深冷处理(DCT),是将合金材料置于-130℃以下的温度以改善其显微组织和提高力学性能[5~7]。Steier等[8]对6101-T4铝合金进行了DCT处理,发现其晶粒尺寸没有明显的变化;高文林等[9]对挤压态7A99铝合金固溶处理后进行多次时效深冷循环处理,发现DCT处理使析出相的等效半径减小、密度降低、晶界第二相(GBP)断续分布、位错密度提高、屈服强度下降8%,但是断面收缩率提高了54%。李茂军等[10]对A356铝合金进行深冷+固溶时效处理,发现晶粒细化,Si相呈细小、弥散分布,位错密度、合金抗拉强度和伸长率提高。Zhou等[11]对2024-T351铝合金进行DCT处理,发现在不降低伸长率的情况下其极限强度和屈服强度都提高了;同时,经DCT处理的试样塑性提高,其断口韧窝尺寸大、较深、分布均匀。Ji等[12]对搅拌摩擦焊(FSW)后的2024-T351铝合金进行深冷-时效处理,发现DCT处理使焊接接头中亚稳相均匀分布,接头的抗拉强度提高了9.6%,伸长率提高了160%。

迄今为止,虽然对铝合金深冷处理及相关复合处理技术的研究取得了一些进展,但是对其强韧化机理的研究尚待深入。鉴于此,本文对变形时效后的7075合金进行重固溶后进行深冷和时效复合处理,研究复合处理对其显微组织和力学性能的影响并分析其强韧化机制。

1 实验方法

实验用7075铝合金的化学成分,列于表1。

表1 实验用7075铝合金的化学成分(质量分数, %)

Table 1

| Zn | Mg | Cu | Si | Mn | Al |

|---|---|---|---|---|---|

| 5.45 | 2.53 | 1.63 | 0.4 | 0.3 | Bal. |

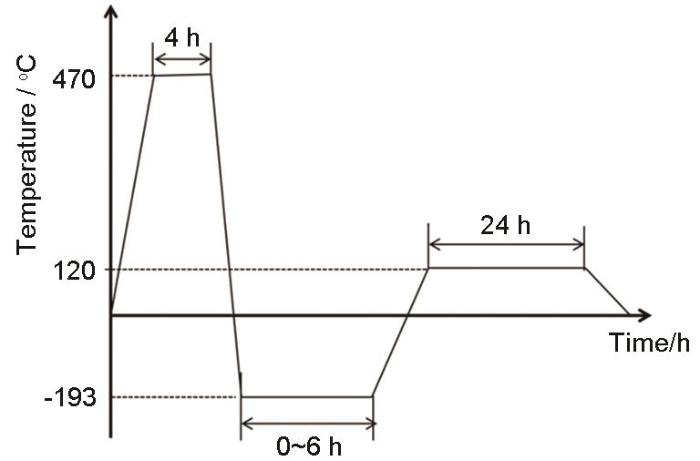

先将7075铝合金在470℃固溶4 h,室温水淬后将其迅速放入液氮中进行不同时间的DCT处理,然后再进行时效处理。DCT-T6处理工艺流程图,在图1中给出。深冷时间为0 h,即为传统T6处理。

图1

使用型号为CMT5105的万能拉伸机测试试样的拉伸性能,拉伸速率为1 mm/min,拉伸试样尺寸如图2所示。使用型号为TalosF200X的透射电镜观察合金的晶界、晶内的析出相种类、尺寸及分布、位错密度和晶粒形貌,加速电压为200 kV。使用型号为SU1510的钨灯丝扫描电镜观察合金拉伸断口的形貌,加速电压为20.0 kV。

图2

2 实验结果

2.1 DCT-T6对合金力学性能的影响

图3给出了深冷时间对7075铝合金拉伸性能的影响。可以看出,深冷时间对合金抗拉强度和伸长率的影响趋势相似。与T6处理相比,DCT-T6处理提高了合金的抗拉强度和伸长率。深冷时间为0~6 h时,随着深冷时间的延长合金的抗拉强度和伸长率都先提高后降低,时间拐点分别为4 h和3 h。深冷时间为4 h时合金的抗拉强度达到最大值645 MPa,比T6处理样品的抗拉强度提高了13.1%;深冷时间为3 h时合金的伸长率达到最大值13%,比T6处理样品的伸长率提高了44.4%。

图3

图3

合金的拉伸性能与深冷时间的关系

Fig.3

Dependence of tensile strength and elongation on soaking time

2.2 DCT-T6对断口形貌的影响

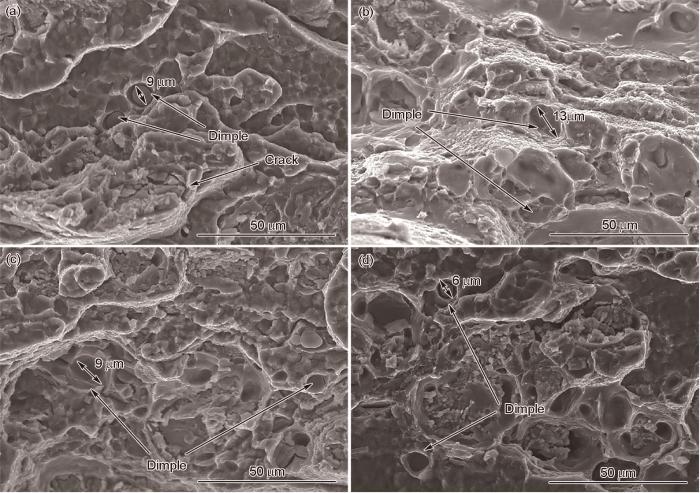

图4

图4

经T6处理和DCT-T6处理后合金拉伸断口的形貌

Fig.4

Fracture morphologies under different process parameters (a) T6, (b) DCT3h-T6, (c) DCT4h-T6, (d) DCT6h-T6

2.3 DCT-T6对合金显微组织的影响

2.3.1 DCT-T6对合金晶粒的影响

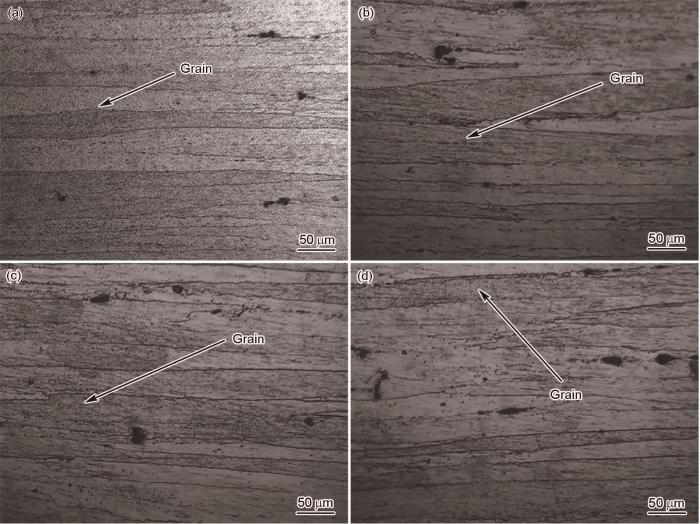

图5给出了深冷时间不同的DCT-T6处理后合金的金相照片。可以看出,深冷时间为0~6 h时,随着深冷时间的延长合金晶粒的形貌未发生明显的改变,都是拉长的带状组织。深冷时间为0 h时,合金晶粒的尺寸约为17 μm;深冷时间为3 h时,合金晶粒的尺寸约为23 μm;深冷时间为4 h时,合金晶粒的尺寸大约为27 μm;深冷时间为6 h时,合金晶粒的尺寸约为20 μm。这表明,在0~6 h范围内,随深冷时间的延长合金晶粒的尺寸没有明显的变化。

图5

图5

不同深冷时间的DCT-T6处理后7075合金的金相照片

Fig.5

Metallography images of 7075 aluminum alloy T6 treated with DCT-T6 at different cryogenic times (a) T6, (b) DCT3h-T6, (c) DCT4h-T6, (d) DCT6h-T6

2.3.2 DCT-T6对晶内析出相的影响

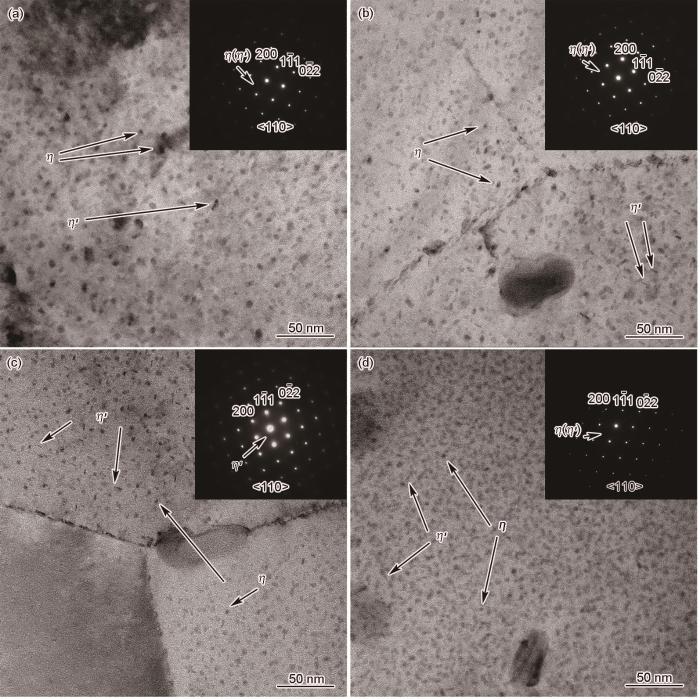

图6

图6

不同深冷时间的DCT-T6处理后7075合金晶内析出相的TEM照片

Fig.6

TEM images of intra-grain precipitates of 7075 aluminum alloy T6 treated with DCT-T6 at different cryogenic times (a) T6, (b) DCT3h-T6, (c) DCT4h-T6, (d) DCT6h-T6

2.3.3 DCT-T6对晶界第二相的影响

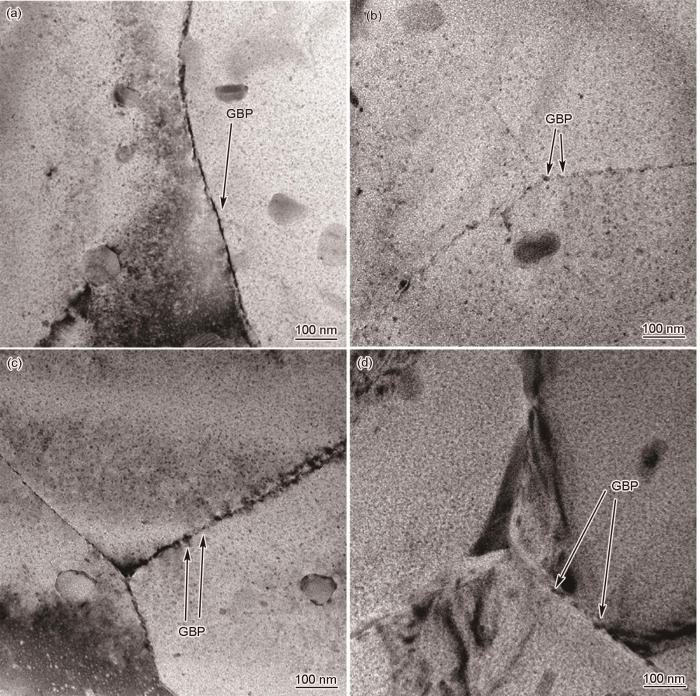

图7

图7

不同深冷时间的DCT-T6处理后合金晶界析出相的TEM照片

Fig.7

TEM images of grain boundary precipitates of 7075 aluminum alloy T6 treated with DCT-T6 at different cryogenic times (a) T6, (b) DCT3h-T6, (c) DCT4h-T6, (d) DCT6h-T6

2.3.4 DCT-T6对位错形貌的影响

图8

图8

不同深冷时间的DCT-T6处理合金中位错的形貌

Fig.8

Dislocation morphologies of 7075 aluminum alloy T6 treated with DCT-T6 at different cryogenic times (a) T6, (b) DCT3h-T6, (c) DCT4h-T6, (d) DCT6h-T6

2.3.5 DCT-T6对亚晶的影响

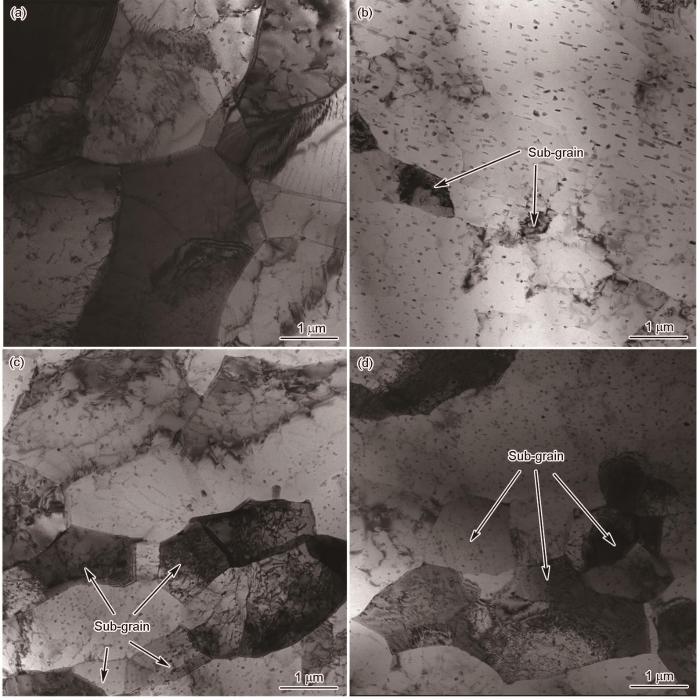

图9

图9

不同深冷时间的DCT-T6处理后合金中亚晶的形貌

Fig.9

Morphologies of sub-grains of 7075 aluminum alloy T6 treated with DCT-T6 at different cryogenic time (a) T6, (b) DCT3h-T6, (c) DCT4h-T6, (d) DCT6h-T6

2.3.6 亚晶的生成

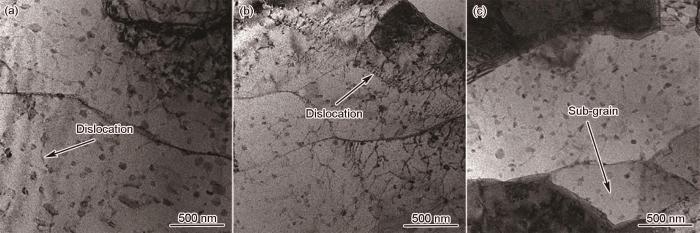

图10

图10

合金中亚晶粒结构的形成

Fig.10

Formation of the sub-grain structure in alloy (a) T6-initial-dislocation; (b) DCT3h-T6-dislocation pile-up; (c) DCT4h-T6-sub-grain

3 讨论

3.1 合金的组织

合金晶内析出相变化的原因是,合金经固溶淬火后的深冷处理提高了α-Al基体的过饱和度,使后续的析出驱动力增大。在时效初期合金中形成了大量GP区,随后发生连续脱溶转变形成η'相和η相;同时,处于低温条件下合金中的原子扩散速率较低、迁移距离较短,抑制了η'相和η相的生长。因此,用DCT-T6处理后晶内析出相的尺寸比T6处理的小。

在0~4 h范围内,随着深冷时间的增加和在析出驱动力的作用下晶内大量的GP区先脱溶转变为η'相使其密度提高;深冷时间为4 h时晶内η'相的密度最高;在4~6 h时范围内,随着深冷时间的延长η'相在析出驱动力的作用下进一步脱溶转变为η相使其密度提高而η'相的密度降低;深冷时间为6 h时晶内η相密度最大[14]。

合金位错密度变化的原因是,温度由室温降低至-193℃,因合金中析出相与α-Al基体相的膨胀系数不同使其产生了微塑性变形进而产生了冷致压应力。根据固体物质物态方程 [10]

体积的变化为

式中V0为当温度为T0时固体的体积,VT为当温度为T时固体的体积,α为膨胀系数。在深冷过程中合金发生的体积收缩,即为体积应变。平均压应力应排除合金原有的内应力并取3个主应力的均值,因此合金受到的平均压应力可表示为

式中K为合金的弹性模量;7075铝合金的膨胀系数为24.3×10-6 K-1,弹性模量为71.7 GPa。计算结果表明,在深冷过程中合金产生的压应力σm=-409 MPa,大于文献[13]中的固溶淬火后310 MPa的屈服强度。合金内应力叠加超过屈服强度,有利于晶粒细化、使位错密度提高。

在后续的时效过程中,位错密度的提高,一方面使合金发生回复再结晶,晶界处的位错快速扩散。在扩散过程中产生一些不稳定的位错,这些不稳定的位错之间的交互作用使亚晶生成[14];另一方面,原子扩散通道增多使晶界析出相的尺寸和间距增大。在0~6 h范围内,随着深冷时间的延长合金产生的微塑性变形量增大而使冷致压应力增大,从而使位错密度提高。因此,深冷时间为6 h时合金中的位错密度最高。位错密度的提高使位错之间发生交互作用而生成亚晶,因此位错密度越大亚晶的数量越多。这表明,深冷时间为6 h时合金中亚晶的数量最多。同时,由于合金中产生了冷致压应力,晶界被认为是应力释放的主要区域。因此,与T6处理相比,采用DCT-T6处理使原本呈连续分布的GBP破碎成细小、断续分布的GBP,且在3~6 h范围内,随着深冷时间的延长位错密度提高使原子扩散通道增多,进而使GBP的尺寸和间距不断增大。深冷时间为3 h时GBP的尺寸最小,深冷时间为6 h时GBP的间距最大。

3.2 合金的性能

式中λ为常数,f为析出相的体积分数,γ为析出相的尺寸。当晶内析出相尺寸相对较大时,即析出相主要为粗大的η相,位错难以切过析出相。因此,位错的运动机制为绕过机制,强化效果可表示为[19]

式中δ为常数,f为析出相的体积分数,γ为析出相的尺寸。这表明,析出相较为细小时7075铝合金的强度与析出相的尺寸和体积分数呈正相关,而当析出相较为粗大时7075铝合金的强度与析出相的体积分数呈正相关,而与析出相的尺寸呈负相关。同时,对于7075铝合金而言,析出相的种类使其强度提高的程度不同,起主要作用的是与基体半共格的η'相,与基体呈非共格的η相的作用较小。故η'相的密度越大,合金的强度越高。

位错密度对合金的强度的影响主要与位错滑移启动力τp有关,根据Peirls-Nabarro公式[20]

当ω增大时τp增大,位错的强化效果更加显著,但是位错密度的提高使合金中的缺陷增多,反而使合金的强度降低。

亚晶对合金的强度的影响,主要与其数量和尺寸有关。亚晶,是原始晶粒破碎和位错重排后存在于合金内的细小晶粒。随着亚晶数量的增加,细晶强化效果更加显著。根据Hall-Petch公式,细晶强化效果与亚晶晶粒的尺寸呈负相关。

合金的塑性,主要与GBP的尺寸和分布有关。基于GBP的分布对合金塑性影响的文献[14],连续分布的GBP对合金的塑性不利。同时,合金的微塑性变形使合金中产生大量位错,位错随着变形的发生不断运动易在晶内缺陷处富集,从而使合金断裂。这表明,粗大的GBP对合金的塑性有害。

综上所述,与T6处理相比,DCT-T6处理使合金晶析出相的尺寸虽略有减小,但是密度却显著提高。且合金中的位错密度及亚晶数量增加,析出强化、位错强化及细晶强化的协同作用使合金的强度提高;此外,GBP的分布也由T6处理后的连续分布变为DCT-T6处理后的断续分布。DCT-T6处理后的GBP尺寸也比T6处理后的小,因此用DCT-T6处理后合金的塑性提高。

在0~4 h范围内,随着深冷时间的不断延长η'相的密度提高、位错密度及亚晶数量增加,位错运动机制由绕过机制变为切过机制,切过强化效果也随之增强;同时,位错强化和细晶强化效果不断增强使合金的强度提高。深冷时间为4 h时,强度到达最大值;在此范围内GBP的分布由连续分布转变为断续分布,尺寸先减小后增大,使合金的塑性先提高后降低。在4~6 h范围内,随着深冷时间的延长合金中粗大的η相不断增多,位错的运动机制由切过机制转变为绕过机制,且位错密度增大后在晶界处塞积,合金受到一定应力时易在晶界处开裂而使合金的强度降低,GBP的尺寸进一步增大使合金的塑性进一步降低。

4 结论

(1) DCT-T6处理能提高7075铝合金中析出相的密度、降低析出相的尺寸,提高位错密度并生成一定数量的亚晶。

(2) 随着深冷时间的延长η'相的密度先提高后降低,η相的密度及位错密度提高。4 h为时间拐点。

(3) 7075铝合金经DCT-T6处理后拉伸性能提高、抗拉强度和伸长率随深冷时间的延长先提高后降低,时间拐点分别为4 h和3 h;深冷时间为4 h时合金的抗拉强度达到最大值645 MPa,深冷时间为3 h时伸长率达到最大值13%。

(4) DCT-T6处理使合金性能提高的机理,是η'相和η相尺寸的减小、密度的提高以及GBP尺寸和分布的改善而产生的弥散强化、位错密度提高产生的位错强化以及亚晶产生的细晶强化。

参考文献

Preparation and cutting performance of diamond coated hard alloy cutting tools for 7075 aviation Al-alloy

[J].

加工7075航空铝合金用金刚石涂层刀具的制备及其切削性能

[J].

Effect of laser heat treatment on microstructure and mechanical property of 7075 Al-alloy

[J].The effect of laser heat treatment, in stead of the retrogression process within the traditional retrogression and re-aging (RRA) treatment, on the microstructure and mechanical property of 7075 Al-alloy was investigated. The results show that the laser heat treatment can effectively replace the regression process of RRA. The hardness of the resulted 7075 Al-alloy exhibits the aging feature with double peaks. After pre-aging, laser treatment (850 W, 2 mm/s) and re-aging, the hardness of 7075 Al-alloy reaches the value of the second peak-aged ones with the highest hardness of 181 HBW, which then presented oxidation-wear character during wear test. The second peak-aged alloy possesses higher hardness and much better tribological performance than the first peak-aged ones. Which may be ascribed to the large number of fine precipitates of η'- and η-phase within the laser treated 7075 Al-alloy.

激光热处理对7075铝合金组织和性能的影响

[J].

Effect of pre-aging on stress corrosion cracking of spray-formed 7075 alloy in retrogression and re-aging

[J].

Prediction model of hot stamping thinning of 7075 aluminum alloy windshield beam

[J].

7075铝合金挡风梁热冲压成形减薄预测模型

[J].

Carbon segregation behavior of high-carbon high-alloy steel during deep cryogenic treatment using 3DAP

[J].

3DAP研究高碳高合金钢深冷处理过程的C偏聚行为

[J].

Effects of cryogenic treatment on mechanical properties and micro-structures of IN718 super-alloy

[J].

The role of Cryogenic dipping prior to ECAP in the microstructure, secondary-phase precipitation, mechanical properties and corrosion resistance of AA6012 (Al-Mg-Si-Pb)

[J].

Effect of a deep cryogenic treatment on wear and microstructure of a 6101 aluminum alloy

[J].

Effect of deep cryogenic treatment of -180℃ on strength and toughness properties and precipitation behavior of 7A99 aluminium alloy

[J].

-180℃深冷处理对7A99铝合金峰值时效强韧性能与析出行为的影响

[J].

Effect of cryogenic + solid solution + ageing composite treatment on microstructure and mechanical properties of A356 alloy

[J].

深冷+固溶+时效复合处理对A356合金微观组织和力学性能的影响

[J].

Tensile properties and microstructures of a 2024-T351 aluminum alloy subjected to cryogenic treatment

[J].

Effects of deep cryogenic treatment and low-temperature aging on the mechanical properties of friction-stir-welded joints of 2024-T351 aluminum alloy

[J].

Effect of the aging process on the micro-structure & properties of 7075 aluminum alloy using electromagnetic bulging

[J].

The influence of cryogenic-aging circular treatment on the microstructure and properties of aluminum matrix composites

[J].

Effects of solution treatment on microstructural and mechanical properties of Al-Zn-Mg alloy by microalloying with Sc and Zr

[J].

Over-aging influenced matrix precipitate characteristics improve fatigue crack propagation in a high Zn-containing Al-Zn-Mg-Cu alloy

[J].

Investigation of mechanical and corrosion properties of an Al-Zn-Mg-Cu alloy under various ageing conditions and interface analysis of η′ precipitate

[J].

Precipitation strengthening model of AA 7055 aluminium alloy

[J].AA 7055 aluminium alloy has been widely applied in aviation and aerospace applications, especially after T7751 heat treatment, owing to its excellent properties, such as high strength and good stress corrosion and fatigue resistances. For 7XXX aluminium alloys, aging hardening is the main strengthening mechanism, and the hardening effect is determined by the microstructural features of precipitates including morphology, composition, volume fraction, nucleation density, and size distribution. To further improve the property of alloy and expand the breadth of applications, establishing a precise predictive model regarding strength performance associated with the precipitates is necessary. In this work, based on the quantitative results of the precipitates obtained using small angle X-ray scattering techniques, the strengthening models of AA 7055 Al alloys aged at 120 and 160oC were investigated. Precipitation kinetics show that at the early stages of aging, the evolution of radius and the half thickness of plate-like precipitates are both linear with t1/2 (t means the aging time). Conversely, at the later stages of aging, they are linear with t1/3. The evolution of the volume fraction of the precipitates follows a JMA (Johnson-Mehl-Avrami)-type equation. Strength contributions from both GPI zones and η' precipitates are considered. Moreover, strengthening modeling considered both the modulus and coherency strain strengthening mechanisms of these two kinds of precipitates that had been built for the AA 7055 Al alloy aged at 120 and 160oC. Therefore, yield strength during aging can be predicted.

AA7055铝合金时效析出强化模型

[J].利用小角度X射线散射技术获得的系列定量信息,综合运用时效析出动力学理论和析出相切过、绕过强化机制,研究了AA 7055铝合金在120和160℃时效过程中的屈服强度演变模型。结果表明,在时效早期盘状析出相的盘面半径和半厚度均与t<sup>1/2</sup> (t为时效时间)成线性关系;在时效后期,析出相尺寸则与t<sup>1/3</sup>成线性关系。时效过程中析出相体积分数与t的变化关系遵循JMA (Johnson-Mehl-Avrami)型表达式。综合考虑了GPI区和η'相2类析出相对合金强度的贡献,并且分别考察了这2类析出相的模量强化机制和共格应变强化机制,最终建立了AA 7055铝合金在120和160℃时效过程中的屈服强度变化模型,确定了该合金时效过程中析出相与屈服强度之间的定量关系。

Effect of multi-stage aging treatments on the precipitation and mechanical properties of Al-Zn-Mg alloys

[J].