M50钢是一种综合性能极佳的高温轴承钢,具有高硬度、高强度、高热稳定性,以及较高的抗高温滚动接触疲劳性能。大尺寸夹杂物和碳化物,是影响M50钢轴承性能的主要因素。它们极易引起材料中的应力集中而使轴承在服役过程中产生裂纹而失效,使轴承的可靠性和使用寿命降低[1~4]。M50钢中的大尺寸碳化物,主要是在铸造过程中从液相中析出并长大的一次碳化物,也称为液析碳化物。这种液析碳化物尺寸较大的主要原因,是其生成主要由元素扩散控制。在钢液的凝固过程中,生成碳化物的C、Cr、Mo、V等溶质元素其扩散速率比在固相中高几个数量级。因此,一次碳化物能快速生成且生长成较大的尺寸[5]。M50钢液中生成的主要液析碳化物是MC和M2C。尤其是较大钢锭中心的冷速较低,合金元素的充分扩散需要更长的时间,使碳化物得以长成更大的尺寸。

液析碳化物一旦生成,后续的热处理很难将其消除,因为碳化物的溶解或固溶依赖碳化物形成元素的扩散。固相中合金元素的扩散速率比在液相中低3~4个数量级[6],因此消除大尺寸碳化物需要较长的时间的高温扩散均匀化退火。去除液析碳化物的一种思路是,在铸造凝固过程中尽可能减少液析碳化物的析出或将其破碎细化[7~13]。Kim等在100Cr6轴承钢中添加稀土Ce生成氧化物,作为凝固奥氏体孕育剂的增大了铸锭的等轴晶区、细化晶粒并减轻凝固偏析,使液析碳化物显著细化[10]。翟启杰等在GCr15轴承钢的连铸过程施加脉冲电场[11~13],促进了晶粒形核和抑制了液析碳化物晶粒的长大。另一种思路是,将锻造等热变形与热处理相结合使液析碳化物破碎细化,从而控制其数量和尺寸[14]。

研究表明,在低氧的GCr15轴承钢中添加高纯净的La、Ce混合稀土可显著提高材料的强韧性和疲劳性能[15~17]。其主要原因是,与普通稀土相比,高纯稀土中含量较低的杂质氧使氧化物显著减少。因此,加入钢液中的稀土氧化物减少,不仅净化了钢液、使夹杂物改性并细化,而且残留的稀土易与空位等缺陷结合促进稀土在钢中的固溶,强化了晶界、迟豫相变并阻碍晶间裂纹扩展。同时,在GCr15钢中添加Ce稀土生成的稀土氧化物、硫化物等夹杂物,成为奥氏体的孕育剂细化了奥氏体和扩大等轴晶区。但是,从M50钢的准二元平衡相图(图1)可见,在凝固过程中从液相最先析出的是高温δ-铁素体,然后才是奥氏体。因此,添加高纯稀土能否细化基体的晶粒和加入的稀土是否影响液析碳化物的析出,还有待深入研究和确认。鉴于此,本文在M50钢液中添加高纯净的La、Ce混合稀土和高纯Ce稀土,研究其对析碳化物的影响,并进行第一性原理分子动力学计算以揭示稀土影响液析碳化物析出的机制。

图1

图1

M50钢的准二元Fe-C平衡相图

Fig.1

Quasi binary Fe-C equilibrium phase diagram of M50 steel

1 实验方法

1.1 实验用钢的制备

用真空感应炉冶炼三支不同成分的M50钢锭,包括不添加稀土(M50)、添加0.13%(质量分数)高纯La、Ce混合稀土(M50-RE、La、Ce的质量比约为4∶6)和添加0.1%(质量分数)高纯Ce稀土(M50-Ce)。稀土中杂质氧的含量低于0.008%(质量分数)。稀土的添加量高于工业中的添加量,以深入研究稀土的作用。

本文主要研究稀土对液析碳化物的作用并不强调最佳稀土添加量,因此没有显著改变稀土的添加量。钢锭的质量为25 kg。切割冒口并取气体棒以测O、S元素含量,取屑测其它元素含量并分析钢锭的化学组成。三支钢锭中Fe元素以外的其它元素的质量分数,列于表1。各主要元素符合M50钢合金元素的控制要求。

表1 冶炼的三支M50钢锭的成分

Table 1

| Samples | C | Cr | Mo | V | Mn | Si | O | Ce | La | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| M50 | 0.82 | 4.28 | 4.11 | 0.97 | 0.28 | <0.05 | 0.0009 | - | - | |

| M50-Ce | 0.85 | 4.33 | 4.32 | 1.01 | 0.27 | 0.05 | 0.0006 | 0.11 | - | Bal. |

| M50-RE | 0.83 | 4.29 | 4.27 | 1.00 | 0.26 | 0.05 | 0.0008 | 0.15 | 0.076 |

在冒口位置切取试样用于成分分析。加入稀土的钢液中夹杂物在冒口处富集,使测得的稀土含量高于添加量。

1.2 第一性原理分子动力学计算

在钢锭中添加的高纯稀土,除了生成部分变质夹杂物,游离的稀土与钢液中的其它原子发生交互作用。这种交互作用对液析碳化物的影响难以用实验表征分析,需要进行原子尺度的模拟计算。因此,采用第一性原理分子动力学计算金属合金液态原子结构。模拟计算不受经验参数的影响,能准确计算合金熔体中原子间的相互作用和原子扩散动力学。计算中使用VASP(Vienna Ab-initio simulation sackage)软件包[18]。对每一步的原子构型,通过对Kohn-Sham能量泛函的最小化求解基态电荷密度,然后根据Hellman-Feynman定理计算出每个原子上的受力,进而用Verlet算法求解牛顿运动方程得到下一步构型中的原子位置。采用正则系综(NVT)和Nose-Hoover热浴法进行动力学模拟,时间步长2 fs。为了揭示Ce对高碳铬钢凝固过程中碳化物形成的影响和加快计算,计算了Fe-Cr-C和Fe-Cr-C-Ce两种简单多组元体系,建立了含有125个原子且具有周期性边界条件的立方超胞,原子组成分别为Fe95Cr10C20和Fe90Cr10C20Ce5。超胞构型先在2300 K完全熔化,消除初始结构的模板效应以得到完全混乱无序的液态构型。然后以200 K的温度间隔降温,在每个温度调整晶胞缩放系数以使外压在0 Pa附近平衡。将平衡构型依次在2100、1900、1700、1500、1300、1100 K运行20 ps,在每个温度选取后5000个动力学步骤以提取原子的运动轨迹进行扩散动力学统计分析。具体计算过程参考了使用第一性原理分子动力学计算Fe-Cr-C体系的文献[19~22]。

2 实验结果

2.1 M50钢液析碳化物的表征

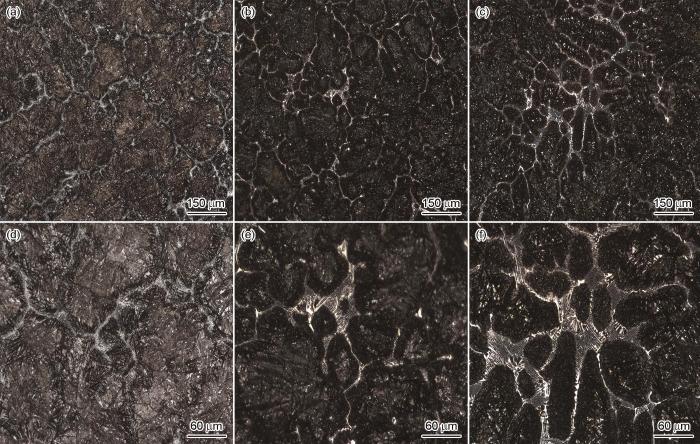

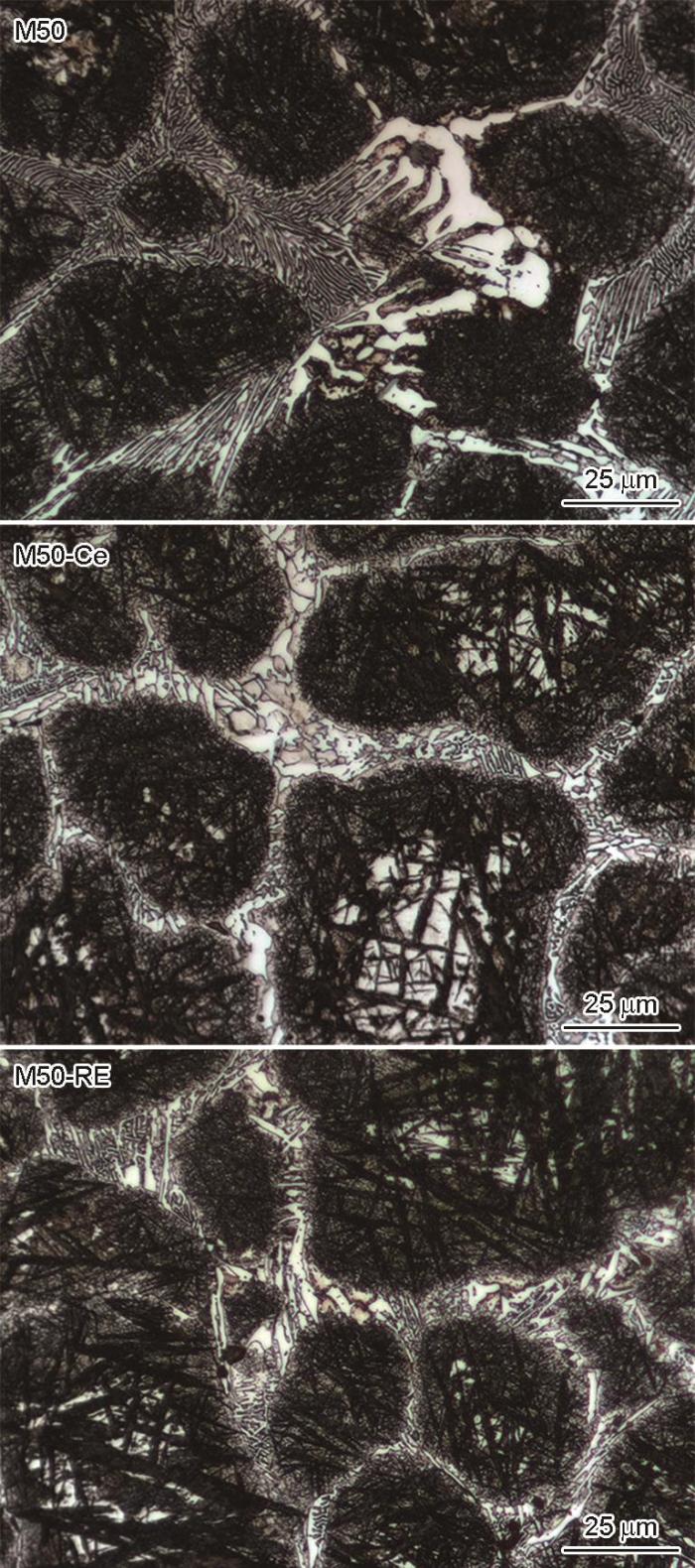

用电火花线切割机在钢锭高度方向的中心位置沿径向从边缘至中心切取尺寸为10 mm×10 mm×10 mm的试样,用砂纸打磨并抛光后用盐酸苦味酸酒精溶液(配比:苦味酸1 g,盐酸5 mL,酒精100 mL)腐蚀,然后用光学显微镜观察钢锭的铸态组织,结果如图2所示。可以看出,三种钢锭的铸态组织主要由马氏体、残余奥氏体和碳化物组成,大尺寸的块状和共晶状液析碳化物分布在晶粒间,两种形貌的碳化物共生(图3)。从图2还可以看出,从钢锭边缘至中心的晶粒之间出现了大量的液析碳化物,分布在晶界交汇处的最粗大。与钢锭中心部位相比,边缘的液析碳化物较少。这与文献[5]中GCr15钢的结果类似,表明M50钢中液析碳化物的生长也受碳化物形成元素的扩散控制。边缘处的冷却较快扩散时间短,碳化物没有足够的时间生长,因此尺寸较小;而中心区域冷却较慢,扩散充分,因此液析碳化物的尺寸较大。

图2

图2

未添加稀土的M50钢锭从边缘至中心的典型铸态金相组织

Fig.2

As-cast microstructure from the edge to the center of M50 steel ingot without rare earth addition (a, b) at the edge of ingot; (c, d) at the half radius; (e, f) at the center

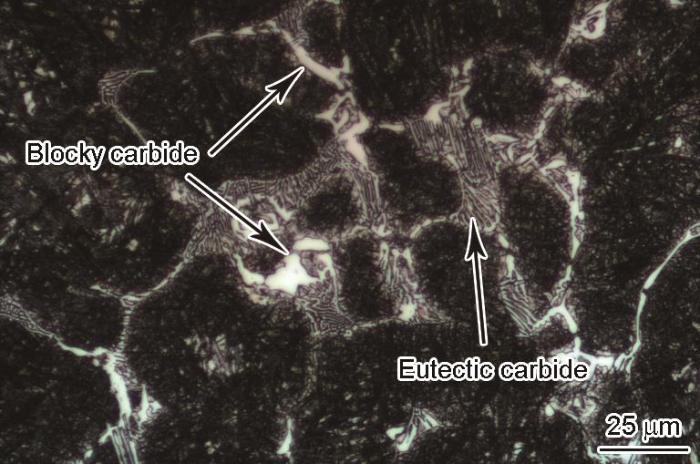

图3

图3

M50钢中典型的块状和共晶状液析碳化物的形貌

Fig.3

Typical morphology of the blocky and eutectic primary carbides in M50 steel

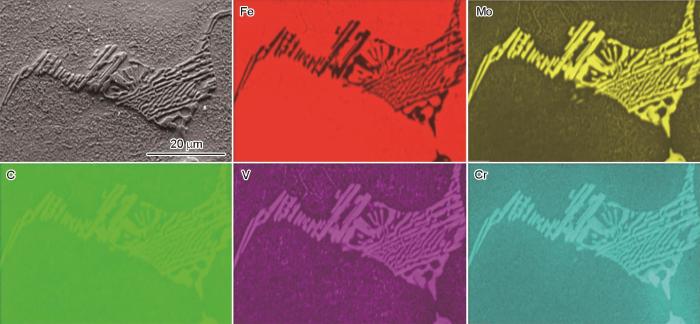

图4给出了未添加稀土的M50钢锭中液析碳化物成分的面扫结果。可以看出,块状碳化物和共晶碳化物都富含C、Cr、Mo、V等溶质元素。添加稀土的M50钢锭中碳化物成分的面扫结果表明,其成分分布与未添加稀土的相同,在碳化物中未检测到La或Ce元素。

图4

图4

未添加稀土的M50钢液析碳化物能谱面扫分析结果

Fig.4

EDS map scanning analysis results of primary carbide in M50 steel without adding rare earth

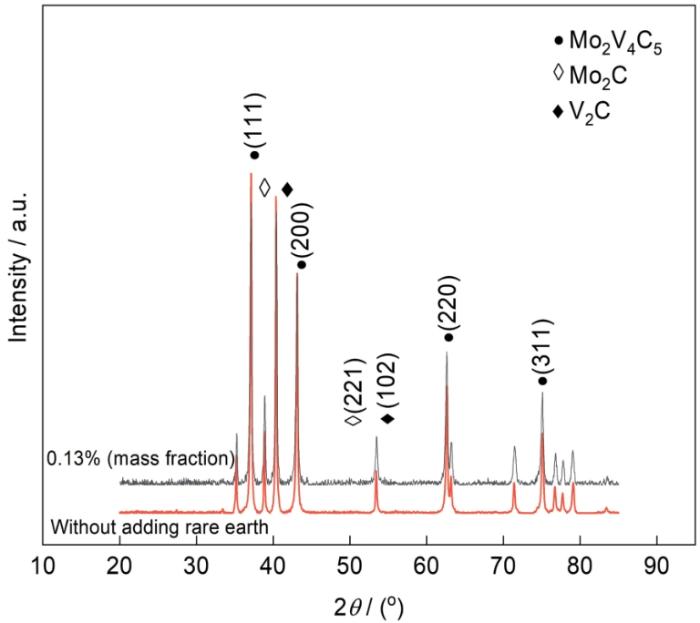

为了确定M50钢中碳化物的物相结构,进行了碳化物颗粒的电解萃取实验。块状试样的尺寸为10 mm×60 mm×5 mm,将线切割痕迹磨去后将其在无水乙醇中超声清洗5 min。将试样与电源负极相连作为阳极,放置于300 mL的10%盐酸甲醇溶液中。电源提供0.2~0.5 A的恒流。电解时环境温度为-20℃。电解完成后过滤电解液,将提取出的碳化物粉末干燥后用于XRD衍射分析,以解析碳化物的物相结构。衍射角为20°~80°,扫描速度为10 (°)/min。因为二次碳化物非常细小,过滤出的碳化物主要是大颗粒的块状液析碳化物。

图5给出了电解萃取的M50钢碳化物粉末的XRD谱,图中的实心圆表示MC型碳化物,菱形表示M2C型碳化物,空心菱形表示Mo2C,实心菱形表示V2C。可以看出,M50钢凝固析出的碳化物化学组成并不固定,Mo、V元素之间的比值有一定的浮动,但是总体上金属原子和碳原子的比值符合MC和M2C结构的1∶1和2∶1。实际的M2C型碳化物衍射峰应该在Mo2C和V2C的峰之间,碳化物的衍射峰与Mo2C相比向右偏移,与V2C相比向左偏移。为了进一步明确碳化物的形貌、结构和成分之间的关系,进行了EPMA成分的定量检测。在M50、M50-RE钢锭的相同部位切取4组试样,每组试样测3个点,每个点分别测量了块状和共晶状碳化物中Fe、Cr、V、Mo、C元素的含量,以明确两种形貌的液析碳化物其成分是否不同。点分析的成分平均测量结果,列于表2。从表2可以看出,两种碳化物都富含Cr、Mo、V金属元素。共晶碳化物中的金属元素与碳元素的比例约为2∶1,符合M2C结构的原子比,金属元素中Mo原子的百分比较高;块状碳化物中的金属元素与碳元素的比例约为1∶1,符合MC结构的原子比,V原子的分数比较高。从表2还可以看出,与块状碳化物相比,共晶碳化物中Cr的含量更高。EPMA也未在碳化物中检测出稀土。

图5

图5

M50钢液中析出碳化物粉末的XRD衍射谱

Fig.5

XRD diffraction of primary carbide powder in M50 steel

表2 EPMA定量分析的液析碳化物成分统计平均结果

Table 2

| Element | Mass fraction / % | Atomic fraction / % | ||

|---|---|---|---|---|

| Blocky | Eutectic | Blocky | Eutectic | |

| Fe | 3.426 | 7.007 | 2.443 | 6.285 |

| Cr | 4.621 | 15.304 | 3.538 | 14.744 |

| V | 35.963 | 10.317 | 28.113 | 10.146 |

| Mo | 40.539 | 59.948 | 16.826 | 31.303 |

| C | 14.802 | 8.995 | 49.078 | 37.520 |

3 讨论

3.1 稀土对液析碳化物的影响

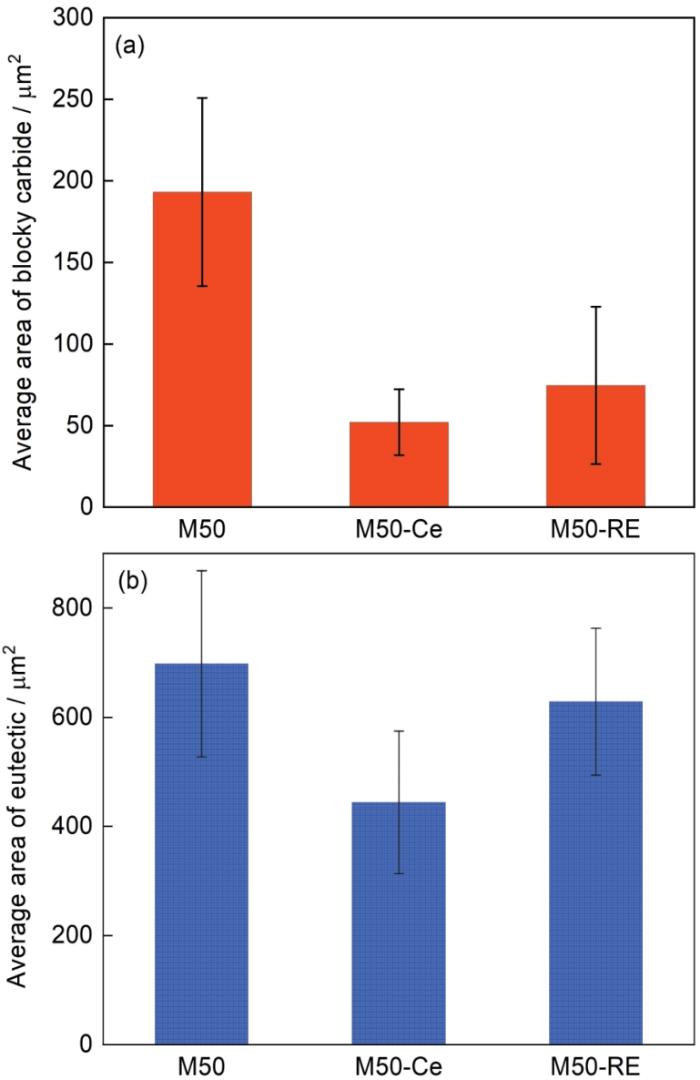

上述结果表明,添加稀土对M50钢液中析碳化物的成分几乎没有影响,但是液析碳化物的形貌和大小变化较大。图6给出了M50、M50-Ce和M50-RE钢锭中心的铸态组织。可以看出,未添加稀土的钢中块状碳化物最多,添加稀土后尤其是添加高纯Ce后块状碳化物减少,共晶碳化物的面积也减小。三种不同钢锭中块状碳化物面积的统计结果,如图7a所示。图中给出了每种钢锭中心区域试样10张500倍照片的金相组织中块状碳化物面积的随机平均值统计分析。统计结果表明,M50钢中出现了大尺寸块状碳化物,添加稀土后块状碳化物的面积明显减小,其中M50-Ce的块状碳化物平均面积最小,减小为未添加的1/4左右。M50-RE误差棒较大的原因是,少量大尺寸块状碳化物产生了较大的统计误差,其余块状碳化物尺寸与M50-Ce接近。这表明,添加稀土使M50钢中大尺寸块状液析碳化物减小。

图6

图6

添加不同稀土的三支钢锭中心铸态微观组织

Fig.6

As-cast microstructure at the center of the three ingots with addition of different rare earth

图7

图7

添加不同稀土的三支钢锭中块状和共晶碳化物面积的统计平均

Fig.7

Statistical average of the area of blocky (a) and eutectic (b) carbides in the three ingots with different rare earth additions

在M50钢凝固的末期,在三个或多个奥氏体晶粒围成的富含溶质的残余液相中碳化物形核和生长,使周围的溶质含量急剧降低。此时液体又以很高的过冷度冷却,奥氏体很容易形核和生长,而排出的溶质又促进了邻近碳化物的形核和生长。两相相互促进的生长使残余液相转化为奥氏体与碳化物的共晶组织。共晶组织的生长不需要溶质元素的长距离扩散,因此能在奥氏体枝晶包围的残余液相中快速生长,使其面积比块状碳化物的面积大很多。Du等[23]使用原位激光共聚焦显微镜加热铸态M50钢液析碳化物,发现一部分M2C型共晶碳化物在大约1200℃溶解,一部分则转变为块状MC型碳化物或杆状M2C型碳化物,影响碳化物的后续状态。因此,为了分析添加稀土对这类共晶碳化物的影响,与块状碳化物类似,统计了室温下三种钢锭中心的铸态组织中共晶莱氏体的面积分数,结果如图7b所示。可以看出,共晶碳化物的平均面积比块状碳化物大3倍以上,添加稀土后大尺寸共晶组织团的面积减小,而添加高纯铈稀土的钢锭其效果更加显著。但是,添加稀土对共晶碳化物的影响没有对块状碳化物的影响显著,其原因可能与共晶组织从最后的残余液相中生长析出不需要溶质长程扩散有关。

3.2 稀土影响液析碳化物析出的机制

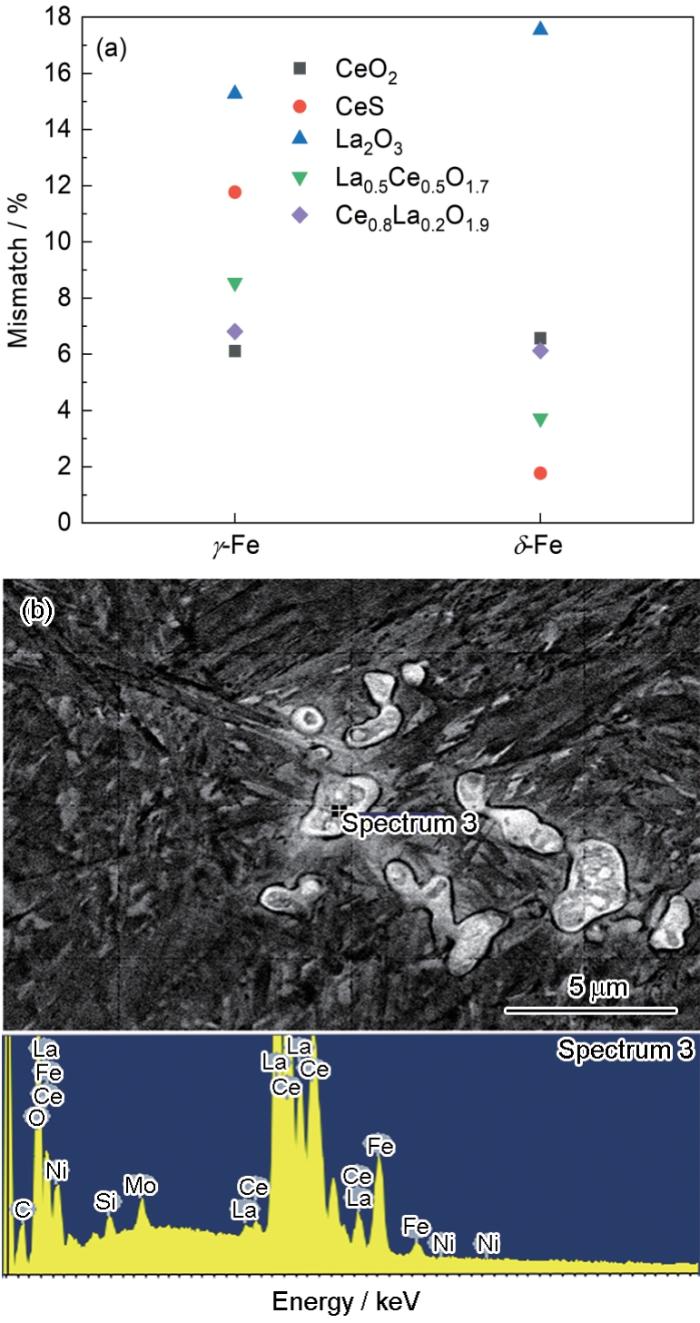

上述表征分析表明,添加高纯稀土影响钢锭中液析碳化物的形貌和大小,但是不改变碳化物的化学成分和结构。加入钢液中的高纯La、Ce稀土以两种形式存在:一是与钢液中的Al2O3和MnS等夹杂物反应生成CeO2等富含稀土的氧化、硫化物或者稀土氧硫化物;未发生化学反应的残留稀土则与钢液中的C等溶质元素发生交互作用,凝固后与空位等发生作用以团簇的形式固溶在基体中。现有研究表明,与钢液中的夹杂物反应生成的高熔点稀土夹杂物,凝固时成为奥氏体的异质形核剂促进了固相形核而使奥氏体晶粒细化[10, 24]。从相图可以看出,M50钢液中先析出的是高温δ-铁素体。为了确定这些夹杂物能否成为δ-铁素体的形核剂,使用Bramfitt二维模型[25]计算了错配度

其中,(hkl)s为基底的低指数晶面,(hkl)n为形核相的低指数晶面,[uνw]s为(hkl)s晶面的低指数晶向,

图8

图8

稀土夹杂物与奥氏体错配度的统计和M50-RE钢锭中的稀土夹杂物

Fig.8

Statistics of mismatch between rare earth inclusions and austenite (a) and rare earth inclusion in as-cast structure (b)

图9

表3 三支钢锭中的二次枝晶间距

Table 3

| Secondary dendrite spacing / μm | Average / μm | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| M50 | 73.7 | 101.5 | 39.4 | 55.0 | 44.5 | 51.9 | 47.7 | 64.2 | 59.7 |

| M50-Ce | 52.4 | 39.3 | 41.4 | 40.1 | - | - | - | - | 43.3 |

| M50-RE | 47.1 | 51.3 | 59.1 | 50.9 | 52.9 | 60.2 | 63.2 | - | 55.0 |

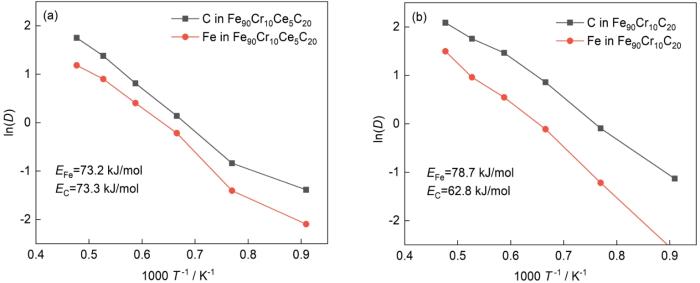

加入的高纯稀土使夹杂物变质,残留的稀土与钢液中的其它元素发生原子间的相互作用。尤其是稀土在钢中的固溶度非常低,在凝固后期游离的稀土与C等溶质元素一起被排出到液相中且随着凝固的进行不断富集。因此,虽然游离稀土的含量较低,但是与其它合金元素发生原子间相互作用的概率随着凝固的进行逐渐提高。为了研究液相中Ce原子对Fe、C元素扩散动力学的影响,进行了第一性原理分子动力学计算。结果表明,合金元素Mo、V元素在碳化物中严重富集,而Cr元素在凝固末期析出液析碳化物时溶质含量变化相对较小[23]。这表明,Fe-Cr-C三元体系凝固时更加稳定,因此选取Fe-Cr-C体系研究添加Ce原子对Fe、C元素扩散系数和激活能的影响。第一性原理分子动力学计算效率非常低,因此没有直接计算Ce在M50钢熔体中的作用。

在Fe-Cr-C体系(Fe95Cr10C20)的基础上将部分Fe原子用稀土原子替代,建立了Fe-Cr-Ce-C立方超胞(Fe90Cr10Ce5C20)。两种超胞结构均在2300 K完全熔化,然后以200 K的温度间隔降温至1100 K,以对比研究两种体系合金液态原子的扩散动力学。先统计分析了不同温度时各元素原子的均方根

位移与时间的关系。其中N为某种元素的原子个数,t为时间。由于液相中原子的迁移表现为典型的随机行走,均方位移与时间呈现明显的线性关系。在此基础上,使用爱因斯坦关系式

计算扩散系数。用此公式分别求出了不同温度下Fe、C两种元素的自扩散系数,如图10所示。可以看出,Ce原子的加入显著减小了Fe和C原子的扩散系数,尤其是C原子扩散系数的减小更明显。从图10可以看出,两种体系在2100~1300 K的液体状态扩散系数的对数与温度的倒数基本上呈线性关系。然后根据阿伦尼乌斯公式D=D0exp(-E/RT),绘制出扩散系数的对数与温度倒数的关系曲线,通过线性拟合求出Fe、C元素的扩散激活能垒。Fe95Cr10C20体系的EFe=78.7 kJ/mol,EC=62.8 kJ/mol,而Fe90Cr10-Ce5C20体系的EFe=73.2 kJ/mol,EC=73.3 kJ/mol。因此与Fe95Cr10C20体系相比,Fe90Cr10Ce5C20体系中C原子扩散能垒增大了10.5 kJ/mol,而Fe原子扩散能垒降低了5.5 kJ/mol。分析结果表明,半径和体积较大的Ce原子阻碍C原子的扩散,即Ce原子的体积效应减弱了C原子的扩散;另一方面,化学性质活泼的Ce与C原子较强的相互吸引也阻碍了C原子的扩散。而Fe原子与Ce原子没有相互吸引且扩散能垒有所降低,因此Fe原子扩散系数的下降源于Ce原子与Fe原子运动的大体积碰撞效应。原子作用的计算结果表明,Ce的添加减弱了C原子的扩散能力且阻碍了C原子在液相中的迁移,从而降低了碳化物长大速率,使从液相中析出的碳化物更加弥散分布。Ce与C较强的化学作用使微量Ce的添加对液态体系中C的扩散影响更加显著,而对化学性质相近的Cr、Mo、V元素扩散的影响与Fe类似。

图10

图10

Ce原子对液态Fe-Cr-C体系原子动力学的影响

Fig.10

Effect of Ce atoms on atomic dynamics of liquid Fe-Cr-C system

4 结论

(1) M50钢中析出两种形貌的液析碳化物,一种是V含量较高的块状MC型碳化物;另一种是Mo含量较高的M2C型共晶碳化物。添加高纯稀土不改变钢液中两种液析碳化物的成分和结构,但是使液析碳化物尤其是块状碳化物的尺寸减小。

(2) 在M50钢中添加高纯稀土生成的含稀土夹杂物尤其是含Ce的夹杂物,成为高温δ-铁素体和奥氏体的形核剂能促进固相形核、减小奥氏体枝晶的尺寸和二次枝晶臂间距,能阻碍碳化物形成元素的长程扩散和抑制块状液析碳化物的长大,还能在一定程度上减小共晶组织团的尺寸。

(3) 对Ce在钢液中原子作用机制的第一性原理分子动力学计算结果表明,游离的Ce能降低钢液中Fe和C的扩散系数,从而降低碳化物的生长速率。

参考文献

Rotational bending fatigue life and fatigue crack initiation mechanism of Cr4Mo4V bearing steel

[J].The rotational bending fatigue life and fatigue crack initiation mechanism of Cr4Mo4V bearing steel were studied by means of rotating bending fatigue test at room temperature. The rotational bending fatigue test was carried out on a PQ1-6 rotary bending fatigue test machine. The fatigue limit and <em>S</em>-<em>N</em> curve were measured by the up-down method. The fracture of the fatigue specimen was observed by SEM, and the crack initiation source type and crack propagation behavior were analyzed. The effect of defect size on fatigue life was analyzed by the ratio <em>σ</em>'/<em>σ</em><sub>w,defect</sub> of the nominal stress amplitude at the location of the defect to the measured ultimate fatigue strength of the defect. The results show that the safety fatigue limit of Cr4Mo4V bearing steel is 1019MPa, and the <em>S-N</em> curve data of Cr4Mo4V bearing steel shows a downward trend and a large dispersion. Fracture observation shows that there are five types of initiation, namely surface defects leading to initiation, near-surface carbides leading to initiation, near-surface non-metallic inclusions leading to initiation, internal non-metallic inclusions leading to initiation and internal carbides initiation. Internal crack fractures have fish-eye features. When the fatigue life exceeds 10<sup>7</sup> cycles, a granular bright area (GBF) is observed in the vicinity around the internal initiation source carbides. The fatigue fracture was observed with broken carbides, and the broken carbide increased the crack growth rate. Carbides cracking can occur in the bearing steel Cr4Mo4V under the action of cyclic stresses. These fractured carbides attract the crack tip leading to faster growth rate. Influence of carbide size on the near surface initiation can be quantitatively analyzed by using the critical volume density of carbides. The values of <em>σ</em>'/<em>σ</em><sub>w,defect</sub> are higher than 1 and the larger the <em>σ</em>'/<em>σ</em><sub>w,defect</sub>, the shorter the fatigue life is.

Cr4Mo4V轴承钢旋转弯曲疲劳寿命及疲劳裂纹萌生机理

[J].

Damage evolution around primary carbides under rolling contact fatigue in VIM-VAR M50

[J].

Bearing steel microstructures after aircraft gas turbine engine service

[J].

The role of primary carbides in fatigue crack propagation in aeroengine bearing steels

[J].

Effect of cooling rate on the precipitation mechanism of primary carbide during solidification in high carbon-chromium bearing steel

[J].Bearing is one of the most technologically important engineering components in machines. With the development of several advanced steel-refining technologies to suppress the detrimental effect of nonmetallic inclusions on the mechanical properties of materials, the impact of carbides on the service life of bearings has gradually highlighted. The carbides have become a key factor in determining the performance of a bearing, particularly for primary carbides formed during the solidification of high carbon-chromium bearing steel. Therefore, exploring the formation mechanism of primary carbides and their control strategies is vital to improve the manufacturing process of bearing steel as well as the service life and reliability of bearings. To clarify the formation mechanism of primary carbides and the effects of the processing technique, as well as the addition of rare earth elements, a modified type of GCr15 high carbon-chromium bearing steel with and without rare earth elements was remelted and solidified at different cooling rates. After solidification, the quantity, area, average size, and chemical composition of the primary carbide in the as-cast bearing steel were characterized and analyzed via OM, EPMA, SEM, and XRD. The results show that the type of carbide in GCr15 series bearing steel is M3C cementite with high Cr content (more than 15%, mass fraction). The nucleation rate of M3C cementite increased with the increase in the cooling rate; thus, the number of carbides increased considerably. However, at very high cooling rates, the primary austenite was refined and the diffusion time of C and Cr elements required to form carbides declined; therefore, the size of carbides was reduced significantly, resulting in more uniform dispersion of the carbides. Moreover, the addition of rare earth elements could refine the primary austenite, and subsequently, refine the carbide to some extent. Considering the properties of the primary carbides at different cooling rates, the kinetic formation mechanism for the primary carbide in high carbon-chromium bearing steel during solidification is proposed.

冷速对高碳铬轴承钢液析碳化物凝固析出机制的影响

[J].为明确液析碳化物的形成与工艺的关系和产生机制,以及受添加稀土元素的影响,对添加稀土元素和未添加稀土元素的GCr15系连铸高碳铬轴承钢进行了不同冷却速率下的重熔凝固实验。试样凝固完毕后,采用OM、EPMA、SEM和XRD等表征和分析了铸态轴承钢中的液析碳化物的数量、面积、平均尺寸和化学成分等与冷却速率的关系,以及添加稀土元素的影响效果。结果表明,GCr15系轴承钢液析碳化物的类型为M<sub>3</sub>C型渗碳体,Cr含量较高,可达15% (质量分数)以上,并且随冷速增加,其数量明显增加。但是,当冷却速率较快时,初生奥氏体细化,同时因形成碳化物所需的C、Cr元素扩散时间减少,碳化物尺寸显著减小,且分布更加弥散均匀。通过对比分析添加稀土元素对凝固组织的影响,发现稀土元素有细化奥氏体进而细化液析碳化物的作用。根据不同冷速下液析碳化物的特点,提出了高碳铬轴承钢凝固过程一次碳化物形成的动力学机制。

Revisiting dynamics and models of microsegregation during polycrystalline solidification of binary alloy

[J].Microsegregation formed during solidification is of great importance to material properties. The conventional Lever rule and Scheil equation are widely used to predict solute segregation. However, these models always fail to predict the exact solute concentration at a high solid fraction because of theoretical assumptions. Here, the dynamics of microsegregation during polycrystalline solidification of refined Al-Cu alloy is studied via two- and three-dimensional quantitative phase-field simulations. Simulations with different grain refinement level, cooling rate, and solid diffusion coefficient demonstrate that solute segregation at the end of solidification (i.e. when the solid fraction is close to unit) is not strongly correlated to the grain morphology and back diffusion. These independences are in accordance with the Scheil equation which only relates to the solid fraction, but the model predicts a much higher liquid concentration than simulations. Accordingly, based on the quantitative phase-field simulations, a new analytical microsegregation model is derived. Unlike the Scheil equation or the Lever rule that respectively overestimates or underestimates the liquid concentration, the present model predicts the liquid concentration in a pretty good agreement with phase-field simulations, particularly at the late solidification stage.

Steels for bearings

[J].

Formation mechanism of carbon segregation for bearing steel concasting billet and its influencing factors

[J].

轴承钢连铸坯碳偏析的形成机理及影响因素

[J].

Fatigue crack nucleation and propagation at clustered metallic carbides in M50 bearing steel

[J].

Reduction of segregation during casting of 100Cr6 bearing steel by cerium inoculation

[J].

Columnar to equiaxed transition during solidification of small ingot by using electric current pulse

[J].

Effect of peak value and discharge frequency of electric current pulse on solidification structure of Fe-1C-1.5Cr bearing steel

[J].

Application of PMO solidification homogenization technology in continuous casting production of GCr15 bearing steel

[J].

PMO凝固均质化技术在连铸GCr15轴承钢生产中的应用

[J].

Effect of multi-direction forging on carbide evolution of M50 steel

[J].

多向锻造对M50钢一次碳化物破碎机制的影响

[J].

Effect of cerium addition on microstructure and mechanical properties of high-strength Fe85-Cr4Mo8V2C1 cast steel

[J].

Lanthanum additions and the toughness of ultra-high strength steels and the determination of appropriate lanthanum additions

[J].

Modelling and characterisation of stress-induced carbide precipitation in bearing steels under rolling contact fatigue

[J].

Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set

[J].

Ab initio study of local structures during cooling of liquid Fe-C and Fe-Cr-C alloys

[J].

Thermomechanical properties of iron and iron-carbon alloys: density and thermal contraction

[J].

A unified formulation of the constant temperature molecular dynamics methods

[J].

Canonical dynamics: equilibrium phase-space distributions

[J].

Formation mechanism of MC and M2C primary carbides in as-cast M50 bearing steel

[J].

Effects of rare earth on the microstructure and impact toughness of H13 steel

[J].

The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron

[J].