奥氏体不锈钢的加工有不同的形变处理过程,例如热轧和冷轧。在奥氏体不锈钢的冷轧过程中,剧烈的塑性变形使其强度显著提高而塑性大幅度降低。较低的塑性限制了冷轧后奥氏体不锈钢的应用[8],因此需要对形变后的金属材料进行退火等热处理以产生需要的组织和性能[9]。电脉冲处理(Electropulsing treatment,EPT)是一种近年来极受关注的金属材料处理方式,其特点是高能和瞬时完成。脉冲电流经过金属材料时产生的焦耳热效应和电子风的共同作用引起金属材料基体的再结晶[10,11]、相变[12,13]以及裂纹愈合[14~16],从而使材料的组织和性能发生变化。Ma等[17,18]研究了EPT对冷轧316L奥氏体不锈钢组织和力学性能的影响,发现除了传统的热处理工艺EPT也可调控奥氏体不锈钢的组织和力学性能。本文对冷轧后的316L奥氏体不锈钢轧板在液氮温度下就那些电脉冲处理,研究其低温拉伸性能以及拉伸过程中的微观组织演化。

1 实验方法

表1 实验用316L不锈钢的化学成分

Table 1

| Element | Cr | Ni | Mo | C | Si | Mn | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Content | 16.54 | 11.22 | 2.02 | 0.02 | 0.36 | 1.43 | 0.02 | 0.03 | Bal. |

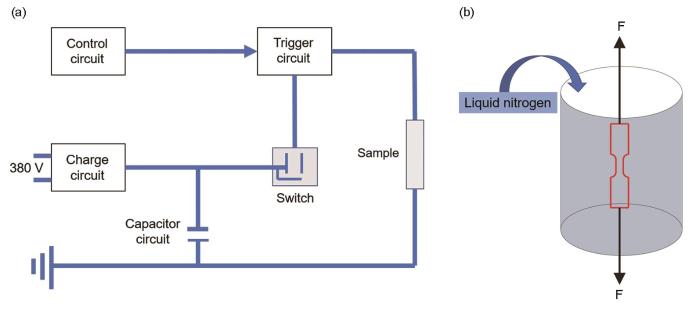

图1

图1

电脉冲处理和在液氮温度下拉伸实验的示意图

Fig.1

Schematic illustrations of the EPT experiment (a) and the tensile test in the liquid nitrogen environment (b)

将电脉冲处理后的狗骨状拉伸试样机械研磨,使其表面平整和无氧化层。分别在室温(293 K)和液氮温度(77 K)下使用INSTRON 5982拉伸试验机进行应变速率为10-3 s-1的单轴拉伸实验,使用如图1b所示的液氮储存装置使试样始终浸泡在液氮中。

将拉伸前、后的样品进行机械抛光,用10%高氯酸和90%酒精的混合溶液对其电解抛光(电解抛光的参数为20 V,1 min)后表征其微观组织。用X射线衍射仪(XRD)进行物相分析,扫描范围为40~100°,扫描速率为5 (°)/min。为了分析晶粒取向和织构,在配备Channel 5软件的LEO Supra 35扫描电子显微镜(SEM)进行电子背散射衍射(EBSD)实验。从拉伸后的试样上(靠近拉伸断口部位)切取直径为3 mm的薄片并将其机械研磨至厚度约为40 μm,然后在含10%高氯酸和90%乙醇的混合酸溶液中在23 V、-15℃条件下对其进行双射流电解抛光,制备出具有合适薄区的样品,任何用FEI Tecnai F30透射电子显微镜(TEM)进一步分析其微观组织以及形变特征。

2 结果和讨论

2.1 电脉冲处理对样品微观组织的影响

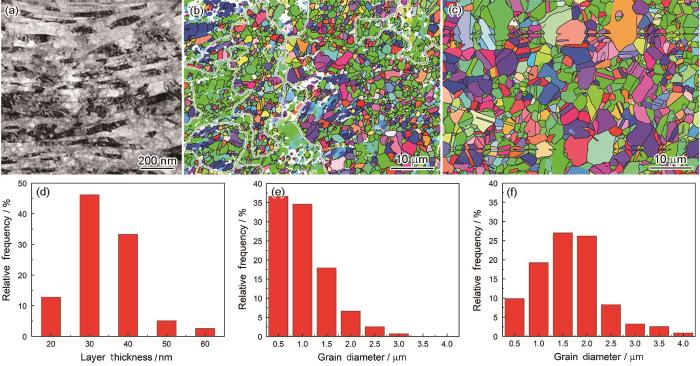

采用TEM和EBSD表征了电脉冲前后样品的微观结构,结果如图2所示。图2a给出了冷轧316L不锈钢试样原始组织的透射电子显微镜照片。可以看出,经90%冷轧后的微观组织,有高密度位错的平行排列的纳米板条。图2b给出了经过EPT-7LN电脉冲处理后样品的EBSD反极图,其中仍有部分区域为“马赛克色”。其原因是,变形组织的Kikuchi线模糊无法成功解析,表明这些区域仍为原始的变形组织。另外,在大部分区域出现了细小、等轴的再结晶晶粒,表明该EPT-7LN样品有部分再结晶的状态。根据无法解析区域的像素点统计,计算出EPT-7LN样品的再结晶比例为71.42%。当电脉冲电压增加到EPT-7.5LN时,样品的微观组织已由轧制后的变形组织完全转变为等轴的再结晶晶粒,如图2c所示,可见图中没有无法解析的区域,完全再结晶的等轴晶粒的晶粒尺寸比EPT-7LN样品明显增大,且出现了大量的退火孪晶。退火孪晶的孪晶界的分布如图3所示,其中红色线为孪晶界。可以看出,液氮电脉冲处理后退火孪晶出现在试样的再结晶区域范围内。由于EPT-7.5LN样品已经完成了再结晶,孪晶界在整个样品中均匀分布。用截线法测量了电脉冲处理前后样品的片层厚度或晶粒大小,并统计了其尺寸分布,如图2d~f所示。图2d给出了冷轧316样品中片层晶粒厚度的统计,可见其片层厚度为30~40 nm。图2e、f表明,EPT-7.5LN样品的晶粒尺寸为1.0~2.0 μm,平均晶粒尺寸为1.67 μm,可见其晶粒尺寸明显大于EPT-7LN样品的平均晶粒尺寸1.02 μm。在液氮温度下施加电脉冲后,冷轧的316L不锈钢由原先的纳米板条状组织转变为了等轴晶组织。这表明,液氮温度下的电脉冲也可使轧制后的奥氏体不锈钢发生再结晶,调控其组织。

图2

图2

拉伸实验用样品的微观组织

Fig.2

Microstructures of the tensile specimen before and after EPT (a) TEM image of the cold-rolled sample, (b, c) EBSD inverse pole figure (IPF) maps of the EPT-7LN and EPT-7.5LN samples, (d) lamellar thickness distribution diagram, (e, f) grain diameter distribution diagrams

图3

图3

液氮电脉冲后试样的晶界照片

Fig.3

Grain average misorientation map with grain boundaries of the sample after treated with EPT-7LN (a) and EPT-7.5LN (b)

2.2 室温和液氮温度的拉伸性能

EPT-7LN、EPT-7.5LN以及原始冷轧试样在77 K和293 K下的力学性能,如图4所示。从图4a可以看出,经电脉冲处理后的316L不锈钢在77 K和293 K温度下的拉伸曲线明显不同。电脉冲处理后的316L不锈钢在77 K时的抗拉强度(UTS)、屈服强度(YS)和延伸率(EL),都显著比在293 K拉伸时的高,且在77 K时拉伸曲线的加工硬化比在293 K拉伸时高,出现了明显的二次加工硬化。为了更直观地表现不同温度下不同样品的加工硬化行为,计算了各个样品的加工硬化率。图4b给出了在不同温度下EPT-7LN和EPT-7.5LN样品的加工硬化曲线。可以看出,在77 K温度拉伸时其加工硬化曲线出现了明显的两个阶段,加工硬化率先下降再上升再下降。在第一个阶段77 K与293 K拉伸时的加工硬化率相当,但是在第二个阶段77 K拉伸的加工硬化率开始变高,即出现了二次加工硬化。这种二次加工硬化,有助于同步提高强度和塑性。同时,面心立方结构(FCC)合金的屈服强度具有温度依赖性,受热成分和非热成分的影响[19,20]。其中,强度受热成分的影响对变形温度敏感。随着变形温度的提高热激活位错的滑移克服了晶格摩擦势垒和原子的钉扎效应,使屈服强度降低[21]。在不同温度下不同样品的拉伸性能(包括屈服强度、抗拉强度及均匀延伸率),列于表2。可以看出,EPT-7LN样品在77 K拉伸时的YS和UTS分别是293 K的2.18倍和1.96倍,EPT-7.5LN分别为2.03倍和2倍;原始冷轧样品在77 K拉伸时的屈服强度是293 K的1.14倍,延伸率为293 K的5.32倍。同时,EL也大幅度提高。此外,在相同的温度拉伸,7.5LN-77 K试样的强度低于7LN-77 K试样,但是EL相对增加。其原因是再结晶程度不同和晶粒尺寸不同,EPT-7LN样品为不完全再结晶状态,且晶粒尺寸明显小于EPT-7.5LN的样品。晶粒尺寸对材料强度的影响,可用Hall-Petch关系

图4

图4

EPT-7LN和EPT-7.5LN以及冷轧态样品在不同温度下拉伸的工程应力-应变曲线和加工硬化曲线

Fig.4

Mechanical response of the EPT-7LN, EPT-7.5LN and cold-rolled samples under tensile tests at different temperatures (a) engineering stress-strain curves and (b) strain-hardening rate curves

表2 在不同温度下样品的拉伸力学性能

Table 2

| YS/MPa | UTS/MPa | EL/% | |

|---|---|---|---|

| Cold-rolled-293 K | 1463 | — | 7.1 |

| EPT-7LN-293 K | 543 | 936 | 19.1 |

| EPT-7.5LN-293 K | 448 | 808 | 38.7 |

| Cold-rolled-77 K | 1665 | 1816 | 37.8 |

| EPT-7LN-77 K | 1184 | 1836 | 55.2 |

| EPT-7.5LN-77 K | 912 | 1617 | 65.5 |

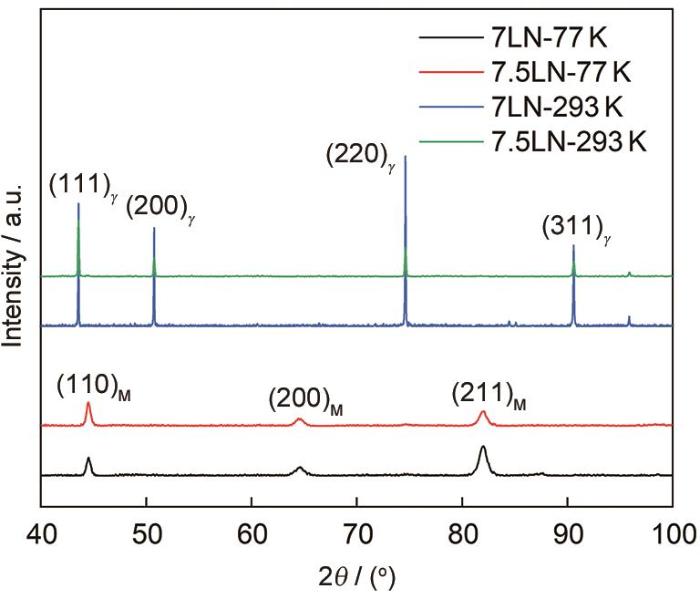

2.3 电脉冲处理后样品的拉伸变形机制

为了揭示不同温度拉伸试验时力学性能变化与微观结构变化之间的关系,用XRD谱表征了室温和低温拉伸后试样物相组成,结果如图5所示。在77 K进行拉伸试验时,XRD谱中已不存在奥氏体峰,全部是马氏体峰。这表明,拉伸样品由原本的奥氏体组织转变为马氏体组织,即发生了马氏体相变。而在室温拉伸时,样品仍为拉伸前的完全奥氏体组织,即电脉冲处理使316L不锈钢在77 K拉伸变形发生了马氏体相变。用TEM照片进一步对比分析了样品在293 K和77 K拉伸时的不同变形机制,如图6所示。图6a给出了EPT-7LN样品在293 K拉伸后的微观组织,可见主要为部分再结晶的状态,与原始试样的EBSD结果相同。图6b 给出了EPT7.5LN样品在293 K拉伸后的微观组织,可见晶粒较大且晶粒内部有高密度位错,部分位错已经缠结形成位错壁。同时还可以观察到许多变形孪晶,如图6b中的黑色方框区域所示。从图6a、b可见,在室温下316L不锈钢的变形机制为位错滑移和形变孪晶[17]。而图6c、d表明,在77 K拉伸后样品中除了出现位错还出现了大量平行排列的马氏体板条(如图中黑色方框区域所示),但是没有变形孪晶。上述结果表明,316L不锈钢在293 K时的变形机制以变形孪晶和位错滑移为主,77 K时的变形机制以马氏体相变和位错滑移为主。

图5

图5

室温和低温拉伸后的XRD谱

Fig.5

XRD spectra after tensile test at room temperature and cryogenic temperature

图6

图6

用TEM照片表征试样在拉伸变形后的微观组织特征

Fig.6

TEM images show the tensile deformed microstructures of the sample (a) EPT-7LN-293 K; (b) EPT-7.5LN-293 K; (c) EPT-7LN-77 K; (d) EPT-7.5LN-77 K

电脉冲处理后的样品在低温条件下表现出优异的强度、良好的延性和稳定的应变硬化能力,因为样品在77 K发生了马氏体相变,产生了相变诱导塑性(Transformation induced plasticity,TRIP)效应 [22]。层错能(Stacking fault energy,SFE)是影响材料变形机制的决定性因素之一。金属材料的层错能小于20 mJ/m2,导致形变诱发马氏体相;材料的层错能为20~45 mJ/m2时,主要以产生变形孪晶为主要的变形机制;层错能大于45 mJ/m2时,变形机制以位错滑移为主[23]。而奥氏体不锈钢钢在室温下的层错能

计算结果表明,在室温下本文实验用的316L不锈钢的层错能为36.051 mJ/m2,塑性变形机制以变形孪晶为主。随着温度的降低层错能逐渐减小,77 K时的层错能为25.251 mJ/m2,明显低于293 K时的层错能,接近应变诱导马氏体相变的临界层错能。除了低温引起的层错能变化促进马氏体相变外,在拉伸过程中产生的形变也诱导马氏体相变。马氏体转变过程中的驱动力为新相与母相间的自由能之差, 而当变形引起的机械驱动力与化学驱动力叠加并达到相变驱动力时,就会发生应变诱发马氏体转变。温度和形变的双重作用,提高了马氏体的转变速率和转变量[25]。TRIP效应引起样品在低温拉伸时强度和塑性的进一步提高,显著提高了该材料的加工硬化率。马氏体相变的发生,使二次加工硬化以及加工硬化曲线上出现两个不同的应变硬化阶段。产生第一硬化阶段的原因,是奥氏体晶格微应变的迅速增加。随着应变的增加,奥氏体逐渐向马氏体转变。在第二个硬化阶段,在变形过程中马氏体相变迅速积累,使随后的变形过程以马氏体的变形为主,加工硬化速率也随之变化[26]。

3 结论

(1) 冷轧316L不锈钢经过不同能量的电脉冲处理后具有不同的微观组织特征,EPT-7LN样品具有部分再结晶组织而EPT-7.5LN样品具有完全再结晶组织且其平均晶粒尺寸较大。

(2) EPT-7LN和EPT-7.5LN样品在室温(293 K)和低温(77 K)拉伸时的力学性能显著不同。在77 K拉伸时EPT-7LN样品的YS、UTS以及EL分别为1184 MPa、1836 MPa和55.2%,EPT-7.5LN样品的对应性能分别为912 MPa、1617 MPa以及65.5%。低温拉伸时的YS、UTS和EL,都远高于在室温拉伸时的相应性能指标。

(3) 电脉冲处理后的316L不锈钢在室温和77 K时的变形机制不同,在293 K以变形孪晶和位错滑移为主,而在77 K以形变后所产生的应变诱导马氏体相变为主。在77 K拉伸变形样品的拉伸强度-塑性同步提高,其主要机制是,低温层错能较低使形变诱导马氏体相变易于发生,从而导致拉伸加工硬化率的提高。

参考文献

Effectiveness of using low-temperature coolants in machining to enhance durability of AISI 316L stainless steel for reusable biomedical devices

[J].Austenitic stainless steels are currently used for the manufacture of reusable medical instruments, thanks to their combination of elevated strength, corrosion resistance, biocompatibility and low cost. However, during their service life, they are subjected to repeated sterilization cycles, which lead to the loosening of the surface oxide stability and, thus, decrease their durability. In the present study, the influence of different machining cooling conditions on the in-service corrosion behaviour of the AISI 316L stainless steel is investigated with the aim of increasing its resistance to the sterilization cycles. In particular, the effects of low-temperature coolants, namely Liquid Nitrogen (LN2) and gaseous Nitrogen (N2) cooled by LN2 to -100 degrees C, were investigated and compared to those of dry and wet cutting. The machined surface integrity was characterized in terms of microstructure, hardness, residual stresses and surface roughness. Electrochemical studies, making use of potentiodynamic and cyclic polarization tests, were carried out to evaluate the corrosion resistance of the machined surfaces. It was found that the AISI 316L microstructure near the machined surface was significantly affected by the machining cooling strategies The effectiveness of using low-temperature coolants in machining of stainless steels for the manufacture of reusable medical devices was therefore demonstrated.

Mechanical tests on the ITER PF 316L jacket after compaction

[J].

Cryorolling impacts on microstructure and mechanical properties of AISI 316 LN austenitic stainless steel

[J].

Effect of retained/reversed austenite on improving -196℃ cryogenic impact property of high strength stainless steel

[J].High strength stainless steel 0Cr16Ni6 treated by quenching+low temperature tempering, and maraging stainless steel 00Cr11Ni11MoTi treated by over aging were studied by means of mechanical properties tests, SEM and XRD, and the effects of retained/reversed austenite in the tested steels on -196℃ cryogenic notched tensile strength and impact property were analyzed. The results show that, with the nearly same strength and toughness of the tested steels at room temperature, the notch tensile strength and impact property of the 0Cr16Ni6 steel are significantly higher than that of the 00Cr11Ni11MoTi steel at -196℃. According to the residual/reversed austenite contents quantitatively calculated based on the relative intensities of the martensite and austenite diffraction peaks far from the fracture and near the fracture, it is found that nearly 90% retained austenite in the 0Cr16Ni6 steel transforms into strain-induced martensite during the formation and propagation of cracks, which improves cryogenic impact property remarkably. But the reversed austenite formed by over-aging of the 00Cr11Ni11MoTi steel has higher stability, which is not suitable for strain-induced martensite transformation to occur, so the improvement of -196℃ cryogenic toughness is limited.

残留/逆转变奥氏体对改善高强度不锈钢-196℃超低温冲击性能的影响

[J].采用力学性能测试、SEM和XRD等手段研究了淬火+低温回火处理的0Cr16Ni6高强度不锈钢和过时效处理的00Cr11Ni11MoTi马氏体时效不锈钢,并分析了残留/逆转变奥氏体对试验钢超低温缺口抗拉强度和冲击性能的影响。结果表明,在两种试验钢室温强韧性相近的情况下,0Cr16Ni6钢在超低温下(-196℃)的缺口抗拉强度和冲击性能显著优于00Cr11Ni11MoTi钢。根据冲击试样远离断口和断口附近马氏体/奥氏体衍射峰的相对强度分别定量计算的残留/逆转变奥氏体含量,发现在裂纹形成和扩展过程中0Cr16Ni6钢有接近90%的残留奥氏体通过应变诱发相变生成马氏体,显著改善了超低温韧性;而过时效00Cr11Ni11MoTi钢形成的逆转变奥氏体具有较高的稳定性,难以发生应变诱发马氏体相变,改善超低温韧性作用程度有限。

Study on strength of austenitic stainless steel under liquid-nitrogen temperature

[J].

液氮温度下奥氏体不锈钢强度试验研究

[J].

Low Temperature deformation behavior of high-nitrogen nickel-free austenitic stainless steels

[J].

新型无Ni高N奥氏体不锈钢的低温变形行为

[J].利用冲击实验、拉伸实验、XRD和TEM对2种不同N含量的无Ni高N奥氏体不锈钢低温变形行为进行了研究. 结果表明, 高N奥氏体不锈钢在低温下发生明显的韧脆转变和加工硬化现象. 在实验材料的Mn含量水平内, 提高Mn含量能够改善高N奥氏体不锈钢的低温塑性和韧性, 降低其韧脆转变温度. 18Cr-12Mn-0.55N钢在低温拉伸变形时会发生形变诱导马氏体相变, 但马氏体转变量很少,降低温度对马氏体转变量无明显影响. 形变诱导马氏体能提高高N奥氏体不锈钢的加工硬化能力, 但降低了钢的低温塑性和韧性. 加工硬化能力和层错能随温度的降低而降低是Fe-Cr-Mn高N奥氏体不锈钢在低温下发生脆断的主要原因.

Effect of strain rate on microstructure evolution and mechanical property of 316LN austenitic stainless steel at cryogenic temperature

[J].The uniaxial tensile property of 316LN austenitic stainless steel (ASS) plate at -40 ℃was examined by strain rates of 5×10-4 s-1 and 1×10-2 s-1 respectively, while the microstructure evolution was characterized by means of OM, TEM, SEM, XRD and 3D profile profiler. The results showed that the deformation induced martensite transformation occurred in 316LN austenitic stainless steel at cryogenic temperature, and the martensite transformation decreased with the increase of strain rate. The yield strength increased with the increase of strain rate, while the tensile strength and elongation decreased with the increase of strain rate. The tensile fractured surface showed typical ductile fracture. The deformed microstructure composed mainly of dislocation tangles and T-M(twin-matrix)lamellar structures. With the increase of strain rate, the dislocation tangles aggravated and the interlamellar spacing of T-M(twin-matrix)lamellar structures reduced.

应变速率对低温拉伸316LN奥氏体不锈钢微观组织和力学性能的影响

[J].以两种应变速率(5×10<sup>-4</sup> s<sup>-1</sup>和1×10<sup>-2</sup> s<sup>-1</sup>,分别代表慢速拉伸和快速拉伸)对316LN奥氏体不锈钢板状试样进行低温(-40℃)单轴拉伸实验,借助金相显微镜(OM)、透射电镜(TEM)、扫描电镜(SEM)、X射线衍射仪(XRD)及三维形貌轮廓仪分析了拉伸变形过程中的微观组织演变和力学性能变化规律。结果表明,316LN奥氏体不锈钢在低温拉伸条件下发生形变诱导马氏体相变,且马氏体转变量随着应变速率的增加而减少;屈服强度随着应变速率的增加而升高,抗拉强度和延伸率则随着应变速率的增加而降低;拉伸断口形貌均呈现出典型的韧性断裂特征。变形组织均以位错缠结和T-M(Twin-matrix)层片状组织为主,随着应变速率的增加,位错缠结程度加剧,T-M层片状组织的层片间距减小。

Mechanical analysis of crack tip in cold working 316L stainless steel

[J].

冷加工316L不锈钢裂尖力学分析

[J].

Tailoring the microstructure and mechanical properties of AISI 316L austenitic stainless steel via cold rolling and reversion annealing

[J].

Enhancement of ductility in Mg-3Al-1Zn alloy with tilted basal texture by electropulsing

[J].The microstructure and texture evolution in a cold-rolled AZ31 magnesium alloy during electropulsing treatment (EPT) are investigated and correlated with the mechanical properties. The microstructure is effectively refined, and a tilted basal texture develops gradually during EPT. The yield stress in the treated samples is lower than that in the cold-rolled sample, indicating that texture softening is dominant over strengthening because of grain refinement. The phenomenon is primarily the result of the tilted basal texture. EPT improves the tensile ductility of the EPT samples significantly, albeit slightly compromising the tensile strength. The mechanism of the microstructure evolution during electropulsing is discussed from the viewpoint of grain-boundary motion. Moreover, the ductility enhancement is discussed in terms of the deformation mechanism and texture of the Mg alloy.

The effects of electropulsing on the recrystallization behavior of rolled pure tungsten

[J].

Rapid hardening of AISI 4340 steel induced by electropulsing treatment

[J].

Effects of electropulsing on the microstructure and microhardness of a selective laser melted Ti6Al4V alloy

[J].

Declined fatigue crack propagation rate of a high-strength steel by electropulsing treatment

[J].

The effect of high current pulsing on persistent slip bands in fatigued copper single crystals

[J].

Recovery of tensile properties of twinning-induced plasticity steel via electropulsing induced void healing

[J].

Hardening and softening mechanisms in a nano-lamellar austenitic steel induced by electropulsing treatment

[J].

Anisotropic electroplastic effects on the mechanical properties of a nano-lamellar austenitic stainless steel

[J].

The influence of stacking fault energy on the microstructural and strain-hardening evolution of Fe-Mn-Al-Si steels during tensile deformation

[J].

Thermally activated dislocation dynamics in austenitic FeMnC steels at low homologous temperature

[J].

Temperature dependence of the flow stress of Fe-18Mn-0.6C-xAl twinning-induced plasticity steel

[J].

Effect of temperature on the stacking fault energy and deformation behaviour in 316L austenitic stainless steel

[J].

Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe-Mn-C alloys

[J].

Cryogenic mechanical properties of 316L stainless steel fabricated by selective laser melting

[J].

Quantitative analysis of the martensite transformation and microstructure characterization during cryogenic rolling of a 304 austenitic stainless steel

[J].Advanced material processing techniques have been successfully used to produce metals or alloys with submicro- or nano-sized grain structures with some possibly required harsh working environment that limits their industrial application. Cryogenic deformation might promote extensively severe deformation or distortion of metals or alloys (such as Al or aluminium alloys, Cu or copper alloys, Ti, Zr, etc.) so as to accumulate higher deformation energy (e.g., higher defect density) for the depression of the (dynamic) recovery, which will contribute to the microstructure refinement. Presently, the macro-/micro-structural evolution, the martensitic transformation as well as its effect on the mechanical property during the cryogenic and room temperature rolling of 304 metastable austenitic stainless steel were studied. It shows that the cryogenic rolling can effectively accelerate the martensitic transformation, e.g., after 20% cryogenic rolling the volume fraction of the transformed martensitic is equal to that after 50% room temperature rolling, and finally the cryogenic rolling can promote the complete martensitic transformation. Also the through-thickness uniformity of the martensitic transformation after cryogenic rolling is significantly better than that of the room temperature rolled one, which can help to improve the through-thickness performance uniformity. It is found that the deformation mechanisms are different for cryogenic and room temperature rolling metastable austenitic stainless steel: the martensitic transformation and its deformation occur in the former while austenitic deformation in the latter. The cryogenic rolling can quickly induce higher hardness than that of the room temperature rolled one, and the hardness tends to be equal finally because of the minimized dislocation density difference between these two rolled steels. TEM results indicate that the orientation relationship between the transformed martensite and the old austenite in the cryogenic and room temperature rolled sheets can still keep the K-S (Kurduumov-Sachs) relationship.

304奥氏体不锈钢超低温轧制变形诱发马氏体转变的定量分析及组织表征

[J].研究了304亚稳态奥氏体不锈钢在超低温和室温轧制变形过程中的宏、微观组织演变, 变形引起的马氏体转变及其对合金性能的影响. 结果表明, 超低温轧制比室温轧制能更有效地加速马氏体转变, 其中20%超低温轧制变形便可实现50%室温轧制变形下的马氏体转变量, 且超低温轧制变形最终可实现完全的马氏体转变. 同时, 超低温轧制引起的马氏体转变在板厚方向上较均匀, 显著优于室温轧制板材的板厚方向均匀性, 有助于提高亚稳态奥氏体不锈钢板厚方向性能的均匀性. 分析认为, 亚稳态奥氏体不锈钢在超低温和室温轧制过程中具有不同的变形机理, 前者主要以马氏体转变及其变形为主, 后者以奥氏体变形为主. 超低温轧制所获板材的硬度比室温轧制板材增长迅速, 但随变形量增大位错密度差距缩小, 最终导致两者硬度趋于一致. TEM表征结果表明, 超低温和室温轧制过程中引起的马氏体与母相基体间的取向关系遵循K-S (Kurduumov-Sachs)关系.