采用气路封严技术,能有效优化发动机叶尖端部与壳体内壁的间隙从而降低发动机的能耗[4,5]。热喷涂,是一种成本低、喷涂效率高的表面改性技术[6,7]。采用热喷涂在壳体内壁制备的可磨耗封严涂层密封效果好和可修复能力强[8],在航空发动机领域得到了广泛的应用。随着航空发动机服役环境的恶化人们对发动机的性能提出了更高的要求,其壳体内壁的封严涂层逐渐从低中温向高温(800℃以上)转变。丁坤英等[9]用等离子喷涂技术在Ni718合金表面制备氧化钇稳定氧化锆(YSZ)涂层并加入了不同质量分数的TiO2包覆聚苯酯材料,研究了涂层的磨耗性能。WANG等[10]用等离子喷涂技术将YSZ前驱体与YSZ纳米粒子混合制备YSZ封严涂层,研究了涂层的孔隙率和结合强度。陶瓷涂层热膨胀系数与基体不匹配和陶瓷的本征脆性,是导致涂层在高温环境下剥落失效的主要原因[11,12]。为解决这一问题,人们用沉淀、混合、溶胶-凝胶、溅射和化学镀等方法处理陶瓷粉末[13~15]。化学镀有较好的均镀能力且金属材料与陶瓷的结合力良好,是解决上述问题的有效方法之一。在耐热耐磨陶瓷材料中,莫来石的热导率低、耐高温性、抗蠕变性和化学性质稳定[16,17],常与其它粉末混制作高温零部件的防护涂层。但是用上述方法制备的涂层中莫来石的含量较低,制约了该类涂层的应用[18,19]。用化学镀对莫来石粉末进行包覆,一方面提高了复合涂层的热膨胀系数[20],另可提高涂层中莫来石的含量和涂层与基体间的润湿性。鉴于此,本文先用化学镀对莫来石粉末进行Ni-P镀层的包覆,然后用大气等离子喷涂技术制备莫来石涂层和包覆粉末涂层,对比分析两组涂层的高温摩擦磨损性能。

1 实验方法

1.1 Ni-P/莫来石包覆粉末的制备

实验用包覆Ni-P镀层的底材商用莫来石其粒径为30~60 μm,施镀前先对莫来石进行除油、粗化、敏化和活化预处理。其中除油液为10 g/L的氢氧化钠溶液,粗化液为25%的氢氟酸,敏化液为16 g/L氯化亚锡和40 mL/L盐酸的混合液,活化液为0.3 g/L氯化钯和4 mL/L盐酸的混合液。化学镀使用的主要试剂有:硫酸镍、次磷酸钠、柠檬酸钠和氯化铵。

表1 因素水平设计表

Table 1

| Level | Nickel sulfate, A/g·L-1 | Sodium hypophosphite, B/g·L-1 | Temperature, C/℃ | pH, D |

|---|---|---|---|---|

| 1 | 15 | 10 | 40 | 4.5 |

| 2 | 20 | 20 | 60 | 5 |

| 3 | 25 | 30 | 80 | 5.5 |

1.2 涂层的制备

图1

图1

喷涂粉末的形貌

Fig.1

SEM images of sprayed powder (a) mullite powder, (b) coated mullite powder, (c) NiCrAlY powder

表2 大气等离子喷涂参数

Table 2

| Items | NiCrAlY coating | Mullite coating |

|---|---|---|

| Arc current/A | 600 | 500 |

| Voltage/V | 60 | 70 |

| Argon gas flow rate/L·min-1 | 40 | 45 |

| Hydrogen gas flow rate/L·min-1 | 15 | 15 |

| Powder gas flow rate/L·min-1 | 5 | 8 |

| Spray distance/mm | 90 | 90 |

| Spray angle/(°) | 90 | 90 |

| Gun speed/m·s-1 | 0.3 | 0.2 |

1.3 性能表征

先将两组涂层打磨抛光,然后使用HT-1000球盘式高温摩擦磨损试验机测试两组涂层在800℃高温下的摩擦学性能。图2给出了球盘式摩擦磨损实验机原理。测试条件为:对磨材料是直径为6 mm的Si3N4小球,正向载荷为5 N,频率为5 Hz,摩擦时间为30 min。用超景深三维显微系统VHX6000观察涂层磨痕轮廓和磨痕截面面积,用公式

图2

图2

球盘式摩擦磨损实验机的原理图

Fig.2

Schematic diagram of ball-disc friction and wear testing machine

用JSM-6700F型场发射扫描电镜(FE-SEM)观察粉末和涂层磨损前后的微观形貌,并用附带的能谱仪(EDS)分析成分。用D8 ADVANCE X射线衍射仪(XRD;CuKα =0.154187 nm,10°~90°)分析粉末和涂层的物相组成。用HV-1000型维氏显微硬度仪测试涂层的表面硬度,加载载荷为2 N,加载时间为10 s,涂层硬度取15个不同位置压痕点的平均值。

2 结果和讨论

2.1 正交试验结果

以包覆前后粉末的相对增重△m(1 g粉末镀后增加的质量)作为评价指标,正交试验结果列于表3。

表3 正交表和正交试验结果

Table 3

| Number | A | B | C | D | △m |

|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 0.0374 |

| 2 | 1 | 2 | 2 | 2 | 0.1052 |

| 3 | 1 | 3 | 3 | 3 | 0.1828 |

| 4 | 2 | 1 | 2 | 3 | 0.2308 |

| 5 | 2 | 2 | 3 | 1 | 0.3364 |

| 6 | 2 | 3 | 1 | 2 | 0.2831 |

| 7 | 3 | 1 | 3 | 2 | 0.1314 |

| 8 | 3 | 2 | 1 | 3 | 0.2714 |

| 9 | 3 | 3 | 2 | 1 | 0.3024 |

| K1 | 0.3254 | 0.3996 | 0.5919 | 0.6762 | |

| K2 | 0.8503 | 0.7130 | 0.6384 | 0.5197 | |

| K3 | 0.7052 | 0.7683 | 0.6506 | 0.6850 | |

| R | 0.5249 | 0.3687 | 0.0587 | 0.1653 |

由表3中的极差分析可知,各因素对试验指标影响主次的顺序为:A>B>D>C,即硫酸镍影响最大,其次是次磷酸钠,而温度的影响最小。取各因素效应值K的最大值得到化学镀镍的工艺参数为:硫酸镍 20 g/L,次磷酸钠30 g/L,温度80℃,pH=5.5。

2.2 镀层的形貌和相组成

图3给出了正交试验优化后包覆粉末的形貌和能谱。可以看出,莫来石粉末表面包覆的Ni-P镀层均匀、致密,未出现明显的聚集型包覆。从图3b可见,在莫来石表面成功包覆了Ni-P镀层,包覆层中含有约71.86%(质量分数)的Ni和4.12%的P。此外,还存在少量莫来石粉末的Al、Si、O等元素。根据化学镀反应机理[20],初始反应时Ni粒子在反应界面处形成原子团,然后沉积在活化表面[25]。粉末表面粗化程度不同,因此初始沉积时Ni粒子先在表面能较高处沉积形成孤岛状结构。随着反应的进行Ni粒子在三维方向聚集生长成镀层。随着反应的进行粉末表面的Ni粒子薄膜成为活化点,促进了反应的进行,溶液中的Ni-P粒子处于同一体系使莫来石表面沉积的Ni-P粒子较为均匀。

图3

图3

包覆粉末形貌和能谱

Fig.3

SEM and EDS images of coated mullite powder (a) coated mullite powder, (b) EDS of area A

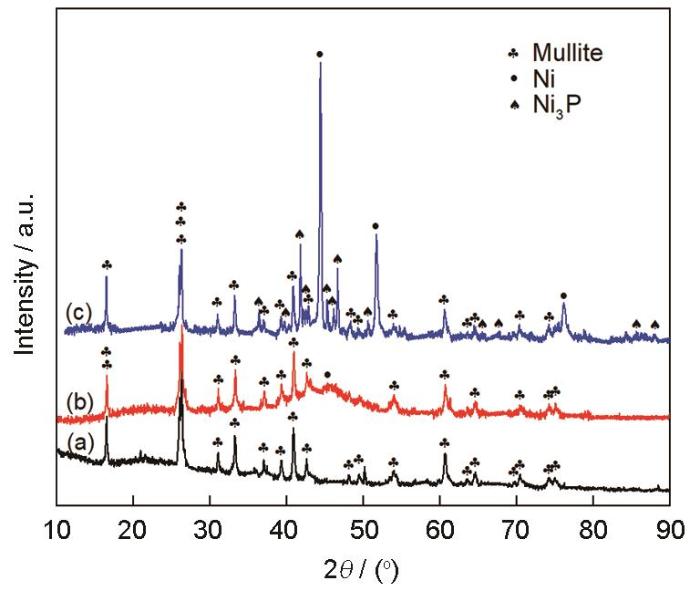

图4给出了莫来石粉末和包覆粉末的XRD谱。从图4b可见,在包覆粉末的XRD谱2θ=45°处出现了明显的弥散峰,是非晶态结构的典型特征。在包覆过程中,镀层中的P含量影响镀层的结晶形态。随着镀层厚度的增大P含量逐渐提高,使镀层发生由晶态向非晶态的转变[27]。在氩气气氛中在850℃对包覆粉末进行1 h热处理,使包覆粉末的非晶态弥散峰消失(图4c),出现了包含Ni和Ni3P相的晶体峰,表明镀层由非晶态向晶态转变。在热处理过程中,随着温度的提高镀层先发生结构弛豫,随后P扩散迁移生成了Ni晶体和亚稳态的Ni8P3、Ni12P5等中间相[28];随着温度的进一步提高Ni8P3和Ni12P5等中间相分解生成了Ni3P稳态相,最终使镀层由非晶态转变为晶态。

图4

图4

粉末的XRD衍射谱

Fig.4

X-ray diffraction patterns of powder (a) mullite powder, (b) coated mullite powder, (c) heat-treated coated mullite powder

2.3 涂层的微观结构

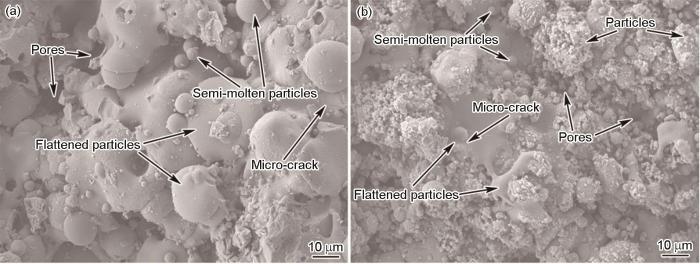

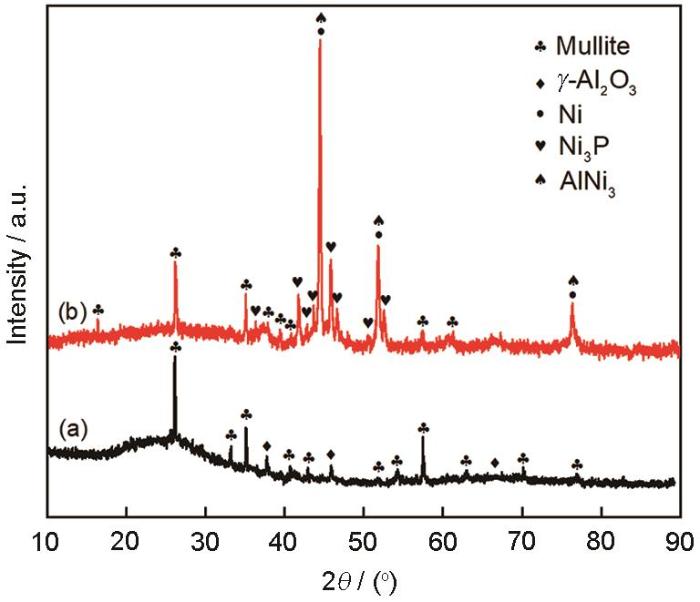

图5给出了涂层表面的形貌。可以看出,两组涂层均包含熔化区、半熔融颗粒、孔隙和微裂纹,其中微裂纹是由熔融颗粒快速打到基体表面急速冷却形成的。与图5a中涂层1不同的是,图5b中部分包覆粉末以未熔态直接嵌合在涂层中。其原因是,包覆粉末表面有Ni-P镀层,在喷涂过程中注入到等离子焰流边缘的包覆粉末,其部分喷涂热量被镀层吸收,而较高的喷涂速度使部分包覆粉末未熔而直接嵌合在涂层中[29]。图6给出了涂层的XRD谱。从图6a可见,涂层1主要由莫来石相和少量γ-Al2O3相组成,在谱中2θ=20°~30°处出现了一个明显的非晶态峰。其原因是,熔融粉末与基体之间较大的温度差使熔融颗粒快速打到基体表面急速冷却形成了非晶相。图6b中的涂层2主要由Ni、AlNi3、Ni3P和莫来石相组成,其中的莫来石相来自高温下熔融的莫来石和部分嵌入在涂层中的未熔莫来石颗粒。高速等离子焰流使包覆粉末表面的镀层和部分包覆粉末熔化生成了AlNi3和Ni3P等硬质相,这有利于涂层硬度的提高。

图5

图6

图6

涂层的XRD衍射谱

Fig.6

X-ray diffraction patterns of coating (a) coating 1, (b) coating 2

公式

2.4 涂层高温摩擦学性能

图7

图7

800℃时涂层的摩擦系数与摩擦时间的关系

Fig.7

Variation curves of friction coefficient with friction time of coatings at 800℃

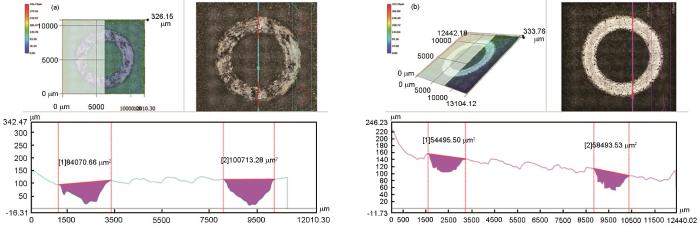

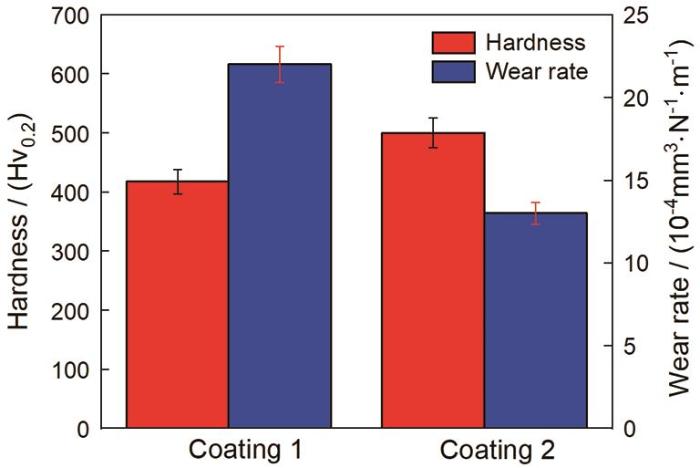

图8给出了摩擦磨损后涂层的三维磨痕轮廓图。可以看出,涂层1有较深且较宽的磨痕,涂层2的磨痕浅且窄,说明用包覆粉末制备的涂层其耐磨性更好。两组涂层磨痕的周边凸起较少,但磨痕底部均出现了不同程度的凸起,这是摩擦过程中的发生的塑性变形引起的。图9给出了涂层的磨损率和硬度。从图9可见,与涂层1相比,涂层2的硬度更高、磨损率更低。涂层的物相分析结果表明,高温等离子焰流使涂层2的层间及涂层与粘接层间的固溶体相溶,析出的AlNi3和Ni3P等硬质相使涂层的硬度提高。材料的耐磨性与其自身的硬度和韧性有关,材料的硬度越大、韧性越好,其耐磨性能也越好[31]。在800℃涂层1中的莫来石均处于熔融态堆叠在基体表面,其层间未形成有效的冶金结合且涂层硬度低。这导致其在摩擦过程中抵抗对磨小球外法向压力和推撵力的能力降低,从而使涂层的耐磨性降低;涂层2中引入的Ni-P合金层使涂层韧性提高,层间AlNi3和Ni3P等冶金相的生成且涂层硬度变大,提高了涂层在摩擦中抵抗对磨小球的能力,从而使涂层的耐磨性提高。

图8

图9

2.5 涂层的磨损形貌

图10给出了摩擦磨损后涂层磨痕形貌。从图10a可见,涂层1的磨损严重,磨痕较宽,磨痕表面有大量磨屑且出现密集的梨沟,梨沟清晰,呈现塑性变形。其原因是,涂层1的硬度高且脆,即涂层中莫来石的本征脆性。当涂层1与高硬度的对磨小球接触时循环应力在涂层表面逐渐积累,脆性大的莫来石很容易从涂层表面剥落成为磨屑。随着摩擦的进行,大量硬质莫来石磨屑夹杂在涂层与对磨小球间形成了“三体磨粒磨损”[32]。这增大了磨损表面的粗糙度,加剧了涂层的磨损。同时,涂层1中莫来石层间的结合方式主要以机械结合为主,这也降低了涂层的耐磨性。与涂层1相比,图10b中涂层2的磨痕窄,磨痕表面磨屑少,梨沟浅,梨沟密度低。其原因是,涂层2中包覆粉末的Ni-P镀层提高了涂层的整体韧性和层间结合力,使涂层的耐磨性提高;另一方面,涂层2中有AlNi3和Ni3P等硬质冶金相,因此在摩擦过程中凸出的硬质颗粒降低了对磨小球与涂层的接触面积,使涂层的剥落减少,提高涂层的耐磨性。两组涂层的磨痕形貌表明,莫来石涂层在摩擦过程中以塑性变形和磨粒磨损为主。

图10

图10

涂层磨痕的形貌

Fig.10

Worn surface morphology of coating (a) coating 1, (b) high magnification of A, (c) coating 2, (d) high magnification of B

3 结论

(1) 在莫来石表面化学镀镍,硫酸镍对镀层质量的影响最大,次磷酸钠次之,温度的影响最小。

(2) 用最佳工艺制备的镀层,均匀、致密和没有聚集性包覆。热处理使镀层由非晶态向晶态发生转变,生成了含有Ni3P的硬质相。

(3) 与莫来石涂层相比,包覆粉末涂层中引入的Ni-P镀层提高了涂层硬度,降低了涂层的摩擦系数。喷涂后形成的AlNi3和Ni3P等硬质冶金相提高了涂层的耐磨性。两组涂层的磨损形式,主要为塑性变形和磨粒磨损。

参考文献

Research progress of aero-engine blade materials and anti-fatigue grinding technology

[J].

航空发动机叶片材料及抗疲劳磨削技术现状

[J].

Research status of the silm-riding gas seal technologies in aeroengine

[J].

航空发动机气膜密封技术的发展

[J].

Experimental investigation on integrated cooling efficiency of turbine blade

[J].

涡轮叶片综合冷却效率实验研究

[J].

Research progress of ceramic-based cigh cemperature cealing coating for ceroengines

[J].

航空发动机陶瓷基高温封严涂层研究进展

[J].高温封严涂层应用在航空发动机高压压气机和涡轮等气路封严部位,可以减少转子和静子之间的间隙,提高发动机效率、降低油耗,是当前研究的热点。从金属基高温封严涂层和陶瓷基高温封严涂层两个方面分别进行分析,总结国内、外高温封严涂层的发展及研究现状,指出我国在陶瓷基高温封严涂层研究和应用领域存在的差距;分析YSZ陶瓷基封严涂层失效的主要原因,并且分别从陶瓷涂层显微形态优化和显微组织优化两个角度进行展开,分析当前提高YSZ陶瓷基封严涂层热循环寿命的研究成果和存在的问题;探索了基于贝壳仿生结构设计和晶须增韧机理分别对涂层显微形态优化和显微组织优化的新思路,以及新技术面临的问题。在此基础上,展望了新型陶瓷基高温封严涂层的发展方向。

Formation and properties of porous ZrO2-8%Y2O3 coatings

[J].

Thermomechanical properties and thermal cycle resistance of plasma-sprayed mullite coating and mullite/zirconia composite coatings

[J].

Research status of aluminum coating prepared by thermal spraying technology and its corrosion resistance in 3.5% NaCl solution

[J].

热喷涂技术制备铝涂层及其在3.5%NaCl溶液中耐腐蚀性的研究现状

[J].

Effects of blade material characteristics on the high-speed rubbing behavior between Al-hBN abradable seal coatings and blades

[J].

Abradable properties of porous YSZ coatings

[J].

多孔YSZ涂层的制备和可磨耗性

[J].

Preparation and characterization of YSZ abradable sealing coating through mixed solution precursor plasma spraying

[J].Yttria-stabilized zirconia (YSZ) ceramic matrix abradable sealing coatings were prepared by plasma spraying of a blend of YSZ solution precursor with YSZ nano-particles. The microstructure and phase compositions of the prepared abradable sealing coatings were analyzed by scanning electron microscopy (SEM), transmission electron microscopy (TEM), and X-ray diffraction (XRD). In addition, the mechanical, high-temperature oxidation, and tribological properties of the coatings were systematically investigated. The results show that addition of YSZ nano-particles increased porosity and bond strength and decreased the hardness of the coating. The optimum performance value was achieved by addition of 5 g nano-particles into the coating. The coatings maintained excellent thermal stability through a ten-cycle thermal shock test at 1150 degrees C. The 8YSZ-5 coating had an improved oxidation constant of 5.540 x 10(-4) and exhibited remarkable oxidation kinetics at 1150 degrees C. The friction coefficient of the mixed solution precursor coating was remarkably decreased compared with a traditional ceramic matrix abradable sealing coating. The results indicate that mixed solution precursor plasma spraying increased abradable sealing coating application performance.

Mullite whisker toughened mullite coating to enhance the thermal shock resistance of SiC pre-coated carbon/carbon composites

[J].

Study on system and properties of typical wear-resisting coating materials by plasma spraying

[J].

等离子喷涂典型耐磨涂层材料体系与性能现状研究

[J].

The preparation of Cu-coated Al2O3 composite powders by electroless plating

[J].

The reduction reaction of silver ions on the surface of silica

[J].

银离子在二氧化硅粒子表面上的成核反应

[J].

Microstructure and properties of TiAlCrN ceramic coatings deposited by hybrid HiPIMS/DC magnetron co-sputtering

[J].

Structure and properties of mullite—A review

[J].

Preparation of plasma sprayed mullite coating on stainless steel substrate and investigation of its environmental dependence of friction and wear behavior

[J].

Research on heat insulation and thermal shock properties of NiCr-mullite composite ceramic coating

[J].

镍铬-莫来石复合陶瓷涂层热障及抗热震性能的研究

[J].

Mullite/metal composite thermal barrier coating deposited by micro-plasma spraying

[J].

微弧等离子喷涂制备莫来石/金属复合热障涂层

[J].

Electroless Ni-P plating on mullite powders and study of the mechanical properties of its plasma-sprayed coating

[J].

Wear behaviour of electroless Ni-P coatings and optimization of process parameters using Taguchi method

[J].

Effects of chemical Ni plating of reinforcing particles on properties of SiCp/Fe composite

[J].

<p>SiCp were nickel-plated by means of chemical deposition to investigate the effects of the plating treatment on mechanical properties of SiCp/Fe composites. It was found that the coating thickness on SiCp can be controlled by amount of total input nickel chloride in the chemical solution. When the molar ratio of the nickel chloride versus hypophosphite is 1:3 and the temperature is within 93–95℃, the reduction of nickel chloride on the surface of the particles approaches to near 100%. When SiCp size is 45μm and the volume fraction is 10%, tensile strength of the composite is the best increased by 22.9%. After SiC particle surface nickel plated, the final elongation of SiCp/Fe composite is also improved significantly. The elongation is increased up to 30% with the plating when the particle size is 21μm and the volume fraction is 15% for nickel plated.</p>

碳化硅颗粒化学镀镍对铁基复合材料性能的影响

[J].

采用化学镀方法对SiC粒子表面镀镍, 研究了镀镍对SiCp/Fe复合材料力学性能的影响。结果表明: 镍盐量与还原剂量为1 : 3、温度为93--95℃时, 镍盐可以近100%镀在SiC粒子表面, 控制镍盐加入量可控制镀层的厚度。SiC表面镀镍的粒度为45 μm、体积分数为10%的复合材料, 其抗拉强度最大提高22.9%。SiC表面镀镍的SiC粒度为21 μm、体积分数为15%时, 复合材料的延伸率提高近30%。

Electroless plating nickel on T10A steel

[J].

针织器材用T10A钢表面化学镀镍工艺

[J].

Optimization process for electroless composite plating of Ni-P-Cu-PTFE by orthogonal test

[J].

正交试验法优化Ni-P-Cu-PTFE复合化学镀工艺

[J].

Deposition behavior and mechanism of electroless plating Ni-Zn-P alloy coating on low-carbon steel surface

[J].

低碳钢表面化学镀Ni-Zn-P合金镀层的沉积行为及沉积机理

[J].

Fabrication of electroless copper-plated composites by dopamine surface functionalization

[D].

多巴胺修饰制备表面化学镀铜复合材料的研究

[D].

Crystallization process of heat-treated amorphous Ni-P alloy coating

[J].

热处理非晶态Ni-P合金镀层的晶化过程

[J].

Microstructure and thermal cycle resistance of plasma sprayed mullite coatings made from secondary mullitized natural andalusite powder

[J].

Effects of mullite contents and particle size on tribological properties of copper-iron matrix composites

[J].

莫来石含量及粒径对铜铁基复合材料摩擦学性能的影响

[J].

Polytetrafluoroethylene matrix composites synergistically filled with mullite and carbon fiber and its tribological performances

[J].

莫来石与碳纤维协同填充的聚四氟乙烯基复合材料及其摩擦学性能

[J].