ZG04Cr13Ni4Mo不锈钢的主要合金元素,有C、Cr、Ni和Mo等。其中Cr元素是提高材料抗腐蚀性能的关键元素,其最低铬含量为11.7%(质量分数,下同),Cr含量过高使材料中产生高温δ相,使其综合力学性能降低[4]。为了消除材料中的高温δ相,需要控制合金元素Ni的含量。添加Ni元素不仅能降低钢中高温δ相含量[4~6],还有利于进一步提高低碳马氏体不锈钢中的铬含量,从而使材料同时具有良好的耐蚀性和韧性。但是Ni含量过高将使正火处理后的ZG04Cr13Ni4Mo钢中存留部分残余奥氏体,影响钢的强度。大量的研究表明,ZG04Cr13Ni4Mo不锈钢中镍含量应控制在3.8%~4.5%,且镍铬当量比应满足Nieq/Creq≥0.42以消除δ相[7]。

1 实验方法

设计和制备两个系列的材料:1、Cr含量为12%,Mo含量为0.30%~0.62%,2、Cr含量为13%,Mo含量为0.31%~0.63%。两系列材料的成分,列于表1。使用真空感应方式熔炼上述8支不同元素含量的25 kg钢锭。使用线切割从铸锭中下部取样,分别进行1323 K正火+893 K回火(一次回火)、1323 K正火+893 K回火+863 K二次回火(两次回火)的热处理。按照国标加工直径为5 mm的拉伸试样,测试其室温单轴拉伸的屈服强度、抗拉强度和延伸率等性能。

表1 试验用钢的化学成分

Table 1

| No. | C | Si | Mn | Cr | Ni | Mo |

|---|---|---|---|---|---|---|

| 1# | 0.037 | 0.35 | 0.73 | 12.04 | 4.04 | 0.30 |

| 2# | 0.035 | 0.34 | 0.73 | 11.91 | 4.01 | 0.40 |

| 3# | 0.04 | 0.34 | 0.75 | 11.95 | 3.98 | 0.53 |

| 4# | 0.035 | 0.35 | 0.73 | 11.91 | 3.95 | 0.62 |

| 5# | 0.04 | 0.35 | 0.74 | 12.94 | 3.99 | 0.31 |

| 6# | 0.035 | 0.34 | 0.73 | 12.86 | 3.95 | 0.41 |

| 7# | 0.038 | 0.34 | 0.74 | 12.88 | 3.98 | 0.53 |

| 8# | 0.037 | 0.35 | 0.74 | 12.97 | 3.96 | 0.63 |

使用Linseis L78/RITA热膨胀仪测量8种试验钢的相变点。先将实验试样加工成直径为3 mm、长度为10 mm的样品,然后以0.05 K/s的速率加热至1323 K,保温30 min后以100 K/s的速率冷至室温,测量Mo元素含量不同的试验钢的奥氏体化开始温度(As点)和奥氏体化结束温度(Af点)。用D/Max-2500 PC型X射线衍射仪测量一次回火和二次回火试样的相结构,根据GB 8362计算试样中逆变奥氏体的体积分数。

2 实验结果

2.1 Mo含量对材料相变点的影响

图1

图1

ZG04Cr13Ni4Mo不锈钢的相变点As和Af随Mo含量的变化

Fig.1

Variations of As and Af with different Mo contents in ZG04Cr13Ni4Mo stainless steels (a) Cr: 12%; (b) Cr: 13%

2.2 一次回火后的力学性能

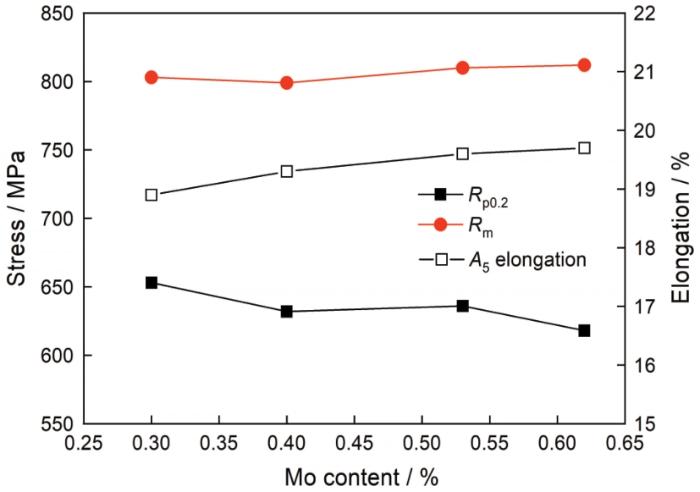

图2给出了Cr含量为12%时,不同Mo含量材料经893 K回火处理后的屈服强度、抗拉强度和延伸率。可以看出,随着Mo含量提高材料的抗拉强度基本上保持稳定(略有提高);屈服强度逐渐降低,但整体变化不大(当Mo含量从0.30%增加到0.62%时,材料屈服强度变化不超过30 MPa);而材料的延伸率略有提高。

图2

图2

Cr含量为12%而Mo含量不同的材料在893 K回火处理后的室温拉伸性能

Fig.2

Variations of Rp0.2, Rm and A5 Elongation at room temperature with different Mo contents in ZG04Cr13Ni4Mo stainless steels with 12%Cr after 893 K one-stage tempering

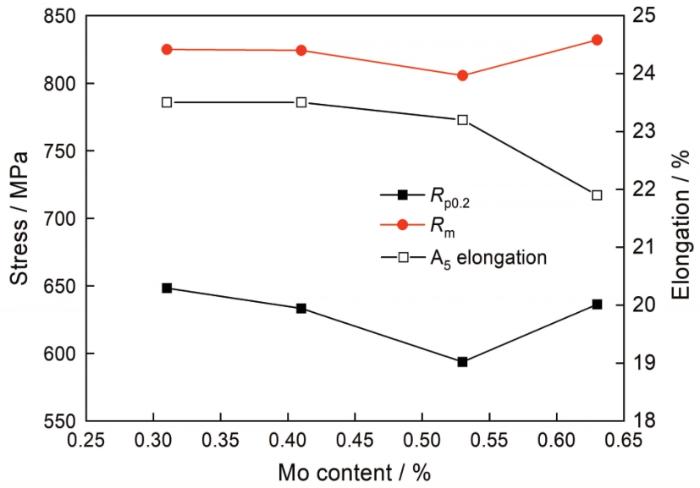

图3给出了Cr含量为13%时,不同Mo含量材料经893K回火处理后的室温拉伸性能。可以看出,与12%Cr含量系列试样不同,随着Mo含量的提高材料的屈服强度和抗拉强度几乎不变(略有提高),延伸率稍有提高。

图3

图3

Cr含量为13%而Mo含量不同的材料在893 K回火处理后的室温拉伸性能

Fig.3

Variations of Rp0.2, Rm and A5 Elongation at room temperature with different Mo contents in ZG04Cr13Ni4Mo stainless steels with 13%Cr after 893 K one-stage tempering

2.3 二次回火后的力学性能

图4给出了Cr含量为12%系列材料经893 K+863 K两次回火后的屈服强度、抗拉强度和延伸率。可以看出,随着Mo含量的增加,两次回火处理后材料的抗拉强度略有提高,屈服强度呈现出波动的特征,而延伸率则先降低后提高(变化量为~1%)。

图4

图4

Cr含量为12%而Mo含量不同的材料两次回火处理后的室温拉伸性能

Fig.4

Variations of Rp0.2, Rm and A5 elongation at room temperature with different Mo contents in ZG04Cr13Ni4Mo stainless steels with 12%Cr after 893 K+863 K two-stage tempering

图5给出了Cr含量为13%的系列材料经两次回火后单轴拉伸屈服强度、抗拉强度和延伸率随Mo含量的变化。可以看出,随着Mo含量的提高两次回火处理后材料的屈服强度和抗拉强度均先略微降低然后提高,而延伸率则先是基本上不变,而后略有降低。

图5

图5

Cr含量为13%而Mo含量不同的材料两次回火处理后的室温拉伸性能

Fig.5

Variations of Rp0.2, Rm and A5 elongation at room temperature with different Mo contents in ZG04Cr13Ni4Mo stainless steels with 13%Cr after 893 K+863 K two-stage tempering

3 讨论

3.1 Mo含量对一次回火试样性能的影响

表2 实验用钢一次回火和二次回火热处理后逆变奥氏体的体积分数

Table 2

| 1# | 2# | 3# | 4# | 5# | 6# | 7# | 8# | |

|---|---|---|---|---|---|---|---|---|

| 893 K tempering | <2% | <2% | <2% | <2% | <2% | 3.9 | 6.7 | 6.8 |

| 893 K+863 K tempering | 16.2 | 14.5 | 15.1 | 16.0 | 18.8 | 18.8 | 18.2 | 17.6 |

13%Cr系列材料一次回火后的性能随Mo含量的变化规律与12%Cr系列材料有所不同,其主要原因是,随着Cr含量的提高材料的As相变点继续降低。13%Cr系列材料经过893 K回火处理后材料中的逆变奥氏体含量明显提高,在拉伸过程中发生的相变诱导塑性(TRIP效应)更加明显。随着Mo含量的提高,13%Cr系列材料的As点逐渐降低,因此高Mo含量的8#样品中逆变奥氏体的含量显著高于Mo含量低的5#样品中逆变奥氏体的含量。含量较高的逆变奥氏体在拉伸过程中发生形变诱导马氏体相变而产生TRIP效应[15],从而使材料的屈服强度、抗拉强度和延伸率都随着Mo含量的提高而提高。但是,Mo含量不同的样品中逆变奥氏体的含量变化并不大,因此材料的宏观力学性能的变化也不大。

3.2 Mo含量对二次回火试样性能的影响

在893 K一次回火后ZG04Cr13Ni4Mo的显微组织由基体回火马氏体、少量逆变奥氏体和少量新生未回火马氏体组成(因高温奥氏体稳定性不足而在冷却过程中重新转变为马氏体),且在微观尺度上材料中元素的分布不均匀,导致在二次回火过程中发生复杂的组织演化[7]:一次回火后新生的马氏体在二次回火过程中发生回火,且部分马氏体再次转变为逆变奥氏体以及二次回火加热和保温过程中生成的奥氏体在随后冷却时再次转变为马氏体。因此,二次回火后材料的显微组织中主要包含回火马氏体、逆变奥氏体和新生马氏体三种组织。这三种组织中新生马氏体的强度最高,回火马氏体次之,逆变奥氏体强度最低。

从表2可以看出,无论是12%Cr系列还是13%Cr系列材料,随着Mo含量的提高两次回火后其中的逆变奥氏体含量变化不大。但是如图1所示,随着Mo含量的提高材料的As点降低。这意味着,在回火温度相同的情况下,随着Mo含量的提高在加热和保温过程中从马氏体转变为奥氏体的量增加。最终不同样品中逆变奥氏体含量相差不大,说明在二次回火的冷却过程中新生马氏体量随着Mo含量的提高而增加。这部分新生马氏体将使材料的屈服和抗拉强度提高。同时,Mo含量的提高进一步提高了低碳马氏体的抗回火能力,使Mo含量高的材料中回火马氏体的强度高于Mo含量低材料中回火马氏体的强度。上述两方面的影响表明,随着Mo含量的提高经893 K+863 K两次回火处理后的ZG04Cr13Ni4Mo钢其屈服和抗拉强度呈现出逐渐提高的趋势。

4 结论

(1) 12%Cr系列和13%Cr系列ZG04Cr13Ni4Mo不锈钢的As相变点均随着Mo含量的提高而降低,相变点的变化影响后续两相区回火钢的组织演化及其宏观力学性能。

(2) 经过893 K一次回火处理的12%Cr系列ZG04Cr13Ni4Mo钢,随着Mo含量从~0.3%提高到~0.6%,随着Mo含量的提高材料的抗拉强度保持稳定,屈服强度降低;而13%Cr系列材料的屈服强度、抗拉强度和延伸率都随着Mo含量的提高而小幅提高。

(3) 经过893 K+863 K回火处理的材料其强度主要受基体回火马氏体的回火程度和新生马氏体的含量的影响,随着Mo含量从~0.3%提高到~0.6%,12%Cr系列和13%Cr系列ZG04Cr13Ni4Mo钢的抗拉强度均略有提高。

参考文献

Fatigue strength of USP treated ASTM CA6NM for hydraulic turbine runner

[J].

Comparison of the resistance to cavitation erosion and slurry erosion of four kinds of surface modification on 13-4 Ca6NM hydro-machinery steel

[J].

Mechanical properties of modified cast martensitic stainless steel CA6NM with addition of molybdenum and nitrogen

[A].

Investigating and manufacturing of ZG0Cr13Ni4Mo martensitic stainless steel

[J].

ZG0Cr13Ni4Mo马氏体不锈钢研制

[J].

Microstructure and mechanical properties of 06Cr13Ni4Mo steel Treated by quenching-tempering-partitioning process

[J].A heat treatment process, quenching-tempering-partitioning (Q-T-P), has been applied to a low carbon martensitic stainless steel 06Cr13Ni4Mo. By using this process, ultrafine reversed austenite can be obtained at room temperature. The microstructures of the reversed austenite and the martensite matrix were characterized by transmission electron microscopy (TEM) and energy dispersive spectroscopy (EDS) in detail. The results show that the ultrafine reversed austenite is enriched in Ni resulting in the austenite stability at room temperature. Two new types of nano-scale carbide precipitates are found in the martensite matrix. Detailed analysis suggests that the two nano-scale precipitates can be identified as ω phase and λ phase carbides, respectively. The orientation relationship between the ω phase and matrix is <graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="189/img_1.png"/>, while that between the λ phase precipitate and matrix is <graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="189/img_2.png"/>. For the present steel, the ultrafine reversed austenite and carbide precipitates obtained by Q-T-P treatment provide a good combination of high strength and toughness.

Microstructure and property control of 13Cr4Ni stainless steel and its application in Three Gorges turbine runner

[D].

13Cr4Ni不锈钢组织性能控制及其在三峡水轮机转轮上的应用

[D].

Toughness and microstructure of 13Cr4NiMo high-strength steel welds

[J].

Microstructure characterization and hardness distribution of 13Cr4Ni multipass weld metal

[J],

Effect of Mo content on microstructure and properties of 00Cr12Ni9Mo(x)Cu2Ti margaging stainless steel

[J].

Mo含量对00Cr12Ni9Mo(x)Cu2Ti马氏体时效不锈钢组织和性能的影响

[J].

Investigation on phase transformation of low carbon martensitic stainless steel ZG06Cr13Ni4Mo in tempering process with low heating rate

[J].

低加热速率下ZG06Cr13Ni4Mo低碳马氏体不锈钢回火过程的相变研究

[J].

Investigation of the mechanical stability of reversed austenite in 13%Cr-4%Ni martensitic stainless steel during the uniaxial tensile test

[J].

In situ investigation on the deformation-induced phase transformation of metastable austenite in Fe-13%Cr-4%Ni martensitic stainless steel

[J].

Investigation of the evolution of retained austenite in Fe-13%Cr-4%Nimartensitic stainless steel during intercritical tempering

[J].

Investigation of TRIP effect in ZG06Cr13Ni4Mo martensitic stainless steel by in situ synchrotron high energy X-ray diffraction

[J].

ZG04Cr13Ni4Mo马氏体不锈钢中TRIP效应的同步辐射高能X射线原位研究

[J].