Sanicro25钢兼具良好的抗氧化性能、抗腐蚀性、可焊性以及优异的高温蠕变性能,是制造下一代超超临界锅炉过热器和再热器的主要候选材料[4~8]。Sanicro25钢,是在传统奥氏体钢中加入W/Co/Cu/Nb元素制备的一种新型奥氏体耐热钢。这种新型高铬、镍奥氏体耐热钢,兼具固溶强化和沉淀强化的高温力学性能。在蠕变过程中Sanicro25钢晶内生成的大量弥散纳米级Cu-rich相和MX相沉淀物(Nb、C和N组成)对位错运动的阻碍以及生成的第二相弥散强化,使其蠕变性能提高[2,8,9]。此外,Sanicro25钢中的置换固溶原子(例如Nb、W等)和间隙固溶原子(C、N)等元素溶入

1 实验方法

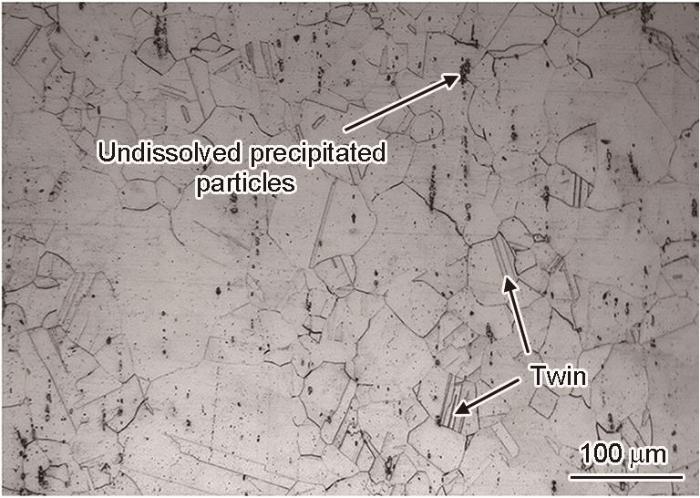

实验用Sanicro25钢(奥氏体耐热钢)的名义化学成分(质量分数,%)为:Ni(23.5-26.6)-Cr(21.5-23.5)-W(2.0-4.0)-Cu(2.0-3.5)-Co(1.0-2.0)-Nb(0.30-0.60)-N(0.15-0.30)-C(0.04-0.1)-Mn(0.6)-Si(0.4)-P(0.03)-S(0.015)(最大值)和Fe(余量)。实验用材料是经过固溶(1417~1523 K)处理的无缝钢管(外径为54 mm,壁厚为9 mm)。图1给出了Sanicro25钢的金相组织形貌,可见其由均匀的等轴奥氏体、大量的退火孪晶以及未溶解的富Nb、Cr和N的沉淀颗粒组成[9, 17]。

图1

图1

Sanicro25钢的金相组织形貌

Fig.1

Austenitic heat-resistant steel (Sanicro25 steel) OM morphology

用机械蠕变机(RDJ 30)进行材料的一系列蠕变试验,蠕变实验参数列于表1。应力为130~240 MPa,温度为973~1023 K。沿着无缝钢管的轧制方向截取标准蠕变试样,直径为5 mm,标距为25 mm。用OM和TEM等技术表征蠕变后试样的微观结构演变。先将OM测试样品机械研磨和抛光,然后在室温下用HCl (20 mL)+H2O (20 mL)+CuSO4 (5 g)溶液腐蚀。TEM测试样品的制备:用砂纸机械研磨至厚度约50 μm,然后打成直径约为3.0 mm的圆形薄片;最后在10%的高氯酸酒精混合溶液(-25℃)中进行电解双喷。用SEM表征蠕变后断口的表面形貌。

表1 Sanicro25钢的实验参数

Table 1

| Material | Temperature, T / K | Applied stress, σ / MPa |

|---|---|---|

| Sanicro25 steel | 973 | 180 |

| 220 | ||

| 240 | ||

| 998 | 150 | |

| 180 | ||

| 220 | ||

| 1023 | 130 | |

| 180 | ||

| 220 | ||

| 240 |

2 实验结果

2.1 Sanicro25钢的蠕变变形行为

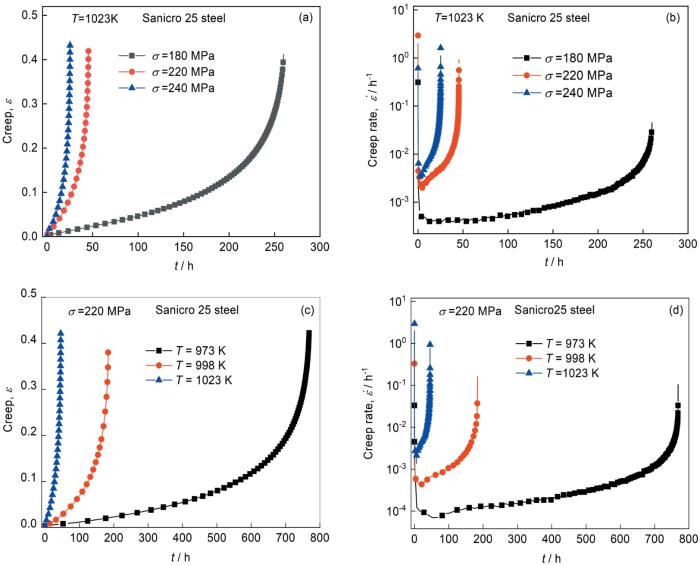

图2

图2

Sanicro 25钢的蠕变曲线

Fig.2

Creep curve characteristics for Sanicro 25 steel (a) (b) at different applied stresses (c) (d) at different temperatures

2.2 最小蠕变速率与应力、温度的经验关系

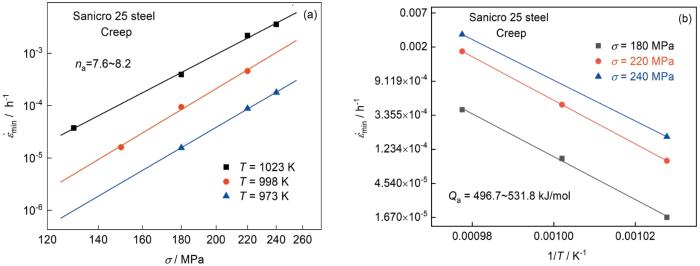

图3

图3

Sanicro25钢蠕变最小速率与应力和温度的关系

Fig.3

Minimum creep rate as a function of stress and temperature for Sanicro25 steel (a) Minimum creep rate vs. applied stress; (b) Minimum creep rate vs. the reciprocal of temperature

2.3 蠕变断裂的特征

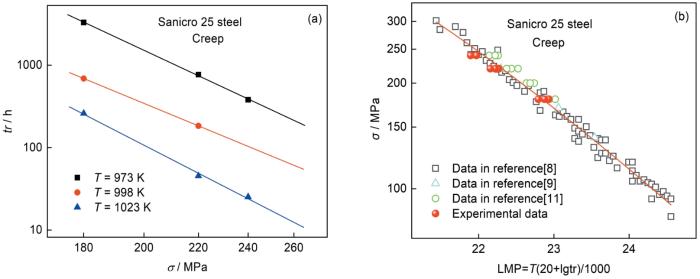

在不同温度下材料的断裂寿命均随着加载应力增加而下降(图4a),而且在双对数坐标下符合线性关系

图4

图4

Sanicro25钢蠕变断裂寿命与加载应力的关系

Fig.4

Creep fracture life as a function of applied stress for Sanicro25 steel (a) Log-log plot of ruptured time vs. applied stress; (b) Larson-Miller parameter curve

其中

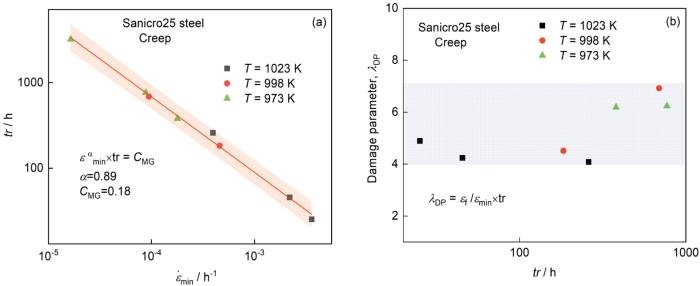

图5a给出了Sanicro25钢在不同温度下的断裂寿命与最小蠕变率的关系。可以看出,断裂寿命数据符合Monkman-Grant(M-G)方程

图5

图5

Sanicro25钢蠕变断裂寿命与最小蠕变速率的关系及其损伤特征

Fig.5

Relationship between fracture life and minimum creep rate and damage characteristics of Sanicro25 steel (a) Monkman-Grant relationship (b) Damage parameters characteristics

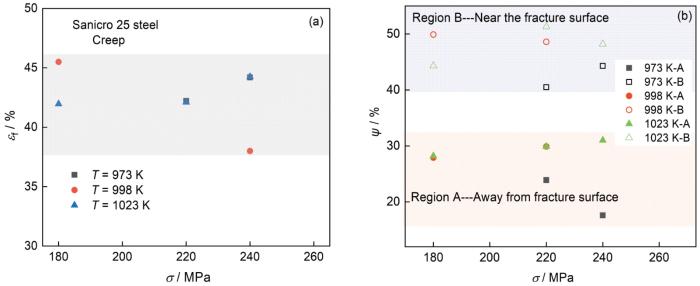

图6

图6

Sanicro25钢的蠕变断裂塑性

Fig.6

Creep fracture plasticity characteristics of Sanicro25 steel (a) Fracture strain (b) Section shrinkage of different region

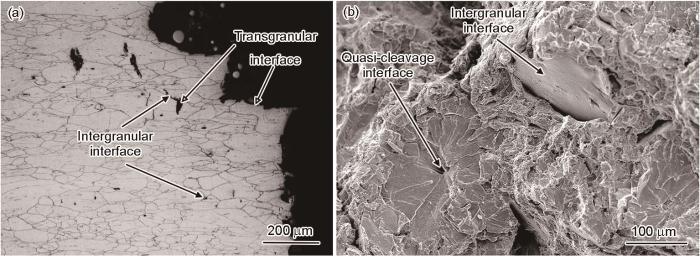

图7

图7

Sanicro25钢蠕变的截面和断口形貌

Fig.7

Creep cross-sectional and fracture morphology of Sanicro25 steel (T=973 K; σ=240 MPa) (a) OM cross-sectional morphology (b) SEM fracture morphology

3 讨论

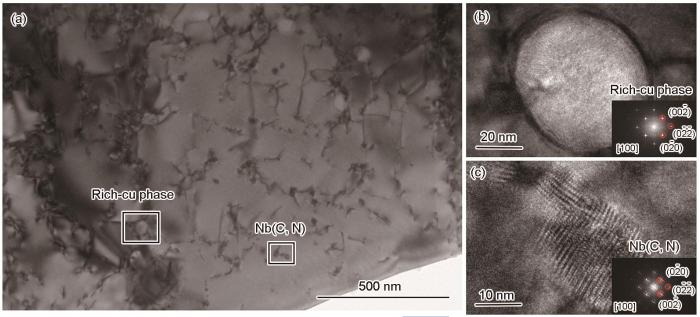

图8

图8

Sanicro 25钢在1023K和220MPa蠕变后的TEM结构特征

Fig.8

TEM microstructural characteristics of Sanicro 25 steel after creep at 1023 K and 220 MPa (a) Interaction of dislocations with fine precipitates. HRTEM micrograph and corresponding to SAED pattern; (b) Cu-rich phase (c) Nb (C, N)

实验得出的材料的表观应力指数(

除了第二相弥散强化,Sanicro25钢还有固溶强化。溶质原子的溶入引起基体金属的晶格畸变,从而产生了内应力。蠕变时溶质原子偏聚在位错周围形成的溶质气团(例如柯氏气团),使溶质原子与位错的弹性交互作用能增大。位错运动时,溶质气团扩散随之运动,限制了位错的自由滑移使其滑移而出现牛顿粘滞性。另外,如果溶质与位错的弹性交互作用能较小,则在位错周围不能形成溶质气团。这时位错运动的阻力很小,滑移速度较高,而位错的攀移较慢。如果位错的粘滞性滑移速度高于位错攀移速度,则蠕变被位错攀移控制;反之则被位错的粘滞性滑移控制[28]。

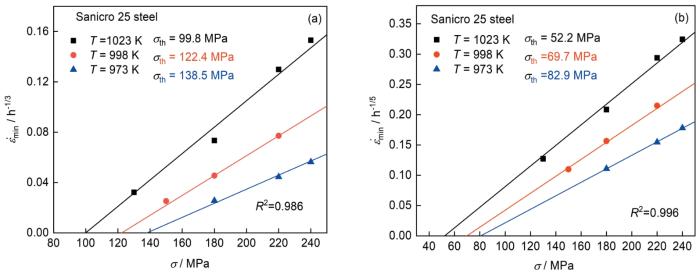

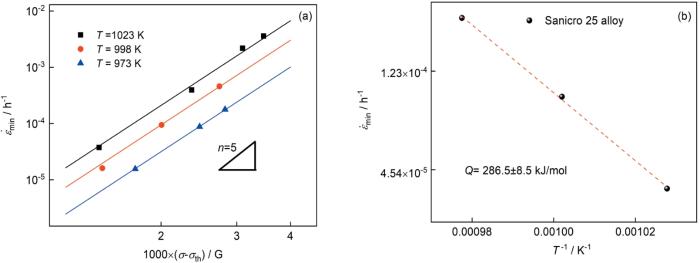

依据不同的变形机制(应力指数n为3或者5),用线性外延法可计算出不同温度下材料蠕变的门槛值。图9给出了基于假定的蠕变机制计算出的不同温度下Sanicro25钢的门槛应力。图9a、b给出了假定不同应力指数蠕变门槛值的求解过程。同时,用所求的门槛值计算了相应的真实激活能和最佳线性拟合参数,结果列于表2。分析结果表明,n=3时线性拟合参数

图9

图9

基于假定的蠕变机制计算的不同温度下Sanicro25钢的门槛应力

Fig.9

Threshold stresses of Sanicro25 steel calculated based on assumed creep mechanism at different temperatures (a) Viscous glide mechanism: n=3; (b) Dislocation climbing control mechanism: n=5

表2 Sanicro25钢的蠕变门槛值应力分析

Table 2

| Assumed stress exponent, n | Temperature, T/K | Threshold stress, | Avg. correlation coeffcient R2/pct | Avg. Activation energy, Q/kJ·mol-1 |

|---|---|---|---|---|

| 3 | 973 | 138.5±1.9 | 0.986 | 206.8±6.2 |

| 998 | 122.4±1.3 | |||

| 1023 | 99.8±3.0 | |||

| 5 | 973 | 82.9±3.9 | 0.995 | 286.5±8.5 |

| 998 | 69.7±1.4 | |||

| 1023 | 52.2±2.4 |

图10

图10

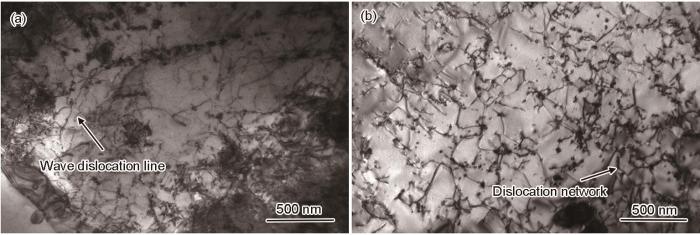

不同温度下基体内的位错-细小沉淀物相互作用的明视场TEM图像

Fig.10

Bright-field TEM image of dislocation-fine precipitates interactions within the matrix at different temperature (a) 973 K-220 MPa; (b) 1023 K-220 MPa

图11

图11

不同温度下Sanicro25钢的真实应力指数和激活能

Fig.11

True stress exponents and activation energy of Sanicro25 steel at different temperatures (a) Log-log plot of the minimum creep rate vs. effective stress (b) Semi-log plot of the

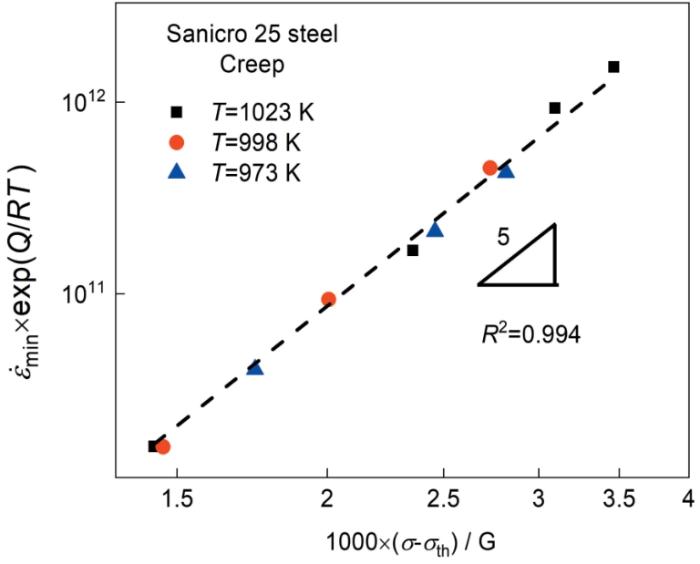

图12

图12

不同温度下Sanicro25钢归一化的最小蠕变速率

Fig.12

minimum creep rate normalizated of Sanicro25 steel at various temperatures

4 结论

(1) Sanicro25钢的最小蠕变速率与加载应力符合幂率关系,其蠕变的表观应力指数为7.6~8.2,表观激活能为496.7~531.8 kJ/mol。

(2) 在Sanicro25钢的蠕变过程中,在晶内析出的纳米级Cu-rich相和Nb(C, N)相阻碍位错的运动,出现蠕变门槛值。随着温度的升高位错易于热激活攀移越过颗粒障碍使门槛值降低,相应的位错组态由波状的位错线转化为位错网格。

(3) 引入门槛值修正蠕变本构模型,可确定材料的真实应力指数(n=5)和真实激活能(Q=286.5±8.5 kJ/mol)。材料的蠕变变形机制是点阵自扩散协助下的位错攀移。

(4) Sanicro25钢的蠕变寿命符合Monkman-Grant关系,其断裂是以穿晶为主的混合模式。

参考文献

A review on biomass as a fuel for boilers

[J].

Precipitation behavior of Cu-rich phase in 18Cr9-Ni3CuNbN austenitic heat-resistant steel at early aging stage

[J].

18Cr9Ni3CuNbN奥氏体耐热钢中富Cu相的早期析出行为

[J].应用三维原子探针技术研究了600℃超超临界电站锅炉过热器/再热器用18Cr9Ni3CuNbN奥氏体耐热钢中强化相富Cu相的早期析出行为, 并绘制出富Cu相在18Cr-9Ni型奥氏体耐热钢中的C曲线。结果表明: 在高温时效过程中富Cu相无论在650℃还是在700℃均能较快地析出, 其形成过程都是在短时间内先形成富Cu偏聚区, 随着时效时间的延长Cu原子继续扩散到富Cu偏聚区, 其它原子如Fe, Cr, Ni等则被排出富Cu偏聚区而扩散到奥氏体基体中, 最终形成富Cu相。

Microstructure and precipitates of alloy 617B used for 700℃ advanced ulta-supercritical power units

[J].The microstructure and precipitates of the creep-ruptured and aged alloy 617B at 750oC were characterized by means of scanning electron microscopy (SEM) and transmission electron microscopy (TEM).The polygonal (or strip-type) M23C6 particles with a complex face-centered cubic (fcc) structure locate along grain boundaries and inside grains, and granular γ ′ phase particles with an ordered fcc-structure inside grains were observed during creep and aging. The precipitates grown up with test time. The comparative observation of the aged and creep-ruptured alloy samples revealed that the applied stress did not affect the growth of γ ′ phase obviously, but affect the precipitation of carbides at grain boundaries greatly. The stress leads to the sharp growth and agglomation of M23C6 particles after a long time creep test.

700℃超超临界机组用617B镍基合金的组织结构和析出相

[J].

Low cycle fatigue behavior of Sanicro25 steel at room and at elevated temperature

[J].

A Czyrska-Filemonowicz Microstructure and chemical composition of the oxide scale formed on the sanicro 25 steel tubes after fireside corrosion

[J].

Design of alumina forming FeCrAl steels for lead or lead-bismuth cooled fast reactors

[J].

First-principles evaluation of the effect of alloying elements on the lattice parameter of a 23Cr25NiWCuCo austenitic stainless steel to model solid solution hardening contribution to the creep strength

[J].

Strengthening mechanisms and creep rupture behavior of advanced austenitic heat resistant steel SA-213 S31035 for A-USC power plants

[J].

High-temperature deformation and fracture mechanisms of an advanced heat resistant Fe-Cr-Ni alloy

[J].

Microstructure and texture study on an advanced heat-resistant alloy during creep

[J].

Dislocation creep modelling of Sanicro 25 based on microstructural evolution and particle hardening mechanism

[J].

High temperature creep of Sanicro 25 austenitic steel at low stresses

[J].

Creep rupture assessment of new heat-resistant Sanicro 25 steel using different life prediction approaches

[J].The paper deals with creep life and creep strength estimations of Sanicro 25 steel through various continuum damage models and modified extrapolation methods. Four different continuum damage models, i.e., modified K-R model, Dyson model, W-T model and modified W-T model considering the stress-dependent failure strain, were incorporated into numerical simulations using user subroutines so as to analyze the creep strain behavior and the creep rupture time. In the case of 700 degrees C, the predicted creep rupture lifetimes determined from modified K-R model, Dyson model, W-T model and modified W-T model all matched with the experimental data, where the modified W-T model provided the best prediction. However, at 750 degrees C, only the predictions using W-T model and modified K-R model matched with the experimental data. The Dyson model and modified W-T model underestimated the creep rupture lifetime. Besides the creep damage approaches, a modified extrapolation method developed by Wilshire (based on the stress-dependent creep activation energy) was also tested and verified to make predictions of creep lifetime under various stress conditions more easily than the creep damage models. A general comparison of the analyses made with different life prediction methods in Sanicro 25 steel was presented in this paper.

Creep properties of pre-deformed F316 stainless steel

[J].Creep properties of the pre-deformed F316 stainless steel by 200 MPa at 650℃, 670℃ and 700℃ were investigated. Results show that by a constant tensile stress of 200 MPa, the time to rupture of the pre-deformed F316 stainless steel decreases, while the steady creep rate and the instantaneous creep strain increase with increasing creep temperature. Ductile fracture is the dominant rupture mode for the pre-deformed F316 stainless steel. Creep cavities are mainly located in the triple junctions of grain boundaries, and the average diameter and the area ratio of the voids decrease in the location with the increasing distance to the fracture surface. In the region with the same distance to the fracture surface, the average diameter and area percentage of the voids increase obviously with the increasing creep temperature. The present pre-deformed F316 stainless steel with high density of twins has a better creep resistance than that of non-pre-deformed ones. Time to rupture by 200 MPa at 350℃ was estimated by using the Larson-Miller and θ-projection methods, respectively. The results show that the θ-projection method can give a better correlation. Besides, the long-term creep reliability of the F316 stainless steel served by 200 MP at 350℃ was discussed based on the Larson-Miller and θ-projection methods.

一级应变硬化F316奥氏体不锈钢的高温蠕变性能

[J].研究了在200 MPa应力下一级应变硬化F316奥氏体不锈钢在650℃、680℃和700℃的蠕变性能和蠕变断裂行为。结果表明: 在200 MPa 恒定应力下蠕变温度越高其蠕变寿命越短,稳态蠕变速率越大,由应力加载引起的瞬时应变越大。蠕变断裂方式主要为韧性断裂。蠕变孔洞主要分布在三叉晶界等脆弱部位,距离断口越远试样中孔洞的平均尺寸和孔洞面积百分比越小。在与断口距离相同的位置上,随着蠕变温度的提高蠕变孔洞的平均尺寸和面积百分比均明显增大。与未预应变的F316不锈钢相比,具有高密度孪晶的一级应变硬化F316不锈钢具有更大的蠕变抗力。分别基于Larson-Miller 参数法和θ参数法外推计算了350℃/200 MPa下的蠕变寿命,θ参数法的拟合曲线与实际蠕变曲线吻合得较好。根据Larson-Miller参数法和θ参数法,探讨了350℃/200 MPa下一级应变硬化F316奥氏体不锈钢长期服役蠕变可靠性。

Prediction of high temperature creep deformation and rupture life on HP heat reisistanct alloy using Zc parameter

[J].

基于Zc参数的HP耐热合金高温蠕变及持久寿命的预测方法

[J].通过研究HP耐热合金的高温蠕变实验数据,提出一种基于Z<sub>c</sub>参数的高温蠕变变形预测方法,并且利用该方法对HP耐热合金的高温蠕变性能进行预测和分析。结果表明:在1000,980℃和930℃下,蠕变应变分别为0.5%和1%时,预测数据与HP耐热合金的蠕变实验数据符合较好。同时利用基于Z<sub>c</sub>参数的高温蠕变变形预测方法对HP耐热合金的高温持久寿命进行了评估,结果表明由该方法得到的预测主曲线与耐热合金的持久实验数据吻合较好。

Creep, low cycle fatigue and creep-fatigue properties of a modified HR3C

[J].

Chapter 1-Fundamentals of Creep in Materials

[M].

Creep behavior and microstructural evolution of a Fe-20Cr-25Ni (mass percent) austenitic stainless steel (Alloy 709) at elevated temperatures

[J].

High-temperature creep behavior and microstructural evolution of an 18Cr9Ni3CuNbVN austenitic stainless steel

[J].

Steady-State Creep Behavior of Super304H Austenitic Steel at Elevated Temperatures

[J].Creep behavior of Super304H austenitic steel has been investigated at elevated temperatures of 923-973 K and at applied stress of 190-210 MPa. The results show that the apparent stress exponent and activation energy in the creep deformation range from 16.2 to 27.4 and from 602.1 to 769.3 kJ/mol at different temperatures, respectively. These high values imply the presence of a threshold stress due to an interaction between the dislocations and Cu-rich precipitates during creep deformation. The creep mechanism is associated with the dislocation climbing governed by the matrix lattice diffusion. The origin of the threshold stress is mainly attributed to the coherency strain induced in the matrix by Cu-rich precipitates. The theoretically estimated threshold stresses from Cu-rich precipitates agree reasonably with the experimental results.

Creep and precipitation behaviors of AL6XN austenitic steel at elevated temperatures

[J].

Effect of High-Temperature Ageing on Microstructure and Creep Properties of S31042 Heat-Resistant Steel

[J].

高温时效处理对S31042耐热钢组织和蠕变性能的影响

[J].

Creep behaviour of 14Cr-15Ni-Ti stainless steel at 923K

[J].

Dislocation-particle interactions in magnesium alloys

[J].

Threshold stresses in materials containing dispersed particles

[J].

Dislocation configuration in DZ125 Ni-based superalloy after high temperature stress rupture

[J].

DZ125镍基高温合金高温持久断裂后的位错组态

[J].

Viscous glide, dislocation climb and newtonian viscous deformation mechanisms of high temperature creep in Al-3Mg

[J].

Effect of temperature on transitions in creep mechanisms in class-A alloys

[J].

Resistant stress for creep in cast nickel-base superalloys

[J].

铸造镍基高温合金的蠕变阻力

[J].

Serrated yielding in an advanced stainless steel Fe-25Ni-20Cr (wt%)

[J].

An investigation of creep behavior in an SiC 2124 Al composite

[J].