适当的制备方法、合理的热处理工艺和优化成分设计,是调控高速钢中一次碳化物的重要手段。Zhang等[6]采用双雾化喷射成型方法改善了T15高速钢中的元素偏析且借助热等静压的高温高压促进了一次碳化物分解,使其显著细化和球化,将T15高速钢的冲击韧性提高到27 J/cm2。陈年莲[1]用粉末冶金方法制备的T15高速钢中碳化物细小且均匀分布,最大扰度约为传统熔铸方法的4倍。Chaus等[7]研究发现,在1180~1260℃温度范围R6M5高速钢的淬火温度越高,其中的M2C一次碳化物的分解越彻底。Lima等[8]发现,将三次回火温度由540℃提高到560℃可促进MC一次碳化物的溶解和使其分布更均匀,大幅度提高了T15高速钢的弯曲强度。周雪峰等[9]在M2高速钢中添加Al元素促进了M2C共晶碳化物的形貌由纤维状转变成片状,提高了共晶碳化物的均匀性和热稳定性。Wang等[10]向喷射成型的M3∶2高速钢中添加1.95% (质量分数) Nb元素,在600℃时效处理中Nb元素促进了高密度、细小的M2C二次碳化物的析出和抑制了M3C的生长,使其硬度提高了70~90HV。

近年来,在高速钢中添加稀土元素调控组织和改善性能,受到了极大的关注[11~15]。杨文义等[16]研究了Ce元素对M42、M2、M3等高速钢碳化物组织形貌的影响,发现适当含量的Ce元素在碳化物中富集能显著细化MC碳化物或产生MC + M2C复合碳化物为主的高速钢组织。Zhou等[17]对M42高速钢进行稀土处理,使凝固过程中Ce元素在固液界面处偏聚,引起成分过冷致使M2C一次碳化物和奥氏体的生长速率差异增大,使M2C的形貌由层片状转变成颗粒状,在后续热加工过程中的分解和球化使M42硬度提高了1.5 HRC。吴中佳等[18]研究表明,添加少量Ce元素能促使高硼高速钢中的碳化物分布更加均匀并抑制有害的鱼骨状碳化物析出,显著改善了高硼高速钢冲击韧性和耐磨损性能。本文研究Ce元素对T15高速钢铸态组织和力学性能的影响,并揭示Ce元素改善一次碳化物和提高其力学性能的机制。

1 实验方法

用真空感应熔炼炉冶铸不添加Ce和添加Ce的T15高速钢实验铸锭,分别标记为T15A和T15Ce,其化学成分列于表1。

表1 T15高速钢的化学成分

Table 1

| Alloy | C | Si | Mn | P | S | Cr | Mo | W | Co | V | Ce | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T15A | 1.63 | 0.12 | 0.097 | 0.008 | 0.0016 | 4.22 | 0.2 | 12.14 | 4.83 | 5.39 | 0 | Bal. |

| T15Ce | 1.58 | 0.13 | 0.052 | 0.008 | 0.0010 | 4.25 | 0.21 | 12.11 | 4.82 | 5.45 | 0.021 | Bal. |

从T15高速钢铸锭的中心区域用电火花线切割尺寸为10 mm × 10 mm × 7 mm的金相试样,将其研磨抛光后用4%硝酸酒精溶液腐蚀,用光学显微镜(OM;Axio Lab A1,Zeiss)和扫描电子显微镜(SEM;Apreo 2 C,Thermoscientific)观察显微组织。用SEM配备的能谱仪(EDS;Ultim Max,Oxford)分析一次碳化物的元素组成。为了提高准确度,测试一次碳化物的成分取自至少10次EDS点,取其结果的平均值。用扫描电子显微镜配备的电子背散射衍射(EBSD;Nano Oxford)分析一次碳化物。用机械抛光和精密离子刻蚀仪(Leica RES101)制备EBSD样品。使用Image pro软件测量统计二次枝晶间距和一次碳化物的尺寸,每个结果取自至少25个倍数一致的不同视场。用X射线衍射仪(Smart Lab 9k)分析T15高速钢铸态组织的类型及结构,使用MDI jade9软件分析数据以确定相组成和晶体参数。使用电子探针(EPMA;JXA-8530F PLUS)分析T15Ce的区域元素。

用电火花线切割从铸锭中切取尺寸为5 mm × 5 mm × 35 mm的条状样品和直径为11 mm的圆柱样品,分别加工成标准弯曲试样和M10-ϕ5圆棒标准拉伸试样。用洛氏硬度计测定硬度,最大载荷1500 N,保压时间5 s。按照GB/T 228.1A22标准用TSE 105D微机控制电子万能试验机进行室温拉伸实验。按YB/T 5349-2014标准用AG-I500KN电子万能试验机进行室温三点弯曲实验。用高真空超纳米力学试验仪(UNHT HTV)进行纳米压痕实验,最大载荷为30 mN,保持10 s,恒应力速率加载。以上测试均至少进行三次,取其结果的平均值。

2 实验结果

2.1 T15A和T15Ce铸态的金相组织

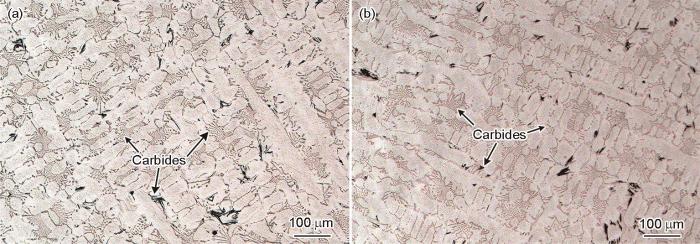

图1给出了T15A和T15Ce的铸态金相组织。可以看出,T15A铸态组织由枝晶组织和分布于枝晶间的共晶碳化物组成,枝晶组织的二次枝晶间距为(40.84±5.78) μm。T15Ce的铸态组织构成与T15A的相同,但是其二次枝晶间距为(37.91±4.03) μm,减小了2.93 μm。这表明,添加Ce元素有效细化了T15高速钢的枝晶组织。

图1

图1

两种不同Ce含量T15高速钢的金相组织

Fig.1

Optical microstructure of as-cast T15A (a) and T15Ce (b) HSSs

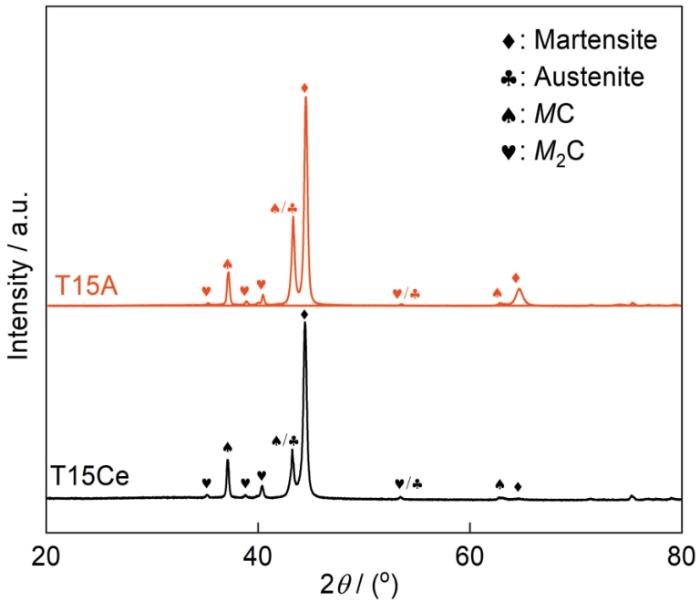

图2给出了两种不同Ce含量T15高速钢的X射线衍射谱。结果表明,T15A和T15Ce的铸态组织包括马氏体、少量残余奥氏体以及MC、M2C一次碳化物。在T15高速钢中添加Ce元素,并没有改变铸态组织的类型。

图2

图2

两种不同Ce含量T15高速钢的X射线衍射谱

Fig.2

X-ray diffraction patterns of as-cast structure of T15A and T15Ce HSSs

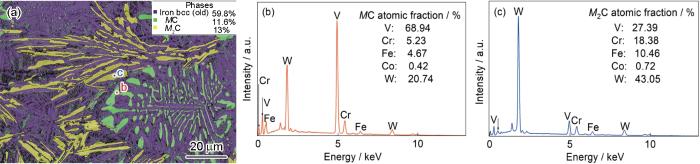

图3

图3

T15A中一次碳化物的EBSD相分布和EDS能谱

Fig.3

EBSD image (a) and EDS profiles (b, c) of primary carbides in T15A HSS

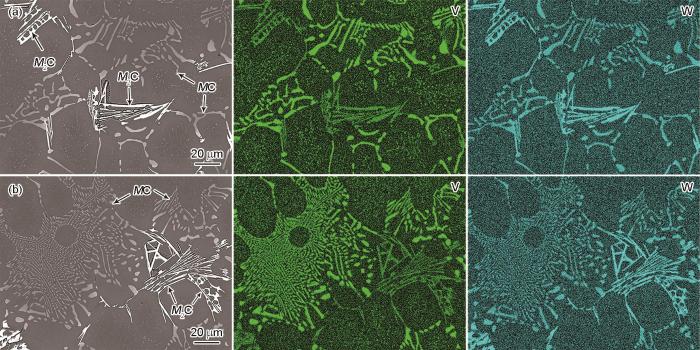

图4给出了T15A和T15Ce中一次碳化物的SEM-BSE (扫描电镜背散射)形貌和特征元素分布。图中两类一次碳化物的衬度不同,M2C为亮白色,MC为暗灰色。T15A铸态组织中的M2C呈现层片状和蜂窝状形貌,MC主要为粗大的条棒状形貌。T15Ce铸态组织中的M2C与T15A中的类似,呈现层片状和蜂窝状形貌;但是,MC的形貌发生了显著变化,主要为细密颗粒状形貌。这表明,添加Ce元素使T15高速钢铸态组织中两类一次碳化物的形貌发生了不同的变化,可能与两类一次碳化物的结构不同有关。

图4

图4

两种不同Ce含量T15高速钢中一次碳化物的SEM-BSE形貌照片和特征元素分布

Fig.4

SEM-BSE morphology and characteristic element mapping images of primary carbides in T15A (a) and T15Ce (b) HSSs

两种不同Ce含量T15高速钢中一次碳化物的特征参数,列于表2。可以看出,T15A中一次碳化物面积分数为15.50%,一次碳化物平均等效直径和最大尺寸分别为4.70 μm和120.20 μm。T15Ce中一次碳化物面积分数为13.88%,一次碳化物的平均等效直径和最大尺寸分别为2.91 μm和105.39 μm。添加Ce后,T15钢铸态组织中一次碳化物的面积分数减少1.62%,平均等效直径和最大尺寸分别减小1.79 μm和14.81 μm。同时,T15A高速中一次碳化物中MC和M2C的面积分数分别为79.82%、20.18%,MC的平均片层间距为3.65 μm;T15Ce高速钢的一次碳化物中MC和M2C的面积分数分别为72.96%、27.04%,MC的平均片层间距为 2.01 μm。这表明,添加Ce元素降低了T15高速钢铸态组织中一次碳化物的总体分数,也降低了一次碳化物的最大尺寸和平均尺寸,有效细化了一次碳化物。特别是,Ce元素的添加改变了MC和M2C两类一次碳化物的相对比例,提高了M2C的含量和显著减小了MC的片层间距。

表2 T15高速钢铸态组织中一次碳化物的特征参数

Table 2

| Alloy | fC / % | fMC / % | f | dMe / μm | dMa / μm | l / μm |

|---|---|---|---|---|---|---|

| T15A | 15.50 | 79.82 | 20.18 | 4.70 | 120.20 | 3.65 |

| T15Ce | 13.88 | 72.96 | 27.04 | 2.91 | 105.39 | 2.01 |

两种不同Ce含量T15高速钢中MC的EDS能谱分析结果,如表3所示。T15A铸态组织中MC的V原子分数为69.58%,Fe和Cr的原子分数分别为4.79%和5.05%。T15Ce铸态组织中MC的V原子百分比为63.42%,Fe和Cr的分别为9.29%和6.02%。由此可见,添加Ce元素使T15A铸态组织中MC元素组成发生变化,V的原子分数降低了6.16%,Fe和Cr的分别提高了4.50%和0.97%。

表3 MC一次碳化物的EDS能谱分析

Table 3

| Alloy | %, atom fraction | ||||

|---|---|---|---|---|---|

| V | Cr | Fe | Co | W | |

| T15A | 69.58±2.6 | 5.05±0.64 | 4.79±0.63 | 0.29±0.13 | 20.31±2.03 |

| T15Ce | 63.42±6.46 | 6.02±1.43 | 9.29±2.03 | 0.49±0.48 | 20.84±3.78 |

2.2 T15高速钢中Ce元素的分布

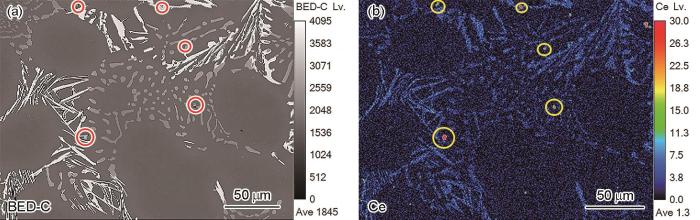

图5

图5

T15Ce高速钢中Ce元素的分布

Fig.5

SEM-BSE morphology (a) and element Ce mapping images (b) of T15Ce HSS

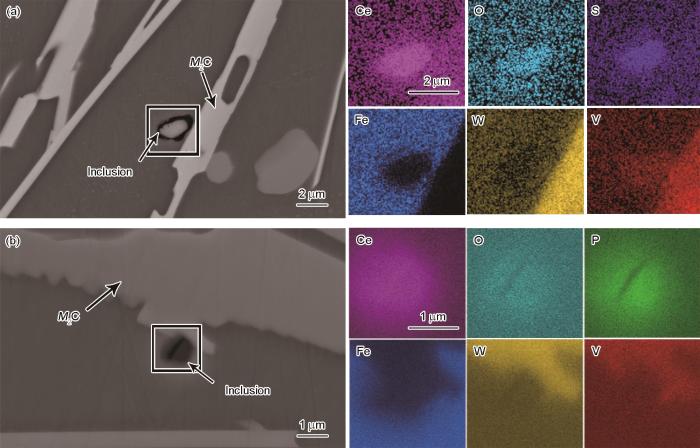

图6

图6

T15Ce高速钢中稀土夹杂物SEM-BSE的形貌和元素分布

Fig.6

SEM-BSE morphology and elements mapping images of Ce-O-S (a) and Ce-O-P (b) in T15Ce HSS

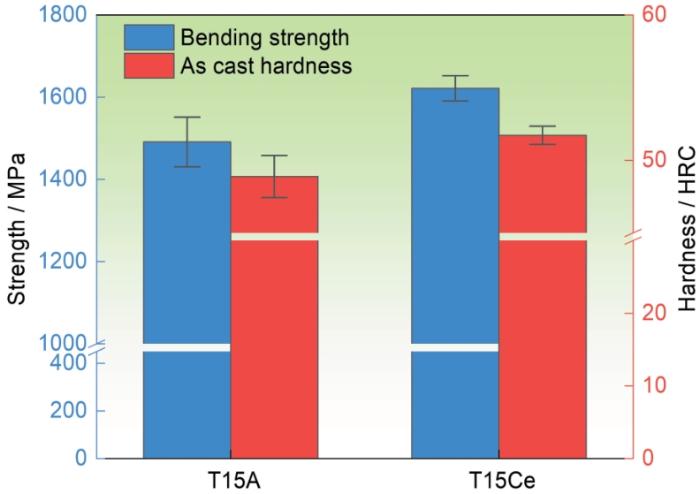

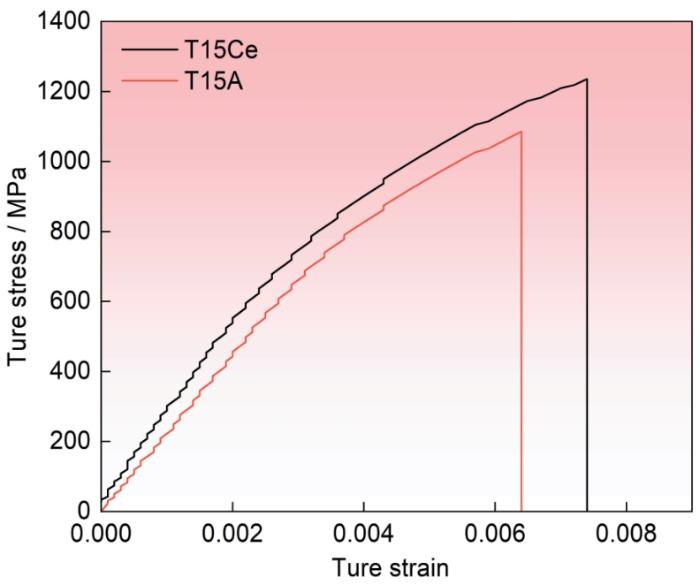

2.3 T15A高速钢的力学性能

图7给出了两种高速钢铸态的硬度和抗弯强度的比较。结果表明,T15A高速钢铸态的洛氏硬度为48.88 HRC,抗弯强度为1491.06 MPa;T15Ce高速钢铸态时的硬度为51.72 HRC,抗弯强度为1621.58 MPa,分别比T15A提高了2.84 HRC和130.52 MPa。图8给出了两种高速钢铸态的室温拉伸应力应变曲线。可以看出,铸态T15高速钢没有明显的屈服阶段,T15A的拉伸断裂应变为0.0064,抗拉强度为1122.41 MPa;T15Ce的拉伸断裂应变为0.0075,抗拉强度为1181.83 MPa,分别比T15A提高了17.18%和5.29%。图9给出了两种高速钢铸态的拉伸断口形貌。可以看出,T15高速钢铸态拉伸试样的断裂方式均为脆性断裂,断口的宏观形貌较为平整均匀,微观形貌为解离台阶组成的“河流花样”,硬脆的一次碳化物在拉伸过程中破裂,作为裂纹源形成了平滑解理面。这表明,添加Ce元素提高了T15高速钢铸态时的力学性能。

图7

图7

两种不同Ce含量T15高速钢的硬度和抗弯强度

Fig.7

Bending strength and hardness of T15A and T15Ce HSSs

图8

图9

图9

两种不同Ce含量T15高速钢铸态的拉伸断口形貌

Fig.9

Morphology of tensile fracture of T15A (a, c) and T15Ce (b, d) HSSs

3 讨论

3.1 Ce对一次碳化物的影响

从图6可见,紧邻稀土夹杂物的M2C有生长台阶。这表明,稀土夹杂物很有可能作为一次碳化物的非均匀形核质点促进了M2C的析出[17]。当夹杂物与碳化物的晶体类型和晶格常数接近,错配度数值越小越有利于非均匀形核[20]。表4和表5分别列出了两类一次碳化物、稀土夹杂物的晶体学参数和稀土夹杂物与两类一次碳化物错配度的计算结果。结果表明,Ce2O3//MC和Ce2O2S//MC错配度分别为3.35%和10.25%,Ce2O3//M2C和Ce2O2S//M2C的错配度分别为7.82%、11.84%,均小于12%。由此可见,稀土夹杂物可以作为基底提供有效形核质点,促进两类一次碳化物的非均匀形核,从而有利于细化一次碳化物。同时,添加Ce元素明显提高了T15高速钢铸态组织中M2C一次碳化物的比例,比不添加Ce元素提高了6.86%。这个结果,可能与较小尺寸的含P稀土夹杂物促进M2C碳化物形核相关[12]。

表4 两类一次碳化物和稀土夹杂物的晶体学参数

Table 4

| Phase | Lattice structure | Space group | Lattice parameter |

|---|---|---|---|

| M2C | Hexagonal | P63/mmc | a = 2.955, c = 4.650 |

| MC | Cubic | Fm | a = 4.180 |

| Ce2O2S | Hexagonal | P | a = 3.976, c = 6.882 |

| Ce2O3 | Hexagonal | P | a = 3.891, c = 6.059 |

表5 碳化物和稀土夹杂物的最小错配度

Table 5

| [uvw]s | [uvw]n | d[uvw]s | d[uvw]n | θ / (°) | δ / % | |

|---|---|---|---|---|---|---|

| (1010)Ce2O3//(0110)M2C | 3.891 | 4.650 | 0 | 7.82 | ||

| 7.201 | 7.520 | 5.273 | ||||

| 6.059 | 5.910 | 0 | ||||

| (1010)Ce2O2S//(0110)M2C | 3.976 | 4.650 | 0 | 11.84 | ||

| 7.947 | 7.520 | 8.178 | ||||

| 6.882 | 5.910 | 0 | ||||

| (1010)Ce2O3//(110)MC | 3.891 | 4.180 | 0 | 3.35 | ||

| 6.059 | 5.911 | 0 | ||||

| 7.201 | 7.240 | 2.340 | ||||

| (0001)Ce2O2S//(110)MC | 3.976 | 4.180 | 0 | 10.25 | ||

| 6.886 | 5.911 | 0 | ||||

| 7.952 | 7.240 | 5.266 |

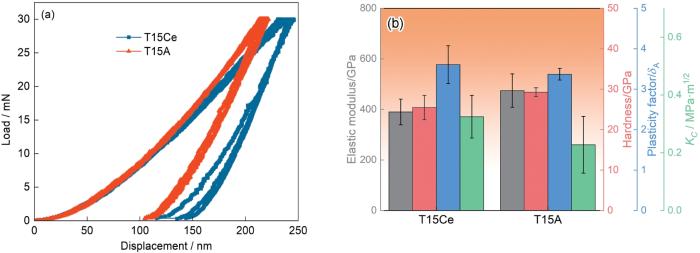

图10给出了T15A和T15Ce铸态组织中MC的纳米压痕测量结果。结果表明,T15A中MC的弹性模量和硬度分别为474.57 GPa和29.28 GPa,T15Ce中MC的弹性模量和硬度分别为390.02 GPa和25.46 GPa。根据图10a中MC的纳米压痕P-H曲线并结合压痕形貌,可以得到MC的塑性因子(δA)和断裂韧性(KC)。结果表明,T15A中MC的塑性因子为0.47,断裂韧性为1.63 MPa·m1/2;T15Ce中MC塑性因子为0.50,断裂韧性为2.32 MPa·m1/2 [13,21]。由此可见,添加Ce元素使T15高速钢铸态组织中MC的性能参数发生了显著变化,弹性模量和硬度分别降低了84.55 GPa和3.81 GPa,塑性因子和断裂韧性分别提高了0.03和0.69 MPa·m1/2。这表明,添加Ce元素在一定程度上软化了MC,但是提高了MC的塑性和韧性。

图10

图10

两种不同Ce含量T15高速钢中MC碳化物的纳米压痕测量结果

Fig.10

P-H curves (a) and hardness, elastic modulus, plasticity factor and fracture toughness (b) of MC carbides in T15A and T15Ce HSSs by nanoindentation

3.2 Ce对力学性能的影响

添加质量分数为0.021%Ce的T15高速钢铸态,其硬度、抗弯强度和抗拉强度分别提高了2.84 HRC、130.52 MPa和59.42 MPa。虽然添加Ce元素并未改变T15高速钢铸态组织类型,但是减小了二次枝晶间距和一次碳化物尺寸,使铸态组织显著细化、提高了强度、塑性和韧性。而且,添加Ce元素使T15高速钢铸态组织中一次碳化物的含量降低了1.62%和MC中V元素减少了6.16%,使基体中有更多的W、V、C等元素固溶,增强了固溶强化[22]。同时,一次碳化物含量的降低和形貌的改善,特别是MC塑韧性的提高,降低了受力时材料内部的应力集中,抑制了裂纹萌生和高速扩展倾向[24, 25]。由此可见,添加Ce元素显著提高了T15高速钢铸态的力学性能。

4 结论

(1) T15高速钢铸态中的Ce元素主要富集在稀土夹杂物颗粒中,少量的分布在一次碳化物中。添加Ce元素并未改变T15高速钢铸态组织类型,但是使其铸态组织明显细化。添加0.021%Ce的T15高速钢其铸态组织中的二次枝晶间距为37.91 μm,比不添加Ce时的40.84 μm减小了2.93 μm。

(2) 添加Ce元素促进了T15高速钢铸态组织中一次碳化物异质形核,降低了一次碳化物含量,显著细化了一次碳化物和改善MC碳化物的塑韧性。添加0.021%Ce的T15高速钢铸态组织中一次碳化物分数由15.50%降低至13.88%,平均等效直径和最大直径分别由4.70 μm、120.25 μm减小至2.91 μm、105.44 μm;MC碳化物的形貌由粗大条棒状变为细密颗粒状,V原子百分比减少6.16%,弹性模量和硬度分别降低84.55 GPa和3.81 GPa,塑性因子(δA)和断裂韧性(KC)分别提高0.03和0.69 MPa·m1/2。

(3) 添加Ce元素显著提高了T15高速钢铸态时的力学性能。添加0.021%Ce的T15高速钢其铸态硬度、抗弯强度和抗拉强度分别为51.72 HRC、1621.58 MPa和1181.83 MPa,比不添加Ce元素分别提高了2.84 HRC、130.52 MPa和59.42 MPa。

参考文献

Study of processing, microstructure and properties of T15 powder high speed steel

[D].

T15粉末高速钢制备及组织和性能研究

[D].

Investigation on rapidly solidified T15 high speed steel powders and its bulk material

[J].

快速凝固T15高速钢粉末及其材料的研究

[J].

In-situ study of microcrack initiation and propagation of M2 high speed steel

[J].

原位研究M2高速钢微裂纹的萌生和扩展

[J].使用扫描电子显微镜(SEM)内的原位加载台对M2高速钢进行了原位拉伸实验。结果表明:在M2高速钢的原位拉伸过程中,微裂纹主要在大尺寸共晶碳化物与基体的界面处萌生和扩展。与回火马氏体相比,裂纹更容易在残余奥氏体上萌生。碳化物的尺寸、形状和种类,对微裂纹的萌生和扩展也有重要的影响。减少块状残余奥氏体、一次共晶碳化物和MC碳化物的数量、减小碳化物的尺寸和改善碳化物形状,可减缓微裂纹的萌生和扩展。

Effects of vanadium and carbon on microstructures and abrasive wear resistance of high speed steel

[J].

Fatigue of cold-work tool steels: Effect of heat treatment and carbide morphology on fatigue crack formation, life, and fracture surface observations

[J].

Microstructure evolution and mechanical properties of T15 high speed steel prepared by twin-atomiser spray forming and thermo-mechanical processing

[J].

Effect of heat treatment on the structure of cast high-speed steel of type R6M5 modified with Tungsten additives

[J].

Effect of different tempering stages and temperatures on microstructure, tenacity and hardness of vacuum sintered HSS AISI T15

[R].

Effect of Aluminum on the solidification microstructure of M2 high speed steel

[J].The effect of aluminum on the solidification microstructure of M2 high speed steel, particularly the morphology and microstructure of eutectic carbides, has been investigated by OM, TEM, SEM, EBSD and XRD. The results show that the as-cast microstructure consists of dislocation martensite and M2C eutectic ledeburite. Excessive amount of aluminum, 1.2%, favors the formation of ferrite and needle-like carbides. After the addition of aluminum, eutectic carbides are distributed more homogeneously. Additionally, the morphology of M2C eutectic carbides transforms from the fibrous to the plate-like, and their microstructure also changes significantly. The plate-like M2C has crystal defects, such as micro-twins and stacking faults, and different growing orientation between adjacent plates whereas the fibrous carbides have few defects and single crystal orientation. Compared to fibrous carbides, the plate-like carbides are much difficult to get spheroidized at high temperature, which is unfavorable for carbide refinement. The ferrite, formed by adding excessive amount of aluminum, cannot be eliminated by ordinary heat treatments, decreasing remarkably the hardness of high speed steel after quenching.

Al对M2高速钢凝固组织的影响

[J].采用OM, TEM, SEM, EBSD, XRD等手段, 分析了不同Al加入量(0%, 0.6%, 1.2%)的M2高速钢的铸态组织, 研究了Al对高速钢凝固组织转变特别是共晶碳化物形貌和微观结构的影响规律. 结果表明, M2高速钢铸态组织主要由位错型马氏体和M<sub>2</sub>C共晶莱氏体组成. 过量Al (1.2%)促进大量铁素体和针状碳化物形成. Al提高了共晶碳化物的分布均匀性, 促进M<sub>2</sub>C形貌由纤维状转变为片状, 并使碳化物微观结构发生明显改变. 片状碳化物表面平行于(0002)晶面, 内部存在微孪晶、层错等缺陷, 片层之间具有不同的晶体取向, 而纤维状碳化物内部缺陷极少, 呈单晶取向. 与纤维状碳化物相比, 加Al后形成的片状碳化物高温加热时不易团球化, 对碳化物尺寸细化不利. 添加过量Al (1.2%)形成的铁素体无法通过常规热处理消除, 使高速钢淬火硬度显著降低.

Effect of Niobium on the secondary precipitates and tempering resistance of spray-formed M3:2 high-speed steel

[R].

Effect of Rare Earth elements on microstructure and hot workability of AISI T15 high speed steel

[J].

Effect of cerium on the primary carbides and inclusions in electroslag remelted M35 high speed steel

[J].

Influence mechanism of Y addition on microstructure, absorbability, mechanical properties of as-cast high speed steel

[J].

Evolutions of micro- and macrostructure by cerium treatment in as-cast AISI M42 high-speed steel

[J].

Segregation of S and P along grain boundary in high speed steels and cleaning action of RE elements

[J].The segregation of the impurities, e. g. S, P, along grain boundaries of as-cast structure and of austenite in the high speed steels as well as the cleaning action of RE elements have been studied by AES. It was found that the more S and P the steels contain, the more their segregation occurs. The segregation becomes remarkably improved by the addition of RE elements, and the enrichment of S at grain boundary goes so far as to vanish when the RE added up to 0.05-0.08%. Some discussion on the segregation and the cleaning action have been also made.

S, P在高速钢晶界上的偏聚与稀土元素的净化作用

[J].

Study on Rare Earth modification of carbides structure of high speed steel

[J].

高速钢碳化物组织稀土改性研究

[J].

Carbide refinement in M42 high speedsteel by rare earth metals and spheroidizing treatment

[J].

Effect of small amount of Ce addition on microstructure and mechanical properties of high-boron high speed steel

[J].

少量铈对高硼高速钢微观组织与力学性能的影响

[J].

Low-oxygen rare earth steels

[J].Rare earth (RE) addition to steels to produce RE steels has been widely applied when aiming to improve steel properties. However, RE steels have exhibited extremely variable mechanical performances, which has become a bottleneck in the past few decades for their production, utilization and related study. Here in this work, we discovered that the property variation of RE steels stems from the presence of oxygen-based inclusions. We proposed a dual low-oxygen technology, and keeping low levels of oxygen content in steel melts and particularly in the raw RE materials, which have long been ignored, to achieve impressively stable and favourable RE effects. The fatigue life is greatly improved by only parts-per-million-level RE addition, with a 40-fold improvement for the tension-compression fatigue life and a 40% enhancement of the rolling contact fatigue life. We find that RE appears to act by lowering the carbon diffusion rate and by retarding ferrite nucleation at the austenite grain boundaries. Our study reveals that only under very low-oxygen conditions can RE perform a vital role in purifying, modifying and micro-alloying steels, to improve the performance of RE steels.© 2022. The Author(s), under exclusive licence to Springer Nature Limited.

The effect of carbide and nitride additions on the het‐erogeneous nucleation behavior of liquid iron

[J].

Comparative measurement of indentation fracture-toughness with Berkovich and Vickers indenters

[J].

Effects of Rare Earth elements in solid solution on ferrite phase transformation and microstructures in steels

[D].

固溶稀土元素对钢中铁素体相变和显微组织的影响研究

[D].

Fracture toughness of carbides in tool steels evaluated by nanoindentation

[J].

Effects of Rare Earth elements on micro‐structure evolution and mechanical properties of 718H pre-hard‐ened mold steel

[J].

Investigation on mechanical properties of high speed steel roll material by nanoindentation

[J].