似于“滚子”,是其摩擦系数远低于另外两组的主要原因。为了进一步研究摩擦机制,对磨痕进行了拉曼测试,结果如图10所示。结果表明,在500~900 cm-1内出现了氧化铬的峰[41],表明在摩擦过程中发生了氧化,尤其在800 cm-1附近的峰最为明显,并且CrN:a-C#80在此处的峰强最大。这表明,生成的硬质氧化铬也是摩擦系数较高的原因。

图9

图9

大气环境下磨痕的SEM形貌

Fig.9

SEM morphologies of wear scars in the atmospheric environment (a) CrN:aC#40, (b) CrN:aC#80, (c) CrN:aC#120

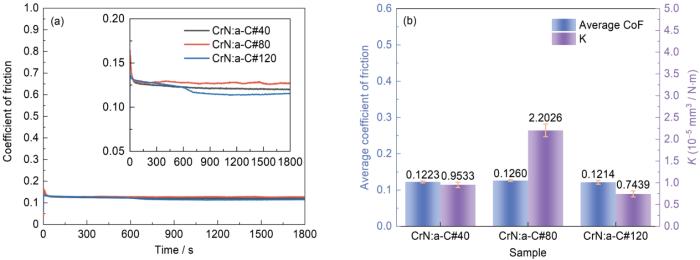

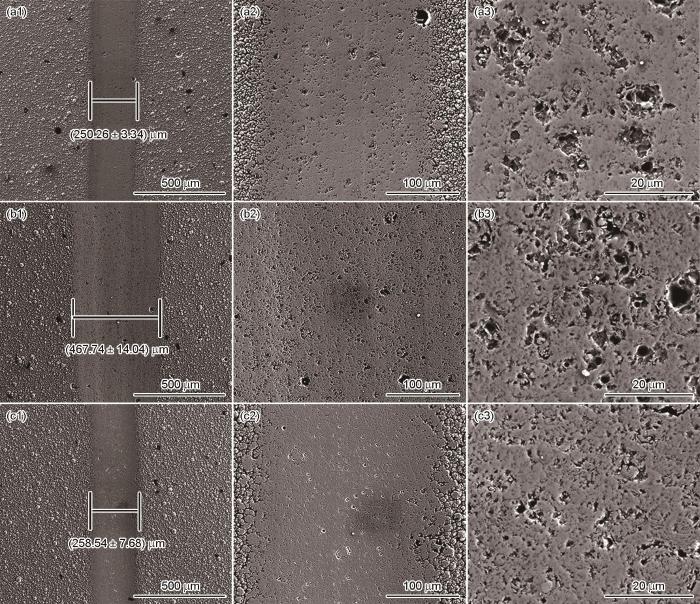

图10

因为工程制造的工况环境常处于油环境下,因此考察了CrN:a-C多相复合涂层在5W-30润滑油环境下的摩擦磨损情况。润滑油使摩擦系数和磨损率显著降低,三组摩擦副之间的摩擦系数差别不大,基本上稳定在0.12。根据干摩擦结果,涂层结构和表面摩擦产物对其摩擦磨损性能有较大的影响。因此,虽然在润滑油作用下涂层摩擦系数和磨损率显著下降,但仍表现出与大气环境下相同的变化规律,如图11和图12所示。对磨痕形貌的观察结果,如图13所示。可以看出,摩擦产生的磨屑被润滑油带走,使磨屑对摩擦磨损的影响降低。但是,涂层磨损表面出现坑洞,其主要原因是多弧离子镀大颗粒在润滑油流体环境中的交变应力作用下发生了疲劳剥落,使摩擦接触表面发生了疲劳磨损。表面颗粒磨痕内的坑洞先变多后变少,使摩擦系数出现轻微的差异。

图11

图11

在油环境下的摩擦曲线、摩擦平均系数与磨损率

Fig.11

Friction curves (a), average coefficient of friction and wear rate (b) in oil environment

图12

图12

油环境下磨痕3D轮廓形貌(1)以及磨痕截面曲线(2)

Fig.12

3D profile of wear scars (1) and cross-sectional curves of wear scars (2) in oil environment (a) CrN:aC#40, (b) CrN:aC#80, (c) CrN:aC#120

图13

图13

在油环境中磨痕的SEM形貌

Fig.13

SEM morphologies of wear scars in oil environment (a) CrN:aC#40, (b) CrN:aC#80, (c) CrN:aC#120

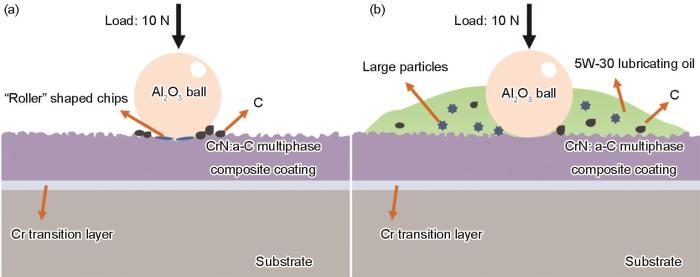

以上结果表明,虽然非晶碳的引入降低了氮化铬涂层的机械性能,但是提高了涂层的摩擦学性能,使CrN:a-C涂层在没有润滑的干摩擦状态和发动机油环境中呈现出低摩擦和低磨损特性。干摩擦时的低摩擦机理,主要是涂层内非晶碳的润滑作用以及滚子状磨损产物的生成。因此,磨损机制主要为磨料磨损。在润滑油环境中主要的低摩擦机理是涂层内的非晶碳润滑作用和与润滑油发生固液复合润滑。因此,磨损机制为磨料磨损和疲劳磨损,如图14所示。

图14

图14

摩擦磨损机理

Fig.14

Diagram of friction and wear mechanism (a: dry friction, b: oil environment)

3 结论

(1) 采用多弧离子镀技术可在316不锈钢表面和铸铁表面制备CrN:a-C多相复合涂层。CrN:a-C多相复合涂层的主要物相,包括CrN、Cr3C7和非晶碳。C2H2流量的提高在涂层中生成大量的非晶碳,抑制了CrN(200)晶面的生长。

(2) 随着C2H2流量的提高CrN:a-C多相复合涂层中非晶碳含量的提高,使其机械性能降低,但是其结合力和硬度仍然较高。

(3) CrN:a-C多相复合涂层的摩擦学性能较好,虽然提高碳含量降低了涂层的机械性能,但是降低了涂层的摩擦系数和磨损率。干摩擦时低摩擦的机理,主要是涂层内部的非晶碳润滑作用以及滚子状磨损产物的生成,磨损机制主要为磨料磨损。在润滑油条件下低摩擦的主要机理,是涂层中非晶碳的润滑作用和与润滑油产生固液复合润滑,磨损机制为磨料磨损和疲劳磨损。

参考文献

Research progress on microstructure and tribological properties of doped diamond-like carbon films

[J].

掺杂类金刚石薄膜微观结构和摩擦学性能的研究进展

[J].

Creep life prediction of alloy 718 for automotive engine materials

[J].

Research progress on micro-texture of cylinder liner-piston ring in internal combustion engine

[J].

内燃机缸套-活塞环微织构设计与研究进展

[J].微织构作为一种良好的表面改性技术已经被广泛应用于改善发动机缸套-活塞环摩擦副的摩擦性能。以微织构的研究方向为依据,分析微织构改善缸套-活塞环表面润滑摩擦性能的作用机制,总结和阐述织构复合化、组合织构以及织构仿生化等方面的研究现状和进展,最后,指出表面织构研究中存在的不足和对下一步研究重点的展望。

The effect of laser machined pockets on the lubrication of piston ring prototypes

[J].

Comparative study on the effects of oil viscosity on typical coatings for automotive engine components under simulated lubrication conditions

[J].

Effect of surface treatment on friction and wear property of piston ring

[J].

表面处理对活塞环摩擦磨损性能影响的试验研究

[J].

Effect of double glow plasma copper Infiltration on the tribological properties of cylinder liner and piston ring

[J].

双辉光离子渗铜对缸套-活塞环摩擦学性能的影响研究

[J].为研究铜元素对缸套-活塞环摩擦学性能的影响,通过双辉光离子渗透技术在缸套材料表面加工出不同厚度的渗铜改性层,使用RTEC多功能摩擦磨损试验机开展不同负载、不同润滑条件下的模拟试验,采集并分析试验过程中的摩擦因数以及试验后体积磨损量和磨损表面形貌,研究渗铜改性层对缸套材料摩擦学性能的影响规律及作用机制。结果表明:渗铜处理可有效降低缸套-活塞环摩擦副的摩擦因数,减少磨损量;高载荷和干摩擦条件下渗铜改性层的减摩抗磨作用效果尤为显著,最高可使摩擦因数分别降低13.15%和30.86%,磨损量分别降低30.70%和38.57%;渗铜后缸套-活塞环磨损表面形貌平整,摩擦表面形成了铜含量较高的润滑膜层,该表面膜起到了减摩、耐磨的作用。

On friction and wear properties of chromium plated piston rings

[J].

镀铬活塞环摩擦磨损性能研究

[J].

Progress in research of surface treatments for piston ring and their tribological performance

[J].

活塞环表面处理及摩擦学性能研究进展

[J].

Development and evaluation of low friction tisicn nanocomposite coatings for piston ring applications

[J].

PVD Cr x N coatings for tribological application on piston rings

[J].

Research status and development trend of piston ring surface treatment technology

[J].

活塞环表面处理技术的研究现状及发展趋势

[J].

Synergistic effects of electroless piston ring coatings and nano-additives in oil on the friction and wear of a piston ring/cylinder liner pair

[J].

Study on friction and wear properties of CrN and AlCrN PVD-coatings under rotationl wear condition

[D].

物理气相沉积CrN和AlCrN涂层转动微动摩擦磨损性能研究

[D].

Study on process methods of preparing TiAlN and DLC coatings by multi-arc ion plating and its effect on tribological properties of line gear pairs

[D].

多弧离子镀制备TiAlN和DLC涂层的工艺方法及其对线齿轮副摩擦学性能的影响

[D].

Structure–property relations in Cr-C/a-C:H coatings deposited by reactive magnetron sputtering

[J].

Comparison of friction and wear properties of several metal carbide and nitride coatings

[D].

几种金属C、N化合物镀层摩擦磨损性能的比较

[D].

Research on frictional behavior of DLC thin film coated piston rings and gray cast iron cylinder liners of different materials

[J].

DLC薄膜涂层活塞环与不同材质灰铸铁气缸套摩擦性能的研究

[J].

Application of Diamond-like Coating on Piston Ring

[J].

类金刚石涂层在活塞环上的应用

[J].

Tribological performance of crn and crn/glc coated components for automotive engine applications

[J].

Lower friction losses with new piston ring coating

[J].

DuroGlide®——next-generation piston ring coatings for fuel-efficient commercial vehicle engines

[J].

DuroGlide®——用于高燃油效率商用车发动机的新一代活塞环涂层

[J].

Scuffing behavior of CKS piston ring with alloy cast iron cylinder liner

[J].

CKS活塞环与合金铸铁缸套的抗拉缸性能分析

[J].

Chromium-based composite diamond chrome CDC application on piston rings in diesel

[J].

铬基复合金刚石镀铬CDC活塞环在柴油机上的应用

[J].

Influence of magnetic field unbalance coefficient on properties of CrN x coatings

[J].

磁场非平衡度对CrNx镀层性能的影响

[J].

Friction and wear performance of carbide (Cr, Fe)7C3-reinforced Fe-based composite coating

[J].

柱状碳化物(Cr, Fe)7C3增强Fe基涂层的摩擦磨损性能

[J].

Tribological studies of coated pistons sliding against cylinder liners under laboratory test conditions: tribological studies of coated pistons sliding against cylinder liners

[J].

Microstructure and properties of CrCN coating on 316L stainless steel

[J].

316L不锈钢表面沉积CrCN薄膜的结构及性能研究

[J].

Cavitation erosion of crn/crcn multilayer coating

[J].

Microstructure, electrochemical and tribocorrosion behaviors of crcn nanocomposite coating with various carbon content

[J].

Effect of carbon target current on ultralow frictional behavior of crcn coatings under glycerol lubrication

[J].

Gradient crcn cathodic arc pvd coatings

[J].

Preparation of crcn super-hard coating

[J].

Structure and tribological properties of AlCrN + CrCN coating

[J].

Tribological properties of crcn/crn multilayer coatings

[J].

Corrosion resistance of 316 stainless steel after low-temperature low-pressure arc plasma nitriding

[J].Low-pressure arc plasma nitriding is a novel rapid plasma nitriding process which can significantly enhance wear and corrosion resistance of austenite stainless steels. In this study, low temperature (~ 400℃) nitriding was applied to AISI 316 austenitic stainless steel (316 SS). A nitriding layer of 15 μm thickness was obtained just after 1 h processing, which is composed of an outer thin sublayer of nanocrystalline expanded austenite (nano-γN) with a trace of Cr nitrides and an inner thick coarse-grained expanded austenite (γN) sublayer. The thin surface nanolayer plays the key role in corrosion resistance of the nitrided layer, which promotes the formation of passive film. And the thickness of the passive film formed on the surface of the nitrided steel is 27 nm, which is two times over that on the bare 316 stainless steel. The corrosion current of nitrided steel is 3.55×10-8 A/cm2 in 3.5% NaCl solution, c.a. one order of magnitude lower than that of the untreated 316 austenite stainless steel (1.99×10-7 A/cm2), which indicated that the nitrided layer had a lower corrosion rate. The pitting corrosion potential was not detected via electrochemical polarization experiments, exhibiting a better pitting corrosion resistance of the nitrided steel.

低温低压电弧等离子体渗氮处理316 不锈钢的耐腐蚀性能

[J].在低温下对316奥氏体不锈钢进行低压电弧等离子体渗氮处理,研究了渗氮处理对不锈钢耐腐蚀性能的影响。结果表明:渗氮层有两个子层,由纳米晶扩张奥氏体和少量的CrN化合物组成的外表层和单一结构的扩张奥氏体内层。由于低压电弧等离子体浓度高,在400℃渗氮1 h得到的渗氮层厚度达到15 μm,表现出很高的渗氮速率。纳米晶外表层是渗氮不锈钢耐腐蚀性能的关键,促进了钝化膜的生成,渗氮后试样表面形成的钝化膜厚度达到27 nm,比原始不锈钢钝化膜的2倍还多。渗氮不锈钢试样的腐蚀电流(3.55×10<sup>-8</sup> A/cm<sup>2</sup>)比基材的腐蚀电流(1.99×10<sup>-7</sup> A/cm<sup>2</sup>)降低一个数量级,表明渗氮后试样的耐腐蚀性能提高了。

Microstructure and mechanical properties of a CrCN/CrN multilayer film

[J].

Electric conductivity and corrosion resistance of amorphous carbon films prepared by direct current magnetron sputtering on 304 stainless steel

[J].The conductive amorphous carbon films were deposited on the 304SS by conventional direct current magnetron sputtering. The effect of substrate bias on the microstructure and property of amorphous carbon films were mainly investigated. The results show that the electrical conductivity and corrosion resistance are improved significantly for the carbon films coated stainless steel in comparison to the untreated ones. Specifically, when the substrate bias was -200 V the contact resistance was about 16.65 mΩcm2, which may be ascribed to the highest fraction of sp2 bonds under the normal compacting force of the fuel cells at 1.5 MPa. The corrosion potential of the carbon films coated stainless steel significantly increased in the simulated PEM fuel cells environment, while the corrosion current density obviously decreased, especially when the bias was -200 V the carbon film performs the best corrosion resistance, which may be attributed to its best compactness, for this case the corrosion current density is 1.22×10-8 A/cm2 and the corrosion potential is 0.25 V.

直流磁控溅射非晶碳膜的导电性和耐蚀性

[J].用直流磁控溅射技术在304不锈钢基体上制备导电非晶碳膜, 重点研究了基体偏压对非晶碳膜微结构、导电性和耐蚀性的影响。结果表明: 与纯不锈钢双极板相比, 经非晶碳膜表面改性的不锈钢表面的导电性和耐蚀性均大幅度提高。当基体偏压为-200 V时在质子交换膜燃料电池组装典型压力(1.5 MPa)下非晶碳膜的sp<sup>2</sup>含量最高, 使改性不锈钢双极板具有最低的接触电阻(16.65 mΩcm<sup>2</sup>); 在模拟质子交换膜燃料电池工作环境的腐蚀溶液中镀膜后不锈钢板的腐蚀电位显著提高, 腐蚀电流明显下降。尤其在偏压-200 V下薄膜具有最佳的致密性, 腐蚀电位为0.25 V, 腐蚀电流密度为1.22×10<sup>-8</sup> A/cm<sup>2</sup>, 耐蚀性能最佳。

Construction of solid-state z-scheme carbon-modified TiO2/WO3 nanofibers with enhanced photocatalytic hydrogen production

[J].

Study on metal-doped diamond-like carbon films synthesized by cathodic arc evaporation

[J].

Improvement in the tribocorrosion performance of crcn coating by multilayered design for marine protective application

[J].

Effects of bias voltage and nitrogen flow rate on the structure and properties of Ni + CrAlYSiN nanocrystalline composite coatings

[J].

偏压和氮气流量对Ni+CrAlYSiN纳米复合涂层性能的影响

[J].采用真空电弧蒸镀技术在高温合金K417上制备Ni+CrAlYSiN纳米复合涂层, 用SEM, EDX, TEM等手段表征了复合涂层的形貌、成分和结构, 研究了基体负偏压和氮气流量对涂层的形貌、结构、成分和性能的影响。结果表明, 涂层主要由γ-Ni, fcc-AlN和fcc-CrN纳米晶组成; 基体偏压由-100 V增至-300 V, 熔滴的尺寸和数量均减小, 涂层中的晶粒尺寸由50 nm减小为30 nm。随着偏压的增大, 涂层中N含量下降, Ni含量增加, Cr和Al的含量先增加后减少; 涂层的沉积速率下降。随着氮气流量的增加, 涂层中的N含量增加, Ni、Cr和Al含量下降; 涂层的沉积速率先增加后减小。偏压为-300 V、氮气流量为225 mL?min<sup>-1</sup> 时, 涂层的硬度达最大值(9.80 GPa), 比NiCrAlYSi涂层的硬度提高约60%, 而耐磨性提高约30%。