为了制备高强高阻尼石墨烯/聚合物复合材料,本文提出在复合材料内部引入界面多重氢键结构,选用石墨烯(Gr)和聚苯乙烯-乙烯-丁二烯-苯乙烯弹性体(SEBS)分别为纳米增强填料和聚合物基体,接枝修饰引入氢键单元,用溶液共混与热压成型工艺制备石墨烯/SEBS复合材料。

1 实验方法

1.1 实验用材料

实验用材料:石墨烯原料,是一种用电解氧化法制备的氧化石墨烯(GO)浆料(固含量为1%),石墨烯层数小于3层,片径尺寸为0.1~3 μm;苯乙烯-乙烯-丁二烯-苯乙烯嵌段共聚物(SEBS)的型号为G1652,苯乙烯含量(质量分数)为30%,数均分子量Mn=70.3 kg·mol-1,密度为0.91 g·cm-3;化学助剂有马来酸酐(MAH, AR)、3-氨基-1,2,4三唑(ATA, CP)、过氧化二异丙苯(DCP, CP)、1-乙基-(3-二甲基氨基丙基)碳酰二亚胺盐酸盐(EDC, CP)、二甲苯(Xylene, AR)、N,N-二甲基甲酰胺(DMF, AR)以及维生素C(Vitamin C, AR)。

1.2 石墨烯与SEBS的接枝改性以及复合材料的制备

将m-Gr与m-SEBS加入二甲苯-DMF有机溶剂中,充分混合后倒入乙醇溶液中使复合物沉淀析出,将其过滤和鼓风干燥后放入模具中在160℃、15 MPa条件下热压成型25 min,自然冷却并保压2 h后得到石墨烯/SEBS复合材料(Gr/SEBS)。复合材料中石墨烯的添加量(质量分数)分别为0、0.1%、0.2%、0.5%和0.75 %。

1.3 结构和性能表征

用Bruker Tensor 27型红外光谱仪测试改性前后的石墨烯与SEBS、以及复合材料的化学基团;用原位变温红外光谱技术(Nicolet iS10-iZ10)表征石墨烯/SEBS复合材料的氢键结构以及其在30~210℃范围内的结构变化。

参照GB/T 528-2009用电子万能材料试验机(5ST, Tinius Olsen)测试复合材料的拉伸-回复循环性能,拉伸速率为50 mm·min-1,最大拉伸应变控制为400%。对循环拉伸应力应变曲线进行面积积分,计算循环过程中的能量滞后损耗(MJ·m-3)。

用动态热机械分析仪(DMA, TA-Q800)测试复合材料的动态力学拉伸性能。测试条件为:单轴拉伸模式,预加载力0.01 N,升温速率3℃·min-1,频率1 Hz,动态应变3%,样品尺寸为14 mm×3 mm×1 mm。

2 结果和讨论

2.1 石墨烯/SEBS复合材料的界面氢键结构

图1给出了石墨烯/SEBS复合材料的界面氢键结构示意图。从图1a可见,SEBS基体为苯乙烯-乙烯-丁二烯的三元嵌段共聚物,具有饱和柔性分子链特征,无法与石墨烯产生强界面相互作用。对其进行自由基取代反应接枝马来酸酐(MAH)基团[22,23],进而与改性剂ATA的氨基发生开环反应,可得带有氢键结构单元(酰胺、三唑和羧酸基团)的ATA改性SEBS(m-SEBS)[21]。图1b给出了石墨烯的表面改性示意图。可以看出,氧化石墨烯(GO)表面的环氧基和羧基可与ATA的氨基分别发生亲核取代与酰胺化反应[18],从而使石墨烯表面接枝ATA(m-Gr)并引入氢键结构单元(酰胺与三唑基团)。由于m-Gr与m-SEBS均含有氢键结构单元,N和O原子可作为氢键受体与邻近的H原子间发生氢键相互作用(图1c),从而在石墨烯/SEBS复合材料界面处形成多重氢键结构,实现组元间的有效应力传递和力学性能的显著提高[24];同时,界面氢键结构易于在复合材料变形过程中发生断裂与再生,从而产生高能量耗散和提高阻尼性能。

图1

图1

石墨烯/SEBS复合材料的界面氢键结构示意图

Fig.1

Schematics of interfacial hydrogen bonds in Gr/SEBS composites (a) ATA-grafted SEBS, (b) ATA-modified graphene, and (c) the interfacial hydrogen bonds between components

2.2 基团的结构

图2给出了石墨烯/SEBS复合材料和组元改性前后的红外光谱。从图2a可见,与改性前的GO和SEBS相比,改性后的m-Gr和m-SEBS均在红外光谱中1690和1540 cm-1附近出现明显的红外特征峰,分别对应酰胺键的C=O与ATA的C-N=C的特征振动峰[25~28];同时,在1260 cm-1出现C-N的特征峰[29, 30]。这些结果均表明,ATA已经成功接枝到SEBS与石墨烯表面。同时,在m-SEBS的谱中可见1726 cm-1处对应的C=O特征振动峰,来源于MAH与ATA开环反应形成的羧酸基团[21]。在复合体系内存在酰胺、三唑、羧酸基团,彼此之间可形成界面氢键结合。此外,与m-Gr和m-SEBS相比,石墨烯/SEBS复合材料的谱中没有新的吸收峰,表明组元间没有形成新的共价键,而是通过氢键相结合[28]。图2b给出了用变温红外技术表征的石墨烯/SEBS复合材料的氢键结构特征。可以看出,随着温度的提高羧酸、酰胺、与三唑基团对应的特征峰都出现不同程度的偏移。1726 cm-1处的羧酸基C=O特征峰、1690 cm-1处的酰胺键C=O特征峰、1540 cm-1处对应的C-N=C振动峰分别偏移至1733 cm-1、1682 cm-1和1518 cm-1,与文献[13,21]报道的结果一致。振动特征峰的偏移可归因于变温过程中氢键的断裂解离引起的相应特征基团振动频率的变化[31],是体系内存在氢键的直接证据。值得指出的是,氢键具有动态可逆、对温度及应力响应敏感的特性,易于在外界作用下发生可逆断裂进而产生能量耗散,从而使复合材料具有较高的阻尼性能[13]。同时,氢键的可逆断裂/再生特性也有利于材料能量的持续耗散和保持较高的力学性能。

图2

图2

GO、m-Gr、SEBS、m-SEBS和石墨烯/SEBS复合材料的红外光谱和变温原位红外光谱

Fig.2

Infrared spectra of the GO, m-Gr, SEBS, m-SEBS, and Gr/SEBS composites (a) and In-situ infrared spectra (b) of Gr/SEBS composites at variable temperatures

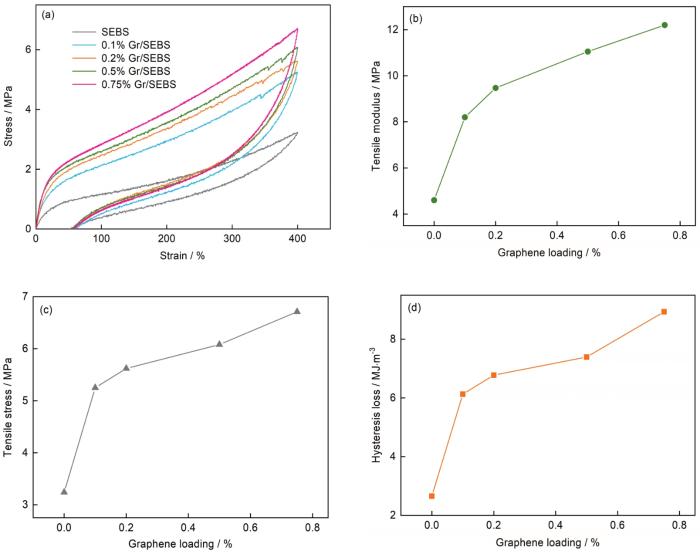

2.3 石墨烯/SEBS复合材料的循环拉伸特性

图3给出了石墨烯/SEBS复合材料在循环拉伸过程中的力学行为。从图3a可见,石墨烯/SEBS复合材料有比纯SEBS更高的拉伸模量和更明显的滞后回线特征,表明石墨烯和氢键网络能显著提高材料的力学性能和能量耗散。从图3b可见,随着石墨烯含量的提高复合材料的拉伸模量不断提高。石墨烯含量(质量分数,下同)为0.75%的复合材料其拉伸模量可达12.2 MPa,比纯SEBS(4.6 MPa)提高了165%。这种力学性能的显著提高主要可归因于组分间较强的界面氢键结合和石墨烯的高本征力学强度,能有效传递应力并承受外界载荷[32]。从图3c中对应的拉伸应力数据也可见相同的力学性能的增强效果。根据滞后回线的面积可评价循环过程中的能量损耗[33]。从图3d可以看出,石墨烯/SEBS复合材料具有比纯SEBS更明显的滞后响应特征和更高的滞后损耗值。0.75%石墨烯/SEBS复合材料的滞后损耗值为8.93 MJ·m-3,比纯SEBS的2.65 MJ·m-3提高了237%,表明石墨烯和界面氢键能显著提高复合材料的能量耗散与阻尼性能。一方面,石墨烯和氢键的引入显著抑制了聚合物分子链的运动,可产生明显的滞后现象;另一方面,石墨烯/SEBS复合材料的丰富界面和界面氢键网络的可逆断裂/再生特性使复合材料在外力作用下的变形过程中通过大量的界面滑移与氢键断裂重排耗散更多的能量,从而表现出显著的滞后损耗及能量耗散能力。

图3

图3

石墨烯/SEBS复合材料的循环拉伸特性

Fig.3

Cyclic tensile mechanical behavior of Gr/SEBS composites (a) cyclic tensile stress-strain curve, (b) tensile modulus, (c) tensile stress at 400% strain, and (d) hysteresis loss

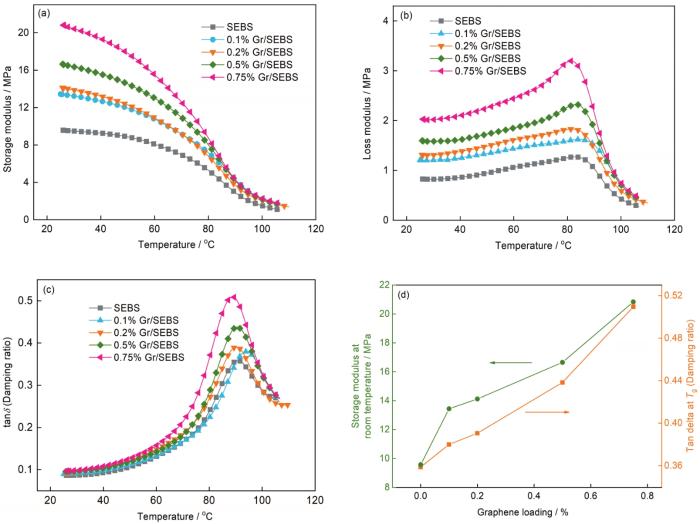

2.4 石墨烯/SEBS复合材料的动态力学性能

图4给出了用动态热机械分析仪(DMA)测量的复合材料的动态力学性能。从图4a可见,所有复合材料的储能模量均显著比纯SEBS的高,且随着石墨烯含量的提高复合材料的储能模量随之提高。这个结果与图3b中复合材料拉伸模量的变化趋势一致。石墨烯含量为0.75%的石墨烯/SEBS复合材料,其常温下的储能模量达到20.83 MPa,比纯SEBS的9.58 MPa提高了117%(图4d),表现出显著的力学增强特性。图4b~c分别给出了复合材料的损耗模量和损耗因子(tanδ)随温度的变化曲线,分别反映了复合材料的能量耗散能力和阻尼性能对温度变化的响应。可以看出,石墨烯/SEBS复合材料比纯SEBS的损耗模量和损耗因子更高。这表明,石墨烯和氢键网络的存在使复合材料在动态变形情况下具有更高的能量耗散能力,其能量耗散的变化趋势也与图3d中循环拉伸测试滞后损耗的变化趋势一致。复合材料的常温能量损耗,主要可归因于在外加载荷作用下氢键界面的可逆断裂/再生。随着温度的提高氢键网络对石墨烯及聚合物的束缚减弱,聚合物分子链段的运动能力增大并通过石墨烯片层的摩擦滑移协同界面氢键的断裂不断耗散能量,使复合材料损耗模量及损耗因子值得以显著提高。从图4d可见,0.75%石墨烯/SEBS复合材料的损耗因子值为0.51,比纯SEBS的0.36提高了42%,表明石墨烯和界面氢键网络的引入能显著提高复合材料的阻尼性能。石墨烯/SEBS复合材料力学性能和阻尼的显著增强,主要归因于石墨烯与SEBS的界面氢键结合、高效应力传递、界面滑移、以及氢键可逆断裂/再生过程中的显著能量耗散。

图4

图4

石墨烯/SEBS复合材料的储能模量、损耗模量、损耗因子以及石墨烯含量不同的成立的储能模量与损耗因子

Fig.4

Dynamic mechanical analyses of Gr/SEBS composites (a) storage modulus, (b) loss modulus, (c) tanδ, and (d) the storage modulus and damping ratio against graphene loadings

3 结论

(1) 在石墨烯和SEBS分子链段分别接枝氢键单元ATA在复合材料组元界面构建了多重氢键网络,可制备具有氢键网络结构的石墨烯/SEBS复合材料。

(2) 石墨烯/SEBS复合材料中的石墨烯及氢键网络显著提高了复合材料的力学强度和阻尼性能,石墨烯/SEBS复合材料的弹性模量、滞后损耗、损耗因子分别比SEBS提高了165%、237%和42%。

(3) 石墨烯/SEBS复合材料的力学和阻尼性能的同时显著提高,主要归因于石墨烯与SEBS间氢键网络的形成、高效应力传递、界面滑移以及氢键可逆断裂/再生过程中的能量耗散。

参考文献

Research and applications of viscoelastic vibration damping materials: A review

[J].

Design and reinforcement: vertically aligned carbon nanotube-based sandwich composites

[J].Carbon nanotube (CNT) reinforcement of polymer composites has not yielded optimum results in that the composite properties are typically compromised by poor dispersion and random orientation of CNTs in polymers. Given the short lengths available for nanotubes, opportunities lie in incorporating CNTs with other structural reinforcements such as carbon fibers (CFs) to achieve improvement over existing composite designs. Growth of vertically aligned CNTs (VACNTs) offers new avenues for designing high-performance composites by integrating CFs and nanotubes into layered 3D architectures. To obtain composites with high rigidity and damping, we have designed and fabricated VACNT-based sandwich composites from simply stacking the freestanding VACNTs and CF fabrics and infiltrating with epoxy matrix. Comparing with the CF/epoxy laminates, the VACNT-based sandwich composites exhibit higher flexural rigidity and damping, which is achieved due to the effective integration of the VACNTs as an interfacial layer between the CF stacks. Furthermore, the lighter weight of these VACNT-based sandwich composites offers advantages in aerospace and transportation applications.

Improved damping and high strength of graphene-coated nickel hybrid foams

[J].Direct growth of graphene on the metal surface opens a door for obtaining high-performance composites in a simple way. In order to obtain both high strength and enhanced damping property of the porous metal, we prepared graphene-coated nickel hybrid foams by chemical vapor deposition technique and investigated the static and dynamic mechanical properties using a dynamic mechanical analyzer and vibration testing systems in detail. We found that the presence of graphene layers could greatly improve both mechanical strength and damping properties of nickel foams. The graphene-coated nickel hybrid foams exhibited high yield strength, compressive modulus, and damping ratio, increased by 46, 22, and 53% in comparison with those of nickel foams. Such significant graphene reinforcement in mechanical and damping properties is mainly attributed to the strong interfacial bonding, remarkable confinement effect, and rich interfaces in hybrid foams. By virtue of its high mechanical strength and enhanced damping properties, the graphene/nickel hybrid foams have great potential to be used as multifunctional composite materials in many fields.

Vibration damping of carbon nanotube assembly materials

[J].

Simultaneously high stiffness and damping in nanoengineered microtruss composites

[J].Materials combining high stiffness and mechanical energy dissipation are needed in automotive, aviation, construction, and other technologies where structural elements are exposed to dynamic loads. In this paper we demonstrate that a judicious combination of carbon nanotube engineered trusses held in a dissipative polymer can lead to a composite material that simultaneously exhibits both high stiffness and damping. Indeed, the combination of stiffness and damping that is reported is quite high in any single monolithic material. Carbon nanotube (CNT) microstructures grown in a novel 3D truss topology form the backbone of these nanocomposites. The CNT trusses are coated by ceramics and by a nanostructured polymer film assembled using the layer-by-layer technique. The crevices of the trusses are then filled with soft polyurethane. Each constituent of the composite is accurately modeled, and these models are used to guide the manufacturing process, in particular the choice of the backbone topology and the optimization of the mechanical properties of the constituent materials. The resulting composite exhibits much higher stiffness (80 times) and similar damping (specific damping capacity of 0.8) compared to the polymer. Our work is a step forward in implementing the concept of materials by design across multiple length scales.

Preparation of Y2O3 hollow spheres and low frequency damping poperties of rubber composite reinforced with Y2O3 hollow spheres

[J].

氧化钇空心微球的制备及其复合橡胶的低频阻尼性能

[J].

Mechanical properties of graphene and graphene-based nanocomposites

[J].

Viscoelastic damping of nanocarbon/epoxy composites

[J].

Energy dissipation due to interfacial slip in nanocomposites reinforced with aligned carbon nanotubes

[J].

Effect of functionalization of single-wall carbon nanotubes (SWNTs) on the damping characteristics of SWNT-based epoxy composites via multiscale analysis

[J].

Effects of functional groups on the graphene sheet for improving the thermomechanical properties of polyurethane nanocomposites

[J].

Engineering graphene wrinkles for large enhancement of interlaminar friction enabled damping capability

[J].

Construction of sacrificial bonds and hybrid networks in EPDM rubber towards mechanical performance enhancement

[J].

Characterization of hydrogen bonding formation and breaking in semiconducting polymers under mechanical strain

[J].Diketopyrrolopyrrole (DPP)-based donor-acceptor conjugated polymers, with increasing amount of weak H-bonding units, namely 2,6-pyridinedicarboxamide (PDCA), inserted as end groups in alkyl side chains were prepared and investigated. In contrast to previously reported DPP polymers containing PDCA units as conjugation breakers along the polymer backbone, PDCA in the alkyl side chains readily produced almost quantitative formation of intermolecular H-bonding even at low PDCA unit content (<10 mol %) as shown by Fourier transform infrared spectroscopy (FTIR). The efficient intermolecular H-bonding was further supported by the appearance of a pronounced vibronic shoulder in the UV-vis spectra and a reduction of interlamellar spacing (from 24.02 to 22.87 angstrom) compared to the neat DPP polymer. Increasing mol % of PDCA units in side chains of DPP conjugated polymers also has a clear effect on the thermal and mechanical properties of the films as investigated by dynamic mechanical analysis (DMA). Polymers with a high loading of PDCA showed a linear increase in both tan delta intensity and temperature at which softening of film cross-linking occurs. In particular, at a comparable mol %, polymers with PDCA units along the conjugated backbone showed a lower transition intensity and on average a 10-20 degrees C higher temperature required for H-bonding breaking. FTIR coupled with crack onset measurements showed that H-bonding breaking during tensile deformation happens only at strains close to crack onset. All these observations suggest that molecular engineering of conjugated polymers bearing H-bonding units has a strong influence on microstructure, thermal and mechanical properties of solution processed films, and final energy dissipation mechanisms in stretchable electronics applications.

Self-healing in supramolecular polymers

[J].

High-strength, tough, and self-healing nanocomposite physical hydrogels based on the synergistic effects of dynamic hydrogen bond and dual coordination bonds

[J].

Highly controllable transparent and conducting thin films using layer-by-layer assembly of oppositely charged reduced graphene oxides

[J].

A new approach to fabricate graphene nanosheets in organic medium: combination of reduction and dispersion

[J].

Reduction of graphene oxide via L-ascorbic acid

[J].

Anion exchange membrane based on sulfonated poly (styrene-ethylene-butylene-styrene) copolymers

[J].

Bioinspired engineering of two different types of sacrificial bonds into chemically cross-linked cis-1,4-polyisoprene toward a high-performance elastomer

[J].

Effect of tunable styrene content on achieving high-performance poly(styrene-b-ethylene-ran-butylene-b-styrene)/graphene oxide nanocomposites

[J].

Peroxide-initiated comonomer grafting of styrene and maleic anhydride onto polyethylene: Effect of polyethylene microstructure

[J].

Themoreversible cross-linking rubber using supramolecular hydrogen-bonding networks

[J].

Cross-linkable nitrile functionalized graphene oxide/poly(arylene ether nitrile) nanocomposite films with high mechanical strength and thermal stability

[J].

Optically tunable amino-functionalized graphene quantum dots

[J].

Lignin-reinforced ethylene-propylene-diene copolymer elastomer via hydrogen bonding interactions

[J].

Amphibious hybrid nanostructured proton exchange membranes

[J].

Cross-linkable nitrile functionalized graphene oxide/poly(arylene ether nitrile) nanocomposite films with high mechanical strength and thermal stability

[J].

Simultaneous reduction, functionalization and stitching of graphene oxide with ethylenediamine for composites application

[J].

Molecular insights into hydrogen bonds in polyurethane/hindered phenol hybrids: evolution and relationship with damping properties

[J].

Effect of polypyrrole modified carbon fiber on interfacial property of composite PPy-carbon fiber/epoxy

[J].

聚吡咯修饰碳纤维/环氧树脂复合材料的界面剪切强度

[J].应用等离子体技术对碳纤维(CF)表面进行预处理,然后进行液相沉积聚吡咯处理。使用X射线光电子能谱仪、原子力显微镜(AFM)、扫描电子显微镜(SEM)和傅立叶红外光谱仪等手段对碳纤维表面形态和结构进行分析与表征,并进行单纤维界面剪切强度试验和SEM观测,研究了碳纤维复合材料的界面粘结性能。结果表明,等离子体预处理碳纤维沉积聚吡咯(PPy)使单纤维界面剪切强度提高了259.3%。分析结果表明,界面剪切强度的提高与纤维/树脂间的机械铆合和界面的作用力有关。等离子体预处理使碳纤维表面的羧基基团增多,在羧基和PPy之间形成氢键,从而提高了碳纤维复合材料的界面性能。