镁合金是目前实际应用中最轻的金属结构材料,在航空航天、国防军事、电子、轨道交通、汽车等领域有广阔的应用前景[1~4]。但是,传统镁合金的绝对强度偏低和室温塑性较差,使其应用范围受到了限制。2001年,Kawamura等[5]首次用快速凝固/粉末冶金技术制备出一种新型高强Mg97Y2Zn1(原子分数,以下无特殊说明合金成分均指原子分数)合金。热挤压后这种合金表现出优异的力学性能,其室温屈服强度超过600 MPa,伸长率也达到5%。后续研究发现[6],Mg97Y2Zn1合金晶粒内部析出的长周期堆垛有序(Long-period stacking ordered, LPSO)相对其优异的力学性能有重要贡献。含LPSO相镁合金因具有优异的室/高温力学性能[7~14],近年来受到学术界和工业界的极大关注。

迄今为止陆续有学者研究发现,多种Mg-RE-TM系合金(RE=Gd、Y、Dy、Er、Nd、Tm等,TM=Zn、Ni、Cu、Al等)中存在LPSO相[8~15]。Wang等[16]研究发现,用少量的Ni取代Zn能明显提高Mg-Gd-Zn合金中LPSO相的含量。其原因是,与Zn相比,Ni在镁基体中的固溶度更低,这有利于LPSO相的析出。Yang等[17]研究了Ni含量对Mg-Y-Ni合金显微组织和拉伸性能的影响。结果表明,Ni含量为0.5%(原子分数)的Mg98.5Y1Ni0.5合金中第二相主要为LPSO相,其室温拉伸性能最佳。研究发现,与Mg96Er3Zn1和Mg96Er3Cu1合金相比,铸态Mg96Er3Ni1合金的室温拉伸性能更优异[18]。

目前,对含LPSO相镁合金的研究主要集中在Mg-RE-Zn[5~8,12,16]、Mg-RE-Ni[11,14,17]和Mg-RE-Cu[4,10,18]等单稀土镁合金,而对添加双稀土的Mg-RE1-RE2-TM合金的研究还比较少[19~21]。Wu等[22]研究发现,添加Y、Nd双稀土对镁合金的强化效果明显好于单独添加Y或Nd,使合金的室温和高温强度显著提高。Rokhlin等[23]的研究也表明,在镁合金中混合加入两种稀土元素使其强度大幅度提高。Y和Er是在镁合金中常用的两种稀土合金化元素,在镁基体中的固溶度较高,共晶温度分别为12.5和33.8。同时,随着温度下降Y和Er的固溶度显著降低,其固溶和时效强化效果显著。研究还发现,Y和Er对镁合金的铸态组织均具有一定的细化作用[24]。鉴于此,本文用重力铸造方法制备3种双稀土镁合金Mg97Y2-x Er x Ni1(x=0.5、1、1.5)并对其进行固溶处理,研究其组织和拉伸性能。

1 实验方法

实验用Mg97Y2-x Er x Ni1(x=0.5、1、1.5)合金用功率为5KW的SG2-5-12型井式电阻炉熔炼,原料为纯镁锭(99.96%,质量分数)、纯Ni片(99.97%)、Mg-30Er和Mg-30Y中间合金。重力铸造的浇注温度为720℃。在熔炼和浇注过程中用混合气体(99%CO2+1%SF6,体积分数)进行保护。

用电感耦合高频等离子体发射光谱仪(ICP-AES)测定铸态合金的化学成分,结果列于表1。在520℃对铸态合金试样固溶处理,保温12 h后水淬。

表1 实验合金的成分

Table 1

| Alloys | Mg | Y | Er | Ni |

|---|---|---|---|---|

Mg97Y1.5Er0.5Ni1 Mg97Y1Er1Ni1 Mg97Y0.5Er1.5Ni1 | Bal. Bal. Bal. | 5.04 3.42 1.78 | 3.11 6.43 9.47 | 2.29 2.11 2.31 |

用D8 ADVANCE型X射线衍射仪(XRD)测定合金的相组成。用SU1510型扫描电镜(SEM)和配套的能谱仪(EDS)观察合金的微观组织和分析相的成分。使用Image J软件统计合金的平均晶粒尺寸、第二相平均宽度和体积分数。用Talos F200X场发射透射电子显微镜(TEM)分析合金的第二相结构,使用离子减薄仪制备TEM试样。在WDW-E100D型微机控制电子万能试验机上进行室温拉伸试验,拉伸速率为1 mm/min,每组至少使用4个平行试样,取其结果的平均值。用SEM观察拉伸试样断口的形貌。

2 结果和讨论

2.1 铸态合金的组织和拉伸性能

图1

图1

铸态Mg97Y2-x Er x Ni1合金的XRD谱

Fig.1

XRD spectra of as-cast Mg97Y2-x Er x Ni1 alloys

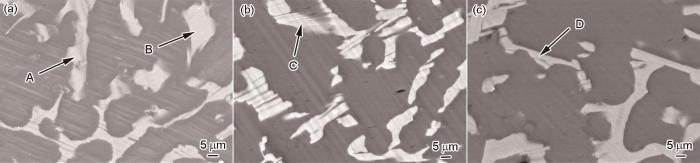

图2分别给出了铸态Mg97Y1.5Er0.5Ni1、Mg97Y1Er1Ni1和Mg97Y0.5Er1.5Ni1合金的背散射电子(BSE)照片。可以看出,3种合金的微观组织均主要由α-Mg基体(深灰色衬度)和沿晶界析出的块状第二相(浅灰色衬度)组成。分别对3种合金中的第二相进行EDS能谱分析,结果列于表2。从表2可见,Mg97Y1.5Er0.5Ni1合金中第二相(A点)中的Ni与Y+Er的原子比为0.92,接近1∶1,符合Mg-RE-TM合金LPSO相中TM与RE元素的比值范围[8,11,14,18]。结合XRD结果可知,该块状第二相为LPSO相。Mg97Y1Er1Ni1和Mg97Y0.5Er1.5Ni1合金中的块状第二相(B点、C点)也均为LPSO相。

图2

图2

铸态Mg97Y2-x Er x Ni1合金微观组织的BSE照片

Fig.2

BSE images of as-cast Mg97Y2-x Er x Ni1 alloys (a) x=0.5, (b) x=1 and (c) x=1.5

表2 图2中各微区的EDS分析结果

Table 2

| Position | Mg | Y | Er | Ni |

|---|---|---|---|---|

A B C | 90.69 90.64 90.68 | 3.62 2.36 0.94 | 1.22 2.94 3.72 | 4.47 4.56 4.66 |

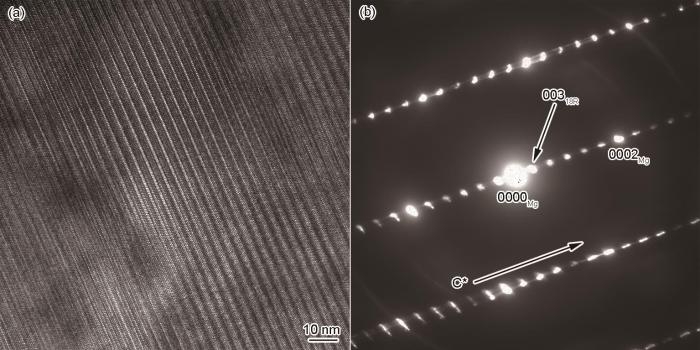

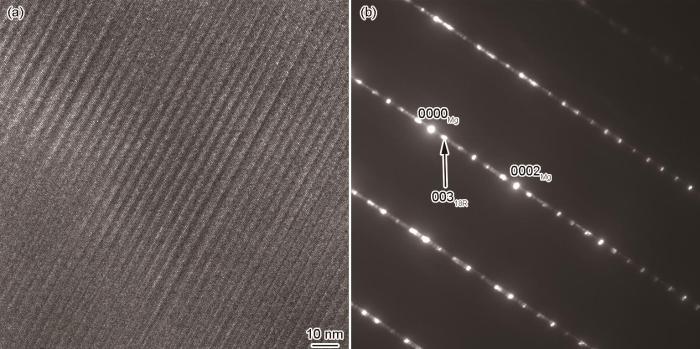

图3a给出了铸态Mg97Y1Er1Ni1合金中LPSO相的高分辨(HRTEM)像。可以看出,LPSO相呈宽度不一的白色和黑色层片状结构且沿[0002]Mg方向周期性堆垛,是典型的LPSO结构原子层排列特征[15,18]。图3b给出了该LPSO相在[

图3

图3

铸态Mg97Y1Er1Ni1合金中LPSO相的HRTEM形貌和选区电子衍射花样

Fig.3

HRTEM image (a) and SAED pattern on zone axes B=[

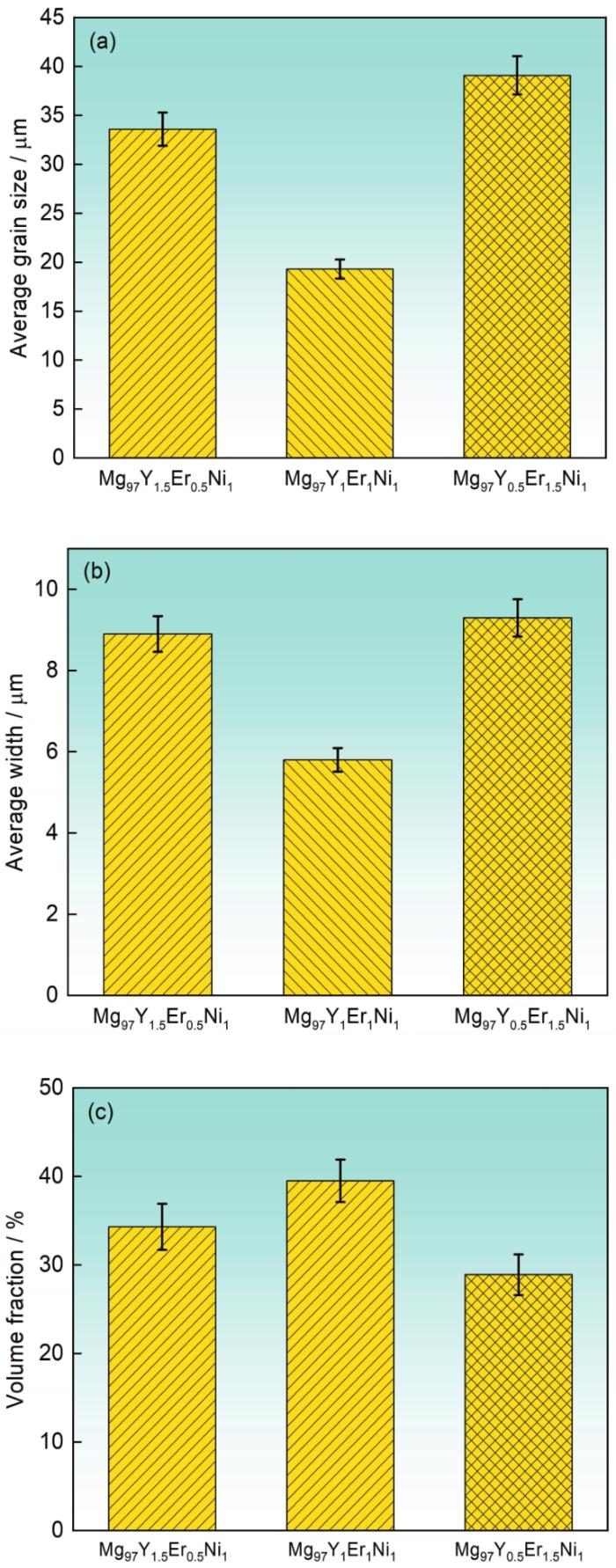

对3种铸态合金的平均晶粒尺寸、第二相平均宽度和体积分数的统计分析结果,如图4所示。由图4a可见,Mg97Y1Er1Ni1合金的晶粒最为细小(尺寸仅为19.3 μm),而Mg97Y0.5Er1.5Ni1合金的晶粒最为粗大(尺寸为39.1 μm)。由图4b可见,Mg97Y1Er1Ni1合金中沿晶界析出的LPSO相其平均宽度最小(仅为5.8 μm),即LPSO相的尺寸最小,且其分布也最为均匀。由图4c可见,Mg97Y1Er1Ni1中LPSO相的体积分数最高(为39.5%),而Mg97Y0.5Er1.5Ni1合金中LPSO相的体积分数最低(为28.9%)。这表明,适当的Y、Er配比,如本实验中的1∶1,能显著细化合金的微观组织和促进LPSO相的析出。

图4

图4

铸态合金的平均晶粒尺寸、LPSO相平均宽度和LPSO相体积分数

Fig.4

Average grain size (a), average width of LPSO phase (b) and volume fraction of LPSO phase (c) in as-cast alloys

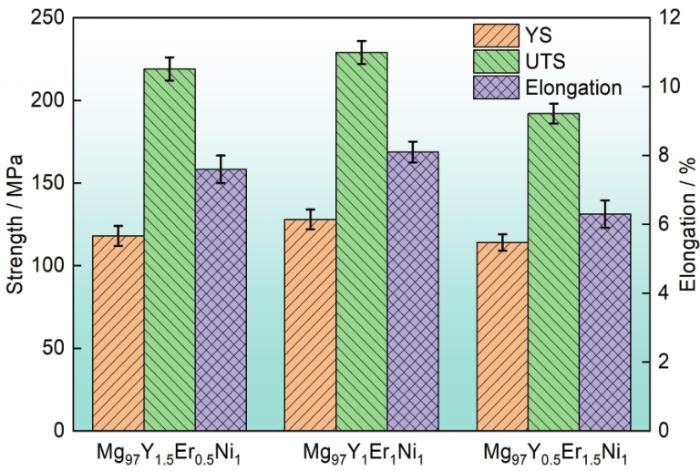

图5给出了铸态Mg97Y1.5Er0.5Ni1、Mg97Y1Er1Ni1和Mg97Y0.5Er1.5Ni1合金的室温拉伸性能。可以看出,Mg97Y1Er1Ni1合金的室温拉伸性能最佳,其屈服强度、极限拉伸强度和伸长率分别为124 MPa、223 MPa和8.0%;Mg97Y0.5Er1.5Ni1合金的室温拉伸性能最差,其屈服强度、极限拉伸强度和伸长率分别为113 MPa、187 MPa和6.1%。

图5

图5

铸态合金的室温拉伸性能

Fig.5

Tensile properties of as-cast alloys tested at room temperature

在3种铸态合金中,Mg97Y1Er1Ni1合金具有最佳的室温拉伸强度和塑性,其原因是:首先,Mg97Y1Er1Ni1合金的晶粒最细小。晶界能阻碍位错运动,晶粒越细小晶界越多,阻碍作用越大,即产生晶界强化。可用Hall-Petch公式

计算由晶界强化产生的合金屈服强度的提高。

式中γ为与泊松比相关的调整系数,其数值为0.35;ε为塑性应变,数值为0.39%;μ和μ∗分别为Mg基体和18R-LPSO相的剪切模量,数值分别为21.5 GPa和16.6 GPa;f为块状18R-LPSO相的体积分数。将铸态Mg97Y1.5Er0.5Ni1、Mg97Y1Er1Ni1和Mg97Y0.5Er1.5Ni1合金中LPSO相的体积分数分别代入

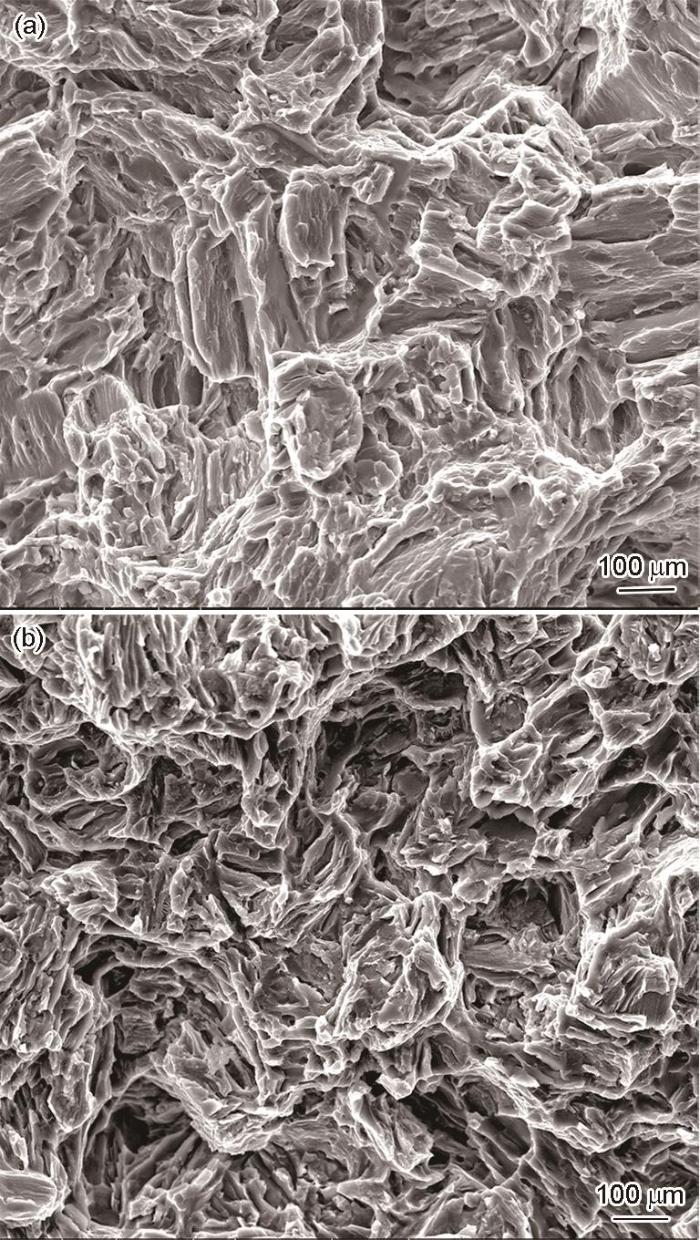

图6

图6

铸态合金室温拉伸断口的形貌

Fig.6

Fracture surface of as-cast Mg97Y0.5Er1.5Ni1 (a) and Mg97Y1Er1Ni1 alloys (b)

2.2 固溶态合金的组织和拉伸性能

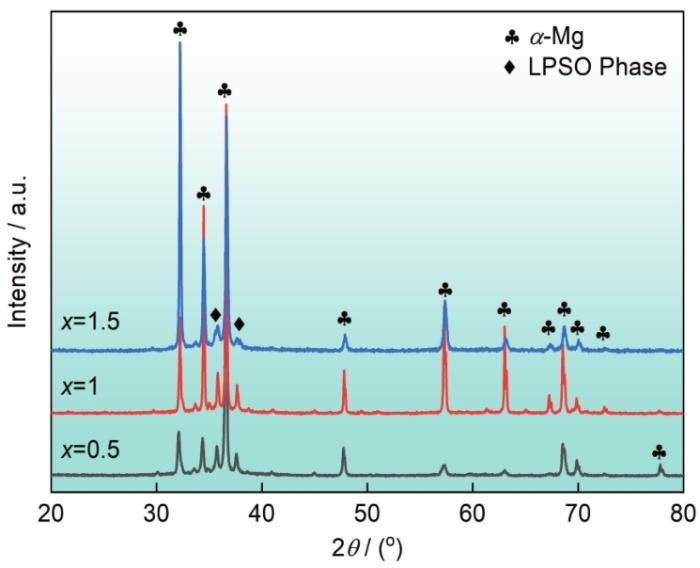

图7分别给出了固溶态Mg97Y1.5Er0.5Ni1、Mg97Y1-Er1Ni1和Mg97Y0.5Er1.5Ni1合金的XRD谱。可以看出,3种固溶态合金均由α-Mg基体和LPSO相组成。这表明,固溶处理没有改变3种合金的相组成。

图7

图7

固溶态Mg97Y2-x Er x Ni1合金的XRD谱

Fig.7

XRD spectra of solution-treated Mg97Y2-x Er x Ni1 alloys

图8分别给出了固溶态Mg97Y1.5Er0.5Ni1、Mg97Y1-Er1Ni1和Mg97Y0.5Er1.5Ni1合金的BSE照片。可以看出,3种固溶态合金的微观组织仍然主要由α-Mg基体(深灰色衬度)和沿晶界分布的块状第二相(浅灰色衬度)组成。对3种合金中第二相的EDS能谱分结果析,列于表3。从表3可见,3种固溶态合金第二相中Ni与Y+Er的原子比均接近1∶1,结合XRD分析结果可以确定其均为LPSO相。由图8a可见,在固溶态Mg97Y1.5Er0.5Ni1合金晶内可观察到非常细小的层片状相(B点),对其EDS能谱分析结果列于表3。根据EDS结果,这种细小层片状相的化学式为Mg98.14(Y,Er)1.86,与α-Mg基体的成分接近。

图8

图8

固溶态Mg97Y2-x Er x Ni1合金微观组织的BSE照片

Fig.8

BSE images of solution-treated Mg97Y2-x Er x Ni1 alloys (a) x=0.5, (b) x=1 and (c) x=1.5

表3 图8中各微区的EDS分析结果

Table 3

| Position | Mg | Y | Er | Ni |

|---|---|---|---|---|

A B C D | 89.48 98.14 89.91 90.39 | 3.86 0.71 2.48 1.32 | 1.48 1.15 2.79 3.51 | 5.18 - 4.62 4.78 |

图9

图9

固溶态Mg97Y1.5Er0.5Ni1合金中LPSO相的HRTEM形貌和选区电子衍射花样

Fig.9

HRTEM image (a) and SAED pattern on zone axes B=[

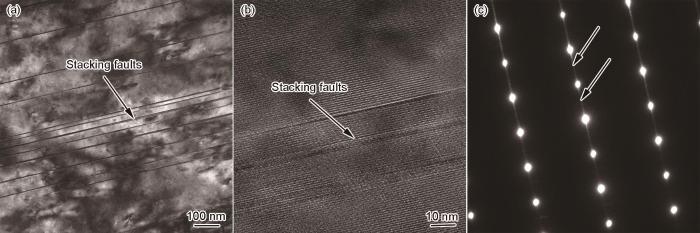

图10a给出了固溶态Mg97Y1.5Er0.5Ni1合金晶内细小层片状相的TEM明场像。可以看出,该层片状相表现为平行于(0002)Mg晶面且宽度不一的细丝状结构。图10c给出了细丝状结构与α-Mg基体叠加的SAED花样,入射电子束平行于

图10

图10

固溶态Mg97Y1.5Er0.5Ni1合金中基面层错的TEM明场像、HRTEM相和选区电子衍射花样

Fig.10

TEM BF image (a), HRTEM image (b) and SAED pattern on zone axes B=[

图11

图11

固溶态合金的平均晶粒尺寸、LPSO相平均宽度和LPSO相的体积分数

Fig.11

Average grain size (a), average width of LPSO phase (b) and volume fraction of LPSO phase (c) in solution-treated alloys

图12分别给出了固溶态Mg97Y1.5Er0.5Ni1、Mg97Y1-Er1Ni1和Mg97Y0.5Er1.5Ni1合金的室温拉伸性能。可以看出,固溶态Mg97Y1Er1Ni1合金的拉伸性能最佳,其屈服强度、极限拉伸强度和伸长率分别为128 MPa、229 MPa和8.1%;固溶态Mg97Y0.5Er1.5Ni1合金的拉伸性能最差,其屈服强度、极限拉伸强度和伸长率分别为114 MPa、192 MPa和6.3%。同时,固溶处理后3种合金的屈服强度、极限拉伸强度和伸长率与铸态(图5)相比均有所提高。其原因是,在高温固溶处理过程中Y、Er溶质原子较高的扩散迁移能力使部分LPSO相溶解,Y、Er溶质原子溶入α-Mg基体中形成过饱和固溶体,使晶格发生畸变。晶格畸变阻碍位错运动,使基体强化。同时,Y、Er溶质原子在α-Mg基体内的扩散使其在晶内的分布更加均匀,从而消除或减弱了枝晶偏析,也有利于提高合金的拉伸性能。需要指出的是,与铸态相比固溶态Mg97Y1.5Er0.5Ni1合金的拉伸强度显著提高,可能与其晶内出现的大量纳米尺度的基面层错有关。基面层错的长径比较大,具有较好的纤维强化效果[9]。

图12

图12

固溶态合金的室温拉伸性能

Fig.12

Tensile properties of solution-treated alloys tested at room temperature

表4分别列出了本文制备的Mg97Y1Er1Ni1合金、2种四元Mg-RE1-RE2-Zn以及2种三元Mg-RE-Ni合金的室温拉伸性能。可以看出,与其他列出的合金相比,无论铸态还是固溶态(T4)的Mg97Y1Er1Ni1合金其综合室温拉伸性能都比较高。

表4 本文制备的Mg97Y1Er1Ni1合金和其他相关合金的室温拉伸性能

Table 4

| Alloys | RE/%, atomic fraction | UTS / MPa | YS / MPa | Elongationg / % | State |

|---|---|---|---|---|---|

Mg97Y1Er1Ni1 Mg97Y1Er1Ni1 Mg96.23Zn0.88Dy2.21Er0.68[26] Mg96.23Zn0.88Dy2.21Er0.68[26] Mg97.5Zn0.9Y0.8Gd0.8[13] Mg97.5Zn0.9Y0.8Gd0.8[13] Mg98.5Y1Ni0.5[17] Mg97Gd2Ni1[16] | 2 2 2.89 2.89 1.6 1.6 1 2 | 223 229 150.51 123.29 228.8 210.2 208 203 | 124 128 84.36 95.79 149 104.6 93 - | 8.0 8.1 6.74 7.03 3.2 7.8 8.0 8.8 | As-cast T4 As-cast T4 As-cast T4 As-cast As-cast |

3 结论

(1) 铸态Mg97Y1.5Er0.5Ni1、Mg97Y1Er1Ni1和Mg97Y0.5-Er1.5Ni1合金均由α-Mg基体和18R-LPSO相组成。Mg97Y1Er1Ni1合金的晶粒最细小,LPSO相的体积分数最高、尺寸最小且分布最为均匀,具有最优的室温拉伸性能。

(2) 在520℃固溶12 h后,Mg97Y1.5Er0.5Ni1、Mg97Y1-Er1Ni1和Mg97Y0.5Er1.5Ni1合金仍然由α-Mg基体和18R-LPSO相组成。在固溶态Mg97Y1.5Er0.5Ni1合金晶内出现基面层错,没有完整的堆垛周期性特征。与铸态相比,3种固溶态合金的室温拉伸性能均有所提高。

参考文献

Recrystallization and texture of magnesium alloy sheet during warm rolling based on multi-scale model

[J].

基于多尺度模型的镁合金薄板温轧再结晶和织构

[J].

Process and properties of graphene reinforced magnesium matrix composites prepared by in-situ method

[J].

原位自生法制备石墨烯增强镁基复合材料的工艺和性能

[J].

Microstructure and mechanical properties of Mg-Al-Ca-Mn-Zn wrought magnesium alloy

[J].

Mg-Al-Ca-Mn-Zn变形镁合金的组织和力学性能

[J].

Evolution of tensile deformation microstructure of Mg-0.4Zn magnesium alloy extruded sheet

[J].

Mg-0.4Zn镁合金挤压板拉伸变形组织的演变

[J].

Rapidly solidified powder metallurgy Mg97ZnlY2 alloys with excellent tensile yield strength above 600 MPa

[J].

Long-period ordered structure in a high-strength nanocrystalline Mg-1at% Zn-2at% Y alloy studied by atomic-resolution Z-contrast STEM

[J],

High-resolution electron microscopy on the X-Mg12ZnY phase in a high strength Mg-Zn-Zr-Y magnesium alloy

[J].

Deformation mechanisms and mechanical properties of (0001) Mg-Zn-Y 18R-LPSO single crystals

[J].A promising Mg-Zn-Y alloy with the long-period stacking ordered (LPSO) second phase has been developed for about twenty years. Because the LPSO phase has the unique 18R crystal structure, particularly for its packing sequence along [0001], as well as it plays an important role in strengthening mechanisms, it is interesting to clarify in terms of mechanical properties and deformation mechanisms. In this study, uniaxial micro-pillar compression tests are conducted on LPSO along the [0001] direction. At the same time, nanoindentation system equipped with the Berkovich tip is used to extract the basic mechanical properties of (0001) plane. The basal dislocations are found to be activated first, causing the bending of the sample. The bending would lead to the shear stress field downward and thus would cause the nucleation and movement of prism dislocations with [0001] Burgers vector. Prism dislocations can form the fatal 45 degrees slip trace inside the micro-pillar and finally go through the whole sample causing fracture. The basal dislocations are found at the Zn6Y8-Mg interface which might be originated from the local strain field between them. (C) 2018 Elsevier B.V.

Strengthening mechanisms acting in extruded Mg-based long-period stacking ordered (LPSO)-phase alloys

[J],The unusual increase in the strength by extrusion is a unique feature of recently developed Mg alloys containing the LPSO phase. In this study, we first elucidated the detailed mechanisms that induce this drastic strengthening. The dependencies of the deformation behavior of a Mg88Zn4Y7 extruded alloy, which contains similar to 86-vol% LPSO phase, on the temperature, loading orientation, and extrusion ratio were examined. It was found that the yield stress of the alloy is drastically increased by extrusion, but the magnitude of the increase in the yield stress is significantly different depending on the loading orientation. That is, the strengthening of the LPSO phase by extrusion shows a strong anisotropy. By the detailed analyses, this was clarified to be derived from the variation in the deformation mechanisms depending on the loading orientation and extrusion ratio. Basal slip was found to govern the deformation behavior when the loading axis was inclined at a 45 to the extrusion direction, while the predominant deformation mechanism varies from basal slip to the formation of deformation kink bands as the extrusion ratio increased when the loading axis was parallel to the extrusion direction. Moreover, it was clarified in this study that the introduction of a deformation-kink-band boundary during extrusion effectively acts as a strong obstacle to basal slip. That is, "the kink band strengthening" was first quantitatively elucidated, which contributes to the drastic increase in the yield stress of the extruded LPSO-phase alloys in the wide temperature range below 400 degrees C. (C) 2018 Acta Materialia Inc. Published by Elsevier Ltd.

Effect of V on the microstructure and mechanical properties of Mg-10Er-2Cu alloy with a long period stacking ordered structure

[J].

Effect of substitution of 1 at% Ni for Zn on the microstructure and mechanical properties of Mg94Y4Zn2 alloy

[J].

Effect of microalloying with boron on the microstructure and mechanical properties of Mg-Zn-Y-Mn alloy

[J].

Effect of heat treatment on LPSO morphology and mechanical properties of Mg-Zn-Y-Gd alloys

[J].

Microstructure, mechanical properties and tribological behavior of two-phase Mg-Y-Cu alloys with long period stacking ordered phases

[J].

Formation and mechanical properties of Mg97Zn1RE2 alloys with long-period stacking ordered structure

[J].

Abundant long period stacking ordered structure induced by Ni addition into Mg-Gd-Zn alloy

[J].

Effects of Ni levels on microstructure and mechanical properties of Mg-Ni-Y alloy reinforced with LPSO structure

[J].

Microstructure and mechanical properties of Mg-Er-Cu/Ni/Zn alloy with long period stacking ordered phases

[J].

Precipitation behavior of the 14H-LPSO structure in Mg-12Gd-2Er-1Zn-0.6Zr alloy

[J].

Effect of Zn content on the microstructure and mechanical properties of Mg-Gd-Y-Zr alloys

[J].

Cluster on interface of LPSO phase and matrix in Mg-Gd-Y-Ni alloy: Atomic scale insight from HAADF-STEM

[J].

Study of the microstructure and mechanical properties of Mg-rare earth alloys

[J].

Nikitina N I. Constitution and properties of the ternary magnesium alloys containing two rare-earth metals of different subgroups

[J].

Correlation between microstructure and mechanical properties of columnar crystals in the directionally solidified Mg-Gd-Y-Er alloy

[J].

Microstructure and damping properties of LPSO phase dominant Mg-Ni-Y and Mg-Zn-Ni-Y alloys

[J].

Effect of Er contents on the microstructure of long period stacking ordered phase and the corresponding mechanical properties in Mg-Dy-Er-Zn alloys

[J].