提高碳纤维复合材料电磁屏蔽性能的方法有:(1) 在碳纤维复合材料表面铺贴金属网[3,4]或金属箔[5],提高其表面电导率从而提高其对电磁波的反射能力。但是这种复合材料的比重大且容易发生分层脱落和电化学腐蚀。(2) 将功能性颗粒(如导电金属粉[6]、陶瓷颗粒[7,8]、碳黑[9,10]、碳纳米管[11~14]、石墨烯[15]、磁性粒子[16~18]等)填充到环氧树脂中制备复合材料,以同步提高其力学强度和电磁屏蔽性能。Zhang等将碳纳米管共混在环氧树脂中制备的碳纤维复合材料,其电磁屏蔽效能从37 dB提高到41 dB[11]。但是,功能性填料被树脂基体包裹难以形成连续的功能性网络和纳米填料易于团聚难以在树脂中均匀分散,极大地限制了电磁屏蔽性能的提高[19]。(3) 在环氧树脂基体中构筑连续的功能性网络结构。采用石墨烯泡沫或碳纳米管海绵作为电磁屏蔽功能层,使其在复合材料中形成连续导电通路并利用其多孔结构增强对电磁波的多重反射,从而提高其电磁屏蔽性能[20~22]。但是,用化学气相沉积或水热高温合成制备这种连续的网络结构,其工艺复杂和温度较高,难以实现规模化生产[23]。近年来,纳米材料的低温合成和自组装技术发展迅速。以碳纤维为基底在其表面原位生长碳纳米管[24]、石墨烯[25]、以及功能性粒子[14,26,27],可提高碳纤维导电/导热和电磁屏蔽等性能。Qiu等用磁性氧化石墨烯修饰碳纤维制备出混杂碳纤维复合材料,其电磁屏蔽效能达46.33 dB[25]。氧化锌(ZnO)是一种典型的半导体材料,具有优异的介电损耗、宽频率吸收且其形态结构可调控[28,29],作为新型吸波剂受到了极大的关注。Jiao等报道,采用原位生长方法将ZnO包覆在碳纤维表面,可提高碳纤维对电磁波的吸收能力[30]。但是,将ZnO包覆在碳纤维表面使碳纤维的电导率降低,难以构筑多层次的功能性网络结构,不利于复合材料电磁屏蔽性能的提高。基于此,本文在ZnO修饰的碳纤维表面原位沉积碳纳米管(CNT)使其成为CNT-ZnO混杂修饰的碳纤维,进而通过叠层铺设与树脂真空浸渍制备混杂复合材料,研究其组元、界面相互作用、微观结构、电导率以及电磁屏蔽性能。

1 实验方法

1.1 实验用材料

型号为T700的碳纤维(Carbon fiber,CF),正交编织布、六水合硝酸锌(Zn(NO3)2·6H2O,AR)、六亚甲基四胺(C6H12N4,99.5%)、二水合醋酸锌(Zn(CH3COO)2·2H2O)、聚乙烯亚胺(PEI,50%)、盐酸多巴胺(DA,98%)、异丙醇(C3H8O,98%)、无水乙醇(C2H6O,AR)、甲苯(C7H8,AR)、盐酸(HCl,38%)、三羟甲基氨基甲烷(C4H11NO3,98%)、二茂铁(Fe(C5H5)2,98%)、环氧树脂(EP,IN-2)及其固化剂(AT-30)、噻吩(C4H4S,99.5%)、高纯乙烯、氢气和氩气。

1.2 用氧化锌纳米线修饰碳纤维表面

将碳纤维布在400℃的马弗炉中热处理1 h,然后转移至丙酮溶液中浸泡12 h以去除碳纤维表面上浆剂。将0.8 g盐酸多巴胺加到300 mL三羟甲基氨基甲烷(10 mmol/L,pH 8.5)和100 mL无水乙醇的混合溶液中,搅拌均匀配制成多巴胺混合溶液。将去除上浆剂的CF浸入多巴胺混合溶液中,在常温下反应10 h使多巴胺在碳纤维表面发生聚合反应,将产物水洗干燥后得到聚多巴胺接枝修饰的碳纤维(PDA-CF)。将其加到由2.2 g二水合乙酸锌与500 mL异丙醇混合配制的ZnO种晶溶液中,在常温下静置后在150℃退火以使ZnO种晶析出,重复3次得到ZnO种晶层充分包覆的碳纤维(ZnO seed-CF)。将0.05 mol/L六水合硝酸锌和0.05 mol/L六亚甲基四胺水溶液均匀混合,滴加聚乙烯亚胺(PEI)溶液调节混合溶液的pH值至7~8,得到ZnO生长溶液。将ZnO种晶包覆的CF加到ZnO生长溶液中在90℃反应6 h,ZnO颗粒在碳纤维表面不断析出生长成ZnO纳米线。将其用去离子水反复冲洗后在60℃干燥,得到表面生长ZnO纳米线的碳纤维(ZnO-CF)。用称重法测量出ZnO与CF的质量比为2.6∶97.4。

1.3 碳纳米管-氧化锌-碳纤维复合功能层的制备

用浮动催化化学气相沉积法(FCCVD)制备单壁碳纳米管[31]。将0.25 g二茂铁(催化剂前驱体)、0.07 g噻吩(生长促进剂)和9.1 g甲苯(液相碳源)混合配制成催化剂前驱体溶液。将前驱体溶液在氩气气氛下升温至1100℃,将气流切换至7000 sccm氢气和8.25 sccm乙烯,分别作为载流气体与碳源,用注射泵以0.6 mL/h的速率向管式炉中注入催化剂前驱体溶液使碳纳米管生长。将ZnO修饰的碳纤维布固定在不锈钢滤网上,然后放置在管式炉的尾气端收集CNT,将其过滤沉积30 min后得到表面沉积CNT的ZnO修饰碳纤维(CNT-ZnO-CF)。CNT是单壁碳纳米管,管径为1.2~2.7 nm(平均直径为1.9 nm)。CNT单壁碳纳米管彼此间聚集成束。CNT-ZnO-CF各组元的质量比为0.3∶2.6∶97.1。

1.4 碳纳米管-氧化锌-碳纤维/环氧树脂混杂复合材料的制备

将CNT-ZnO-CF功能层铺设堆叠,用真空辅助树脂传递模塑成型工艺(VARTM)灌注环氧树脂(树脂与固化剂质量比为10∶3),将其在常温下固化24 h后在60℃后固化4 h,制备出厚度为2 mm的碳纳米管-氧化锌-碳纤维/环氧树脂叠层混杂复合材料(CNT-ZnO-CF/EP)。为了比较,分别制备出碳纤维/环氧树脂(CF/EP)与氧化锌-碳纤维/环氧树脂(ZnO-CF/EP)复合材料。表1列出了复合材料的组元成分比例和密度。

表1 复合材料组元的含量和密度

Table 1

| Sample | CNT / % | ZnO / % | CF / % | EP / % | Density / g·cm-3 |

|---|---|---|---|---|---|

| CF/EP | - | - | 50.0 | 50.0 | 1.356 |

| ZnO-CF/EP | - | 1.5 | 50.6 | 47.9 | 1.363 |

| CNT-ZnO-CF/EP | 0.2 | 1.4 | 52.0 | 46.4 | 1.368 |

1.5 结构和性能表征

用光学显微镜(Eclipse LV100D,Nikon)和场发射扫描电子显微镜(SEM,Verios G4 UC,Thermo Scientific)观察碳纤维及其复合材料的微观形貌。用傅里叶变换红外光谱仪(FTIR,Bruker Tensor 27)定性分析CF表面修饰前后官能团的变化,扫描范围为400~4000 cm-1。用拉曼光谱仪(Raman,Jobin Yvon LabRAM HR800)表征CF表面生长ZnO与沉积CNT后的微观结构,激发波长为532 nm。用X射线衍射仪(XRD,Rigaku D/Max-2400)表征CF表面生长的ZnO纳米线的结构,衍射角为10°~80°。在氮气气氛下进行热重分析(TGA,STA 449C)以测定ZnO-CF的组元含量。用密度天平(XS204,METLER TOLEDO)测量复合材料的密度。

用四探针(RTS-9)法测量CF、CNT、ZnO-CF和CNT-ZnO-CF的表面电阻(Rs,Ω),其表面电导率(σs,S/m)为

式中S为复合材料截面积(m2);L为两电极之间的距离(m)。

参照国家标准GB/T 35679-2017测试复合材料的电磁性能。用矢量网络分析仪(Agilent N5230A PNA)和电磁性能软件(Agilent 85071)测试复合材料(尺寸为22.86 mm × 10.16 mm × 2 mm)在8.2~12.4 GHz(X波段)的散射参数(S11和S21)和介电常数(ε′和ε″),并根据

计算电磁屏蔽效能SE[33]。式中R、A和T分别为反射系数、吸收系数和透射系数,SER、SEA、SET分别为复合材料的反射、吸收和总电磁屏蔽效能。试样的损耗角正切值为

式中ε′为介电常数实部,反映材料在电磁波作用下产生极化的程度,与材料储存电荷的能力有关;ε″为介电常数虚部,反映材料在反复极化过程中对电磁波电场分量的损耗大小;tanδ为损耗角正切值,表征材料在施加电场后其介电损耗的能力。

2 结果和讨论

2.1 CNT-ZnO-CF/EP复合材料的制备

图1为CNT-ZnO-CF/EP叠层混杂复合材料的制备流程。为了制备出具有高效电磁屏蔽特性的碳纤维复合材料,在碳纤维表面通过聚多巴胺修饰、ZnO种晶层析出和ZnO纳米线原位生长,得到具有针状结构的ZnO包覆的碳纤维,以提高碳纤维的介电吸收损耗性能。为了进一步提高复合体系的导电性(增强电阻损耗与多重反射),用浮动催化剂化学气相沉积法(FCCVD)在ZnO-CF表面沉积CNT薄膜,形成多组元相互连通的功能性复合网络结构。进而将其进行叠层铺设、采用真空辅助树脂传递成型(VARTM)工艺浸渍环氧树脂,制备出CNT-ZnO-CF/EP叠层混杂复合材料。

图1

图1

CNT-ZnO-CF/EP叠层混杂复合材料的制备流程

Fig.1

Schematic diagram for fabrication of CNT-ZnO-CF/EP laminated hybrid composites

通过引入具有高效介电损耗的ZnO纳米线和高导电CNT功能层和构筑相互连通的功能性网络,使电磁波在复合材料内部形成多重反射与高效吸收损耗,以提高传统碳纤维/环氧树脂复合材料的电磁屏蔽性能。

2.2 ZnO-CF的形貌和微观结构

ZnO是一种典型的半导体材料,具有优异的介电损耗特性。将ZnO加到复合材料中可提高材料的电磁屏蔽性能,其微观形貌及与碳纤维的界面结合也影响复合材料的力学和功能特性[34]。图2给出了CF的表面处理、ZnO纳米线的制备流程和微观形貌。从图2a可见,通过引入聚多巴胺对碳纤维表面改性,在提高CF表面粗糙度的同时还能提高碳纤维的亲水性能。表面的邻苯二酚和亚氨基等官能团能对种晶溶液中的Zn2+形成较强的螯合作用[35],使在退火过程中生成的ZnO种晶层与碳纤维之间形成牢固结合,经水热合成得到ZnO纳米线均匀致密包覆的碳纤维。从图2b~e的扫描电镜照片可见,处理后初始表面光滑的碳纤维,逐渐被生成的聚合物、种晶颗粒以及ZnO纳米线所包覆,得到的ZnO纳米线直径为80~100 nm,长度约为1 μm。这种ZnO针状凸起的形貌比其它形貌(如球形、片状等)有更为复杂的界面,更易于产生较强的空间电荷极化效应(界面极化),从而具有优异的介电损耗性能[36,37]。图2f~i给出了碳纤维表面处理前后的红外光谱、拉曼光谱、XRD以及热失重曲线。从红外光谱可见,与CF相比ZnO-CF的谱中出现了新的特征吸收峰,表明CF表面修饰后新生成了-NH、-OH、-C-O、-Zn-O基团[35,38]。同时,与聚多巴胺修饰的CF(PDA-CF)相比ZnO-CF谱中的特征吸收峰均发生了一定的偏移,表明ZnO与聚多巴胺之间有较强的配位相互作用[35]。在ZnO-CF拉曼光谱的326、431和1136 cm-1处出现了新的特征峰,对应ZnO的多声子振动[39]。ZnO XRD谱中特征衍射吸收峰对应典型的六方晶系纤锌矿结构[39]。根据热失重分析,ZnO与CF的质量比约为3∶97,与称重法得到的数据基本一致。综上所述,通过表面修饰与原位生长可制备出高质量ZnO纳米线紧密包覆的碳纤维,有望显著提升相应复合材料的介电损耗与电磁屏蔽性能。

图2

图2

ZnO-CF的制备过程示意图、CF、PDA-CF、ZnO seed-CF和ZnO-CF的SEM照片、改性碳纤维的红外光谱、拉曼光谱、XRD谱以及热失重曲线

Fig.2

Schematic diagram for fabrication of ZnO-CF (a), SEM images of CF (b), PDA-CF (c), ZnO seed-CF (d), and ZnO-CF (e), FTIR spectra (f), Raman spectra (g), XRD patterns (h), and TGA curves of the modified CF (i)

2.3 CNT-ZnO-CF复合功能层的形貌和结构

为了提高ZnO-CF的导电性以提高电磁反射屏蔽性能,引入高导电的CNT作为反射功能层,将用FCCVD法生长的单壁CNT在载流气氛下通过ZnO-CF织物孔隙进行原位收集(图3a),避免了大长径比和高比表面积所致的CNT团聚缠结、难以实现高效分散,从而使高导电的CNT在ZnO-CF表面的均匀沉积(图3b)。从图3c可见,CNT均匀分布且相互搭接形成多层次孔隙结构的连续导电网络(CNT薄膜的厚度约为25 μm)。这种混杂的多孔网络结构有助于树脂的浸渍成型,高导电的网络结构有助于实现电子的高效传递从而提高复合材料对电磁波的电阻损耗与多重反射损耗[20]。从图3d可见,CNT的谱中有明显的G峰吸收(对应石墨片层的sp2结构),其IG/ID值高达73.74,表明用FCCVD法原位生长的CNT膜具有较高的结构完整性和较少的缺陷,其电导率可达11100 S/m。这种高导电的网络结构改善了树脂浸渍性,有助于实现电子的高效传递从而提高复合材料对电磁波的电阻损耗与多重反射损耗。另一方面,多孔CNT薄膜与针状ZnO纳米线之间的相互啮合锚接,进一步提高了复合体系的介电损耗能力[40]。同时,这种组元间的强相互作用有利于应力的高效传递[41],和实现复合材料的结构/功能一体化。

图3

图3

用FCCVD法在ZnO-CF表面沉积CNT的装置示意图、CF表面沉积ZnO与CNT薄膜后的光学照片、CNT薄膜的SEM照片和拉曼光谱

Fig.3

Schematic diagram for preparation of CNT-ZnO-CF through FCCVD method (a), Optical images of CNT-ZnO-CF (b), SEM image (c) and Raman spectrum of CNT deposited onto ZnO-CF (d)

2.4 叠层混杂复合材料的微观结构

图4给出了叠层混杂复合材料的截面光学照片和脆断扫描电镜照片。从图4a~c可见,用VARTM工艺可使环氧树脂充分浸润碳纤维并形成完整的复合结构。单束碳纤维的厚度约为200 μm,表面生长的ZnO纳米线与沉积CNT薄膜的厚度分别为1 μm和25 μm。组元间彼此相互堆叠且连通贯穿形成多孔网状结构,从而使环氧树脂充分浸渍。图4d-f给出了复合材料在液氮中脆断后的SEM照片,可见与传统的碳纤维与环氧树脂之间的界面脆性断裂形貌(图4d)相比,引入ZnO纳米线与CNT薄膜使混杂复合材料表现出粗糙的断裂表面形貌,清晰可见ZnO与CNT在界面处的断裂拔出,表现为复合材料由脆性断裂向韧性断裂的转变[41]。这种CNT-ZnO-CF叠层结构使碳纤维具有高介电损耗与高效电磁屏蔽功能特性,还形成了较强的界面结合使复合材料保持轻质高强的力学特性。

图4

图4

CF/EP、ZnO-CF/EP、CNT-ZnO-CF/EP复合材料的光学照片以及CF/EP、ZnO-CF/EP和CNT-ZnO-CF/EP复合材料脆断面的SEM照片

Fig.4

Optical images of CF/EP (a), ZnO-CF/EP (b), and CNT-ZnO-CF/EP composites (c) and SEM images of fracture surfaces of CF/EP (d), ZnO-CF/EP (e), and CNT-ZnO-CF/EP composites (f)

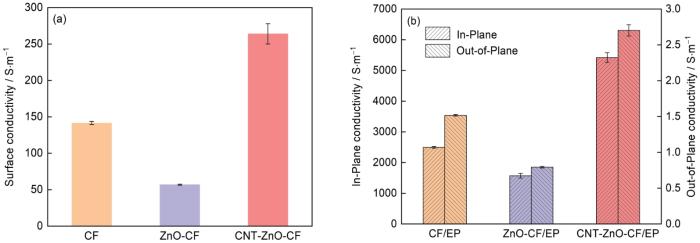

2.5 叠层混杂复合材料的导电性

图5给出了修饰前后碳纤维及其复合材料的导电性能。从图5a可见,初始CF的表面电导率为141.5 S/m,修饰ZnO纳米线后表面电导率有所降低(为56.9 S/m)。其原因是,典型的半导体材料ZnO包覆在碳纤维表面使其导电性降低。在其表面沉积CNT使电导率提高到266.5 S/m,因为高导电性的CNT形成相互连通的网络,有利于对电磁波的多重反射与损耗[20]。CNT-ZnO-CF的电导率仍比纯CNT薄膜的电导率(11100 S/m)低,其与组元成分、叠层结构、接触电阻、以及样品的厚度密切相关[32]。图5b给出了复合材料的面内与面外体积电导率,可见其面内电导率远高于面外电导率。其原因是,碳纤维与CNT膜在面内形成了连续的导电通路,而面外的层间树脂严重阻碍了电子的传输。从图5b可见,在CF表面生长ZnO和沉积CNT后,CNT-ZnO-CF/EP复合材料的面内电导率达到5414 S/m,远高于CF/EP复合材料的电导率(2495 S/m)。这表明,高导电CNT薄膜的引入可显著提高复合材料的电导率,增强对电磁波的电阻损耗和多重反射。CNT-ZnO-CF叠层结构使电磁波在层间的多重反射和ZnO纳米线的高效介电吸收损耗特性,显著提高了碳纤维复合材料电磁屏蔽性能。

图5

图5

CF、ZnO-CF和CNT-ZnO-CF的表面电导率和混杂复合材料的面内与面外体积电导率

Fig.5

Surface electrical conductivity of CF, ZnO-CF and CNT-ZnO-CF (a) and Volume electrical conductivity of laminated hybrid composites along in-plane and out-of-plane directions (b)

2.6 叠层混杂复合材料电磁屏蔽性能

图6给出了用波导法测试的复合材料在X波段(8.2~12.4 GHz)的电磁参数和计算出的电磁屏蔽效能。从图6a可见,修饰ZnO纳米线和沉积CNT薄膜后,CNT-ZnO-CF/EP复合材料的总电磁屏蔽效能(SET)高达50 dB,比CF/EP复合材料的33 dB提高了51.52%。这表明,在传统碳纤维复合材料中引入具有高介电损耗特性的ZnO纳米线和高导电的CNT薄膜,能显著提高其电磁屏蔽性能。进一步分析比较了复合材料的反射效能(SER)与吸收效能(SEA),从图6b可见,所有复合材料的SEA均远高于SER,表明碳纤维复合材料对电磁波的屏蔽以吸收损耗为主。其原因是,碳纤维的电导率仍远小于金属电导率,在其表面难以形成电磁涡流而发生高电磁波反射,电磁波在复合材料内主要通过组元间的多重反射和吸收实现能量衰减。与CF/EP相比,CNT-ZnO-CF/EP具有更高的SEA,表明对碳纤维的表面修饰可显著提高复合材料对电磁波的吸收能力。修饰ZnO纳米线后,复合材料的SEA由20 dB提高到32 dB。其原因是,ZnO纳米线是高效吸波剂,其在交变电场作用下的电偶极子极化和界面极化产生了较高的介电损耗[28]。进一步沉积CNT使复合材料的SEA提高到41 dB,因为CNT薄膜的引入有助于形成连续多孔的导电网络,增强了复合材料对电磁波的多重反射与吸收损耗。同时,CNT与ZnO的相互啮合锚接有助于形成“微电容”结构,易于在交变电场下发生诱导极化而产生显著的介电损耗。图6c中的吸收与反射系数曲线表明,CF经表面修饰是复合材料的反射系数降低、吸收系数增加,进一步表明叠层混杂复合材料比碳纤维复合材料具有更高效的电磁吸收特性。

图6

图6

复合材料的总电磁屏蔽效能、反射与吸收效能、反射与吸收系数、介电常数实部、介电常数虚部、损耗角正切值以及电磁屏蔽机理示意图

Fig.6

Total electromagnetic shielding effectiveness of laminated hybrid composites (a), reflection and absorption effectiveness (b), reflection and absorption coefficients (c) and real part (d), imaginary part (e), and loss angle tangent of dielectric constant for composites (f) and mechanism on electromagnetic shielding of laminated hybrid composites (g)

图6d、e分别给出了复合材料复介电常数的实部(ε′)和虚部(ε″)。ε′和ε″分别表征介电材料的电荷存储与引起电场能量损耗。可用损耗角正切值(tan δ,ε″/ε′)综合评价复合材料的介电损耗性能。从图6d可见,CF经表面修饰后ε′有所降低,因为CF表面被介电常数较低的ZnO纳米线包覆[30]。从图6e、f可见,混杂复合材料的ε″和tanδ比碳纤维复合材料明显增大,ZnO-CF/EP的tanδ从0.19提高到0.46。其原因是,ZnO纳米线优异的介电损耗特性以及其与CF形成异质结构使界面极化损耗增强[30]。经CNT薄膜沉积修饰后,复合材料的介电损耗性能进一步提高(tanδ平均值可达0.61)。其原因是,CNT导电网络增强了对电磁波多重反射与吸收损耗,形成的多组元间异质界面极化也有助于提高对电磁波的吸收损耗。图6g给出了叠层混杂复合材料的电磁屏蔽机理示意图。传统的碳纤维复合材料以电磁波在碳纤维层间的多重反射与吸收为主。表面原位生长ZnO纳米线引入了高介电损耗功能层,ZnO纳米线的阵列结构和丰富界面也增强了对电磁波的多重反射与吸收损耗。沉积高导电CNT薄膜提高了体系的导电性,引入的丰富网络结构也强化了电磁波在材料内部的多重反射损耗。同时,CNT、ZnO和CF间强相互作用形成的异质结构使界面极化损耗能力进一步提高,因此混杂复合材料具有更优异的电磁屏蔽性能。

碳纤维复合材料的电磁屏蔽效能显著依赖纤维含量、样品厚度以及频率范围等因素,因此选取初始屏蔽效能(25~45 dB)相近的碳纤维复合材料进行比较,重点考查改性前后的电磁屏蔽效能和提高幅度。本文制备的CNT-ZnO-CF/EP复合材料的电磁屏蔽效能为50 dB,与初始碳纤维复合材料的33 dB相比提高幅度为51.52%,高于文献报道的结果:碳纤维表面沉积MOF-CNT的复合材料为(34 dB,6%)[14]、树脂共混CNT体系为(41 dB,9.28%)[11]、碳纤维复合材料表面贴附商业铜网为(48.32 dB,21.50%)[4]。本文的结果,也高于部分磁性粒子修饰的复合体系。例如,Fe3O4@GO修饰碳纤维材料为(46.33 dB,26.80%)[25]、Co-CNT修饰碳纤维复合材料为(38.3 dB,42.30%)[42]、聚苯胺修饰碳纤维和CNT改性的芳纶纤维夹层复合材料为(34.43 dB,48.92%)[43]。

本文制备的CNT-ZnO-CF/EP混杂复合材料性能优异,主要归因于ZnO纳米线的高效介电损耗、连续CNT薄膜的高导电性以及混杂多组元之间的协同增强效应。

3 结论

(1) 在碳纤维表面原位生长ZnO纳米线、沉积高导电CNT薄膜以构筑兼具高介电损耗与高导电特性的连续混杂功能性网络,进而采用叠层堆积、真空辅助树脂成型,可制备具有高效电磁屏蔽性能的CNT-ZnO-CF/EP混杂复合材料。

(2) 厚度为2 mm的混杂复合材料,其在X波段的电磁屏蔽效能可达50 dB,比初始碳纤维复合材料提高了51.52%。

(3) 叠层混杂复合材料电磁屏蔽性能的显著提高,可归因于ZnO纳米线的高介电损耗、连续CNT膜的高导电性以及层间多组元界面的多重反射和高效吸收损耗。

参考文献

Recent advances in electromagnetic interference shielding properties of carbon-fibre-reinforced polymer composites—a topical review

[J].Using carbon-fibre-reinforced polymer (CFRP) composites for electromagnetic interference (EMI) shielding has become a rapidly emerging field. This state-of-the-art review summarises all the recent research advancements in the field of electromagnetic shielding properties of CFRP composites, with exclusive attention paid to experimental work. It focuses on (1) important mechanisms and physical phenomena in the shielding process for anisotropic carbon-fibre composites and (2) shielding performance of CFRP materials as reported in the literature, with important performance-affecting parameters. The key properties which directly influence the shielding performance are identified, the most critical being the carbon-fibre concentration along with length for discontinuous carbon-fibre-filled polymers and the lay-up for continuous carbon-fibre-reinforced composites. The effect of adding conductive inclusions such as metal or carbon nanotubes is also reviewed. It is emphasised that processing conditions are strongly linked with the shielding properties of a composite. This is a first review, which covers all the recent advancements in the field of shielding properties of carbon-fibre-reinforced composites, with detailed analysis of factors influencing these properties and clear distinction between continuous and discontinuous reinforcement. It is shown that CFRP composites make a good candidate as an EMI shielding enclosure material.

Effect of polypyrrole modified carbon fiber on interfacial property of composite PPy-carbon fiber/epoxy

[J].In order to improve the interfacial property of carbon fiber composites, the carbon fiber was pretreated by plasma technique and then coated with polypyrrole (PPy) by chemical oxidation polymerization of pyrrole. The surface modified carbon fiber and composite were characterized by SEM, AFM, XPS, FT-IR and IFSS. Results show that the interfacial shear strength of the modified single fiber increased by 259.3%, which may be ascribed to that the plasma pretreatment can increase the amount of polar groups on the surface of the carbon fiber, and facilitate the formation of hydrogen bonds between the carbon fiber and PPy, thus enhancing the interfacial property of the composite PPy-carbon fiber/epoxy.

聚吡咯修饰碳纤维/环氧树脂复合材料的界面剪切强度

[J].应用等离子体技术对碳纤维(CF)表面进行预处理,然后进行液相沉积聚吡咯处理。使用X射线光电子能谱仪、原子力显微镜(AFM)、扫描电子显微镜(SEM)和傅立叶红外光谱仪等手段对碳纤维表面形态和结构进行分析与表征,并进行单纤维界面剪切强度试验和SEM观测,研究了碳纤维复合材料的界面粘结性能。结果表明,等离子体预处理碳纤维沉积聚吡咯(PPy)使单纤维界面剪切强度提高了259.3%。分析结果表明,界面剪切强度的提高与纤维/树脂间的机械铆合和界面的作用力有关。等离子体预处理使碳纤维表面的羧基基团增多,在羧基和PPy之间形成氢键,从而提高了碳纤维复合材料的界面性能。

The preparation and performance study of carbon fiber/epoxy resin composites based on electromagnetic shielding properties strengthen

[J].

基于电磁屏蔽性能强化的碳纤维/环氧树脂复合材料的制备及性能研究

[J].

Nickel-coated nylon sandwich film for combination of lightning strike protection and electromagnetic interference shielding of CFRP composite

[J].

Preparation and performance evaluation of carbon fiber/epoxy composites modified with graphene prepregs

[J].Graphene/carbon fiber/epoxy composites were prepared by autoclave co-curing molding process with graphene prepregs as the functional layer, which were paved on the surface of carbon fiber perform. The effect of graphene prepregs on the internal quality, electromagnetic interference shielding performance and mechanical properties of the composites was investigated by ultrasound scanner, metallograph, four-probe instrument, vector network analyzer and electronic universal material testing machine. The results show that the internal quality of the graphene/carbon fiber/epoxy composites will not be influenced by the addition of graphene prepregs, and there are a good interfacial compatibility between graphene functional layer and carbon fiber structural layer. On this basis, graphene prepregs, which serves as the functional layer, taking advantage of excellent electrical conductivity, can improve the electromagnetic interference shielding performance of the corresponding composites rapidly. With only one layer of graphene prepreg (G105/3234), electromagnetic interference shielding efficiency of carbon fiber/epoxy composites is improved from 27.7 dB to 64.7 dB. Meanwhile, the obtained composites still maintain satisfactory mechanical properties.

石墨烯改性碳纤维树脂基复合材料的制备和性能评价

[J].

Mechanical and electromagnetic shielding properties of Al particle sandwich CFRP composites

[J].CFRP composites are widely used in aerospace due to their excellent mechanical properties, however, due to the anisotropy of the individual plies, the electro magnetic interference(EMI) shielding efficiency(SE) for vertically polarized waves of the unidirectional fiber laminates is poor. In order to protect electronics within these equipments from increasingly severe electromagnetic interference, it is particularly important to enhance the electromagnetic shielding efficiency of the CFRP. In this paper, Al particles were introduced and a conductive network was constructed in the CFRP interlaminar region by condensing the Al particles on the prepreg surface. The effects of different Al particle contents on EMI SE and mechanical properties of composites were studied. With the increase of Al particle contents, the electrical conductivity and the EMI SE of CFRP composites increase. When the Al mass fraction in the resin is 33.3%, the in-plane conductivity of the composites increases by 3 orders of magnitude, the EMI SE of the Al particle sandwich CFRP composites is improved by more than 10 dB in the frequency range of 3-17 GHz. With the increase of Al particle contents, the interlaminar shear strength and bending strength of the composites increase first and then decrease. When the Al mass fraction in the resin is 33.3%, the interlaminar shear strength (ILSS) of the composites increases by 5.2% to 80.5 MPa, and when the Al mass fraction in the resin is 50%, the bending strength of the composites increases by 20% to 1441.0 MPa and the bending modulus increases by 10.2% to 101.83 GPa. It can be seen that the mechanical properties and electromagnetic shielding effectiveness of the Al particles sandwich CFRP composite can be improved simutaneously.It is a kind of structure electromagnetic shielding integrated composite with broad application prospects.

Al颗粒夹层CFRP复合材料力学及电磁屏蔽性能

[J].

Microwave shielding performance of TiO2/Co/GF containing high structure carbon fiber alternate laminate composite

[J].

Investigation on electromagnetic shielding and mechanical properties of zirconia graded carbon fiber/epoxy nanocomposite

[J].

Effect of dielectric and magnetic nanofillers on electromagnetic interference shielding effectiveness of carbon/epoxy composites

[J].Tremendous development in electronic devices and their indiscriminate use has created a severe problem of electromagnetic pollution. Different types of electromagnetic interference (EMI) shielding materials and structures are used to protect electronic devices from the harmful effect of electromagnetic pollution. A present study was conducted to compare the effect of dielectric and magnetic nanofillers on electromagnetic shielding effectiveness (EMI SE) of carbon fiber reinforced composite structures (CFRC). Composites structures were developed using different dielectric and magnetic nanofillers. Effect of nanofillers on microwave absorption properties and reduction in electromagnetic pollution was investigated. Relationship between electrical conductivity and EMI shielding effectiveness in L, S, C, and X-frequency range was also studied. Among the dielectric nanofillers, silicon carbide showed excellent EMI SE in X-frequency range, while among magnetic nanofillers, zinc oxide showed excellent EMI shielding characteristics in a broad frequency range of 100 MHz to 13.6 GHz. Among magnetic nanofillers, CFRC with zinc oxide nanofillers showed the lowest skin depth value of 3.32 × 10−4 mm and among dielectric nanofiller, CFRC with silicon carbide nanofillers gave the lowest skin depth value of 6.49 × 10−4 mm, implying their excellent potential in EMI shielding applications.

Role of cashew shell biochar on EMI shielding behaviour of carbon fibre-epoxy nanocomposites in E, F, I and J band-microwave frequencies

[J].

Ultra-thin carbon fiber reinforced carbon nanotubes modified epoxy composites with superior mechanical and electrical properties for the aerospace field

[J].

Interfacial architecture constructed using functionalized MWNT resulting in enhanced EMI shielding in epoxy/carbon fiber composites

[J].In this work, we have attempted to improve electromagnetic interference (EMI) shielding and mechanical behavior of epoxy/carbon fiber (CF) composite, simultaneously, in the presence of functionalized carbon nanotubes. It is well understood that properties of composite depend on the interface between the filler and matrix. Considering this basic understanding, functionalized carbon nanotubes/epoxy nanocomposites were impregnated into a bidirectional carbon fiber (CF) mat and, further, various mechanical and EMI shielding behaviors were studied. Multiwalled carbon nanotubes were functionalized with branched poly(ethyleneimine) (b-MWNT) to tailor the interface of epoxy/CF composites. Laminates with two layers of CF were fabricated with functional MWNT modified epoxy. Scanning electron microscopy was used to analyze the microstructure of epoxy/CF laminates. Lap shear test was performed to analyze adhesion between the modified epoxy and carbon fiber. Further dynamic mechanical analysis in the temperature range of 30-160 °C was performed. Thermal degradation of composites was studied using a thermogravimetric analyzer. Electrical conductivity of laminates was measured using a four-point method on an Agilent probe station. EMI shielding effectiveness (SE) was measured for 0.5 mm-thin laminates in the Ku band. The b-MWNT modified epoxy/CF composites showed excellent SE of ca. -60 dB and SE of ca. -50 dB, which are of commercial importance. Compared to unmodified epoxy/CF, b-MWNTs/epoxy/CF exhibited 200% increment in EMI SE and 35% enhancement in storage modulus due to the improved interface between the epoxy matrix and carbon fiber.

Carbon nanotube carbon fiber composites study on the performance of EMC

[J].

基于碳纳米管-碳纤维复合材料电磁兼容性能的研究

[J].

Enhancing interfacial and electromagnetic interference shielding properties of carbon fiber composites via the hierarchical assembly of the MWNT/MOF interphase

[J].A metal-organic framework (MOF) based on a conjugated organic ligand and a transition-metal ion was designed and used to construct a novel multiwalled carbon nanotube (MWNT)/MOF interphase via hierarchical assembly on the carbon fiber (CF) surface and was compared to various interphases established by MWNT and MOF. An intertwined MWNT and MOF "jujube core" was randomly dispersed on MWNT@CF and MOF@CF surfaces, while interpenetrating structures with the MWNT network and MOF jujube core were simultaneously observed on MWNT/MOF@CF due to coordination bonds and π-π conjugation effects, which were derived from the MWNT template with carboxyl groups and sp-hybridized domains as well as the secondary growth of MOF to promote self-assembly and the connection of MOF. The transverse fiber bundle test (TFBT) strength and interfacial shear strength (IFSS) of the MWNT/MOF@CF composite were 36.9, 6.1, and 20.8%, 16.3% higher than those of MWNT@CF and MOF@CF composites, which were attributed to the smoothed modulus transition of the stiffening interphase formed by the MWNT/MOF hybrid structure as "armor" to effectively buffer the stress transfer between a carbon fiber and the resin matrix. Compared to MWNT@CF and MOF@CF composites, MWNT/MOF@CF composites had the highest EMI shielding effectiveness, which was attributed to the combined effects of multiple reflections, conductive loss, and interface polarization from the interpenetrating MWNT/MOF hybrid structures, which realized the integration of the structure and function of the carbon fiber composites.

Extraordinary improvement in mechanical properties and absorption-driven microwave shielding through epoxy-grafted graphene "interconnects"

[J].Efficient design of electromagnetic (EM) shielding materials has emerged as a challenging research area in the past decade. To address this issue, we propose thin, lightweight, yet strong epoxy/carbon fiber (CF) composites modified with functionalized graphene oxide (GO) sheets as "interconnects". This strategy resulted in an impressive 175% improvement in the storage modulus, a 100% enhancement in the lap shear strength, and an extraordinary 200% improvement in the shielding effectiveness at a very low GO content (0.5 wt %). First, GO was functionalized with an epoxy prepolymer (namely E-f-GO) to improve the interfacial adhesion with the matrix polymer, epoxy. As a control, epoxy nanocomposites were also prepared with modified GO. It was followed by the fabrication of CF laminates impregnated with epoxy nanocomposites. Covalent functionalization of epoxy chains on GO sheets was confirmed using various techniques like X-ray diffraction, Raman spectroscopy, Fourier transform infrared spectroscopy, atomic force microscopy, and thermogravimetric analysis. Epoxy nanocomposites were analyzed for thermal, mechanical, electrical, and adhesive strength behavior. CF laminates with epoxy nanocomposites were fabricated using vacuum-assisted resin transfer molding. The E-f-GO/epoxy/CF composite exhibited an excellent shielding effectiveness value of -70 dB, and the storage modulus was found to be >40 GPa. The modified composite showed absorption-driven shielding of EM waves and hence can be used as a highly effective EM absorber.

Enhanced electromagnetic interference shielding properties of carbon fiber veil/Fe3O4 nanoparticles/epoxy multiscale composites

[J].

Improved electromagnetic wave shielding capability of carbonyl iron powder-embedded lightweight CFRP composites

[J].

Multilayer-structured carbon fiber fabric/graphene oxide/Fe3O4/epoxy composite for highly efficient mechanical and electromagnetic interference shielding

[J].

Recent advances in carbon-based polymer nanocomposites for electromagnetic interference shielding

[J].

Ultrathin and flexible carbon nanotube/polymer composite films with excellent mechanical strength and electromagnetic interference shielding

[J].

High-performance epoxy nanocomposites reinforced with three-dimensional carbon nanotube sponge for electromagnetic interference shielding

[J].

Multifunctional electromagnetic interference shielding 3D reduced graphene oxide/vertical edge-rich graphene/epoxy nanocomposites with remarkable thermal management performance

[J].

Graphene foams for electromagnetic interference shielding: A review

[J].

Designing of epoxy composites reinforced with carbon nanotubes grown carbon fiber fabric for improved electromagnetic interference shielding

[J].

Magnetic graphene oxide/carbon fiber composites with improved interfacial properties and electromagnetic interference shielding performance

[J].

Electrodeposited carbon fiber and epoxy based sandwich architectures suppress electromagnetic radiation by absorption

[J].Functional polymer composites are in huge demand in electronic industry in general and for electromagnetic interference shielding in particular, due to ease of processing, design flexibility and lightweight. Herein, efforts are made to enhance electromagnetic interference shielding effectiveness in epoxy/carbon fiber composite, by electrodepositing magnetic particles on the surface of carbon fiber. This approach results in 100% enhancement in shielding effectiveness with respect to epoxy/Carbon fiber composites. Electrodeposition, an industrially viable and a scalable technique, is adopted here to obtain nickel decorated carbon fiber. Various nickel deposited carbon fiber morphologies are obtained by varying the applied current. Various microstructures of nickel deposited carbon fiber are obtained and the final parameters are fixed. Further, X-ray diffraction confirms the presence of nickel on the carbon fiber surface. In addition magnetic, electrical, thermal behaviour of nickel deposited carbon fiber is evaluated systematically. Epoxy/carbon fiber composites are fabricated using vacuum assisted resin transfer moulding technique. 2-Layered sandwich structure is prepared with layer 1 as nickel deposited carbon fiber and layer 2 as only carbon fiber. EMI shielding effectiveness is measured in the frequency range of 12-18 GHz. Epoxy with nickel deposited carbon fiber and bare carbon fiber sandwich architecture showed excellent shielding effectiveness up to 50 dB and with maximum absorption of up to 40 dB at 15 GHz. Thermal studies are also carried out to understand the materials response at higher temperature and frequency. Such thin, light-weight, excellent EM absorbers can be used as EMI enclosures for battery casings of hybrid electric vehicles, communication systems etc.

Three-dimensional reduced graphene oxide foam modified with ZnO nanowires for enhanced microwave absorption properties

[J].

Three-dimensional reduced graphene oxide foam modified with ZnO nanowires for enhanced microwave absorption properties

[J].

Oriented polarization tuning broadband absorption from flexible hierarchical ZnO arrays vertically supported on carbon cloth

[J].

Heterogeneous ZnO@CF structures and their excellent microwave absorbing properties with thin thickness and low filling

[J].With the aim to obtain enhanced absorbing performance at small thickness and low filling, a robust strategy to fabricate zinc oxide (ZnO) modified carbon fiber (CF) structures have been successfully prepared by using low temperature hydrothermal method. Due to the multi-interface polarization caused by the high specific surface area of the complex heterostructures and the improvement of impedance matching, the composites show excellent electromagnetic wave absorption properties. Under the condition of low filling content (20 wt%) and ultra-thin thickness (1.5 mm), the excellent absorption performance of minimal reflection loss of -34.4 dB and an effective absorption bandwidth (RL ≤ -10 dB) of 4.94 GHz is achieved. In addition, the effective absorption bandwidth covers the whole 2-18 GHz band with the increase of thickness from 0.5 to 10 mm. This work provides an innovative method for designing the matching layer of carbon-based absorbing materials, and ZnO@CF heterostructure is expected to become a potential absorbing material.

High-performance single-wall carbon nanotube transparent conductive films

[J].A single-wall carbon nanotube (SWCNT) has superior optical, electrical, and mechanical properties due to its unique structure and is therefore expected to be able to form flexible high-performance transparent conductive films (TCFs). However, the optoelectronic performance of these films needs to be improved to meet the requirements of many devices. The electrical resistivity of SWCNT TCFs is mainly determined by the intrinsic resistivity of individual SWCNTs and their junction resistance in networks. We analyze these key factors and focus on the optimization of SWCNTs and their networks, which include the diameter, length, crystallinity and electrical type of the SWCNTs, and the bundle size and interconnects in networks, as well as chemical doping and microgrid design. We conclude that isolated/small-bundle, heavily doped metallic or semiconducting SWCNTs with a large diameter, long length and high crystallinity are necessary to fabricate high-performance SWCNT TCFs. A simple, controllable way to construct macroscopic SWCNT networks with Y-type connections, welded junctions or microgrid design is important in achieving a low resistivity. Finally, some insights into the key challenges in the manufacture and use of SWCNT TCFs and their prospects are presented, hoping to shed light on promoting the practical application of SWCNT TCFs in future flexible and stretchable optoelectronics.

Mechanical and electrical properties of laminated composites containing continuous carbon nanotube film interleaves

[J].

Ultralight graphene foam/conductive polymer composites for exceptional electromagnetic interference shielding

[J].

Increased interface strength in carbon fiber composites through a ZnO nanowire interphase

[J].

In-situ pull-off of ZnO nanowire from carbon fiber and improvement of interlaminar toughness of hierarchical ZnO nanowire/carbon fiber hydrid composite laminates

[J].

Electromagnetic characteristics of different shape ZnO composite

[J].

不同形貌氧化锌的微波电磁性能研究

[J].

Research on solution growth for preparation and electromagnetic wave absorption performance of needle stick-ZnO

[J].

溶液生长法制备多针状氧化锌及其吸波性能的研究

[J].

Optimization of mechanical and tribological properties of carbon fabric/resin composites via controlling ZnO nanorods morphology

[J].

Growth of aligned ZnO nanorods on carbon fabric and its composite for superior mechanical and tribological performance

[J].

Dual synergistic effect of a carbon/metal hybrid network on the mechanical and electromagnetic interference shielding performance in self-assembly enhanced epoxy curing networks

[J].

Synergistic interfacial reinforcement of carbon fiber/polyamide 6 composites using carbon-nanotube-modified silane coating on ZnO-nanorod-grown carbon fiber

[J].

Design of interconnected carbon fiber thermal management composites with effective EMI shielding activity

[J].