目前研究合金纯净化、非金属夹杂物控制和形成机理,重点是改进熔炼工艺。You等[10]研究了电子束精炼FGH4096时夹杂物的类型、富集以及杂质元素和夹杂物的去除,确定了脱氧、去除夹杂物的最佳电子束熔炼功率和熔炼时间。孔豪豪等[11]研究了三联熔炼GH4169夹杂物的类型和分布,发现位于铸锭顶部和边缘部位夹杂物平均尺寸较大和数量密度较高,而远离顶部和边缘部位的夹杂物平均尺寸较小。王迪等[12]根据电渣重熔工艺对GH4169合金夹杂物分布的影响确定车削量,使铸锭的表面质量提高。张华霞等[13]从原料预处理、优化过滤系统和精细化控制等方面研究了FGH96母合金的洁净化控制技术,制备出高纯净度的母合金棒材。赵昊乾等[14]研究了坩埚材质及顶渣成分对钢中夹杂物成分的影响,发现坩埚材质影响钢中[C]、[Si]、[Mn]、[O]等元素的含量,进而影响夹杂物成分。Gao等[15]研究了活性元素Al、Ti添加顺序和坩埚材料对FGH4096夹杂物的影响。

除了改进熔炼工艺提高合金纯净度,采取其它辅助手段也能进一步提高合金的纯净度和降低夹杂物含量。金文中等[16]研究了真空电磁净化技术对K417母合金非金属夹杂物的去除机理,发现施加旋转磁场可使非金属夹杂向铸锭心部聚集、长大并向冒口位置上浮,切除冒口即可降低母合金中夹杂物含量。张新房等[17]研究脉冲电流对夹杂物去除的影响,阐明了电流控制夹杂物的机理。蒲永亮等[18]选用多种复合盐净化处理返回料,分析净化处理后返回料中的杂质元素和夹杂物含量,从而为返回料的净化和再利用提供技术支持。本文使用不同品质的金属铬原料,用真空感应熔炼工艺制备GH4169母合金铸锭,研究铬原料品质对杂质元素、非金属夹杂物类型、含量以及尺寸的影响以及夹杂物的形成机理。

1 实验方法

实验用原材料为高纯金属铬,普通金属铬和微碳铬铁,使用VIM-F25型25 kg真空感应炉和氧化钙坩埚熔炼三根直径为85 mm、长度为500 mm的GH4169母合金铸锭(编号分别为1#,2#,3#),其中1#锭的原材料为高纯金属铬,2#锭为普通金属铬,3#锭为微碳铬铁。GH4169的实际化学成分列于表1。

表1 真空感应熔炼的GH4169母合金的实际化学成分

Table 1

| Sample No. | C | Al | Ti | Mo | Nb | Cr | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| 1# | 0.034 | 0.63 | 1.00 | 2.98 | 5.20 | 18.17 | 52.2 | Bal. |

| 2# | 0.031 | 0.75 | 1.00 | 3.00 | 5.27 | 18.35 | 51.8 | Bal. |

| 3# | 0.035 | 0.68 | 0.98 | 3.01 | 5.29 | 18.22 | 51.6 | Bal. |

在三根母合金的相同部位切取五根直径为4 mm长度为6 mm的粒状样品,每根的质量为0.5~1.0 g,将其表面打磨光亮。另取5 g屑状样品和尺寸为30 mm×30 mm×10 mm的块状样品,分别在乙醇中超声清洗。

用TCH-600氧氮氢分析仪检测样品的O、N含量,用X射线荧光光谱仪检测P、Si、Mn含量,用碳硫分析仪检测S含量。检测标准分别为HB 5220.49-2008《高温合金化学分析方法第49部分:脉冲加热-红外、热导法测定氧、氮含量》、GB/T 16597-2019《冶金产品分析方法X射线荧光光谱法通则》和HB 5220.6-2008《高温合金化学分析方法第6部分:高频感应燃烧-红外线吸收法测定硫含量》。

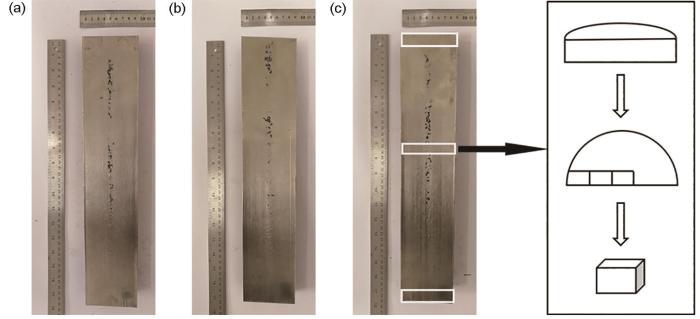

分别在母合金的顶部,中部和底部的边缘、1/2半径处和中心处分别切取尺寸为15 mm×10 mm×8 mm的径向样品,取样示意图如图1所示。

图1

图1

GH4169母合金的宏观形貌和取样位置

Fig.1

Macro microstructure and location of sample in GH4169 ingot (a) 1#,(b) 2#,(c) 3#

将金相试样在手动磨抛机上磨抛处理后,用带有能谱分析仪(EDS)的FEI-F50场发射扫描电镜观察非金属夹杂物的成分和形貌,以确定其非金属夹杂物类型。在铸锭的边缘、1/2半径和中心处各随机选取50个不同的视场(放大倍数为2000),使用Photoshop,Image-Pro plus 6.0软件分别统计三根母合金铸锭顶部、中部和底部的非金属夹杂物面积百分比含量和数量密度,并统计不同类型夹杂物的含量。

2 结果和讨论

2.1 母合金中杂质元素的含量

表2列出了不同品质金属铬原材料中杂质元素的含量。可以看出,高纯金属铬中的O、N、S元素含量都低于普通金属铬,P和Si元素含量与普通金属铬相差不大。微碳铬铁合金(是炼钢时的重要合金添加剂)的含碳量小于0.15%,P、S、Si元素的含量远高于高纯金属铬和普通金属铬。

表2 铬原材料中杂质元素的含量(质量分数,%)

Table 2

| O | N | P | S | Si | Mn | |

|---|---|---|---|---|---|---|

| Purity Cr | 0.032 | 0.001 | ≤0.002 | 0.0009 | 0.054 | - |

| Ordinary Cr | 0.098 | 0.010 | ≤0.002 | 0.0021 | 0.052 | - |

| Micro-carbon ferrochrome | - | - | 0.021 | 0.015 | 1.07 | - |

表3列出了母合金铸锭中杂质元素的含量,这些铸锭是使用不同品质的金属铬经真空感应熔炼的。不同品质的金属铬原材料使母合金中气体元素的含量明显不同,1#母合金中的O含量为1.8×10-5(体积分数),N含量为9×10-6(体积分数)。与1#母合金中气体元素含量相比,2#中O含量降低约2/5,N含量提高约4倍。其原因是,用常规冶炼方法无法完全去除气体杂质。3#母合金的O含量略有下降,N元素含量约提高11倍,因为微碳铬铁中约占其体积30%的气体(主要是N2和H2)显著提高了合金中气体元素的含量。

表3 母合金铸锭中杂质元素的含量

Table 3

| Sample No. | O | N | P | S | Si | Mn |

|---|---|---|---|---|---|---|

| 1# | 0.0018 | 0.0009 | 0.002 | 0.0009 | 0.027 | 0.016 |

| 2# | 0.0011 | 0.0035 | 0.002 | 0.0009 | 0.013 | 0.015 |

| 3# | 0.0013 | 0.0095 | 0.005 | 0.0019 | 0.400 | 0.100 |

从表3还可以看出,不同品质金属铬原材料使使母合金中杂质元素的含量不同。1#母合金中P含量为0.002%(质量分数,下同),S含量为0.009%,Si含量为0.027%,Mn含量为0.016%。2#母合金中P、S、Mn的含量没有明显的不同,Si含量为0.013%,约为1#母合金的1/2。3#母合金中P的含量为0.005%,S含量为0.019%,Si含量为0.400%,Mn含量为0.100%,杂质元素的含量都有不同程度的提高,分别提高了约1.5倍、1.11倍、13.8倍和5.25倍。与高纯金属铬相比,使用普通金属铬使母合金铸锭中Si的含量降低,使用微碳铬铁使Si和Mn的含量显著提高,P和S的含量略有提高。

以上分析表明,不同品质的金属铬明显影响母合金中杂质元素的含量。普通金属铬会降低母合金中的Si含量和O含量,但是会提高N的含量。微碳铬铁则显著提高各种杂质元素的含量,包括气体元素含量。

2.2 夹杂物的类型

用SEM-EDS观察分析上述试样的结果表明,GH4169母合金铸锭中夹杂物的类型主要有三类:氧化物,碳氮化物,以氧化物夹杂为形核中心,外层为碳氮化物的复合型夹杂。表4列出了夹杂物的类型和平均尺寸。

表4 GH4169母合金中夹杂物的类型和平均尺寸

Table 4

| Inclusion type | Average size/μm | |

|---|---|---|

| Oxide | (Al, Mg)O | 1.11±0.047 |

| (Al, Ca)O | ||

| (Al,Mg,Ca)O | ||

| Nitride | (Ti,Nb)(C,N) | 1.00±0.046 |

| Mixed | (Al,Mg)O-(Ti,Nb)(C,N) | 1.83±0.134 |

| (Al,Mg,Ca)O-(Ti,Nb)(C,N) |

图2给出了GH4169母合金中单层夹杂物的形貌和能谱。可以看出,氧化物夹杂为圆润的多边形和近圆形。平均尺寸约为1.11 μm,作为碳化物的形核中心,也有少量单独存在的氧化物夹杂。用EDS化学成分分析的结果表明,其化学元素主要为Al和O元素,有少量Mg元素和Ca元素,成分为(Al,Mg)O,(Al,Ca)O和(Al,Mg,Ca)O,其中(Al,Ca)O形貌为圆形,夹杂含量极少。

图2

图2

GH4169母合金中单层夹杂物的形貌和成分

Fig.2

Morphology and composition of monolayer inclusions in GH4169 ingot

碳氮化物夹杂的形貌多为带有尖锐棱角的四边形或多边形,尺寸范围为0.5~2.5 μm,平均尺寸约为1.00 μm。EDS的分析结果表明,其化学元素主要为Ti、Nb、N、C,成分为(Ti,Nb)(C,N)。复合型夹杂物的尺寸范围为1~5 μm,平均尺寸约为1.83 μm。以氧化物夹杂为核心外层包覆生长的碳氮化物夹杂,形状为带有棱角的多边形,含量高且分布广泛。EDS分析结果表明,其化学元素主要为Ti、Nb、N、C和Al、Mg、Ca、O,成分为(Al,Mg)O-(Ti,Nb)(C,N)或(Al,Mg,Ca)O-(Ti,Nb)(C,N),面扫图如图3所示。

图3

图3

GH4169母合金中复合型夹杂物的形貌和元素分布

Fig.3

Morphology and element scanning of composite inclusions in GH4169 ingot (a) (Al, Mg) O - (Ti, Nb) (C, N), (b) (Al, Mg, Ca) O - (Ti, Nb) (C, N)

2.3 夹杂物的含量

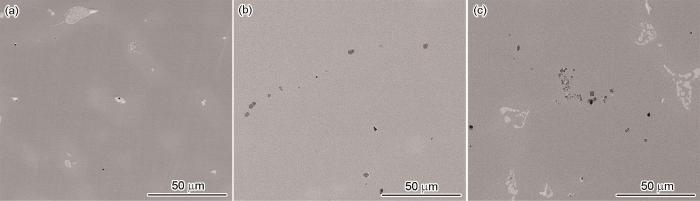

图4给出了3根母合金中夹杂物的聚集情况。可以看出,1#母合金中只有氧化物夹杂,且数量很少,十分分散。2#和3#母合金中的夹杂物多为碳氮化物夹杂和复合型夹杂,单独的氧化物夹杂数量极少。夹杂物数量明显增加且聚集,尤其是3#中的夹杂物尺寸不一且聚集。

图4

图4

GH4169中夹杂物的聚集

Fig.4

Aggregation of inclusions in GH4169 (a) 1#, (b) 2#, (c) 3#

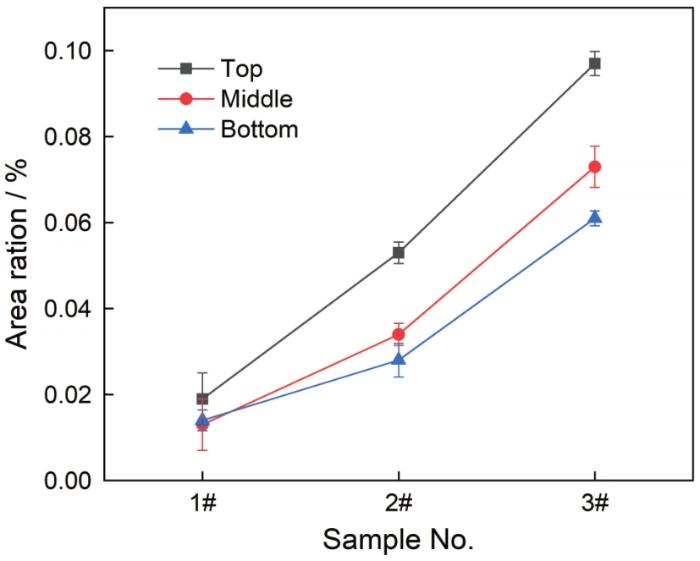

统计GH4169母合金顶部、中部和底部夹杂物的含量,其折线图在图5中给出。可以看出,三根母合金中夹杂物的含量呈现明显提高的趋势,且顶部夹杂物的含量高于底部。这表明,在浇铸过程中出现了夹杂物上浮。

图5

图5

GH4169母合金中顶部、中部和底部夹杂物的含量

Fig.5

Content of top, middle and bottom inclusions in GH4169 ingot

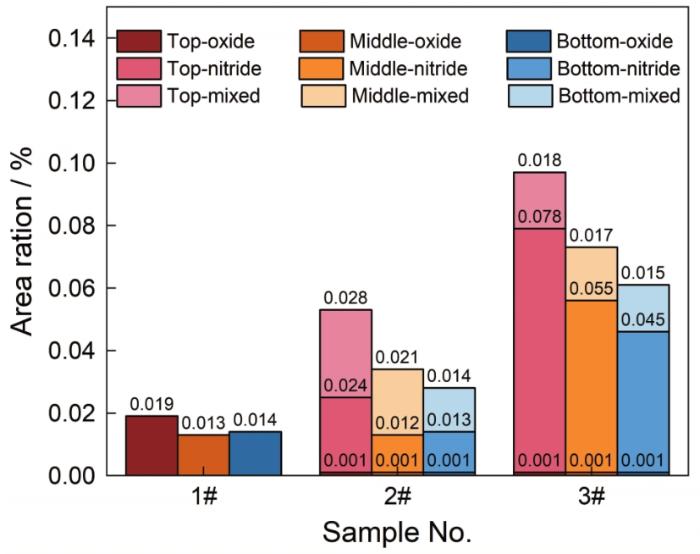

GH4169母合金顶部、中部和底部试样中三类夹杂物的面积分数的统计结果,在图6中给出。可以看出,1#母合金中只有氧化物夹杂,顶部、中部和底部的含量分别为0.019%、0.013%和0.014%。2#母合金中氧化物夹杂的含量均为0.001%,顶部、中部和底部碳氮化物夹杂的含量分别为0.024%、0.012%和0.013%,复合型夹杂的含量为0.028%、0.021%和0.014%。3#母合金中氧化物夹杂的含量均为0.001%,顶部、中部和底部的碳氮化物夹杂含量分别为0.078%、0.055%和0.045%,复合型夹杂的含量为0.018%、0.017%和0.015%。

图6

图6

GH4169母合金中各类夹杂物的含量

Fig.6

Content of various types of inclusions in GH4169 ingot

1#、2#和3#母合金总夹杂物的含量均从顶部到底部递降,其中2#和3#母合金中顶部的碳氮化物夹杂和复合型夹杂的含量最高,从顶部到底部递降。与2#相比,3#母合金中复合型夹杂的含量明显降低,但是碳氮化物夹杂的含量明显提高。其原因是,N在合金中的存在方式有两种,一是固溶于合金基体中,另一种是形成氮化物夹杂。原材料中N元素较少,易固溶于合金基体内,难以析出形成氮化物夹杂。2#母合金N的含量为3.8×10-5(体积分数),3#母合金中N含量为9.6×10-5(体积分数),而其O含量相差不大。当氧化物夹杂优先存在于合金液中时,形成的碳氮化物夹杂会以氧化物为形核中心继续生长。当N含量很高时,如3#,碳氮化物夹杂不依附于氧化物夹杂而单独析出,或多种共同析出。

图7给出了不同尺寸非金属夹杂的数量密度。1#母合金中夹杂物的尺寸大多为小于1 μm其范围为1~2 μm,数量密度为0.084/mm2,尺寸为2~5 μm的夹杂物数量密度为0.009/mm2,尺寸偏小。2#母合金中尺寸小于1 μm的夹杂物数量密度为0.031/mm2,尺寸为1~2 μm的夹杂物数量密度为0.187/mm2,尺寸为2~5 μm的夹杂物数量密度为0.156/mm2,尺寸大于5 μm的夹杂先出现,数量密度为0.002/mm2。不同尺寸夹杂物的数量密度表明,2#母合金中夹杂物的尺寸较大。3#母合金中各种尺寸的夹杂物其数量密度分别为0.276、0.509、0.322和0.029/mm2。所有尺寸夹杂物的数量密度都明显增大,说明3#母合金中夹杂物的数量多,且大量的碳氮化物和复合型夹杂聚集形成大尺寸夹杂。

图7

2.4 夹杂物的形成机理

实验结果表明,GH4169母合金中夹杂物的类型主要有:氧化物夹杂(Al,Mg)O、(Al,Ca)O、(Al,Mg,Ca)O,碳氮化物夹杂(Ti,Nb)(C,N)和复合型夹杂(Al,Mg)O-(Ti,Nb)(C,N)、(Al,Mg,Ca)O-(Ti,Nb)(C,N)。使用JMatPro软件进行模拟分析,以揭示母合金中非金属夹杂物的形成机理。

2.4.1 JMatPro模拟计算

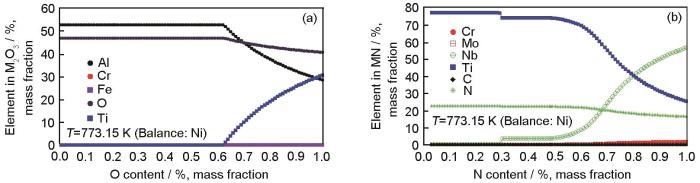

根据热力学和动力学原理,使用JMatPro软件分析夹杂物的元素和含量对析出的影响。先计算GH4169合金的平衡相图,GH4169合金平衡凝固时夹杂物的析出过程为L+M2O3→L+M2O3+γ→L+M2O3+γ+MN→L+M2O3+γ+MN+MC。可以看出,在液相线温度以上就已经出现M2O3夹杂,在液固两相区间先后析出MN夹杂和MC析出相。另外,根据GH4169合金的实际成分进行模拟计算,图8给出了合金平衡凝固时析出的M2O3夹杂和MN夹杂中的所有元素的含量随合金中O元素和N元素的变化。可以看出,合金中的M2O3夹杂和MN夹杂中的M元素为Al、Cr、Fe、Ti和Cr、Mo、Nb、Ti、C;GH4169合金中的O含量和N含量低于0.1%时,M2O3夹杂的主要成分为Al2O3,MN夹杂的主要成分为TiN。

图8

图8

JMatPro模拟计算夹杂物中各元素的变化

Fig.8

JMatPro simulates and calculates the changes of various elements in inclusions (a) M2O3, (b) MN

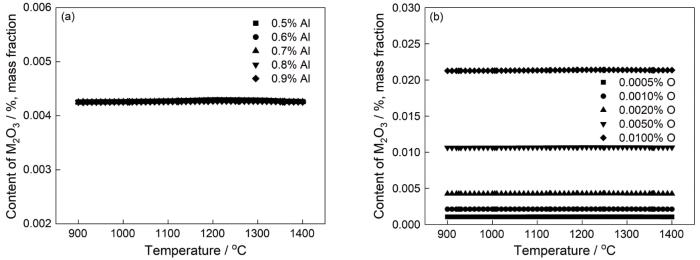

图9

图9

元素Al和O分别对M2O3夹杂物析出含量的影响

Fig.9

The influence of the elements Al and O on the precipitation content of M2O3 inclusions (a) Al content change, (b) O content change

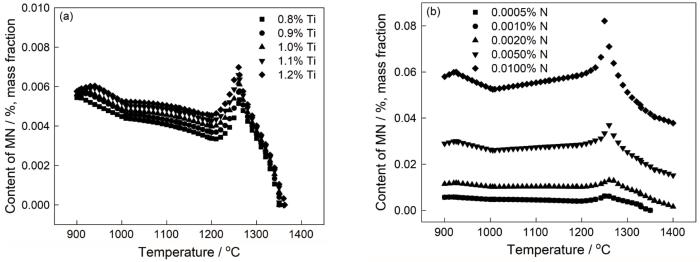

图10

图10

元素Ti和N分别对MN夹杂物析出含量的影响

Fig.10

Influence of the elements Ti and N on the precipitation content of MN inclusions (a) Ti content change, (b) N content change

M2O3和MN夹杂的含量,分别随O含量和N含量的提高而显著提高。当氧含量从0.0005%提高到0.0010%时M2O3含量从0.0010%提高到0.0022%,约提高1.2倍。随着O含量的提高M2O3夹杂的含量呈线性提高,O含量为0.0100%时M2O3含量为0.0212%,提高了20倍。与M2O3的平稳变化相比,MN含量的变化是波动的。但是在总体上,MN含量随着N元素含量的提高而提高。N元素含量从0.001%提高到0.010%,MN的含量从0.005%提高到0.045%。

2.4.2 非金属夹杂物的形成机理

图11

图11

CaO坩埚与合金液的反应以及氧化物夹杂形成的示意图

Fig.11

Schematic illustration of the reaction between CaO crucible and alloy liquid and the formation of oxide inclusions

设冶炼温度为1600℃,由

根据Van’t Hoff等温方程有

又因为

式(

其次,合金液冲刷坩埚的内表面,使内表面部分颗粒脱落而在合金液中溶解。上述推理表明,稳定的CaO在熔炼过程中很少被合金中的活泼元素还原,但是因其含量太高而有少量[Ca]溶于合金熔体中;坩埚中MgO的含量低,但是因其性能不稳定而有[Mg]溶于合金熔体中。

经由上述反应溶入合金液中的[Ca]和[Mg]与Al2O3反应生成(Al,Mg)O夹杂、(Al,Ca)O夹杂和(Al,Mg,Ca)O夹杂,其反应方程式为

TiN与TiC同属面心立方结构,晶格常数相差较小。TiC极易与先析出的TiN互溶生成Ti(C, N)[25]。同时,在降温过程中在已生成的Ti(C, N)中溶入部分铌元素而形成(Ti,Nb)(C, N)。

含有O和N元素时,在液相线温度以上先生成以Al为主要元素的氧化物夹杂,温度降低至固液两相温度区间时生成以Ti为主要元素的碳氮化物夹杂。在此基础上,碳氮化物夹杂以先生成的氧化物夹杂为异质形核核心先生长,生成内层为圆形的氧化物、外面包覆生长碳氮化物的复合型夹杂物。

3 结论

(1) 随着金属铬纯度的提高母合金铸锭中杂质元素的含量显著降低,其中N含量(体积分数)从9.5×10-5降低到9.0×10-5。

(2) 随着金属铬纯度的提高母合金铸锭中夹杂物的类型由氧化物、碳氮化物和复合型夹杂物共存转变为只有氧化物夹杂;母合金铸锭的总夹杂物含量由0.231%降低到0.046%,不同尺寸的夹杂物含量均降低,其中小于5 μm的夹杂物数量密度从1.107、0.374递减到0.177 mm-2,尺寸大于5 μm的夹杂物甚至消失。

(3) 使用JMatPro模拟计算得出氧化物和氮化物夹杂的含量分别与O、N含量呈正相关关系,与Al、Ti等合金元素的含量无关。

参考文献

Microstructure development in electron beam-melted Inconel 718 and associated tensile properties

[J].

Element segregation in GH4169 superalloy large-scale ingot and billet manufactured by triple-melting

[J].GH4169 has the advantage of excellent comprehensive mechanical properties, good oxidation and corrosion resistance, etc., which have been widely used in aero engine with the largest consumption. The GH4169 parts include high pressure compressor disk, turbine disk, shaft, gearbox and forged blade, et al. With the development of technology and the requirement of cost reducing, the size of GH4169 ingot and billet increases gradually at home and abroad. However, element segregation becomes more and more severe as the size of GH4169 ingot and billet increases, which will significantly degrade their mechanical properties. In this work, the large-scale GH4169 superalloy ingot (diameter 508 mm) was prepared by triple smelting, vacuum induction melting (VIM)+electro sag remelting (ESR)+vacuum arc remelting (VAR). Then, large-scale GH4169 billet (diameter 240 mm) was obtained from this prepared ingot via two-step high temperature homogenization heat treatment and cogging-forging. The element composition and microstructure at different positions of these large-scale ingot and billet were analyzed by SEM, TEM, EPMA and EDS. The results show that the segregation degree of element Al in GH4169 ingot is small, while those of elements Nb, Ti and Mo are large. Moreover, a lot of secondary phases were precipitated at the interdendritic regions of GH4169 ingot, including MC, Laves and δ phase. In the GH4169 billet prepared in our work, no "freckle" or "white spot" macro segregation was recognized, and the micro-element segregation was eliminated. Furthermore, combined with computational simulation, the chemical composition uniformity and main mechanical properties of GH4169 and Inconel 718 billets were compared. The statistical analysis using sample variance of macro chemical composition shows that the uniformity of chemical composition in GH4169 billet produced by different manufactures is different. The regional element segregation results in some vacillation on the mechanical properties of GH4169 billet. It is proposed that this regional element segregation can be further depressed by elaborately controlling the triple melting process and optimizing the homogenization heat treatment and forging process.

三联熔炼GH4169合金大规格铸锭与棒材元素偏析行为

[J].

Development in powder production technology of Ni-based superalloy

[J].

镍基高温合金粉末制备技术的发展现状

[J].

Effect of inclusion size and distribution on low cycle fatigue properties of an FGH97 superalloy

[J].

夹杂物尺寸及分布对FGH97高温合金低周疲劳性能的影响

[J].

Effect of inclusions on low cycle fatigue lifetime in a powder metallurgy nickel-based superalloy FGH96

[J].

Study on crack initiation and propagation induced by inclusion in nickel-base P/M superalloy

[J].

镍基粉末高温合金中夹杂物导致裂纹萌生和扩展行为的研究

[J].

Fracture character of low cycle fatigue of P/M superalloy FGH97

[J].<p>Powder metallurgy (P/M) nickel–based superalloy FGH97 has been researched in recent 10 years in China which is particularly suitable for producing aircraft engine disks and shafts <em>etc..</em> In the range of operating temperature, the resistance to low cycle fatigue (LCF) of P/M nickel– based superalloy is one of the most important performances. In this paper the fracture features of LCF on P/M nickel–based superalloy FGH97 were investigated. The study focused on macroscopic and microscopic features of LCF fractures under 650 ℃, 980—30 MPa, 1 Hz test conditions by optical microscope and SEM. The types and morphologies of failure origins were observed. The effects of failure origin location and type, shape and size of defects located in fracture on LCF life were discussed. The results show that LCF life of all the specimens of FGH97 is over 5000 cyc under above test conditions. Statistically, 23% of LCF failure origins are on sample surface, 47% near surface and 30% in interior of samples. There are statistically three types of the LCF failure origins in this alloy: 5% of grain facet, 15% of powder particle and 80% of inclusion. Based on the statistical analysis and theoretical calculation of the influences of three types of LCF failure origins on LCF life, it can be concluded that the LCF life can be more severely affected by the inclusion than by the abnormal powder particle and partial plastic deformation.</p>

粉末冶金高温合金FGH97的低周疲劳断裂特征

[J].

Influence mechanism of inclusion size on low cycle fatigue of powder metallurgy superalloy

[J].

夹杂物尺寸对粉末高温合金低周疲劳寿命影响的机制

[J].

Research on inclusions in powder metallurgy superalloy-a review

[J].

粉末高温合金中夹杂物问题的研究进展

[J].

Removal inclusions from nickel-based superalloy by induced directional solidification during electron beam smelting

[J].

Type and distribution of inclusion in GH4169 nickel-based superalloy

[J].

GH4169铸锭中夹杂物的类型及分布规律

[J].

Distribution of inclusions on surface of GH4169 ESR ingot

[J].

GH4169电渣重熔铸锭表层夹杂物分布规律

[J].

Research on purification control technology of FGH96 master alloy

[J].

FGH96母合金洁净化控制技术的研究

[J].

Effect of crucible material and top slag composition on the inclusion composition of tire cord steel

[J].

坩埚材质及顶渣成分对帘线钢夹杂物成分的影响

[J].

Investigation on the formation mechanism of non-metallic inclusions in high-aluminum and titanium-alloyed Ni-based superalloy

[J].

Electromagnetic purification of master alloy ingot of K417 superalloy in vacuum

[J].

K417高温合金母合金锭真空电磁净化技术研究

[J].

Regulating the non-metallic inclusions by pulsed electric current in molten metal

[J].Non-metallic inclusions generally reduce the properties of steels, such as reducing transverse mechanical properties, initiating cracks, reducing fatigue life and inducing corrosion. Reducing the number and changing the morphology of inclusions can significantly improve the performance of steels. Therefore, inclusion removal and its morphology control in steel have always been the focus issue. Although the bottom-blown argon, electromagnetic stirring and filtration can remove inclusions to a certain extent, these methods are difficult to effectively remove inclusions smaller than 20 μm in size and cannot effectively control the morphology of the inclusions. Recently, electric current has become a new method for inclusion removal and morphology control. This article briefly reviews the hazards of inclusions and their control methods, and reviews the effects of current on the removal, orientation and morphological evolution of inclusions in metal melts in detail, and introduces three mechanisms of current-controlled inclusion separation: electrophoresis, electrical free energy driving and electromagnetic repulsion. Electrophoresis theory believes that inclusions in the melt are charged, and they migrate parallel to the direction of the current under the action of the electric field force. While the electrical free energy driving and electromagnetic repulsion hold that inclusions migrate perpendicular to the direction of the current. The current waveforms significantly affect the removal efficiency of inclusions. Compared with direct current and alternating current, the pulsed electric current has a stronger ability to remove inclusions, especially pulsed electric current can effectively separate inclusions with a size larger than 5 μm in the molten steel. In addition, the pulse current can not only control the orientation and morphology of the inclusions, but also affect the morphology of the bubbles; the inclusions tend to be refined, spheroidized and arranged parallel to the current under the action of the pulse current. Finally, the research status of current-controlled inclusion separation is summarized, and future research trends are analyzed. At the same time, the application and prospect of pulsed current in anti-clogging of submerged entry nozzle was also analyzed. Due to the low energy consumption, excellent inclusion removal efficiency and easy process equipment, pulsed current separation technique is expected to become a new technology for removing inclusions and suppressing nozzle blockage in the future.

脉冲电流调控金属熔体中的非金属夹杂物

[J].通常非金属夹杂物会降低钢铁材料的性能,例如降低横向力学性能、萌生裂纹、减低疲劳寿命和诱发腐蚀。减少夹杂物的数量和改变夹杂物的形态可以显著提升钢铁材料的性能。所以,钢中夹杂物的去除以及形态控制一直以来都是研究的热点。虽然通过底吹Ar气、电磁搅拌和过滤方法可以在一定程度上去除夹杂物,但是上述方法难以有效地去除尺寸小于20 μm的夹杂物,并且不能有效地控制夹杂物的形态。最近,电流成为一种夹杂物去除与形态控制的新方法。本文简要综述了夹杂物的危害及其控制手段,并且详细回顾了电流对金属熔体中夹杂物的去除、取向和形态演变的影响,并介绍了电流控制夹杂物的3种机理:电泳、电自由能驱动、电磁斥力。电泳理论认为熔体中的夹杂物带有电荷,夹杂物在电场力的作用下平行于电流方向迁移。电自由能驱动理论和电磁斥力理论认为夹杂物垂直于电流方向迁移。电流波形显著影响夹杂物的去除效果,与直流电、交流电相比,脉冲电流具有较强的夹杂物去除能力,尤其是脉冲电流能够有效分离钢液中尺寸为5 μm以上的夹杂物。此外,脉冲电流不仅可以控制夹杂物取向与形态,还可以对气泡的形态产生影响;脉冲电流作用下夹杂物趋于细化、球化并平行于电流排列。最后,对电流控制夹杂物的研究现状进行了总结,并分析了未来的研究趋势。同时,对脉冲电流在抑制浸入式水口堵塞中的应用进行分析与展望。由于脉冲电流能耗低、夹杂物去除效果好以及工艺装备简易的优点,有望成为未来去除夹杂物、抑制水口堵塞的新技术。

Effects of compound salt purifiers on composition and microstructure of GH4169 returned alloy

[J].

复合盐净化剂对GH4169返回料成分和组织的影响

[J].

Kinetics study of nitrogen removal from liquid IN718 alloy during vacuum induction melting

[J].

Deep deoxidation and desulfurization of cast superalloy K417G

[J].

铸造高温合金K417G深度脱氧脱硫的研究

[J].

Purification in alloy GH3625 through vacuum induction remelting

[J].

真空感应重熔GH3625合金纯净化研究

[J].

Effect of vacuum level on the interfacial reactions between K417 superalloy and Y2O3 crucibles

[J].

Reassessment of TiN(s)=Ti+N equilibration in liquid iron

[J].

Investigation on the formation mechanism of Ti-bearing non-metallic inclusions in Fe-Al-Ti-O-N alloy by inductive separation method

[J].