退火温度对Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的组织结构和性能的影响

李云飞 1 , 2 , 3 , 王金贺 1 , 3 , 张龙 1 , 3 , 李正坤 1 , 付华萌 , 1 , 3 , 朱正旺 1 , 3 , 李宏 1 , 王爱民 1 , 3 , 张海峰 1 , 3

1.中国科学院金属研究所 中国科学院核用材料与安全评价重点实验室 沈阳 110016

2.中国科学技术大学材料科学与工程学院 沈阳 110016

3.中国科学院金属研究所 师昌绪先进材料创新中心 沈阳 110016

Effect of Annealing Temperature on Microstructure and Properties of a High-entropy Alloy Fe35 Ni30 Cr20 Al10 Nb5

LI Yunfei 1 , 2 , 3 , WANG Jinhe 1 , 3 , ZHANG Long 1 , 3 , LI Zhengkun 1 , FU Huameng , 1 , 3 , ZHU Zhengwang 1 , 3 , LI Hong 1 , WANG Aimin 1 , 3 , ZHANG Haifeng 1 , 3

1.CAS Key Laboratory of Nuclear Materials and Safety Assessment, Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China

2.School of Materials Science and Engineering, University of Science and Technology of China, Shenyang 110016, China

3.Shi -Changxu Innovation Center for Advanced Materials, Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China

通讯作者: 付华萌,研究员,hmfu@imr.ac.cn ,研究方向为非晶合金制备技术

责任编辑: 吴岩

收稿日期: 2023-05-08

修回日期: 2023-06-05

基金资助:

国家重点研发计划 (2021YFA0716303 )中核集团领创科研项目 中国科学院0到1项目

Corresponding authors: FU Huameng, Tel: 13654219196 , E-mail:hmfu@imr.ac.cn

Received: 2023-05-08

Revised: 2023-06-05

摘要

系统地研究了退火处理温度对低熔点高熵合金Fe35 Ni30 Cr20 Al10 Nb5 (摩尔比)的组织结构和性能的影响。结果表明:随着退火温度的提高,铸态Fe35 Ni30 Cr20 Al10 Nb5 合金中富Fe-Cr元素的fcc相的体积分数逐渐减少,Laves相和B2-NiAl相的体积分数逐渐增大。准静态压缩实验结果表明,铸态样品的压缩塑性变形能力良好。随着退火处理温度的提高合金的屈服强度先提高后降低,在700℃退火的样品其屈服强度最高(为1247.7 MPa),但是塑性变形量比铸态有所降低。压缩屈服强度随退火处理温度降低,可归因于基体fcc相在高温下的分解。电化学测试结果表明,这种合金的耐腐蚀能力随退火处理温度的提高而单调提高,在900℃退火的样品其腐蚀电位为-72.02 mV。

关键词:

金属材料 高熵合金 退火处理 力学性能 耐腐蚀性能

Abstract

The effect of annealing-temperature on the microstructure and properties of the low-melting point high-entropy alloy Fe35 Ni30 Cr20 Al10 Nb5 (molar ratio) were systematically investigated. The results show that with the increasing annealing-temperature, the volume fraction of Fe-Cr-rich fcc phase gradually decreases, while the volume fraction of Laves phase and B2-NiAl phase gradually increases for the as-cast alloy. The quasi-static compression test results show that the as-cast alloy has good compressive plastic deformation ability, and the yield strength of the alloy increases and then decreases as the annealing-temperature increases. The decrease in compression yield strength with the rising annealing-temperature is mainly attributed to the decomposition of the fcc phase at higher temperatures. The electrochemical test results show that the corrosion resistance of the alloy increases monotonically with the annealing-temperature, and the free-corrosion potential of the alloy annealed at 900o C is -72.02 mV.

Keywords:

metallic materials high entropy alloy annealing treatment mechanical properties corrosion resistance

本文引用格式

李云飞, 王金贺, 张龙, 李正坤, 付华萌, 朱正旺, 李宏, 王爱民, 张海峰. 退火温度对Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的组织结构和性能的影响 [J]. 材料研究学报 , 2024, 38(4): 241-247 DOI:10.11901/1005.3093.2023.255

LI Yunfei, WANG Jinhe, ZHANG Long, LI Zhengkun, FU Huameng, ZHU Zhengwang, LI Hong, WANG Aimin, ZHANG Haifeng. Effect of Annealing Temperature on Microstructure and Properties of a High-entropy Alloy Fe35 Ni30 Cr20 Al10 Nb5 [J]. Chinese Journal of Materials Research 10.11901/1005.3093.2023.255

21世纪初Cantor等[1 ] 和Ye等[2 ] 分别提出了多组元合金和高熵合金(HEAs)概念,其主要组成元素多于或等于5种,后来又发展出三种或四种组元的中熵合金。高熵或中熵合金打破了传统合金只含有一种或两种组元的理念,提高了合金的强度、耐磨性和耐腐蚀性。Fe-Co-Ni-Cr-Al体系高熵合金具有优异的综合力学性能,是目前较为成熟的高熵合金体系[3 ~5 ] 。Fe4 CrNiAl0.5 Ti0.5 高熵合金[6 ] 的屈服强度达到1930 MPa,同时塑性超过70%。Lu等[7 ] 提出了共晶高熵合金的概念,这类合金的铸造流动性较好并且熔点较低,由于其特别的组织结构,合金在力学和耐腐蚀性能方面有着优异表现[8 ,9 ] 。用电弧熔炼的AlCoCrFeNi2.1 高熵合金其室温拉伸断裂强度超过1 GPa,拉伸塑性超过15%[10 ] 。

这种高性能共晶高熵合金可应用在某些极端服役环境,但是所含的Co元素使其核电领域的抗辐照性能降低。研究者针对核电使役环境分析发现,Nb元素具有低中子吸收截面和优异的耐腐蚀性。Shi等[11 ] 研究了Nb对暴露在含氧熔融Pb中的Fe-Ni-Cr-Al高熵合金的组织结构和腐蚀行为的影响,发现Nb元素的加入可大大提高Fe-Ni-Cr-Al高熵合金在熔融Pb中的耐腐蚀性。Hamdy等[8 ] 在奥氏体不锈钢中加入Nb元素,发现其在3.5%NaCl(质量分数)溶液中的耐腐蚀性能随着Nb含量的提高而提高。这表明,无Co、兼具良好耐腐蚀性的Fe-Ni-Cr-Al-Nb高熵合金的应用前景良好。系统分析Fe/Ni比例对该体系合金结构和性能的影响发现,Fe35 Ni30 Cr20 Al10 Nb5 高熵合金具有优异的综合性能,Nb元素的引入可提高其耐腐蚀性和固溶强化[12 ,13 ] 。大量的研究结果表明,热处理对调控合金的组织结构和性能也有显著的影响。鉴于此,本文系统研究热处理温度对Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的组织结构的影响,探讨组织演变规律、评价准静态加载条件下高熵合金力学性能随热处理温度的变化规律,并揭示其在3.5%NaCl(质量分数)溶液中的耐腐蚀性能及其机理。

1 实验方法

实验用纯金属原料的纯度为99.9%(质量分数)。用真空电弧熔炼实验用高熵合金纽扣锭,其名义成分为Fe35 Ni30 Cr20 Al10 Nb5 (摩尔比)。在惰性的保护气氛下进行真空电弧熔炼,纽扣锭反复熔炼5次以保证合金成分的均匀性。选择在SXL-1400C箱式电阻炉中进行退火处理,退火温度分别为700、800和900℃,保温24 h后空冷至室温。

用MTISYJ-400高精密划片切割机从退火后的高熵合金棒上切取直径为5 mm长度为7.5 mm的压缩试样。用KB30SRFA硬度仪测试样品的硬度,加载载荷为200 g,加载时间为10 s。用INSTRON 5582电子万能试验机测试样品准静态力学性能,应变速率为1 × 10-3 s-1 。利用Gamry Interface 1000电化学工作站测试样品的耐腐蚀性能,参比电极为饱和甘汞电极(SCE),辅助电极为Pt片,扫描电压频率为0.333 mV/s。使用Rigaku Smartlab型X射线衍射仪(XRD)表征合金的晶体结构,扫描范围为10°~90°,扫描速率为10 (°)/min。使用附带能谱仪(EDS)的JSM-7001F场发射扫描电镜(FE-SEM)表征合金的微观形貌以及元素分布。

2 实验结果

2.1 微观组织结构

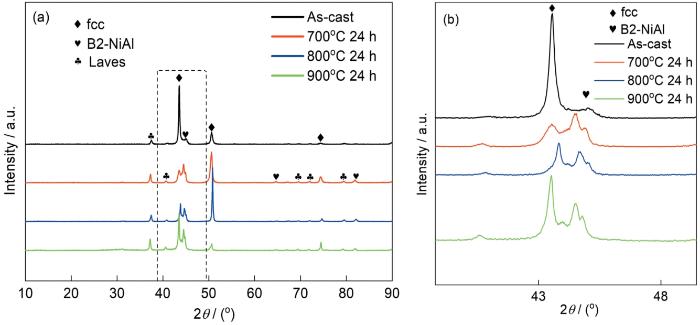

图1 给出了铸态和退火后的Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的XRD谱。根据与标准PDF卡片的比对,铸态Fe35 Ni30 Cr20 Al10 Nb5 高熵合金主要由fcc、B2-NiAl双相结构组成,XRD谱中还出现了Fe2 Nb Laves相的衍射峰,PDF卡片编号为17-0908。随着退火温度的提高,B2-NiAl相衍射峰的强度逐渐提高而峰位向低角度偏移,Fe2 Nb相衍射峰的数量明显增多。退火温度为800℃时fcc相的衍射峰向右偏移,表明第二相的析出使晶格常数改变,如图1b 所示。随着退火温度的提高Fe2 Nb相衍射峰增强,表明退火处理温度的提高促进了Fe2 Nb相的生成。同时,fcc相的衍射峰随着退火处理温度的提高而减少,表明在高温下fcc相可能发生了分解。

图1

图1

不同状态Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的XRD谱

Fig.1

XRD spectra of Fe35 Ni30 Cr20 Al10 Nb5 high-entropy alloy in different states

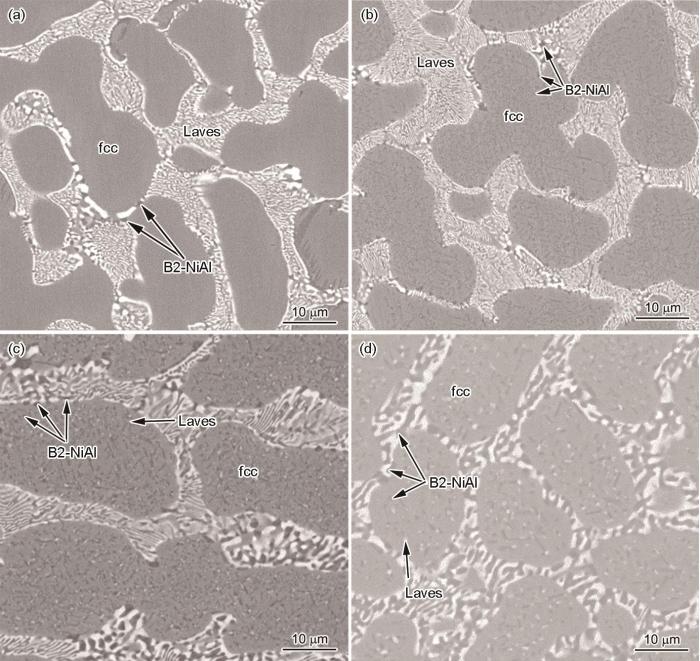

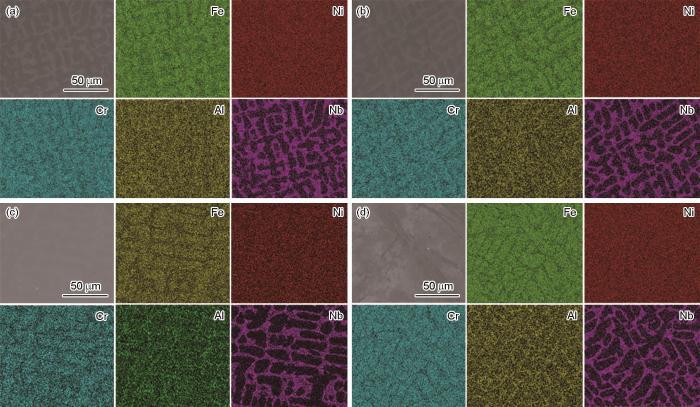

图2a ~2d 给出了不同退火态Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的背散射像(BSE),图3 给出了不同状态高熵合金的成分面分布(EDS)。铸态合金呈现树枝晶组织形貌,枝晶臂的宽度约为10 μm,在枝晶间形成了网状的共晶组织形貌。图中的深色枝晶基体为fcc富Fe-Cr相,枝晶间的白色区域为Fe2 Nb化合物,黑色点状析出物为B2-NiAl相,各组成相在图2 中分别用箭头标出。随着退火温度的提高,深色枝晶臂的尺寸逐渐增大,合金中富Fe-Cr相的溶解使其体积分数减少,而B2-NiAl相和Fe2 Nb金属间化合物的体积分数呈现增大的趋势。在800℃退火后的合金其组织形貌发生粗化,在枝晶相中析出了大量的Fe2 Nb化合物和B2-NiAl相。在900℃退火后枝晶间B2-NiAl相的含量大幅度提高,枝晶中仍然有大量Fe2 Nb化合物和B2-NiAl相。表1 列出了EDS检测到的Fe35 Ni30 Cr20 Al10 Nb5 合金不同区域的化学成分。

图2

图2

不同状态Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的微观形貌

Fig.2

Microstructure of Fe35 Ni30 Cr20 Al10 Nb5 high-entropy alloy in different states (a) as-cast, (b) 700o C, (c) 800o C, (d) 900o C

图3

图3

不同状态Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的EDS面分布

Fig.3

EDS surface distribution of Fe35 Ni30 Cr20 Al10 Nb5 high entropy alloy in different states (a) as-cast, (b) 700o C, (c) 800o C, (d) 900o C

2.2 力学性能

图4a 给出了Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的铸态和不同热处理温度试样的室温压缩应力-应变曲线。铸态合金的硬度为341.6HV,屈服强度为712.9 MPa,在700℃退火试样的屈服强度提高到1247.7 MPa,随着退火处理温度的提高合金的强度硬度下降,在900℃退火后合金的屈服强度下降到611.8 MPa,硬度为365.2HV。图4b 给出了退火温度对合金的屈服强度和硬度的影响。可以看出,在准静态压缩过程中所有试样均发生断裂,退火后合金的压缩塑性变差。

图4

图4

不同状态Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的准静态压缩性能

Fig.4

Quasi-static compression properties of Fe35 Ni30 -Cr20 Al10 Nb5 high-entropy alloy under different states

2.3 耐腐蚀性能

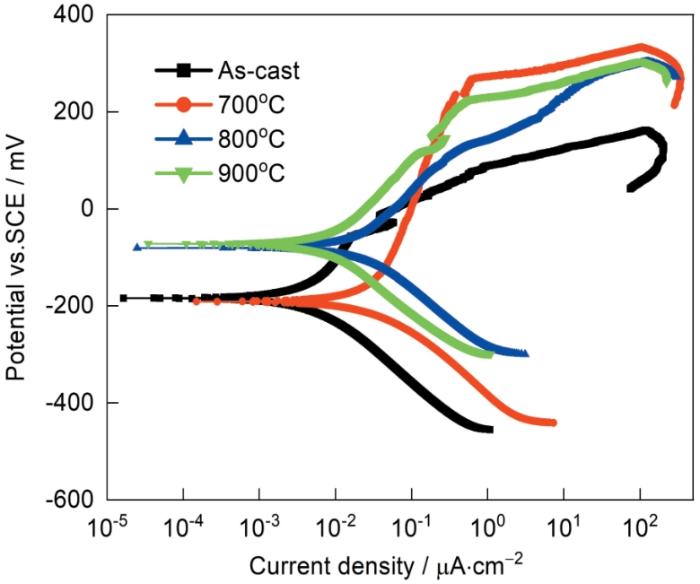

图5 给出了Fe35 Ni30 Cr20 Al10 Nb5 高熵合金在3.5% NaCl (质量分数)溶液中的动电位极化曲线,腐蚀参数列于表2 。由图5 可见,不同状态的合金试样其动电位极化曲线都出现了明显的钝化区。根据合金中元素的特性推测,Al、Cr和Nb等元素腐蚀后生成了钝化膜。由表2 可知,在700℃退火后的试样其耐腐蚀性能与铸态相比没有明显的变化。而随着退火温度的提高,在800和900℃退火的试样其耐腐蚀性能有很大的提高,在900℃退火的样品其耐腐蚀性能最好,腐蚀电位为-72.02 mV。这表明,低温退火并不能提高合金的耐腐蚀性能,随着退火温度的提高其耐腐蚀性能随之提高。

图5

图5

不同状态的Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的动电位极化曲线

Fig.5

Dynamic potential polarization curves of Fe35 Ni30 Cr20 Al10 Nb5 high-entropy alloy under different states

3 讨论

3.1 组织结构

由于合金组元的熔点差异较大并且熔炼时冷却速率较高,原子半径较大的Al、Nb元素会发生偏聚,导致出现第二相。为了进一步探究相形成机理,本文计算了合金组元中各元素之间的混合焓(ΔH mix ),如表3 所示。Fe、Ni和Cr元素之间的ΔH mix 很小,表明它们之间倾向于形成固溶体结构[14 ~16 ] 。但是,Fe元素和Nb元素在该合金体系中的结合强度较高(ΔH mix = -16 kJ/mol)而Fe元素的含量又比较高,解释了Nb倾向于在枝晶间富集和生成Fe2 Nb化合物。此外,Ni元素和Al元素之间较高的混合焓,使合金中倾向于生成B2-NiAl相。

已报道的Fe-Ni-Cr-Al体系高熵合金多为单相bcc结构,而本文实验中的铸态Fe35 Ni30 Cr20 Al10 Nb5 合金其相组成较为复杂。Zhang等[17 ] 认为当平均原子尺寸差δ ≤ 6.6%时,高熵合金更容易形成固溶体结构。根据文献[18 ]中公式

δ = ∑ i = 1 n c i ( 1 - r i r ¯ ) 2

计算出Fe35 Ni30 Cr20 Al10 Nb5 合金的δ 为5.17%,低于高熵合金的平均原子尺寸差,式中r i 为第i 个元素的原子半径,c i 为第i 个元素的原子分数,r ¯ = ∑ i = 1 n c i r i δ 增强了合金的固溶体相的形成能力,因此铸态合金形成了fcc、B2相以及Fe2 Nb三者共存的复杂相结构。在高温退火后的合金中金属间化合物的含量提高,fcc相结构发生分解。

3.2 力学性能

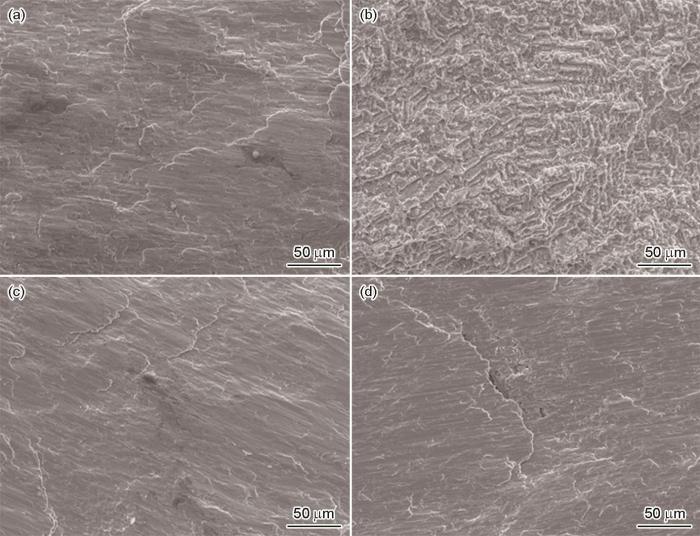

由于晶格畸变效应会对位错运动造成阻碍,所以高熵合金的屈服强度往往比传统合金要高[20 ] 。在压缩试验中,样品的制备状态往往会影响其屈服强度。铸态合金由于冷却速率较高,会在合金内部产生内应力。对合金进行热处理后,内应力会得到释放,屈服强度会有所降低。但是,在700℃退火的样品其屈服强度却异常地提高。图6 给出了不同状态Fe35 Ni30 Cr20 Al10 Nb5 合金的压缩断口形貌。由图6 可见,在700℃退火样品其断口形貌发生显著的变化:不同于铸态、在800和900℃退火的样品,断口表面凹凸不平而没有形成明显的滑移痕迹。这表明,裂纹在扩展过程中受到了较大的阻碍,使合金的屈服强度明显提高。在800和900℃退火的样品中fcc基体发生分解和有序B2相和Fe2 Nb金属间化合物的含量提高,使大量的Laves相连接成片。于是,在压缩过程中极易萌生裂纹且很难阻止其扩展,使合金的强度和塑性降低。

图6

图6

不同状态Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的准静态压缩断口形貌

Fig.6

Quasi-static compression fracture morphology of Fe35 Ni30 Cr20 Al10 Nb5 high-entropy alloy in different states (a) as-cast, (b) 700o C, (c) 800o C, (d) 900o C

3.3 耐腐蚀性能

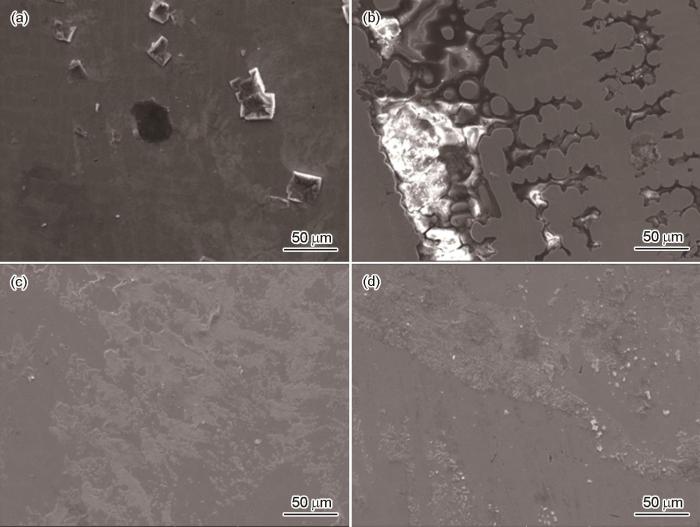

高熵合金的耐腐蚀性能与合金中相结构有关,还与相含量有密切的关系。各种相的共同作用,决定了合金的耐腐蚀性能。图7 给出了不同状态Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的电化学腐蚀形貌。从图7a 可以看出,铸态合金表面腐蚀后出现了点蚀,是一些小尺寸孔隙而不是尺寸较大的腐蚀孔,圆形点蚀的最大直径约20 μm。在700℃退火的样品腐蚀后枝晶相中出现了很多腐蚀坑,因为枝晶相中Nb元素含量较低不能生成稳定的钝化膜,使其耐腐蚀性能较低。在800和900℃退火的样品其腐蚀表面较为平整,生成了较为严密的钝化膜。其原因是,在这两种合金的枝晶相中都析出了大量的点状Fe2 Nb金属间化合物。这些金属间化合物生成一层较厚的钝化膜使基体不受腐蚀离子的侵蚀,因此其耐腐蚀性能较高。这表明,高温退火后在合金的枝晶相中析出的Fe2 Nb金属间化合物在电化学腐蚀过程中生成一层致密的钝化膜降低了腐蚀溶液对基体的侵蚀,从而使其耐腐蚀性能提高。

图7

图7

不同状态Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的电化学腐蚀形貌

Fig.7

Electrochemical corrosion morphology of Fe35 Ni30 Cr20 Al10 Nb5 high-entropy alloy in different states: (a) as-cast, (b) 700o C, (c) 800o C, (d) 900o C

4 结论

(1) 铸态Fe35 Ni30 Cr20 Al10 Nb5 高熵合金含有fcc和少量bcc双相结构的富Fe-Cr相和B2-NiAl相,并在枝晶间析出网状Fe2 Nb金属间化合物。随着退火温度的提高合金中富Fe-Cr相的体积分数逐渐减少,B2-NiAl相和Fe2 Nb金属间化合物的体积分数增加。

(2) 在准静态下铸态合金的塑性变形能力良好,塑性变形量接近20%,但是屈服强度随退火温度的提高先提高后降低,退火温度为700℃时其屈服强度最高(达到1247.7 MPa),是合金中Fe2 Nb金属间化合物与基体共同作用的结果。退火温度为900℃时合金的屈服强度最低(为611.8 MPa),其原因是在高温下基体fcc相分解。

(3) 在900℃退火的合金在3.5%NaCl(质量分数)溶液中的耐腐蚀性能最高,腐蚀电位为-72.02 mV,其次是在800℃退火的合金、铸态合金和在700℃退火的合金。其原因是,在高温退火过程中枝晶相中析出了大量的Fe2 Nb金属间化合物。富含Nb元素的枝晶相在表面生成一层致密的钝化膜,从而使合金的耐腐蚀性提高。

参考文献

View Option

[1]

Cantor B Chang I T H Knight P et al Microstructural development in equiatomic multicomponent alloys

[J]. Mater. Sci. Eng. , 2004 , 375 -377 A: 213

[本文引用: 1]

[2]

Ye J W Chen S K Lin S J et al Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes

[J]. Adv. Eng. Mater. , 2004 , 6 : 299

[本文引用: 1]

[3]

Cao L G Zhu L Zhang L L et al Microstructure evolution and mechanical properties of rapid solidified AlCoCrFeNi2.1 eutectic high entropy alloy

[J]. Chin. J. Mater. Res. , 2019 , 33 (9 ): 650

[本文引用: 1]

曹雷刚 , 朱 琳 , 张磊磊 等 快速凝固AlCoCrFeNi2.1 共晶高熵合金的微观组织演变和力学性能

[J]. 材料研究学报 , 2019 , 33 (9 ): 650

DOI

[本文引用: 1]

使用真空快速凝固设备制备不同直径的AlCoCrFeNi<sub>2.1</sub>合金铸棒和薄带,研究了冷却速率对多主元共晶高熵合金的微观组织和力学性能的影响。结果表明,全部试样均由FCC和B2两相组成。不同直径的合金铸棒均为常规共晶组织,只在表层某些位置观察到胞状共晶组织。铸棒的直径越小,冷却速率越大,规则共晶组织的片间距(λ)越小,其屈服强度越高。当铸棒直径由8 mm减小至2 mm时表层区域的λ值由530.4 μm减小至357.0 μm,轴心区域的片间距由712 μm减小至474 μm,合金的屈服强度由690 MPa提高到877 MPa。结合合金薄带的微观组织分析结果表明,随着冷却速率的提高AlCoCrFeNi<sub>2.1</sub>合金依次形成规则和非规则混合共晶组织、胞状共晶组织和树枝状组织。

[4]

Zhao R F Ren B Zhang G P et al Effect of Co content on the phase transition and magnetic properties of Co x

[J]. J. Magn. Magn. Mater. , 2018 , 468 : 14

[5]

Schuh B Mendez-Martin F Völker B et al Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCr-FeMnNi high-entropy alloy after severe plastic deformation

[J] Acta Mater. , 2015 , 96 : 258

[本文引用: 1]

[6]

Ji Y Zhang L Lu X et al Microstructural optimization of Fe x 0.5 Ti0.5 high entropy alloys toward high ductility

[J]. Appl. Phys. Lett. , 2021 , 119 : 141903

[本文引用: 1]

[7]

Lu Y P Dong Y Guo S et al A promising new class of high-temperature alloys: eutectic high-entropy alloys

[J]. Sci. Rep. , 2014 , 4 : 6200

DOI

PMID

[本文引用: 1]

High-entropy alloys (HEAs) can have either high strength or high ductility, and a simultaneous achievement of both still constitutes a tough challenge. The inferior castability and compositional segregation of HEAs are also obstacles for their technological applications. To tackle these problems, here we proposed a novel strategy to design HEAs using the eutectic alloy concept, i.e. to achieve a microstructure composed of alternating soft fcc and hard bcc phases. As a manifestation of this concept, an AlCoCrFeNi2.1 (atomic portion) eutectic high-entropy alloy (EHEA) was designed. The as-cast EHEA possessed a fine lamellar fcc/B2 microstructure, and showed an unprecedented combination of high tensile ductility and high fracture strength at room temperature. The excellent mechanical properties could be kept up to 700 degrees C. This new alloy design strategy can be readily adapted to large-scale industrial production of HEAs with simultaneous high fracture strength and high ductility.

[8]

Hamdy A S El-Shenawy E El-Bitar T The corrosion behavior of niobium bearing cold deformed austenitic stainless steels in 3.5% NaCl solution

[J]. Mater. Lett. , 2007 , 61 : 2827

[本文引用: 2]

[9]

Wang H Liu P Chen X H et al Mechanical properties and corrosion resistance characterization of a novel Co36 Fe36 Cr18 Ni10 high-entropy alloy for bioimplants compared to 316L alloy

[J]. J. Alloys Compd. , 2022 , 906 : 163947

[本文引用: 1]

[10]

Gao X Z Lu Y P Zhang B et al Microstructural origins of high strength and high ductility in an AlCoCrFeNi2.1 eutectic high-entropy alloy

[J]. Acta Mater. , 2017 , 141 : 59

[本文引用: 1]

[11]

Shi H Fetzer R Jianu A et al Influence of alloying elements (Cu, Ti, Nb) on the microstructure and corrosion behaviour of AlCrFeNi-based high entropy alloys exposed to oxygen-containing molten Pb

[J]. Corros. Sci. , 2021 , 190 : 109659

[本文引用: 1]

[12]

Brady M P Magee J Yamamoto Y et al Co-optimization of wrought alumina-forming austenitic stainless steel composition ranges for high-temperature creep and oxidation/corrosion resistance

[J]. Mater. Sci. Eng. , 2014 , 590A : 101

[本文引用: 1]

[13]

Luo R Chen L L Zhang Y X et al Characteristic and mechanism of dynamic recrystallization in a newly developed Fe-Cr-Ni-Al-Nb superalloy during hot deformation

[J]. J. Alloys Compd. , 2021 , 865 : 158601

[本文引用: 1]

[14]

Chen Y Y Duval T Hung U D et al Microstructure and electrochemical properties of high entropy alloys—a comparison with type-304 stainless steel

[J]. Corros. Sci. , 2005 , 47 (9 ): 2257

[本文引用: 1]

[15]

Chen Y Y Hong U T Shih H C et al Electrochemical kinetics of the high entropy alloys in aqueous environments—a comparison with type 304 stainless steel

[J]. Corros. Sci. , 2005 , 47 (11 ): 2679

[16]

Wang W R Wang W L Wang S C et al Effects of Al addition on the microstructure and mechanical property of Al x

[J]. Intermetallics , 2012 , 26 : 44

[本文引用: 1]

[17]

Zhang Y Zhou Y J Lin J P et al Solid-solution phase formation rules for multi-component alloys

[J]. Adv. Eng. Mater. , 2008 , 10 (6 ): 534

[本文引用: 1]

[18]

Wen C Mo W W Tian Y W et al Research progress on solid solution strengthening of high entropy alloys

[J]. Mater. Rep. , 2021 , 35 : 17081

[本文引用: 1]

文 成 , 莫湾湾 , 田玉琬 等 高熵合金固溶强化问题的研究进展

[J]. 材料导报 , 2021 , 35 : 17081

[本文引用: 1]

[19]

Takeuchi A Inoue A Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element

[J]. Mater. Trans. , 2005 , 46 (12 ): 2817

[本文引用: 2]

[20]

Jiang B B Yu Y Cui J et al High-entropy-stabilized chalcogenides with high thermoelectric performance

[J]. Science , 2021 , 371 (6531 ): 830

DOI

PMID

[本文引用: 1]

Thermoelectric technology generates electricity from waste heat, but one bottleneck for wider use is the performance of thermoelectric materials. Manipulating the configurational entropy of a material by introducing different atomic species can tune phase composition and extend the performance optimization space. We enhanced the figure of merit () value to 1.8 at 900 kelvin in an n-type PbSe-based high-entropy material formed by entropy-driven structural stabilization. The largely distorted lattices in this high-entropy system caused unusual shear strains, which provided strong phonon scattering to largely lower lattice thermal conductivity. The thermoelectric conversion efficiency was 12.3% at temperature difference Δ = 507 kelvin, for the fabricated segmented module based on this n-type high-entropy material. Our demonstration provides a paradigm to improve thermoelectric performance for high-entropy thermoelectric materials through entropy engineering.Copyright © 2020 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Microstructural development in equiatomic multicomponent alloys

1

2004

... 21世纪初Cantor等[1 ] 和Ye等[2 ] 分别提出了多组元合金和高熵合金(HEAs)概念,其主要组成元素多于或等于5种,后来又发展出三种或四种组元的中熵合金.高熵或中熵合金打破了传统合金只含有一种或两种组元的理念,提高了合金的强度、耐磨性和耐腐蚀性.Fe-Co-Ni-Cr-Al体系高熵合金具有优异的综合力学性能,是目前较为成熟的高熵合金体系[3 ~5 ] .Fe4 CrNiAl0.5 Ti0.5 高熵合金[6 ] 的屈服强度达到1930 MPa,同时塑性超过70%.Lu等[7 ] 提出了共晶高熵合金的概念,这类合金的铸造流动性较好并且熔点较低,由于其特别的组织结构,合金在力学和耐腐蚀性能方面有着优异表现[8 ,9 ] .用电弧熔炼的AlCoCrFeNi2.1 高熵合金其室温拉伸断裂强度超过1 GPa,拉伸塑性超过15%[10 ] . ...

Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes

1

2004

... 21世纪初Cantor等[1 ] 和Ye等[2 ] 分别提出了多组元合金和高熵合金(HEAs)概念,其主要组成元素多于或等于5种,后来又发展出三种或四种组元的中熵合金.高熵或中熵合金打破了传统合金只含有一种或两种组元的理念,提高了合金的强度、耐磨性和耐腐蚀性.Fe-Co-Ni-Cr-Al体系高熵合金具有优异的综合力学性能,是目前较为成熟的高熵合金体系[3 ~5 ] .Fe4 CrNiAl0.5 Ti0.5 高熵合金[6 ] 的屈服强度达到1930 MPa,同时塑性超过70%.Lu等[7 ] 提出了共晶高熵合金的概念,这类合金的铸造流动性较好并且熔点较低,由于其特别的组织结构,合金在力学和耐腐蚀性能方面有着优异表现[8 ,9 ] .用电弧熔炼的AlCoCrFeNi2.1 高熵合金其室温拉伸断裂强度超过1 GPa,拉伸塑性超过15%[10 ] . ...

Microstructure evolution and mechanical properties of rapid solidified AlCoCrFeNi2.1 eutectic high entropy alloy

1

2019

... 21世纪初Cantor等[1 ] 和Ye等[2 ] 分别提出了多组元合金和高熵合金(HEAs)概念,其主要组成元素多于或等于5种,后来又发展出三种或四种组元的中熵合金.高熵或中熵合金打破了传统合金只含有一种或两种组元的理念,提高了合金的强度、耐磨性和耐腐蚀性.Fe-Co-Ni-Cr-Al体系高熵合金具有优异的综合力学性能,是目前较为成熟的高熵合金体系[3 ~5 ] .Fe4 CrNiAl0.5 Ti0.5 高熵合金[6 ] 的屈服强度达到1930 MPa,同时塑性超过70%.Lu等[7 ] 提出了共晶高熵合金的概念,这类合金的铸造流动性较好并且熔点较低,由于其特别的组织结构,合金在力学和耐腐蚀性能方面有着优异表现[8 ,9 ] .用电弧熔炼的AlCoCrFeNi2.1 高熵合金其室温拉伸断裂强度超过1 GPa,拉伸塑性超过15%[10 ] . ...

快速凝固AlCoCrFeNi2.1 共晶高熵合金的微观组织演变和力学性能

1

2019

... 21世纪初Cantor等[1 ] 和Ye等[2 ] 分别提出了多组元合金和高熵合金(HEAs)概念,其主要组成元素多于或等于5种,后来又发展出三种或四种组元的中熵合金.高熵或中熵合金打破了传统合金只含有一种或两种组元的理念,提高了合金的强度、耐磨性和耐腐蚀性.Fe-Co-Ni-Cr-Al体系高熵合金具有优异的综合力学性能,是目前较为成熟的高熵合金体系[3 ~5 ] .Fe4 CrNiAl0.5 Ti0.5 高熵合金[6 ] 的屈服强度达到1930 MPa,同时塑性超过70%.Lu等[7 ] 提出了共晶高熵合金的概念,这类合金的铸造流动性较好并且熔点较低,由于其特别的组织结构,合金在力学和耐腐蚀性能方面有着优异表现[8 ,9 ] .用电弧熔炼的AlCoCrFeNi2.1 高熵合金其室温拉伸断裂强度超过1 GPa,拉伸塑性超过15%[10 ] . ...

Effect of Co content on the phase transition and magnetic properties of Co x

0

2018

Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCr-FeMnNi high-entropy alloy after severe plastic deformation

1

2015

... 21世纪初Cantor等[1 ] 和Ye等[2 ] 分别提出了多组元合金和高熵合金(HEAs)概念,其主要组成元素多于或等于5种,后来又发展出三种或四种组元的中熵合金.高熵或中熵合金打破了传统合金只含有一种或两种组元的理念,提高了合金的强度、耐磨性和耐腐蚀性.Fe-Co-Ni-Cr-Al体系高熵合金具有优异的综合力学性能,是目前较为成熟的高熵合金体系[3 ~5 ] .Fe4 CrNiAl0.5 Ti0.5 高熵合金[6 ] 的屈服强度达到1930 MPa,同时塑性超过70%.Lu等[7 ] 提出了共晶高熵合金的概念,这类合金的铸造流动性较好并且熔点较低,由于其特别的组织结构,合金在力学和耐腐蚀性能方面有着优异表现[8 ,9 ] .用电弧熔炼的AlCoCrFeNi2.1 高熵合金其室温拉伸断裂强度超过1 GPa,拉伸塑性超过15%[10 ] . ...

Microstructural optimization of Fe x 0.5 Ti0.5 high entropy alloys toward high ductility

1

2021

... 21世纪初Cantor等[1 ] 和Ye等[2 ] 分别提出了多组元合金和高熵合金(HEAs)概念,其主要组成元素多于或等于5种,后来又发展出三种或四种组元的中熵合金.高熵或中熵合金打破了传统合金只含有一种或两种组元的理念,提高了合金的强度、耐磨性和耐腐蚀性.Fe-Co-Ni-Cr-Al体系高熵合金具有优异的综合力学性能,是目前较为成熟的高熵合金体系[3 ~5 ] .Fe4 CrNiAl0.5 Ti0.5 高熵合金[6 ] 的屈服强度达到1930 MPa,同时塑性超过70%.Lu等[7 ] 提出了共晶高熵合金的概念,这类合金的铸造流动性较好并且熔点较低,由于其特别的组织结构,合金在力学和耐腐蚀性能方面有着优异表现[8 ,9 ] .用电弧熔炼的AlCoCrFeNi2.1 高熵合金其室温拉伸断裂强度超过1 GPa,拉伸塑性超过15%[10 ] . ...

A promising new class of high-temperature alloys: eutectic high-entropy alloys

1

2014

... 21世纪初Cantor等[1 ] 和Ye等[2 ] 分别提出了多组元合金和高熵合金(HEAs)概念,其主要组成元素多于或等于5种,后来又发展出三种或四种组元的中熵合金.高熵或中熵合金打破了传统合金只含有一种或两种组元的理念,提高了合金的强度、耐磨性和耐腐蚀性.Fe-Co-Ni-Cr-Al体系高熵合金具有优异的综合力学性能,是目前较为成熟的高熵合金体系[3 ~5 ] .Fe4 CrNiAl0.5 Ti0.5 高熵合金[6 ] 的屈服强度达到1930 MPa,同时塑性超过70%.Lu等[7 ] 提出了共晶高熵合金的概念,这类合金的铸造流动性较好并且熔点较低,由于其特别的组织结构,合金在力学和耐腐蚀性能方面有着优异表现[8 ,9 ] .用电弧熔炼的AlCoCrFeNi2.1 高熵合金其室温拉伸断裂强度超过1 GPa,拉伸塑性超过15%[10 ] . ...

The corrosion behavior of niobium bearing cold deformed austenitic stainless steels in 3.5% NaCl solution

2

2007

... 21世纪初Cantor等[1 ] 和Ye等[2 ] 分别提出了多组元合金和高熵合金(HEAs)概念,其主要组成元素多于或等于5种,后来又发展出三种或四种组元的中熵合金.高熵或中熵合金打破了传统合金只含有一种或两种组元的理念,提高了合金的强度、耐磨性和耐腐蚀性.Fe-Co-Ni-Cr-Al体系高熵合金具有优异的综合力学性能,是目前较为成熟的高熵合金体系[3 ~5 ] .Fe4 CrNiAl0.5 Ti0.5 高熵合金[6 ] 的屈服强度达到1930 MPa,同时塑性超过70%.Lu等[7 ] 提出了共晶高熵合金的概念,这类合金的铸造流动性较好并且熔点较低,由于其特别的组织结构,合金在力学和耐腐蚀性能方面有着优异表现[8 ,9 ] .用电弧熔炼的AlCoCrFeNi2.1 高熵合金其室温拉伸断裂强度超过1 GPa,拉伸塑性超过15%[10 ] . ...

... 这种高性能共晶高熵合金可应用在某些极端服役环境,但是所含的Co元素使其核电领域的抗辐照性能降低.研究者针对核电使役环境分析发现,Nb元素具有低中子吸收截面和优异的耐腐蚀性.Shi等[11 ] 研究了Nb对暴露在含氧熔融Pb中的Fe-Ni-Cr-Al高熵合金的组织结构和腐蚀行为的影响,发现Nb元素的加入可大大提高Fe-Ni-Cr-Al高熵合金在熔融Pb中的耐腐蚀性.Hamdy等[8 ] 在奥氏体不锈钢中加入Nb元素,发现其在3.5%NaCl(质量分数)溶液中的耐腐蚀性能随着Nb含量的提高而提高.这表明,无Co、兼具良好耐腐蚀性的Fe-Ni-Cr-Al-Nb高熵合金的应用前景良好.系统分析Fe/Ni比例对该体系合金结构和性能的影响发现,Fe35 Ni30 Cr20 Al10 Nb5 高熵合金具有优异的综合性能,Nb元素的引入可提高其耐腐蚀性和固溶强化[12 ,13 ] .大量的研究结果表明,热处理对调控合金的组织结构和性能也有显著的影响.鉴于此,本文系统研究热处理温度对Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的组织结构的影响,探讨组织演变规律、评价准静态加载条件下高熵合金力学性能随热处理温度的变化规律,并揭示其在3.5%NaCl(质量分数)溶液中的耐腐蚀性能及其机理. ...

Mechanical properties and corrosion resistance characterization of a novel Co36 Fe36 Cr18 Ni10 high-entropy alloy for bioimplants compared to 316L alloy

1

2022

... 21世纪初Cantor等[1 ] 和Ye等[2 ] 分别提出了多组元合金和高熵合金(HEAs)概念,其主要组成元素多于或等于5种,后来又发展出三种或四种组元的中熵合金.高熵或中熵合金打破了传统合金只含有一种或两种组元的理念,提高了合金的强度、耐磨性和耐腐蚀性.Fe-Co-Ni-Cr-Al体系高熵合金具有优异的综合力学性能,是目前较为成熟的高熵合金体系[3 ~5 ] .Fe4 CrNiAl0.5 Ti0.5 高熵合金[6 ] 的屈服强度达到1930 MPa,同时塑性超过70%.Lu等[7 ] 提出了共晶高熵合金的概念,这类合金的铸造流动性较好并且熔点较低,由于其特别的组织结构,合金在力学和耐腐蚀性能方面有着优异表现[8 ,9 ] .用电弧熔炼的AlCoCrFeNi2.1 高熵合金其室温拉伸断裂强度超过1 GPa,拉伸塑性超过15%[10 ] . ...

Microstructural origins of high strength and high ductility in an AlCoCrFeNi2.1 eutectic high-entropy alloy

1

2017

... 21世纪初Cantor等[1 ] 和Ye等[2 ] 分别提出了多组元合金和高熵合金(HEAs)概念,其主要组成元素多于或等于5种,后来又发展出三种或四种组元的中熵合金.高熵或中熵合金打破了传统合金只含有一种或两种组元的理念,提高了合金的强度、耐磨性和耐腐蚀性.Fe-Co-Ni-Cr-Al体系高熵合金具有优异的综合力学性能,是目前较为成熟的高熵合金体系[3 ~5 ] .Fe4 CrNiAl0.5 Ti0.5 高熵合金[6 ] 的屈服强度达到1930 MPa,同时塑性超过70%.Lu等[7 ] 提出了共晶高熵合金的概念,这类合金的铸造流动性较好并且熔点较低,由于其特别的组织结构,合金在力学和耐腐蚀性能方面有着优异表现[8 ,9 ] .用电弧熔炼的AlCoCrFeNi2.1 高熵合金其室温拉伸断裂强度超过1 GPa,拉伸塑性超过15%[10 ] . ...

Influence of alloying elements (Cu, Ti, Nb) on the microstructure and corrosion behaviour of AlCrFeNi-based high entropy alloys exposed to oxygen-containing molten Pb

1

2021

... 这种高性能共晶高熵合金可应用在某些极端服役环境,但是所含的Co元素使其核电领域的抗辐照性能降低.研究者针对核电使役环境分析发现,Nb元素具有低中子吸收截面和优异的耐腐蚀性.Shi等[11 ] 研究了Nb对暴露在含氧熔融Pb中的Fe-Ni-Cr-Al高熵合金的组织结构和腐蚀行为的影响,发现Nb元素的加入可大大提高Fe-Ni-Cr-Al高熵合金在熔融Pb中的耐腐蚀性.Hamdy等[8 ] 在奥氏体不锈钢中加入Nb元素,发现其在3.5%NaCl(质量分数)溶液中的耐腐蚀性能随着Nb含量的提高而提高.这表明,无Co、兼具良好耐腐蚀性的Fe-Ni-Cr-Al-Nb高熵合金的应用前景良好.系统分析Fe/Ni比例对该体系合金结构和性能的影响发现,Fe35 Ni30 Cr20 Al10 Nb5 高熵合金具有优异的综合性能,Nb元素的引入可提高其耐腐蚀性和固溶强化[12 ,13 ] .大量的研究结果表明,热处理对调控合金的组织结构和性能也有显著的影响.鉴于此,本文系统研究热处理温度对Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的组织结构的影响,探讨组织演变规律、评价准静态加载条件下高熵合金力学性能随热处理温度的变化规律,并揭示其在3.5%NaCl(质量分数)溶液中的耐腐蚀性能及其机理. ...

Co-optimization of wrought alumina-forming austenitic stainless steel composition ranges for high-temperature creep and oxidation/corrosion resistance

1

2014

... 这种高性能共晶高熵合金可应用在某些极端服役环境,但是所含的Co元素使其核电领域的抗辐照性能降低.研究者针对核电使役环境分析发现,Nb元素具有低中子吸收截面和优异的耐腐蚀性.Shi等[11 ] 研究了Nb对暴露在含氧熔融Pb中的Fe-Ni-Cr-Al高熵合金的组织结构和腐蚀行为的影响,发现Nb元素的加入可大大提高Fe-Ni-Cr-Al高熵合金在熔融Pb中的耐腐蚀性.Hamdy等[8 ] 在奥氏体不锈钢中加入Nb元素,发现其在3.5%NaCl(质量分数)溶液中的耐腐蚀性能随着Nb含量的提高而提高.这表明,无Co、兼具良好耐腐蚀性的Fe-Ni-Cr-Al-Nb高熵合金的应用前景良好.系统分析Fe/Ni比例对该体系合金结构和性能的影响发现,Fe35 Ni30 Cr20 Al10 Nb5 高熵合金具有优异的综合性能,Nb元素的引入可提高其耐腐蚀性和固溶强化[12 ,13 ] .大量的研究结果表明,热处理对调控合金的组织结构和性能也有显著的影响.鉴于此,本文系统研究热处理温度对Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的组织结构的影响,探讨组织演变规律、评价准静态加载条件下高熵合金力学性能随热处理温度的变化规律,并揭示其在3.5%NaCl(质量分数)溶液中的耐腐蚀性能及其机理. ...

Characteristic and mechanism of dynamic recrystallization in a newly developed Fe-Cr-Ni-Al-Nb superalloy during hot deformation

1

2021

... 这种高性能共晶高熵合金可应用在某些极端服役环境,但是所含的Co元素使其核电领域的抗辐照性能降低.研究者针对核电使役环境分析发现,Nb元素具有低中子吸收截面和优异的耐腐蚀性.Shi等[11 ] 研究了Nb对暴露在含氧熔融Pb中的Fe-Ni-Cr-Al高熵合金的组织结构和腐蚀行为的影响,发现Nb元素的加入可大大提高Fe-Ni-Cr-Al高熵合金在熔融Pb中的耐腐蚀性.Hamdy等[8 ] 在奥氏体不锈钢中加入Nb元素,发现其在3.5%NaCl(质量分数)溶液中的耐腐蚀性能随着Nb含量的提高而提高.这表明,无Co、兼具良好耐腐蚀性的Fe-Ni-Cr-Al-Nb高熵合金的应用前景良好.系统分析Fe/Ni比例对该体系合金结构和性能的影响发现,Fe35 Ni30 Cr20 Al10 Nb5 高熵合金具有优异的综合性能,Nb元素的引入可提高其耐腐蚀性和固溶强化[12 ,13 ] .大量的研究结果表明,热处理对调控合金的组织结构和性能也有显著的影响.鉴于此,本文系统研究热处理温度对Fe35 Ni30 Cr20 Al10 Nb5 高熵合金的组织结构的影响,探讨组织演变规律、评价准静态加载条件下高熵合金力学性能随热处理温度的变化规律,并揭示其在3.5%NaCl(质量分数)溶液中的耐腐蚀性能及其机理. ...

Microstructure and electrochemical properties of high entropy alloys—a comparison with type-304 stainless steel

1

2005

... 由于合金组元的熔点差异较大并且熔炼时冷却速率较高,原子半径较大的Al、Nb元素会发生偏聚,导致出现第二相.为了进一步探究相形成机理,本文计算了合金组元中各元素之间的混合焓(ΔH mix ),如表3 所示.Fe、Ni和Cr元素之间的ΔH mix 很小,表明它们之间倾向于形成固溶体结构[14 ~16 ] .但是,Fe元素和Nb元素在该合金体系中的结合强度较高(ΔH mix = -16 kJ/mol)而Fe元素的含量又比较高,解释了Nb倾向于在枝晶间富集和生成Fe2 Nb化合物.此外,Ni元素和Al元素之间较高的混合焓,使合金中倾向于生成B2-NiAl相. ...

Electrochemical kinetics of the high entropy alloys in aqueous environments—a comparison with type 304 stainless steel

0

2005

Effects of Al addition on the microstructure and mechanical property of Al x

1

2012

... 由于合金组元的熔点差异较大并且熔炼时冷却速率较高,原子半径较大的Al、Nb元素会发生偏聚,导致出现第二相.为了进一步探究相形成机理,本文计算了合金组元中各元素之间的混合焓(ΔH mix ),如表3 所示.Fe、Ni和Cr元素之间的ΔH mix 很小,表明它们之间倾向于形成固溶体结构[14 ~16 ] .但是,Fe元素和Nb元素在该合金体系中的结合强度较高(ΔH mix = -16 kJ/mol)而Fe元素的含量又比较高,解释了Nb倾向于在枝晶间富集和生成Fe2 Nb化合物.此外,Ni元素和Al元素之间较高的混合焓,使合金中倾向于生成B2-NiAl相. ...

Solid-solution phase formation rules for multi-component alloys

1

2008

... 已报道的Fe-Ni-Cr-Al体系高熵合金多为单相bcc结构,而本文实验中的铸态Fe35 Ni30 Cr20 Al10 Nb5 合金其相组成较为复杂.Zhang等[17 ] 认为当平均原子尺寸差δ ≤ 6.6%时,高熵合金更容易形成固溶体结构.根据文献[18 ]中公式 ...

Research progress on solid solution strengthening of high entropy alloys

1

2021

... 已报道的Fe-Ni-Cr-Al体系高熵合金多为单相bcc结构,而本文实验中的铸态Fe35 Ni30 Cr20 Al10 Nb5 合金其相组成较为复杂.Zhang等[17 ] 认为当平均原子尺寸差δ ≤ 6.6%时,高熵合金更容易形成固溶体结构.根据文献[18 ]中公式 ...

高熵合金固溶强化问题的研究进展

1

2021

... 已报道的Fe-Ni-Cr-Al体系高熵合金多为单相bcc结构,而本文实验中的铸态Fe35 Ni30 Cr20 Al10 Nb5 合金其相组成较为复杂.Zhang等[17 ] 认为当平均原子尺寸差δ ≤ 6.6%时,高熵合金更容易形成固溶体结构.根据文献[18 ]中公式 ...

Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element

2

2005

... Fe、Ni、Cr、Al、Nb二元合金的混合焓[19 ] ...

... Mixed enthalpies (ΔH mix ) of Fe, Ni, Cr, Al, Nb binary alloys[19 ] (kJ·mol-1 ) ...

High-entropy-stabilized chalcogenides with high thermoelectric performance

1

2021

... 由于晶格畸变效应会对位错运动造成阻碍,所以高熵合金的屈服强度往往比传统合金要高[20 ] .在压缩试验中,样品的制备状态往往会影响其屈服强度.铸态合金由于冷却速率较高,会在合金内部产生内应力.对合金进行热处理后,内应力会得到释放,屈服强度会有所降低.但是,在700℃退火的样品其屈服强度却异常地提高.图6 给出了不同状态Fe35 Ni30 Cr20 Al10 Nb5 合金的压缩断口形貌.由图6 可见,在700℃退火样品其断口形貌发生显著的变化:不同于铸态、在800和900℃退火的样品,断口表面凹凸不平而没有形成明显的滑移痕迹.这表明,裂纹在扩展过程中受到了较大的阻碍,使合金的屈服强度明显提高.在800和900℃退火的样品中fcc基体发生分解和有序B2相和Fe2 Nb金属间化合物的含量提高,使大量的Laves相连接成片.于是,在压缩过程中极易萌生裂纹且很难阻止其扩展,使合金的强度和塑性降低. ...