Zr合金的抗中子截面吸收系数较小(0.18 bar)并具有良好的耐蚀性能,是制造核反应堆体系的重要结构材料[1]。但是,2011年日本福岛发生的核泄漏事故暴露了Zr合金包壳材料性能的不足。为了提高反应堆系统的安全裕度,提出了发展耐事故容错(Accident-tolerance fuel, ATF)包壳材料,以替代现在的Zr合金包壳[2]。目前对ATF包壳材料的要求,是提高其抗高温蒸汽氧化性能和在高温下的短时力学性能。Fe-Cr-Al合金具有与Zr合金相当的中子性、良好的抗辐照损伤能力[3,4]、优异的抗高温水蒸气能力,成为耐事故容错包壳材料的候选者[5]。Fe-Cr-Al合金(10-10 g2·cm2·s-1)的1673 K氧化动力学常数比Zr合金高(10-6 g2·cm2·s-1)4个数量级,表明其具有良好的耐蚀性能[2]。

在研究Fe-Cr-Al合金性能的初期,调整Cr与Al元素的配比得到了具有最佳耐蚀性和抗氧化性能的Fe-13Cr-4.5Al (%,质量分数)合金成分[6]。但是三元合金在高温下表现为单一的铁素体基体,缺少第二相粒子对晶界的钉扎使其在高温下晶粒粗化严重和力学性能显著下降。提高工程合金在高温下的力学性能,主要是通过析出第二相实现。例如,在Ni基高温合金中γ基体上析出γ'粒子,可显著提高其高温力学性能[7];在Fe-Cr-Ni-Al合金的BCC基体上析出B2和L21,使其在973 K具有优异抗高温蠕变性能[8,9]。而对于Fe-Cr-Al合金,常规强化的碳化物粒子在温度高于1173 K时将大量溶解到基体中,从而大大降低析出强化效果。而六方结构的Fe2M Laves相即使在1273 K的高温下也大量存在,其在晶界的分布能有效抑制晶粒长大,从而确保其高温下的组织稳定性。因此,Laves相强化的Fe-Cr-Al合金是目前发展的主要对象[10~12]。基于此,Sun[13]等设计了Fe-Cr-Al-Mo-Nb合金,在BCC基体上析出弥散的六方Fe2(Mo, Nb)型Laves相使其室温屈服强度(σYS=620 MPa)远高于碳化物强化的合金(σYS=400 MPa),在1014 K的屈服强度(σYS=100 MPa)也显著高于Fe-13Cr-4.5Al (%,质量分数)合金(σYS=53 MPa),表明Laves相强化相可提高其力学性能。但是,Fe-Cr-Al-Mo-Nb合金中的Laves相在1273 K以上发生剧烈回溶,体积分数由~5.1%下降到1473 K的~0.1%,从而使其高温组织不稳定和力学性能降低。为了提高Laves相在高温下的稳定性,可用合金化方法在Mo/Nb基础上添加Ta元素。目前的研究结果表明,在MoNb合金基础上添加微量的Ta元素确实延缓了Laves相粒子的回溶,在1273 K短时热处理后仍有2.4%的粒子留存在晶界和晶内,但是甚至在1473 K也依然有0.05%的第二相粒子分布在晶界,影响其组织稳定性[14]。这些结果表明,添加微量合金化元素确实能显著提高合金的高温组织稳定性。

Zr元素也是Laves相的形成元素,从二元相图可知添加微量元素对钢的微观组织有重要的影响。不同元素生成的Laves相的高温溶解温度也显著不同。例如,Fe2Ta(2048 K)和Fe2Zr(1946 K)型Laves相的析出温度远高于Fe2Mo(1761 K)和Fe2Nb(1900 K)等Laves相。据此可以推断,在添加Ta/Zr的合金中Laves相在高温下可能具有更高的稳定性。为了提高合金的高温组织稳定性和力学性能,本文在Fe-Cr-Al-Mo-Nb合金中添加不同成分的Ta/Zr元素,研究其对合金中第二相粒子的形貌、尺寸、数量、稳定性以及显微硬度的影响。

1 实验方法

在Fe-Cr-Al-Mo-Nb合金中添加不同含量的Ta和Zr元素,采用真空电弧熔炼方法在高纯Ar气氛中制备四种合金铸锭。用电感耦合等离子体光谱仪测量了Fe-Cr-Al合金的实际化学成分,结果列于表1。

表1 设计的Fe-Cr-Al-M合金化学成分(质量分数,%)

Table 1

| Alloy | Fe | Cr | Al | Mo | Nb | Ta | Zr |

|---|---|---|---|---|---|---|---|

| No.1 | 78.61 | 13.55 | 4.75 | 2.08 | 1.01 | - | - |

| No.2 | 78.36 | 13.51 | 4.73 | 2.08 | 0.67 | 0.65 | - |

| No.3 | 78.61 | 13.55 | 4.73 | 2.08 | 0.90 | - | 0.11 |

| No.4 | 78.28 | 13.50 | 4.73 | 2.08 | 0.45 | 0.87 | 0.11 |

在1473 K将铸锭热轧成合金板使其总厚度从60 mm减小到10 mm,然后在不同温度进行固溶处理以消除在热轧过程中析出的Laves相粒子。No.1和No.2合金的固溶温度为1423 K,No.3和No.4合金的固溶温度为1523 K,并将四种合金板在1473 K下退火10 min。在1073 K将四种合金板热轧使其总厚度从10 mm减小到3 mm,再在873 K进行温轧使板材的厚度从3 mm减小到2 mm,并将四种金属板在1073 K退火30 min。最后,将合金板在873 K时效处理24 h后水淬。为了研究第二相粒子在高温下的稳定性,分别将合金板在1273 K、1373 K和1473 K高温热处理1 h,然后均进行水淬。通过磨样、抛光、并用20%HF+10%HNO3+70%H2O(体积分数)腐蚀液腐蚀制备金相样品。

用OLYMPUS光学显微镜(OM)和Zeiss Supra55扫描电子显微镜(SEM)观察不同状态合金中第二相粒子的形貌。使用Bruker D8 Focus X射线衍射仪(XRD, CuKα, λ=0.15406 nm)检测设计合金的相组成。用SHIMADZUEPMA-1600电子探针对时效处理后合金中的第二相粒子进行了定量点成分分析和对回溶处理后合金中第二相粒子进行元素面分析。使用Image-Pro6.0软件统计SEM图片中析出相的面积分数Af (至少6张),并用面积分数近似代替体积分数f (f =Af);用ImageJ测量析出相粒子的尺寸,分别测量杆状析出相粒子的长和宽并取平均值(至少4张图片),测量球状粒子的直径。使用Image-Pro6.0软件计算析出相的体积分数和晶粒尺寸。在300 g/15 s的测试条件下,使用HVS-1000维氏硬度仪测量系列合金不同状态的显微硬度,每个样品各测量10次取其结果的平均值。

2 实验结果

2.1 系列合金的微观组织

图1给出了设计的Fe-Cr-Al-M系列合金温轧后的微观组织。从图1a可见,温轧后合金的晶粒具有流线型组织,没有明显的回复再结晶,在873 K时效24 h后晶粒仍保持流线型(图1b)。从图1c~f的背散射电子像中可以看出,温轧后的合金在铁素体基体上弥散分布着两种不同尺寸的粒子。一种为尺寸较大的初生粒子,其长度约为2.1 μm,宽度约为1.0 μm;一种为分布在晶粒内部的细小第二相粒子(~90 nm)。四种合金析出粒子的体积分数分别为fNo.1=2.7%,fNo.2=2.4%,fNo.3=2.8%,fNo.4=1.9%。对比四种合金可见,添加Ta/Zr元素会促进细小第二相粒子的析出,对初生的粗大粒子也有一定的延缓作用。图2给出了设计合金在873 K时效24 h后的XRD谱,可见其主要由BCC α-Fe和Laves相的两相构成。

图1

图1

No.2合金温轧和时效后的OM以及系列合金轧制态的背散射电子像

Fig.1

OM (a, b) and back-scattered electron images (c~f) of the rolled state of designed alloys

图2

图2

系列合金873 K/24 h时效后的XRD谱

Fig.2

XRD pattern of the aged alloys at 873 K for 24 h

图3给出了轧制合金板材在873 K时效24 h后的背散射电子像。从图3a可见,在No.1参比合金中,在轧制过程析出的粗大相粒子依然沿变形的粗大晶粒的晶界连续分布(长约2.0 μm, 宽约0.8 μm)(Grain boundary precipitates, GBP),而少量细小的球形第二相粒子则主要分布在晶内,部分再结晶晶粒弥散分布在晶界,其直径约为110 nm,析出粒子的总体积分数为f=3.2%(图3a),用EPMA测出粗大粒子的成分为Fe52.72Cr9.08Al4.40Mo5.39Nb19.56(%,原子分数),其中Fe∶(Mo+Nb)的比例接近2∶1,结合XRD谱可证明亮白色析出相为Fe2(Mo, Nb)型Laves相粒子。在Mo/Nb/Ta改良的No.2合金中,第二相粒子的体积分数比温轧后显著增大(f=3.1%),粒子显著粗化(长~2.6 μm,宽~1.1 μm)(图3b),其主要成分为Fe60.43Cr10.32Al3.94Mo6.20Nb14.60Ta4.52(%,原子分数)。这表明,Laves相以Fe2(Mo, Nb, Ta)为主。从图3b的插图可见,除了晶界上粗大的粒子,No.2合金晶内有大量尺寸细小的球形粒子(~98 nm)。而在No.1合金的基础上添加0.11Zr的No.3合金中,初生的粗大Laves相粒子分布在晶界处。与No.1合金相比,这些Laves相粒子的长度增加到2.6 μm,宽度增加到1.6 μm,体积分数f=3.1%(图3c),其主要成分为Fe63.86Cr10.40Al4.51Mo6.01Nb15.15Zr0.06(%,原子分数),即Mo、Nb、Zr多元素富集。与No.2合金相比,No.3合金晶内细小的球型粒子直径降低到90 nm。在复合添加Ta/Zr的No.4合金中,第二相粒子的体积分数下降到f=2.7%,粒子的长度约为2.3 μm,宽度约为1.2 μm。四种合金中的晶内球型粒子尺寸最为细小(仅为70 nm,图3d),EPMA测定析出粒子的成分为Fe74.09Cr14.74Al8.77Mo0.82Nb1.23-Ta0.34Zr0.04(%,原子分数)。对比四种合金的微观组织发现,Zr元素的添加显著减少了合金中轧制过程析出的粗大第二相粒子的体积分数,而促进了细小Laves相粒子的析出。

图3

图3

Fe-Cr-Al系列合金873 K/24 h时效后的背散射电子像

Fig.3

Back-scattered electron image of the designed alloys at 873 K for 24 h (a) No.1 alloy, (b) No.2 alloy, (c) No.3 alloy and (d) No.4 alloy

对873 K/24 h时效的系列合金在不同温度(1273~1473 K) 进行高温回溶处理,以研究第二相粒子的高温稳定性。图4给出了系列合金在不同温度下回溶处理1 h后的OM组织照片。可以看出,进行1273 K/1 h热处理后设计合金均发生了完全再结晶,晶粒尺寸均约为40 μm (图4a1~d1)。将回溶温度提高到1373 K,No.1合金(~287 μm)和No.2合金(~319 μm)的晶粒都明显粗化(图4a2, b2),而No.3和No.4合金的晶粒尺寸仅为84 μm和105 μm(图4c2, d2)。回溶温度达到1473 K时No.1和No.2合金的晶粒异常长大且尺寸严重不均,其尺寸为490~590 μm;No.3和No.4合金的晶粒尺寸增加到~154 μm和~196 μm(图4a3~d3)。在不同温度回溶处理后晶粒尺寸的变化趋势如图6a所示,可见添加Zr元素能显著细化晶粒。

图4

图4

Fe-Cr-Al系列合金在不同温度回溶处理后的OM

Fig.4

OM of the designed alloys after re-treat at different temperatures 1: 1273 K/1 h, 2: 1373 K/1 h, 3: 1473 K/1 h; (a) No.1 alloy, (b) No.2 alloy, (c) No.3 alloy, and (d) No.4 alloy

图5

图5

Fe-Cr-Al系列合金在不同温度回溶处理后的背散射电子像

Fig.5

Back-scattered electron images of designed alloys after re-treat at different temperatures for 1 h 1: 1273 K/1 h, 2: 1373 K/1 h, 3: 1473 K/1 h; (a) No.1 alloy, (b) No.2 alloy, (c) No.3 alloy, and (d) No.4 alloy

图6

图6

不同状态系列合金的晶粒尺寸、第二相粒子的体积分数和尺寸以及显微硬度

Fig.6

Grain size (a), volume fraction of second phase particles (b), second phase particle size (c), and microhardness (d) of Fe-Cr-Al series alloys in different states

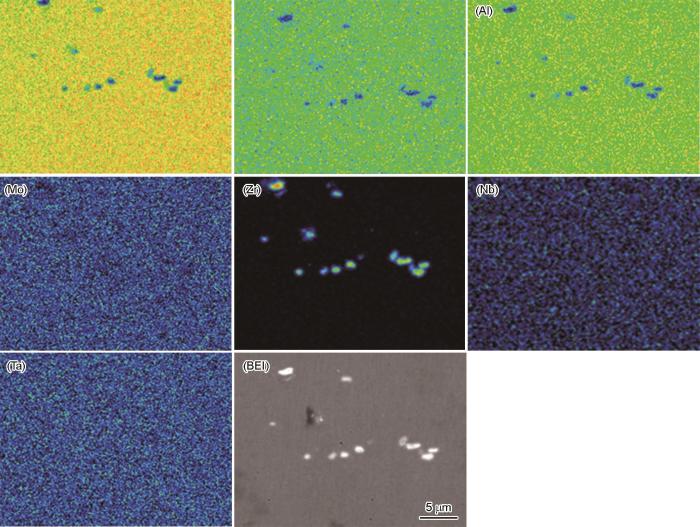

图5给出了系列合金在高温短时热处理后的背散射电子像。可以看出,与时效合金相比,No.1~No.4合金在1273 K/1 h回溶处理后基体中的第二相粒子发生显著粗化和溶解(图5a1~d1)。系列合金中第二相粒子的尺寸由时效后的长~2.4 μm,宽~1.2 μm增加到长2.5~3.5 μm,宽1.0~1.7 μm,体积分数约为1.7%~2.5%。回溶温度升高到1373 K,No.1合金中第二相粒子几乎全部回溶到基体中(图5a2),而添加Ta的No.2合金中仍有少量第二相粒子分布在晶界处,体积分数为f=0.1%(图5b2)。在添加Zr的No.3和添加Ta/Zr的No.4合金中仍有大量的第二相粒子分布在晶界和晶内(图5c2, d2),第二相粒子的体积分数分别为1.2%和0.6%。此外,在添加Ta/Zr的No.4合金中Laves相粒子的尺寸显著比No.3合金的小,表现出更高的稳定性。回溶温度继续升高到1473 K,No.1和No.2合金中的第二相粒子完全回溶(图5a3, b3),而在添加Zr的No.3合金和添加Ta/Zr的No.4合金中仍有少量(fNo.3=0.1%, fNo.4=0.2%)第二相粒子分布在晶界(图5c3, d3)。这些分布在晶界的粒子对晶界的钉扎阻碍了晶粒的进一步长大,使No.3和No.4合金的晶粒较为细小。而No.1和No.2合金的晶粒显著粗化,因为Laves相粒子在高温下的显著溶解使抑制晶界粗化的效果降低,与图4给出的结果一致。图7给出了No.4合金在1473 K/1 h回溶处理后析出粒子的元素面分布图。可以看出,合金中的粒子主要为Zr元素富集,而Fe、Cr和Al元素相对于基体贫化,Mo、Nb和Ta元素完全回溶至基体中,据此可判定Laves相以Fe2Zr为主。图6b~c统计了系列合金在不同温度固溶处理后第二相粒子体积分数和尺寸的变化。可以看出,Zr和Ta/Zr元素的复合添加使合金中少量的第二相粒子即使在1473 K仍然存在,从而提高了合金在高温下的组织稳定性。

图7

图7

EPMA测试的1473 K/1 h热处理的No.4合金的元素面分布图

Fig.7

Element distributions in the re-treated No.2 alloy at 1473 K for 1 h mapped by EPMA

2.2 系列合金的显微硬度

图6d给出了不同热处理状态的系列合金的显微硬度(HV)。温轧后的系列合金其显微硬度都比较高,为275~288 HV。进行873 K/24 h时效后系列合金的显微硬度略有下降,为260~271 HV。其原因是,温轧引入的位错其密度在时效过程中降低使其强化效果的下降,远大于时效过程中的第二相粒子强化,从而使其硬度降低。系列合金进行1273~1473 K/1 h回溶处理后,回溶温度较高和基体晶粒粗化、第二相粒子的大量回溶使其显微硬度下降。系列合金在1273 K/1 h回溶处理后,其显微硬度显著下降约为218~230HV。随着回溶温度提高到1473 K,系列合金的显微硬度基本上不变约为215 HV。

3 讨论

以上结果表明,随着回溶温度的提高系列合金中的Laves相粒子都发生一定程度的溶解。但是,添加不同的合金元素对合金组织稳定性的影响也显著不同。Mo/Nb改良的No.1合金在1373 K短时热处理后基本上没有第二相粒子。而在No.1合金基础上添加Ta元素的合金,在1273 K短时热处理后第二相粒子的体积分数显著高于No.1合金,但在1273 K以上的稳定性不足。与此对比,添加Zr元素的No.3合金和复合添加Ta/Zr的No.4合金,即使在1473 K仍有部分第二相粒子,表明其组织稳定性较高。这种稳定性的差异,与不同元素在α-Fe基体中的固溶度和扩散系数有密切的关系。研究表明,Mo在α-Fe基体中的固溶度由1073 K的4.0%(原子分数)提高到1473 K的14%。而Nb、Ta元素的固溶度即使在1473 K也仅约为1.0%,Zr元素的固溶度仅为0.6%。Zr、Ta、Nb等较小的固溶度使其在合金中溶解较少,随着温度的升高合金元素以第二相粒子的形式析出。因此,随着回溶温度的提高Mo、Nb、Ta元素大量向基体溶解,使No.1合金和No.2合金析出相的体积分数大幅降低。而随着回溶温度的提高,Zr元素则以第二相的形式在高温下存在。同时,因为Mo/Nb/Ta等元素的扩散系数较大(表2)[15~17],在时效初期Laves相中的第二相粒子以Mo/Nb/Ta元素为主。而随着回溶温度的提高固溶度较大的Mo/Nb/Ta元素向基体溶解,而扩散系数和固溶度较小的Zr元素则向Laves相聚集,从而使高温下的Laves相转变为Fe2Zr相,如图7所示。Laves相的回溶温度和Fe2Zr Laves相的熔点(1673 K)也高于Fe2Mo、Fe2Nb等Laves相(1488 K, 1627 K)。这种Zr元素富集的Laves相在高温继续钉扎晶界,抑制晶粒长大并有强化作用,从而显著提高了合金的高温组织稳定性。

表2 元素M在BCC铁素体基体中的不同温度下的扩散系数

Table 2

| M | D0 / m2·s-1 | QM / kJ·mol-1 | D873 K / m2·s-1 | D1473 K / m2·s-1 |

|---|---|---|---|---|

| Zr | 1.20×10-6 | 240.84 | 4.66×10-21 | 3.45×10-15 |

| Ta | 2.35×10-5 | 220.93 | 1.42×10-18 | 3.44×10-13 |

| Nb | 1.27×10-5 | 224.00 | 5.02×10-19 | 1.45×10-13 |

| Mo | 1.48×10-2 | 282.60 | 1.98×10-19 | 1.48×10-12 |

此外,Laves相较高的组织稳定性与其成分的变化也有密切的关系。因为添加的合金元素不同,析出的Laves相的成分也随之发生变化。No.1合金中的Laves相主要为Fe2(Mo, Nb)型,No.2合金中Laves相主要为Fe2(Mo, Nb, Ta)型,而添加Zr的No.4合金中的Laves相主要为Fe2(Mo, Nb, Ta, Zr)型。这表明,合金成分的多元化使Laves相粒子也趋于多元化。这种多元素混合的金属间化合物会产生高熵效应而生成一种高熵金属间化合物[18~20],其稳定性显著高于单主元的Fe2Nb Laves相。从图5可见,在1373 K下No.4合金中的Fe2(Mo, Nb, Ta, Zr)型Laves相粒子其体积分数显著大于No.1合金中的Fe2(Mo, Nb)型Laves相。这种高熵金属间化合物的概念在高熵陶瓷[21~23]、高熵合金[24,25]等多领域受到了极大的关注。回溶后的粒子稳定性表明,No.3和No.4合金中的Fe2M(M=Mo, Nb, Ta, Zr)在1373 K的体积分数显著高于No.1合金中的Fe2Mo、Fe2Nb等析出相。

4 结论

(1) 对Fe-Cr-Al-Mo-Nb合金进行873 K/24 h时效处理后,在铁素体基体上分布有粗大的初生Laves相粒子和细小的球形粒子。Ta/Zr元素的添加抑制了粗大Laves相粒子的析出但是促进了细小粒子的析出。

(2) 在1273 K/1 h回溶处理后,这种合金中的第二相粒子都发生了显著的回溶(f =1.5%~2.7%),其基体晶粒发生了粗化。1473 K/1 h回溶处理后,No.1合金和Ta添加的合金中的第二相粒子全部回溶到基体中,基体晶粒严重粗化,而添加Zr和复合添加Ta/Zr的合金在晶界仍有0.2%粒子,有效抑制了基体晶粒的粗化。

(3) 对于添加Ta/Zr元素的合金,固溶度和扩散系数较小的Zr元素在高温形成Fe2Zr Laves相,从而使其高温的组织稳定性提高。

参考文献

Neutronic analysis of candidate accident-tolerant iron alloy cladding concepts

[J].

High temperature oxidation of fuel cladding candidate materials in steam-hydrogen environments

[J].

Neutronics and fuel performance evaluation of accident tolerant FeCrAl cladding under normal operation conditions

[J].

Neutronic analysis of candidate accident-tolerant cladding concepts in pressurized water reactors

[J].

Oxidation of fuel cladding candidate materials in steam environments at high temperature and pressure

[J].

Development and property evaluation of nuclear grade wrought FeCrAl fuel cladding for light water reactors

[J].

Microstructural stability of low-cost Ni-base superalloys with a high volume fraction of cuboidal γ' nanoprecipitates

[J].

Microstructures and mechanical properties of body-centered-cubic (Al,Ti)0.7(Ni, Co, Fe, Cr)5 high entropy alloys with coherent B2/L21 nanoprecipitation

[J].

Controlled formation of coherent cuboidal nanoprecipitates in body-centered cubic high-entropy alloys based on Al2(Ni, Co, Fe, Cr)14 compositions

[J].

Effect of nanoscale precipitation on strengthening of ferritic ODS Fe-Cr-Al alloy

[J].

Effects of Laves phase particles on recovery and recrystallization behaviors of Nb-containing FeCrAl alloys

[J].

Heterogeneous creep deformations and correlation to microstructures in Fe-30Cr-3Al alloys strengthened by an Fe2Nb Laves phase

[J].

Microstructural control of FeCrAl alloys using Mo and Nb additions

[J].

Influence of Ta/Zr minor-alloying on the high-temperature microstructural stability of cladding Fe-Cr-Al ferritic stainless steels

[J].

Diffusion of molybdenum in α-iron

[J].

Diffusion of niobium in α-iron

[J].

Calculation of impurity diffusivities in α-Fe using first-principles methods

[J].

Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys

[J].Alloy design based on single-principal-element systems has approached its limit for performance enhancements. A substantial increase in strength up to gigapascal levels typically causes the premature failure of materials with reduced ductility. Here, we report a strategy to break this trade-off by controllably introducing high-density ductile multicomponent intermetallic nanoparticles (MCINPs) in complex alloy systems. Distinct from the intermetallic-induced embrittlement under conventional wisdom, such MCINP-strengthened alloys exhibit superior strengths of 1.5 gigapascals and ductility as high as 50% in tension at ambient temperature. The plastic instability, a major concern for high-strength materials, can be completely eliminated by generating a distinctive multistage work-hardening behavior, resulting from pronounced dislocation activities and deformation-induced microbands. This MCINP strategy offers a paradigm to develop next-generation materials for structural applications.Copyright © 2018 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Design of D022 superlattice with superior strengthening effect in high entropy alloys

[J].

Single-phase high-entropy intermetallic compounds (HEICs): bridging high-entropy alloys and ceramics

[J].High-entropy intermetallic compounds (HEICs) were fabricated by mechanical alloying and spark plasma sintering to fill a knowledge gap between the traditional high-entropy alloys (HEAs) and emerging high-entropy ceramics (HECs). Notably, several four- or five-component equimolar aluminides, such as the B2-phase (FeCoNiMnCu)Al, have been made into single-phase HEICs for the first time. Thermodynamic modeling and a reversible, temperature-dependent, phase-stability experiment suggest that such B2-phase HEICs are entropy-stabilized phases. The structure of these HEICs resembles that of HECs with high-entropy mixing of four or five elements of nearly equal fractions in one and only one sublattice, but with significant (∼10%) anti-site defects (differing from typical HECs). A new phase stability rule for forming single B2-phase HEICs is proposed. Five additional HEICs of predominantly D0 phases have also been made. This study broadens the families of equimolar, single-phase, high-entropy materials that have been successfully fabricated.Copyright © 2019 Science China Press. Published by Elsevier B.V. All rights reserved.

High-entropy ceramic thin films; A case study on transition metal diborides

[J].

Ablation-resistant carbide Zr0.8Ti0.2C0.74B0.26 for oxidizing environments up to 3,000℃

[J].Cyclooxygenase-2 isozyme is a promising anti-inflammatory drug target, and overexpression of this enzyme is also associated with several cancers and neurodegenerative diseases. The amino-acid sequence and structural similarity between inducible cyclooxygenase-2 and housekeeping cyclooxygenase-1 isoforms present a significant challenge to design selective cyclooxygenase-2 inhibitors. Herein, we describe the use of the cyclooxygenase-2 active site as a reaction vessel for the in situ generation of its own highly specific inhibitors. Multi-component competitive-binding studies confirmed that the cyclooxygenase-2 isozyme can judiciously select most appropriate chemical building blocks from a pool of chemicals to build its own highly potent inhibitor. Herein, with the use of kinetic target-guided synthesis, also termed as in situ click chemistry, we describe the discovery of two highly potent and selective cyclooxygenase-2 isozyme inhibitors. The in vivo anti-inflammatory activity of these two novel small molecules is significantly higher than that of widely used selective cyclooxygenase-2 inhibitors.

Structure and properties of two Al-Cr-Nb-Si-Ti high-entropy nitride coatings

[J].

A critical review of high entropy alloys and related concepts

[J].

A fracture-resistant high-entropy alloy for cryogenic applications

[J].High-entropy alloys are equiatomic, multi-element systems that can crystallize as a single phase, despite containing multiple elements with different crystal structures. A rationale for this is that the configurational entropy contribution to the total free energy in alloys with five or more major elements may stabilize the solid-solution state relative to multiphase microstructures. We examined a five-element high-entropy alloy, CrMnFeCoNi, which forms a single-phase face-centered cubic solid solution, and found it to have exceptional damage tolerance with tensile strengths above 1 GPa and fracture toughness values exceeding 200 MPa·m(1/2). Furthermore, its mechanical properties actually improve at cryogenic temperatures; we attribute this to a transition from planar-slip dislocation activity at room temperature to deformation by mechanical nanotwinning with decreasing temperature, which results in continuous steady strain hardening. Copyright © 2014, American Association for the Advancement of Science.