1 实验方法

实验用块体合金原料Ti、Zr、Cu、Pd和Mo的纯度高于99.99% (质量分数)。按照(Ti0.4Zr0.1Cu0.36Pd0.14)100 - x Mo x (x =0,1,2,5,原子分数,分别记为Mo0,Mo1,Mo2,Mo5)配料,在熔融Ti锭吸氧和高纯氩气(> 99.999%,质量分数)保护下用电弧炉熔炼母合金。为了确保母合金锭的成分均匀,合金锭反复熔炼至少5次。将炼好的合金锭破碎并清洗后装入石英管,用铜模喷铸法制备出直径为2 mm的棒状试样。

用XRD-7000型X射线衍射仪(XRD,CuKα )分析棒状试样的相组成,用GeminiSEM300场发射扫描电子显微镜观察试样的微观组织和断口形貌。用Zwick Z020型万能材料试验机进行压缩实验,试样的长径比为2∶1,将其两端面磨平并使其垂直于受力方向,应变速率为5.0 × 10-4 s-1。

2 结果和讨论

2.1 微观组织

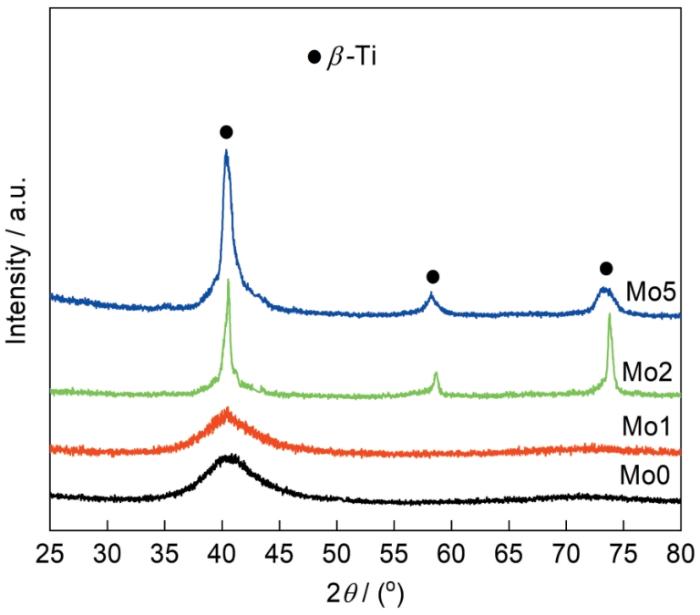

图1给出了4种不同Mo含量的Ti基非晶复合材料试样的XRD谱。可以看出,在Mo0试样(没添加Mo元素)和Mo1试样(添加1%Mo)的谱中只有一个明显的弥散非晶衍射峰,没有出现晶体峰。而在Mo2与Mo5样品的谱中除了非晶衍射峰,还出现了尖锐的晶化峰(标定为β-Ti相)。这表明,在Mo2和Mo5中析出了β-Ti相。从XRD谱中还可见,随着Mo含量的提高β-Ti相的衍射峰强度逐渐提高,表明样品中β-Ti的含量随之提高。

图1

图2

图2

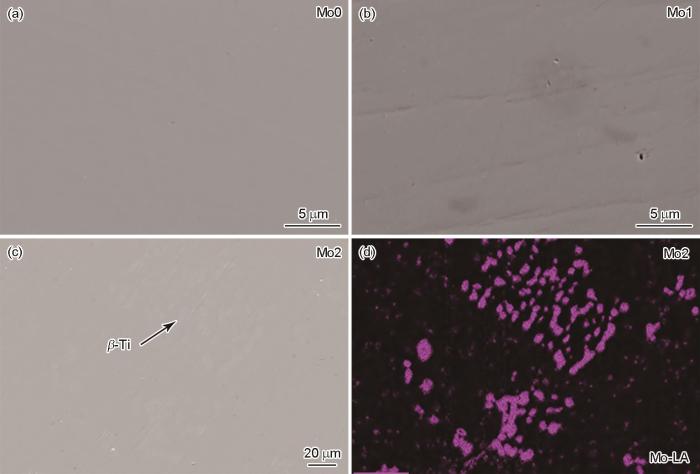

不同Mo含量样品的SEM照片和Mo元素的分布

Fig.2

SEM images of samples at different Mo contents (a) Mo0; (b) Mo1; (c) Mo2 and (d) distribution of Mo element in (c) -plot

上述结果表明,由于Mo在Ti中的固溶度较高,当添加量≤ 1%时Mo元素全部固溶进入基体,难以促进β-Ti相的析出。当Mo添加量≥ 2%时在非晶基体中析出β-Ti相,生成原位自生钛基非晶复合材料且β-Ti相弥散均匀分布。

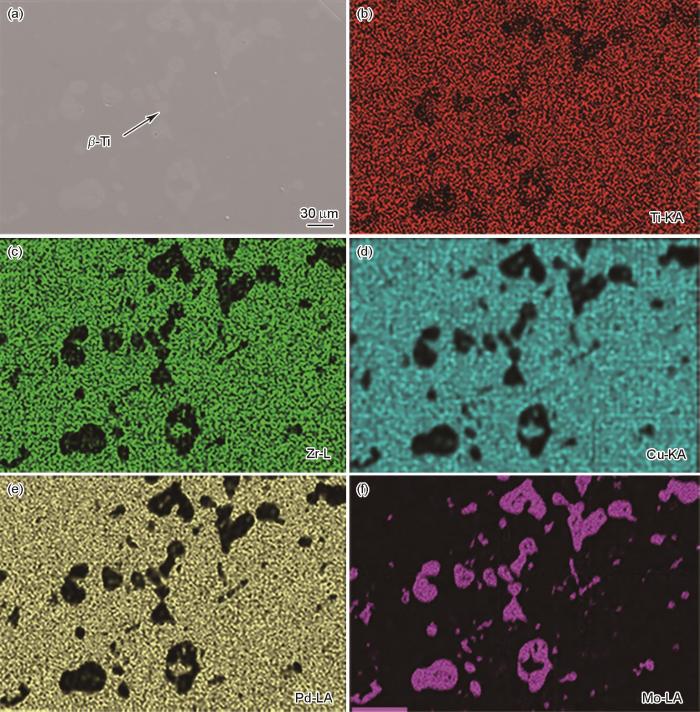

图3

图3

Mo5试样的SEM照片对应的元素面扫图

Fig.3

SEM images of Mo5 specimens (a) and corresponding elemental face sweeps of Ti (b), Zr (c), Cu (d), Pd (e) and Mo (f)

2.2 力学性能

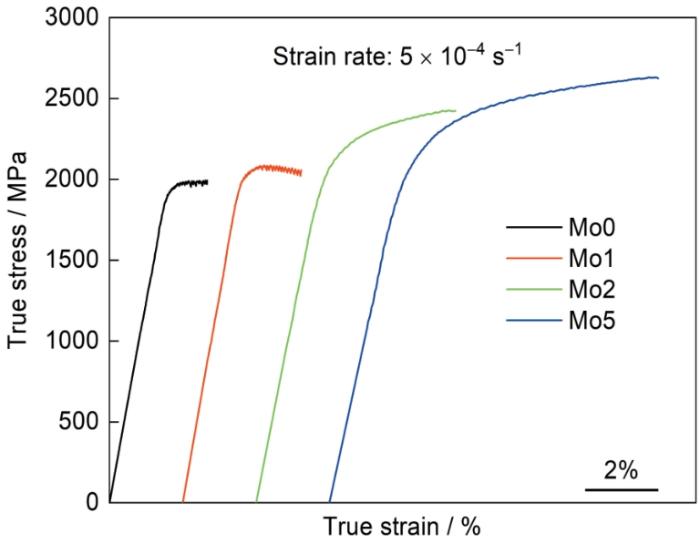

图4给出了不同Mo添加量样品的压缩真应力-真应变曲线,可见所有试样均表现出一定的塑性变形量,而Mo2和Mo5出现了明显的加工硬化现象。随着Mo含量的提高试样的断裂强度和塑性均随之提高。不含Mo的基体合金其断裂强度为1992 MPa,压缩塑性为1.2%;Mo1的断裂强度为2057 MPa,比基体提高了3.3%,塑性为1.7%,比基体有所提高;Mo2和Mo5的断裂强度分别为2422和2630 MPa,塑性分别为3.9%和7.3%,强度比基体分别提高了21.6%和32.0%,塑性比基体分别提高了2.25倍和5.08倍(表1)。上述结果表明,Ti基非晶基体中β-Ti相的析出显著提高了非晶复合材料的室温压缩性能,且β-Ti相的体积分数越高其增强效果越显著。

图4

图4

不同Mo含量试样的室温压缩真应力-应变曲线

Fig.4

Room temperature compression true stress-strain curves for specimens with different Mo contents

表1 不同Mo含量的Ti基非晶复合材料的杨氏模量E、断裂强度σf、屈服强度σy、断裂应变εf、屈服应变εp和加工硬化指数n

Table 1

| Sample | E / GPa | σf / MPa | σy / MPa | εf / % | εp / % | n |

|---|---|---|---|---|---|---|

| Mo0 | 122 | 1992 | 1850 | 2.7 | 1.2 | - |

| Mo1 | 128 | 2057 | 1912 | 3.2 | 1.7 | - |

| Mo2 | 113 | 2422 | 1818 | 5.5 | 3.9 | 0.14 |

| Mo5 | 105 | 2630 | 1772 | 9.0 | 7.3 | 0.20 |

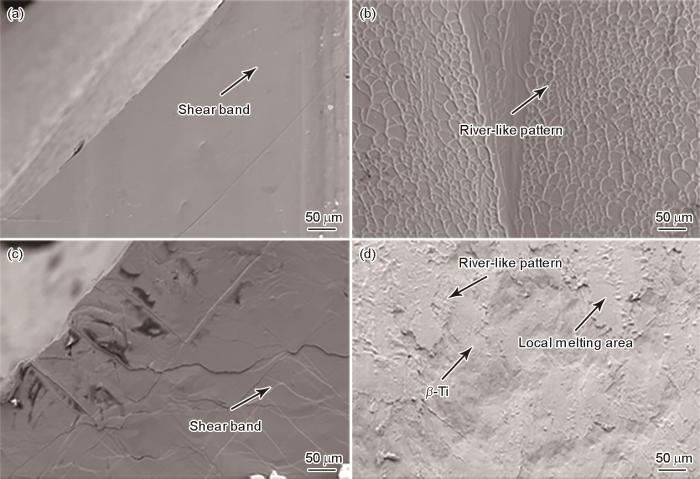

非晶复合材料在室温加载时其中的韧性第二相先屈服变形,随着应力的增大基体中的剪切带形核并扩展[15]。基体中的剪切带在扩展过程中可能绕过韧性相产生分枝或在与第二相的界面停止扩展,也可能在界面增殖生成二次剪切带,最终形成多重剪切带[16]。每条剪切带对应部分塑性变形量,多重剪切带的生成使复合材料的塑性提高,避免了基体内部高度局域化的剪切带失稳转变为剪切带而发生脆性断裂[17]。为了进一步探究不同Mo添加量非晶复合材料的变形机理,对比了Mo0和Mo5试样的压缩断口SEM照片(图5)。图5a、b给出了Mo0试样的断口SEM图像。可以看出,在试样侧面产生了与断面平行的剪切带,但是数量较少,且断面呈非晶合金典型的河流状花样[18]。图5c、d给出了Mo5试样的断口SEM图像,可见比Mo0断裂后侧面产生的剪切带更为明显、数量更多,还产生了大量垂直于断裂方向的二次剪切带。这表明,在变形过程中剪切带的扩展受到原位β-Ti相的阻碍而发生偏转或增殖。Mo5断面不仅呈现出非晶合金经典的河流状花样,还存在大片局部熔化区与β-Ti相,表明剪切带与第二相发生了强烈的交互作用。在非晶复合材料中存在一种特征值,称为加工区域尺寸(Processing zone)[19]。复合组织中第二相的尺寸和相间距越接近此加工区域的尺寸,复合材料的力学性能越优异,这与基体内裂纹前端的张开位移有关。研究表明,Ti基非晶的加工区域尺寸约为20 μm[19]。上述组织分析已给出Mo5中第二相的平均尺寸约为15 μm,体积含量约为20%,由λ = d

图5

图5

不同Mo含量Ti基非晶复合材料的压缩断口及其侧面SEM图像

Fig.5

Compression fractures of the samples with different Mo contents and their lateral SEM images (a, b) Mo0; (c, d) Mo5

3 结论

(1) Mo元素添加量(原子分数)较低(≤ 1%)的Ti40Zr10Cu36Pd14非晶合金,仍为纯非晶合金;在Mo元素添加量≥ 2%的合金中析出均匀分散的细小原位β-Ti相,成为原位塑性β-Ti相增强的Ti基非晶复合材料。

(2) 随着Mo含量的提高β-Ti相的体积分数提高和平均尺寸增大,得到的复合材料的模量逐渐降低,强度和塑性提高。

(3) 在复合材料的变形过程中塑性β-Ti相能阻碍剪切带的快速扩展,使剪切带发生增殖和偏转,生成多重剪切带,提高了材料的室温塑性;同时,β-Ti相的平均尺寸和相间距与基体的加工区域尺寸匹配,增强了第二相与基体间的交互作用,提高了剪切带的稳定性。在复合材料的变形过程中作为塑性相的β-Ti发生形变使其发生明显的加工硬化。

参考文献

Progress and prospect of solidification research for metallic materials

[J].

金属材料凝固过程研究现状与未来展望

[J].

Glass-forming ability and mechanical properties for Mg-Zn-Ca alloys

[J].

Mg-Zn-Ca合金的非晶形成能力及力学性能

[J].

Stress-strain behavior of porous Ni-Ti shape memory intermetallics synthesized from powder sintering

[J].

Porous Ti-based bulk metallic glass with excellent mechanical properties and good biocompatibility

[J].

Stability, phase transformation and deformation behavior of Ti-base metallic glass and composites

[J].

Bioactive titanate nanomesh layer on the Ti-based bulk metallic glass by hydrothermal-electrochemical technique

[J].Titanate nanomesh layers were fabricated on Ti-based bulk metallic glass (BMG) to induce bioactivity in the form of apatite-forming ability. Titanate nanomesh layers were prepared by hydrothermal-electrochemical treatment at 90 degrees C for 2 h, with an aqueous solution of NaOH as an electrolyte. A constant electric current of 0.5 mA cm(-2) was applied between the BMG substrate and a Pt electrode acting as the anode and cathode, respectively. A nanomesh layer, consisting of nanowires (approximately 20 nm in diameter) formed on the BMG. An immersion test in simulated body fluid for 12 days revealed that the titanate nanomesh layer on the BMG promoted the growth of bone-like hydroxyapatite.

Biocompatibility of new titanium alloy TZNT for surgical implant application

[J].

新型外科植入用钛合金TZNT的生物相容性

[J].

New TiZrCuPd quaternary bulk glassy alloys with potential of biomedical applications

[J].

Atomic force microscope nanoindentation behavior of shear bands of bulk metallic glasses

[J].

块体非晶合金剪切带的原子力纳米压痕行为

[J].

Compressive plasticity and toughness of a Ti-based bulk metallic glass

[J].

Nano- to submicro-porous β-Ti alloy prepared from dealloying in a metallic melt

[J].

Towards an understanding of tensile deformation in Ti-based bulk metallic glass matrix composites with BCC dendrites

[J].The microstructure and tension ductility of a series of Ti-based bulk metallic glass matrix composite (BMGMC) is investigated by changing content of the β stabilizing element vanadium while holding the volume fraction of dendritic phase constant. The ability to change only one variable in these novel composites has previously been difficult, leading to uninvestigated areas regarding how composition affects properties. It is shown that the tension ductility can range from near zero percent to over ten percent simply by changing the amount of vanadium in the dendritic phase. This approach may prove useful for the future development of these alloys, which have largely been developed experimentally using trial and error.

Effects of Sn addition on mechanical properties of Ti-based bulk metallic glass composites

[J].

β-type Ti-based bulk metallic glass composites with tailored structural metastability

[J].

Understanding the shear band interaction in metallic glass

[J].

Micromechanisms of plastic deformation of a dendrite/Zr-based bulk-metallic-glass composite

[J].

Stabilization of metallic supercooled liquid and bulk amorphous alloys

[J].

The fracture of bulk metallic glasses

[J].

Fracture of brittle metallic glasses: Brittleness or plasticity

[J].

Microstructure and mechanical behavior of metallic glass fiber-reinforced Al alloy matrix composites

[J].Metallic glass-reinforced metal matrix composites are an emerging class of composite materials. The metallic nature and the high mechanical strength of the reinforcing phase offers unique possibilities for improving the engineering performance of composites. Understanding the structure at the amorphous/crystalline interfaces and the deformation behavior of these composites is of vital importance for their further development and potential application. In the present work, Zr-based metallic glass fibers have been introduced in Al7075 alloy (Al-Zn-Mg-Cu) matrices using spark plasma sintering (SPS) producing composites with low porosity. The addition of metallic glass reinforcements in the Al-based matrix significantly improves the mechanical behavior of the composites in compression. High-resolution TEM observations at the interface reveal the formation of a thin interdiffusion layer able to provide good bonding between the reinforcing phase and the Al-based matrix. The deformation behavior of the composites was studied, indicating that local plastic deformation occurred in the matrix near the glassy reinforcements followed by the initiation and propagation of cracks mainly through the matrix. The reinforcing phase is seen to inhibit the plastic deformation and retard the crack propagation. The findings offer new insights into the mechanical behavior of metal matrix composites reinforced with metallic glasses.