选区激光熔化(Selective laser melting,SLM)是一种典型的金属增材制造技术。SLM工艺成型的零部件致密度高、表面质量好,简单处理后即可服役。316L不锈钢具有良好的耐蚀性能和综合力学性能,是最早用SLM成型的材料,广泛用于能源、汽车工业和生物医学等领域。SLM-316L不锈钢等增材制造零部件服役时经受冲击载荷作用,因此明确材料在高应变率下的变形响应对于保障设备安全有重要的意义。

由于尚未形成行业内广泛接受的增材制造认证流程及金属粉料规范,人们只能通过微观结构、相对密度、显微硬度和力学性能测试明确多种粒径分布的气体雾化316L不锈钢粉末原料对316L不锈钢性能的影响[6]。为了进行增材制造与传统工艺的对比,选取激光近净成形(LENS)[7]、选区激光熔化(SLM)[8]、冷金属过渡焊接(CMT)[9]、金属激光烧结(DMLS)[10,11]、退火锻造[7]等方式制备试样,获取了材料的静、动态[12,13]力学性能。同时,在此基础上研究了工艺参数(如激光功率、建造方向、扫描间距等)[14~16]、建造方向和试样厚度[17]、热处理制度[18]对材料静、动态力学性能的影响。在微观表征方面,人们对LENS-316L材料进行亚毫米到纳米域微观结构的多尺度表征[12],分析了SLM-316L的疲劳破坏情况及裂纹萌生和扩展的特点[19,20],并结合低温变形过程从层错能和晶粒织构角度阐述了SLM-316L高极限强度和低屈服比的微观机制[21]。同时,还结合316L不锈钢材料开展了分子动力学模拟[22]及力学性能的人工神经网络预测,取得了良好的预测精度[23]。

国内外学者测试了用多种增材方式制备的316L不锈钢的静、动态力学性能,并进行了工艺参数优化和微观结构表征。SLM-316L不锈钢在高应变载荷下存在屈服失效风险,且其瞬时塑性变形伴随着晶体结构剧烈变化,但是冲击失效机理尚不明确。本文在前期实验基础上优选工艺参数制备SLM-316L不锈钢试样,分析试样加载前后晶体结构差异以及位错滑移、孪生行为,以揭示高应变率压缩下的微观变形机制。

1 实验方法

1.1 试样的制备

图1

图1

粉末的微观形貌及粒径分布

Fig.1

Micro morphology (a) and particle size distribu-tion of powder (b)

表1 粉末的元素成分分析结果

Table 1

| Elements | Si | Cr | Mn | Mo | Ni | Fe |

|---|---|---|---|---|---|---|

| Mass fraction/% | 0.74 | 17.95 | 0.72 | 2.46 | 10.94 | Bal. |

| Atomic fraction/% | 1.47 | 19.18 | 0.72 | 1.42 | 10.35 | Bal. |

制备试样前对不锈钢粉末进行干燥处理(环境温度200℃,干燥时间2 h),然后用激光选区熔化(SLM)成型设备(TB-SLM280)制备316L不锈钢试样,制备过程中成型仓的氧气含量(体积分数)保持在2×10-4~3×10-4,工艺参数优选为激光功率260 W、扫描速度950 mm/s、扫描间距0.10 mm[24]。根据动态压缩试样设计准则,选取圆柱形316L不锈钢试样的直径为12 mm厚度为5 mm。

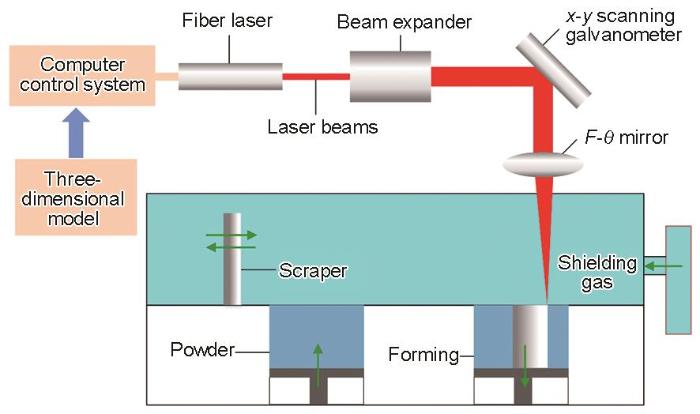

SLM成型设备工作原理如图2所示。先将零件/试样三维模型导入SLM成型设备切片软件,对实体模型进行分层离散化处理,获取各截面轮廓信息并规划扫描路径。设置激光参数,将来自送粉装置的金属粉末材料平铺在基板上,用扫描振镜控制激光束按规划路径对粉末进行选择性照射,使其熔化、凝固形成熔覆层。基板平台下降将金属粉末平铺在熔覆层上,再次用选择性照射产生新的熔覆层并与之前的熔覆层形成冶金结合。重复上述步骤,逐层堆积制备出组织致密的金属试样。

图2

1.2 高应变率压缩实验装置的原理和使用方法

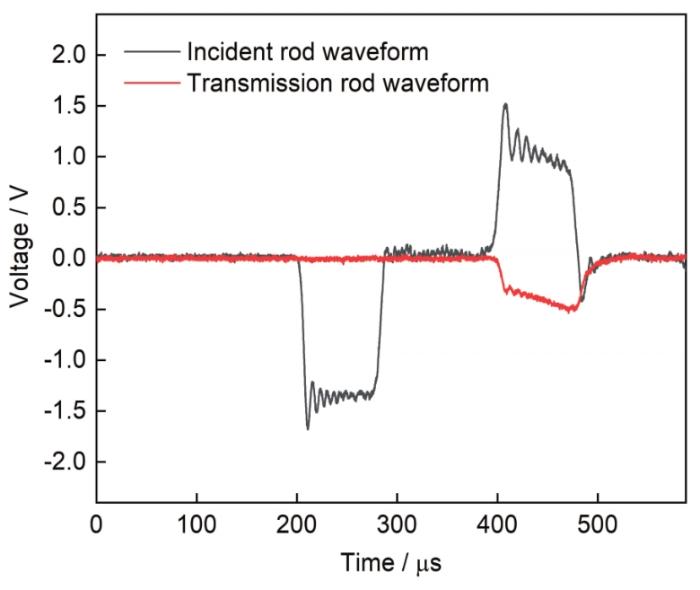

用分离式霍普金森压杆(SHPB)实验装置进行高应变率压缩实验。图3给出了装置的原理图。该装置由加载系统、杆系统和测试系统组成。杆系统包括冲击杆(200 mm)、入射杆(1000 mm)、透射杆(1000 mm)和吸收杆(600 mm)。杆径均为14.5 mm,材料为55CrSi弹簧钢,弹性模量为210 GPa,密度为7.85 g/cm3,波速约为5100 m/s。测试系统包括应变片、超动态应变仪和数据采集装置。

图3

进行SHPB实验需满足一维应力波假定和均匀性假定。为了满足一维应力波假定,选取入射杆和透射杆的长径比为68.97(大于20),入射杆长度为冲击杆的5倍,应变片位于杆中间位置,且距杆两端距离大于10倍杆径。实验时将试样置于入射杆与透射杆之间并在试样与杆的接触面涂抹润滑剂(凡士林)以减少摩擦。

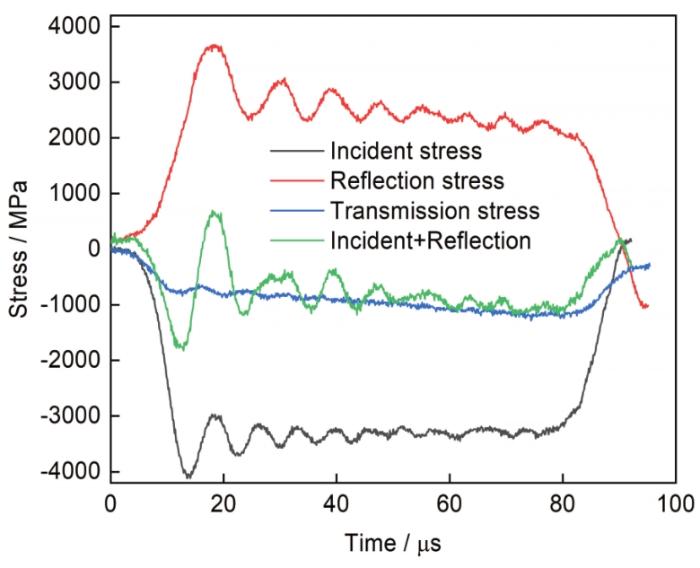

在加载系统高压气体作用下冲击杆以一定的速度撞击入射杆,在入射杆产生入射波并出现弹性应变εi。入射波沿着入射杆传至试样,一部分入射波返回形成反射波,入射杆再次出现弹性应变εr。另一部分透过试样传至透射杆形成透射波,透射杆产生弹性应变εt。在实验过程中调整冲击杆撞击速度可改变试样的加载应变率。试样的平均工程应变率

式中εi、εr和εt分别为入射应变、反射应变和透射应变;c0为杆的弹性波速(m/s),E、A分别为压杆的弹性模量(GPa)和杆的横截面积(mm2);A0、l0分别为试样的面积(mm2)和长度(mm)。

图4

图5

1.3 试样微观结构的表征

图6

图6

微观结构表征试样

Fig.6

Microstructure characterization specimens (a) SLM molding specimen, (b) cuboid specimen

2 实验结果和分析

2.1 试样在高应变率压缩载荷下的力学性能

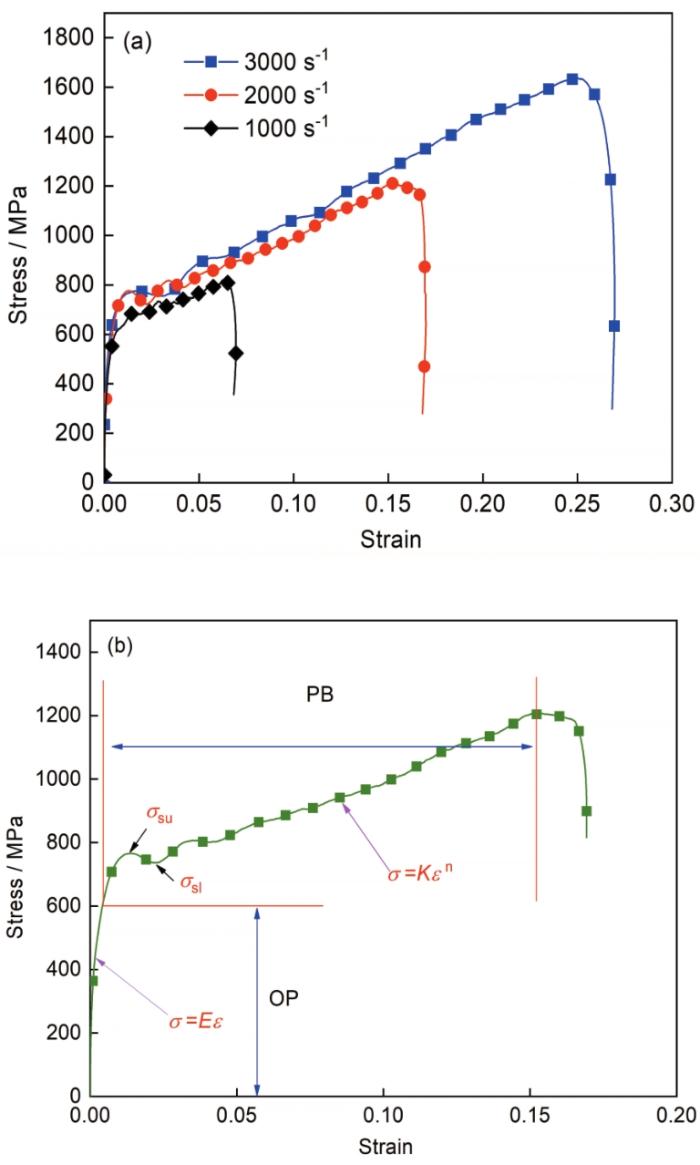

图7

图7

动态压缩应力-应变曲线

Fig.7

Dynamic compressive stress-strain curves (a) stress-strain curves (1000, 2000 and 3000 s-1), (b) analysis of curves

试样在三种应变率下的屈服强度σs分别为677、760和788 MPa,峰值应力分别为819、1209和1635 MPa。试样的屈服强度和峰值应力均随着应变率的增加而增加,较大的峰值应力增幅体现了显著的应变率强化效应。SLM成型316L不锈钢在相同应变率下的屈服强度,略低于传统冷拔成型的316L不锈钢[25]。

2.2 微观形貌

试样是用离散堆积方式制备的,因此其激光扫描平面和建造截面的微观结构不同。为了准确表征三维形貌,分别对激光扫描平面和建造截面进行SEM观测。图8给出了高应变率加载前试样的微观形貌。

图8

图8

高应变率加载前试样的微观形貌

Fig.8

Micromorphology of specimen before high strain rate loading (a) laser scanning plane, (b) construction section, (c) enlarged image of zone I, (d) enlarged image of zone II, (e) enlarged image of zone III

图9

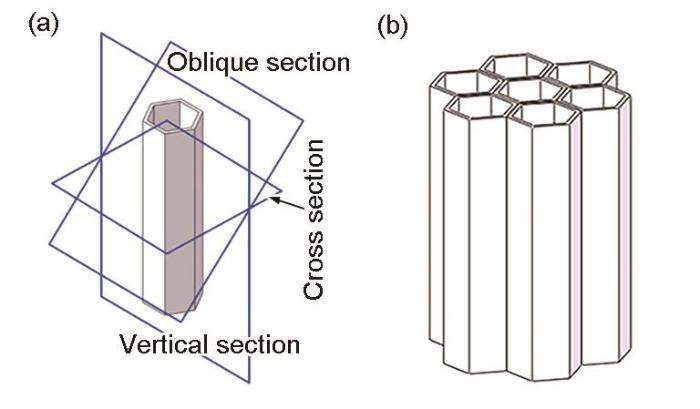

图9

柱状胞晶及其密排结构示意图

Fig.9

Schematic diagram of columnar cell crystal and close-packed structure (a) columnar cell crystal structure, (b) close-packed structure

图10

图10

高应变率加载后试样的微观形貌

Fig.10

Micromorphology of specimen after high strain rate loading (a) laser scanning plane, (b) construction section

2.3 高应变率压缩下的塑性变形行为

为了揭示SLM-316L不锈钢在高应变率压缩下的塑性变形行为,以加载应变率2000 s-1为例,收集加载前后的SLM成型试样(以下简称初始试样和变形试样),分析试样晶体结构的差异以及位错滑移、孪生行为等微观变形机制。

2.3.1 晶体的形貌和取向分析

在SLM成型过程中激光扫描和熔覆层堆积有明显的方向性,因此SLM成型试样的晶体形貌和取向会受成型方向的影响。在高应变率载荷作用下试样在短时间内发生剧烈塑性变形,使晶体的形貌及位相差改变。图11给出了基于EBSD技术绘制的初始试样和变形试样建造截面的晶体取向图、极图和反极图。

图11

图11

晶体形貌和取向分析

Fig.11

Crystal morphology and orientation analysis (a) crystal orientation figure of the initial specimen, (b) crystal orientation figure of the deformed specimen, (c) pole figure and inverse pole figure of the initial specimen, (d) pole figure and inverse pole figure of the deformed specimen

图11c给出了初始试样晶粒的极图和反极图,可见在三个特征晶面{100}、{110}、{111}内均存在取向强度较高的分布点,且极密度较高的点沿乌氏网横、纵轴呈对称分布,晶粒取向有较强的择优性。晶体取向在沿X0方向(建造方向)有平行于(001)方向的择优性,强度为4.89;沿Y0方向即激光扫描方向有平行于(101)方向的择优性,强度为6.91。图11d给出了变形试样晶粒的极图和反极图。可以看出,仅在{111}晶面内出现了一个强度较高的分布点,极密度为9.03,晶粒取向未见较强择优性。对反极图的分析发现,晶体取向沿物体坐标系X0、Y0、Z0方向均未呈现出极强择优性,沿激光扫描平面有平行于(111)方向强度为2.55的取向分布,沿建造方向有平行于(101)方向强度为4.32的取向分布。

上述分析表明,变形试样的晶体择优取向强度显著低于初始试样,高应变率加载使晶体取向的择优性降低。

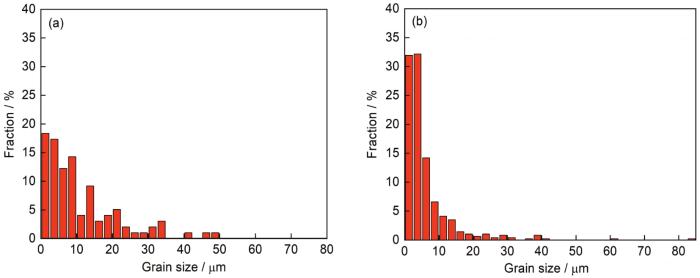

图12给出了试样晶体尺寸的统计,可见试样经高应变率加载后0~4 μm区间内的晶粒数量大幅增加,从35.7%增至64.11%。0~10 μm区间内的晶体数量从62.2%增至84.9%,而尺寸大于10 μm的晶粒数量显著减少,从37.8%降至18.1%。其原因是,晶体的切变行为多发生在晶界处,在高应变率载荷作用下外延生长的柱状晶发生断裂生成了细小的等轴晶。

图12

图12

晶粒尺寸的统计

Fig.12

Statistics of grain size (a) the initial specimen, (b) the deformed specimen

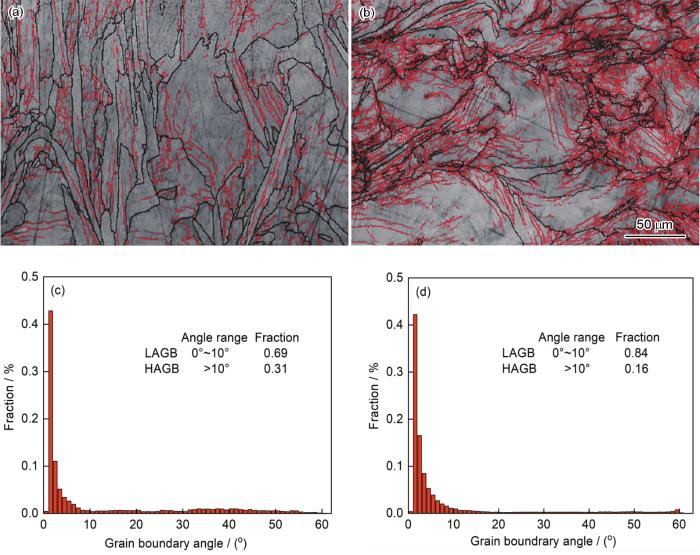

2.3.2 大、小角度晶界和孪晶

图13给出了初始试样和变形试样的大小、角度晶界的分布,给出了试样沿压缩方向观测截面内的大、小角度晶界分布及晶界数目统计,图中的黑色表示大角度晶界(HAGB,相邻晶体位相差大于10°),红色表示小角度晶界(LAGB,相邻晶体的位相差小于10°)。

图13

图13

大角度和小角度晶界分布图

Fig.13

Distribution of large and small angle grain boundaries (a) grain boundary figure of the initial specimen, (b) grain boundary figure of the deformed specimen, (c) grain boundary statistical diagram of the initial specimen, (d) grain boundary statistical diagram of the deformed specimen

图14

图14

孪晶界的分布

Fig.14

Distribution of twin boundaries (a) the initial specimen, (b) the deformed specimen

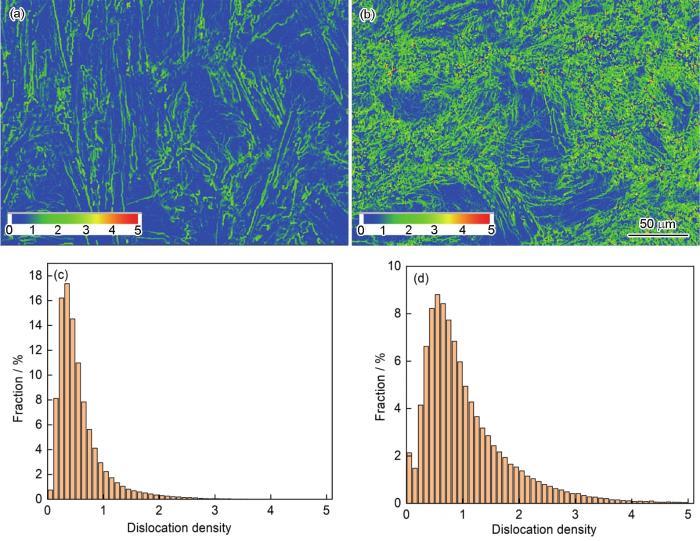

2.3.3 几何位错密度

图15给出了初始试样和变形试样中的核平均取向位错图(Kernel average misorientation,KAM)和几何位错密度图。KAM图可定性地反应材料在塑性变形时的均匀化程度,根据图中色卡颜色可将强度划分为五级。强度较高点表示该处塑性变形程度大,强度点密集分布区域表示该处塑性变形较为集中。

图15

图15

试样的KAM图和位错密度统计

Fig.15

KAM figures and dislocation density statistical diagrams of specimens (a) KAM figure of the initial specimen, (b) KAM figure of the deformed specimen, (c) dislocation density statistical diagram of the initial specimen, (d)dislocation density statistical diagram of the deformed specimen

3 结论

(1) SLM-316L不锈钢试样在高应变率条件下存在典型的弹性和塑性(屈服、强化)阶段。屈服强度和峰值应力均随着应变率的提高而增大,应变率的强化效应显著。

(2) SLM-316L不锈钢的微观组织由截面呈不规则多边形的柱状胞晶密排结构组成,各胞晶的取向差异较大,高应变率加载后外延生长的柱状晶发生断裂形成了细小的等轴晶,晶体的择优取向强度显著降低。

(3) 高应变率载荷使初始占比较高的小角度晶界数量进一步增加,且在集中分布区域内出现明显的交织缠绕。初始试样可观测孪晶界数量极少,高应变率加载后孪晶界的数量大幅度增加,且在小角度晶界交叉缠绕区密集分布。

(4) 试样加载变形后微观组织内产生断裂的大角度晶界、大量小角度晶界和少量孪晶界,变形试样的位错密度随着晶界数量的增加而提高,且高位错密度的分布集中在晶界密集处。在塑性变形过程中,同时存在互相竞争的位错滑移和孪生行为。

参考文献

Impact response and microstructural evolution of 316L stainless steel under ambient and elevated temperature conditions

[J].

Microstructure evolution of 316L steel prepared with the use of additive and conventional methods and subjected to dynamic loads: a comparative study

[J].The mechanical properties and microstructure evolution caused by dynamic loads of 316L stainless steel, fabricated using the Laser Engineered Net Shaping (LENS) technique and hot forging method were studied. Full-density samples, without cracks made of 316L stainless steel alloy powder by using the LENS technique, are characterized by an untypical bi-modal microstructure consisting of macro-grains, which form sub-grains with a similar crystallographic orientation. Wrought stainless steel 316L has an initial equiaxed and one-phase structure, which is formed by austenite grains. The electron backscattered diffraction (EBSD) technique was used to illustrate changes in the microstructure of SS316L after it was subjected to dynamic loads, and it was revealed that for both samples, the grain refinement increases as the deformation rate increases. However, in the case of SS316L samples made by LENS, the share of low-angle boundaries (sub-grains) decreases, and the share of high-angle boundaries (grains of austenite) increases. Dynamically deformed wrought SS316L is characterized by the reverse trend: a decrease in the share of high-angle boundaries and an increase in the share of low-angle boundaries. Moreover, additively manufactured SS316L is characterized by lower plastic flow stresses compared with hot-forged steel, which is caused by the finer microstructure of wrought samples relative to that of additive samples. In the case of additively manufactured 316L steel samples subjected to a dynamic load, plastic deformation occurs predominantly through dislocation slip, in contrast to the wrought samples, in which the dominant mechanism of deformation is twinning, which is favored by a high deformation speed and low stacking fault energy (SFE) for austenite.

Microstructure characterization of 316L deformed at high strain rates using EBSD

[J].

Mechanical properties and microstructure evolution of additive manufactured 316L stainless steel under dynamic loading

[J].

Characteristics of mechanical properties and microstructure for 316L austenitic stainless steel

[J].

Effect of powder feedstock on microstructure and mechanical properties of the 316L stainless steel fabricated by selective laser melting

[J].Additive manufacturing by selective laser melting (SLM) was used to investigate the effect of powder feedstock on 316L stainless steel properties include microstructure, relative density, microhardness and mechanical properties. Gas atomized SS316L powders of three different particle size distribution were used in this study. Microstructural investigations were done by scanning electron microscopy (SEM). Tensile tests were performed at room temperatures. Microstructure characterization revealed the presence of hierarchical structures consisting of solidified melt pools, columnar grains and multiform shaped sub-grains. The results showed that the SLM sample from the fine powder obtained the highest mechanical properties with ultimate tensile strength (UTS) of 611.9 ± 9.4 MPa and yield strength (YS) of 519.1 ± 5.9 MPa, and an attendant elongation (EL) of 14.6 ± 1.9%, and a maximum of 97.92 ± 0.13% and a high microhardness 291 ± 6 HV0.1. It has been verified that the fine powder (~16 μm) could be used in additive manufacturing with proper printing parameters.

Structure/property (constitutive and spallation response) of additively manufactured 316L stainless steel

[J].

Effect of laser power on the mechanical properties of selective laser melted 316L stainless steel

[J].

Dynamic mechanical properties of 316L stainless steel fabricated by an additive manufacturing process

[J].

Preparation of 316L stainless steel products by fused deposition model 3D-printing and effect of La on morphology and distribution of precipitates

[J].

FDM型3D打印316L不锈钢试样和La对析出物形貌和分布的影响

[J].使用微米级316L不锈钢粉末和蜡基粘结剂制备热融性喂料,用FDM型金属3D打印方法和工艺3D打印成形目标模型生胚,经过脱脂和烧结成形为最终金属试样。对制备出的金属试样进行性能表征和测试,验证了此种成形方式的可行性,针对试样中析出物的形貌不规则和晶界上的夹杂物,研究了稀土La对析出物的影响。根据生胚脱脂后形成的微孔结构,提出一种液相添加稀土La的方法。结果表明:用FDM型3D打印能制备316L不锈钢试样,用液相添加法可向生胚中添加微量稀土La,质量比为0.3%的LaCl<sub>3</sub>能显著改善烧结后试样中析出物的微观形貌和分布。

Mechanical performance of additively manufactured austenitic 316L stainless steel

[J].

Flow behavior and microstructure evolution during dynamic deformation of 316L stainless steel fabricated by wire and arc additive manufacturing

[J].

Mechanical characteristics of superimposed 316L lattice structures under static and dynamic loading

[J].

Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel

[J].

State of the art of selective laser melted 316L stainless steel: process, microstructure, and mechanical properties

[J].

激光选区熔化成形316L不锈钢工艺、微观组织、力学性能的研究现状

[J].

Effect of scanning speed on forming defects and properties of selective laser melted 316L stainless steel powder

[J].

扫描速度对选区激光熔化316L不锈钢粉末成形缺陷及性能的影响

[J].

An experimental investigation into influences of build orientation and specimen thickness on quasi-static and dynamic mechanical responses of selective laser melting 316L stainless steel

[J].

Effect of post-heat treatment cooling on microstructure and mechanical properties of selective laser melting manufactured austenitic 316L stainless steel

[J].This paper aims to investigate the influence of different post-annealing cooling conditions, i.e. furnace cooling (heat treatment (HT) 1 – slow cooling) and air cooling (HT 2 – fast cooling), on the microstructure and mechanical properties of selective laser melting (SLM) built austenitic 316L stainless steel (SS).

Fatigue properties and S-N curve estimating of 316L stainless steel prepared by SLM

[J].

Tensile properties of selective laser melted 316L stainless steel

[J].

选区激光熔化316L不锈钢的拉伸性能

[J].对选区激光熔化(selective laser melting,SLM) 316L不锈钢的拉伸性能及断裂机制进行了研究,并对拉伸断裂后的试样进行显微组织表征与分析,探究了拉伸变形过程中微观组织的演化规律。结果表明:采用选区激光熔化技术制备的316L不锈钢具有较好的强塑性匹配,其中晶粒内部纳米尺度胞状结构有助于强度的提升;其拉伸性能明显优于传统手段制备的316L不锈钢。选区激光熔化316L不锈钢在拉伸过程中奥氏体晶粒内部产生形变孪晶,并且形变孪晶的出现存在取向相关,在取向接近<001>的晶粒中不易出现,而在取向接近<110>-<111>的晶粒中较易出现。

Cryogenic mechanical properties of 316L stainless steel fabricated by selective laser melting

[J].

In-situ EBSD investigation of plastic damage in a 316 austenitic stainless steel and its molecular dynamics (MD) simulations

[J].

Modeling high-temperature mechanical properties of austenitic stainless steels by neural networks

[J].

Mechanical properties and constitutive model of selective laser melting 316L stainless steel at different scanning speeds

[J].

High temperature deformation and fracture behaviour of 316L stainless steel under high strain rate loading

[J].

Selective laser melting of bulk immiscible alloy with enhanced strength: Heterogeneous microstructure and deformation mechanisms

[J].To overcome the dimension limits of immiscible alloys produced by traditional techniques and enhance their mechanical properties, bulk Cu-Fe-based immiscible alloy with abundant nanotwins and stacking faults was successfully produced by selective laser melting (SLM). The SLM-produced bulk immiscible alloy displays a heterogeneous microstructure characterized by micro-scaled γ-Fe particles dispersed in fine ε-Cu matrix with a high fraction (~92%) of high-angle grain boundaries. Interestingly, abundant nanotwins and stacking faults are generated in the interior of nano-scaled γ-Fe particles embedded within ε-Cu matrix. The heterogeneous interface of soft domains (ε-Cu) and hard domains (γ-Fe) not only induces the geometrically necessary dislocations (GNDs) but also affects the dislocation propagation during plastic deformation. Therefore, the bimodal heterogeneous interface, and the resistance of nanotwins and stacking faults to the propagation of partial dislocation make the bulk immiscible alloy exhibit an enhanced strength of ~590 MPa and a good ductility of ~8.9%.

Twinning behavior in deformation of SLM 316L stainless steel

[J].