随着航空航天技术的发展燃气涡轮发动机的涡轮前温度和推重比不断提高,对材料的耐高温性能提出了越来越高的要求。Ni3Al亚包晶金属间化合物的熔点高、密度低并具有良好的导热和抗氧化性能,是最有应用前景的高温结构材料[1~3]。但是,多数Ni3Al亚包晶金属间化合物的凝固组织粗大、没有明显的方向性、相匹配不合理和相形态不好。电场的作用可使晶粒和增强相的尺寸以及枝晶间距减小,并促进晶间对流[4]。电场还能减弱微观偏析使凝固组织更为均匀和择优取向生长,改善材料的组织形貌和使力学性能提高。例如,电场能使Al-4.5%Cu(质量分数)合金[5,6]和Pn-Sb-Sn合金[7~13]的凝固组织细化和性能提高。但是,上述研究主要针对低熔点合金[14~17]。同时,包晶金属间化合物的熔点高,难以实时原位观察其凝固过程。本文研究熔点低、与亚包晶金属间化合物的凝固过程类似、都有亚包晶反应的透明有机物凝固组织的演变规律,模拟电场作用对定向凝固亚包晶合金凝固过程和凝固组织的影响,并探讨电场影响金属凝固的机理。

1 实验方法

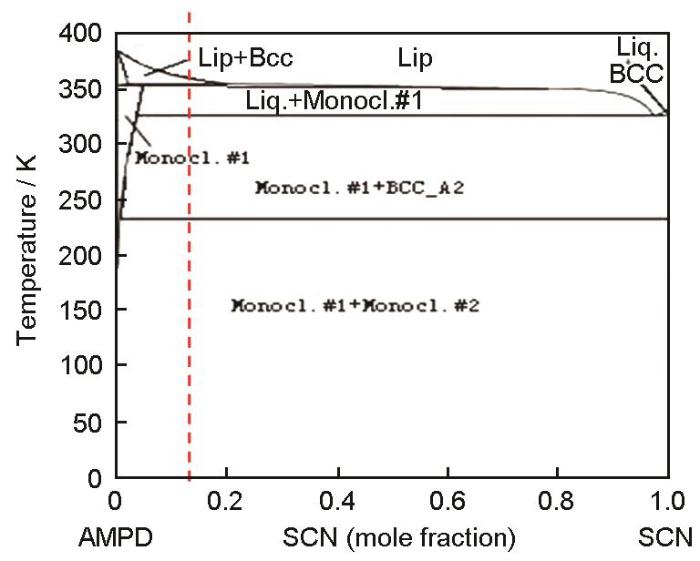

由于金属凝固温度高,很难对其进行原位观察,现有的实验也局限于低熔点合金。由相似理论首先类

图1

| Experimental materials | /Ω·m | Melting entropy/ J·mol-1·K-1 | Melting point/K |

|---|---|---|---|

| AMPD-SCN | 470 | 56.6 | 365 |

再次,对于Ni3Al合金在凝固过程中首先析出的是NiAl相,对NiAl杰克逊因子

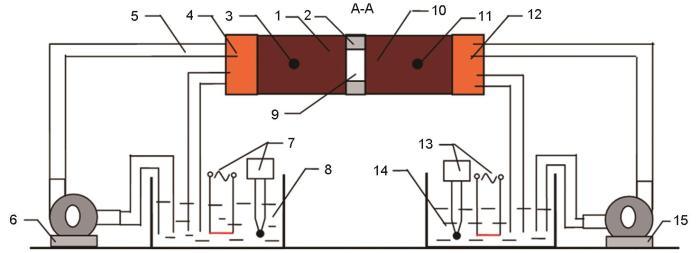

图2给出了物理模拟实验装配图。物理模拟实验平台充分考虑了原型实验的载荷与实验过程的相似性。在定向凝固过程中施加的是直流电流产生的电场,液相接电源正极,固相接电源负极。为了保证物理相似模拟物的熔化,将热端加热到105℃,将冷端温度调节到90℃,用冷端温度控制面板保持温度的稳定。在实验中调节热端和冷端的温度产生一定的温度梯度,以实现定向凝固。实验过程为:将熔区(9)置于显微镜的载物台上并校准显微镜,使用专用软件将电脑与显微镜链接以采集图像。将温度控制系统接通电源,将热端设置在熔点温度以上,用温度调节装置将冷端设置在包晶反应温度以下。温度恒定后打开循环泵,用循环泵和温度控制装置使熔区的冷端和热端温度恒定。实验用物理模拟物熔化后开启电源,使热端接直流电源正极,冷端接负极。调节电流的数值,观察所加的电场对定向凝固亚包晶模拟物结晶过程和组织的影响。

图2

图2

物理模拟的装配图

Fig.2

Assembly drawing of physical simulation experiment 1 (10) heat conducting plate; 2 glass plates; 3 (11) wiring post; 4 (12) heat conducting block; 5 pipes; 6 (15) hot (cold) end circulating pump; 7 (13) heater and thermocouple; 8 (14) heating oil; 9 melting zone

2 实验结果和分析

2.1 电场对结晶过程的影响

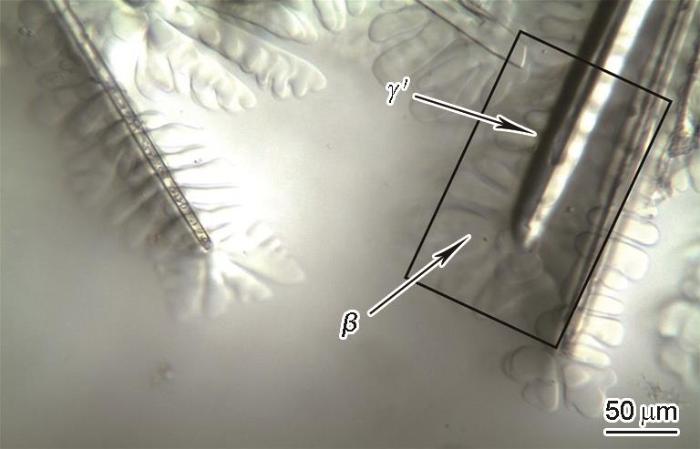

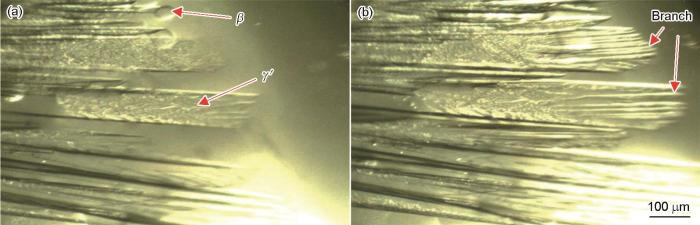

图3

图3

AMPD-4.1%SCN凝固初期的组织形态

Fig.3

Microstructure of AMPD-4.1%SCN at early stage of solidification

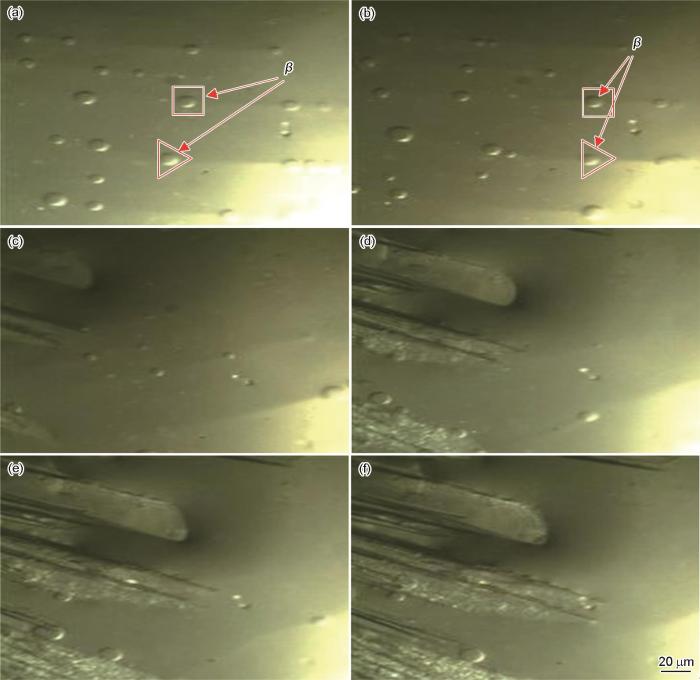

图4

图4

在1.2 mA 直流电流的作用下亚包晶模拟物定向凝固结晶生长的形貌

Fig.4

Directional solidification growth morphology of hypoperitectic simulator under action of 1.2 mA DC current (a) 0 s; (b) 2 s; (c) 4 s; (d) 6 s; (e) 8 s; (f) 10 s

2.2 电场对包晶凝固组织的影响

调整冷端和热端的温度差使温度梯度为4 K·mm-1。图5给出了电流强度为0 mA时亚包晶模拟物定向凝固生长形貌,可见与图3中的结晶形貌相似。图6给出了在1.2 mA直流电流产生的电场的作用下AMPD-4.1%SCN模拟物定向结晶初期两相结晶生长形貌的演变。实验中电场的加载方式相同,冷端与热端的温度梯度为4 k·mm-1,电流的方向为正极接液相,负极接固相。可以看出,包晶

图5

图5

亚包晶模拟物定向凝固生长形貌

Fig.5

Directional solidification growth morphology of hypoperitectic simulator (a) 0 s; (b) 3 s; (c) 6 s; (d) 9 s

图6

图6

在1.2 mA电流专用下亚包晶模拟物的定向结晶形貌

Fig.6

Directional crystallization morphology of hypoperitectic simulator with current intensity of 1.2 mA (a) 0 s; (b) 9 s

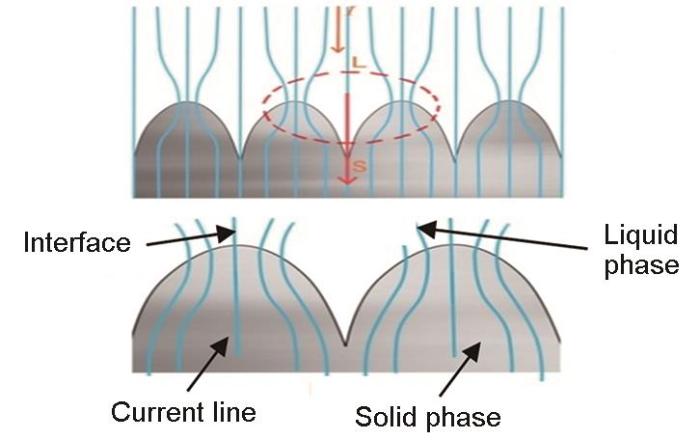

2.3 电场对凝固界面的影响

图7

图8

图8

直流电流影响枝晶尖端形貌演变的原理

Fig.8

Schematic explanation to the influence of DC on the evolution of dendrite tip morphology

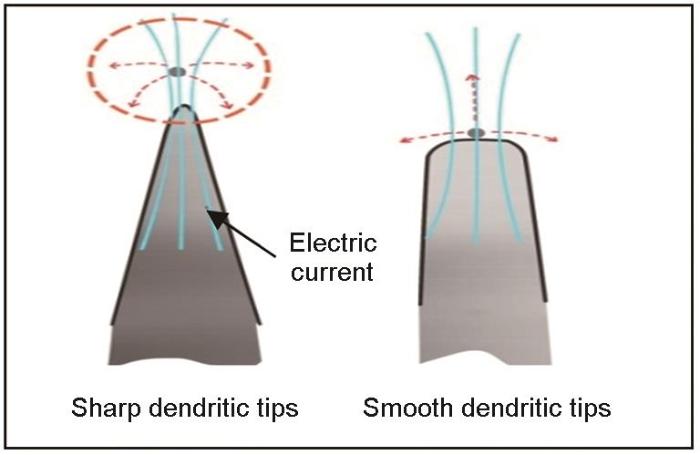

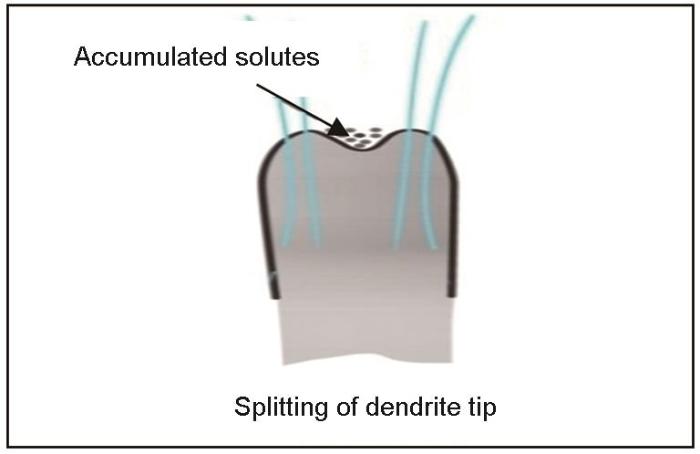

图9给出了枝晶尖端演变的原理图。由于电场对溶质分布的影响,电流的偏聚使中心部位的溶质难以向两侧扩散而堆积,使固-液界面枝晶前沿出现成分过冷,枝晶尖端由圆滑平直的界面向下凹趋势发展,即溶质原子的堆积引起成分过冷,使枝晶中部的生长变缓,枝晶尖端形成下凹的形貌。电场的作用使这些新形成的分枝继续产生电流偏聚和溶质堆积,循环往复上述凝固过程。因此,在电场作用下的定向凝固过程中,产生枝晶尖端特殊的凝固-分裂形貌的原因,是电场引起电流偏聚所产生的焦耳热效应和溶质的堆积引起的成分过冷。

图9

图10

图10

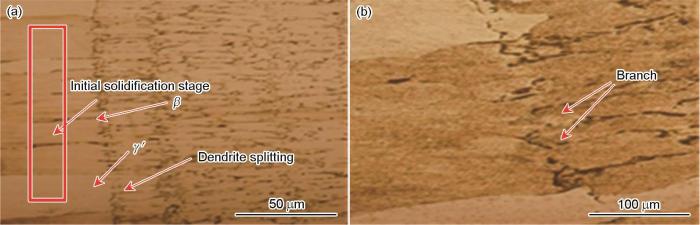

在电流作用下Ni-20Al-10Fe-0.2B定向凝固的最初阶段和枝晶分裂阶段

Fig.10

Directional solidification of Ni-20Al-10Fe-0.2B under electric current (a) initial solidification stage; (b) dendrite splitting stage

3 结论

(1) 在电场作用下定向结晶亚包晶合金模拟物的初生β相呈颗粒状向正极方向迁移,使溶质浓度更接近包晶反应浓度(0.05% SCN),从而促进包晶反应的进行。

(2) 电场的电迁移效应使固-液界面溶体流动改变溶质原子的扩散系数而使

(3) 电场影响定向凝固过程,枝晶尖端特殊的凝固-分裂形貌主要是电场作用引起电流偏聚产生的焦耳热效应和溶质的富集引起的成分过冷引起的。

(4) 电场对亚包晶Ni3Al基合金Ni-20Al-10Fe-0.2B的影响再现了枝晶尖端分裂生长的形貌,亚包晶模拟物与实际包晶合金的凝固过程相似。

参考文献

Effect of B and Cr on elastic strength and crystal structure of Ni3Al alloys under high pressure

Local structure study of Fe dopants in Niedeficit Ni3Al alloys

Study on a statistical unit cell model for Ni3Al-base superalloy

Effect of direct current electric field on the microstructure of ZA27 alloy

[J].

Effect of direct current electric fieid on structure of directionally solidified Al-4.5%Cu alloy

[J].

直流电场对 Al-4.5%Cu合金定向凝固组织的影响

[J].

Effects of electric current pulse on stability of solid/liquid interface of Al-4.5%Cu alloy during directional solidification

[J].

Effect of electric potentiasons on solidification of near eutectic Pn-Sb-Sn alloy

[J].

A novel solidification technique of metals and alloys:Under the influence of applied potential

[J].

Misra techniquel applied to solidification of cast iron

[J].

Control of γ' morphologyin nickel base superalloys through alloy design and densification processing under electric field

[J].

Influences of pulse electric current treatment on solidification microstructures and mechanical properties of Al-Si piston alloys

[J].

Effect of external electric field on solidification structure of alloy

[J].

外加电场对合金凝固组织的影响

[J].

Application of electric current in metal solidification

[J].

电流在金属凝固过程中的应用

[J].

Microstructure and high temperature stress rupture properties of Ru-containing directionally solidified Ni-base superalloy

[J].

Study on the induction solidification process of TiAl intermetallic compound

[D].

TiAl金属间化合物感应凝壳熔炼过程研究

[D].

Effect of surface-tension driven convection on interfacial boundary layer during BaB2O4 single crystal growth

[J].

表面张力对流对BaB2O4晶体生长界面边界层的作用

[J].利用高温光学实时观察方法, 实时地观察了BaB2O4 (BBO)高温熔体的表面张力对流效应以及BBO单晶的旋转生长过程, 计算了固液界面附近的浓度、温度以及动量边界层厚度δC, δT和δV, 并研究了热毛细对流对边界层厚度的影响. 结果发现, 浓度边界层厚度远远小于温度以及动量边界层厚度, 说明晶体生长过程中, 质量扩散在界面输运过程中起着主导性作用, 同时发现, 边界层厚度随体系无量纲Marangoni数的增大而线性地减小.

The formation mechanism of β-BaB2O4 dendrite

[J].

β-BaB2O4枝蔓晶的形成机理

[J].

Organic alloy systems suitable for the investigation of regular binary and ternary eutectic growth

[J].

Thermodynamic description and unidirectional solidification of eutectic organic alloys: IV. Binary system neopentylglycol-succinonitrile and amino-methyl-propanediol-succinonitrile

[J].

Effects of DC cuttent on directional solidification process of TiAl-based alloy

[D].

直流电流对TiAl基合金定向凝固过程的影响

[D].

The impurity effect in the space shuttle dendritic growth experiments with succinonitrile

[J].

Application of continuous electric field in metal solidification

[J].

连续电流场在金属凝固过程中的应用研究

[J].

Cellular growth of Sn-5%Bi alloy in electric field

[J].

电场作用下Sn-5%Bi合金的胞晶生长

[J].本文研究了直流电场作用下Sn-5%Bi合金的胞晶生长。实验结果表明,电场提高了胞晶生长的稳定性,改变胞晶生长形态,显著减少胞晶间距。提出了电场造成上述结果的作用机理。

Pattern selection in fingered growth phenomena

[J].

Qyabtitative phase field modeling of dendrictic growth in two and three dimensions

[J].

Growth mecanism of twin-related and twin-free facet Si sendrites

[J].

Effect of current intensity on microstruture of Ni3Al intermetallics prepared by directional solidification electromagnetic cold crucible technique

[J].

电流强度对冷坩埚定向凝固Ni3Al金属间化合物微观组织的影响

[J].

Effect of electric field on the Al-Cu eutectic interlamellar spacing

[J].

电场对Al-Cu共晶片间距的影响

[J].

Cellular growth of Sn-50% Bi alloy in electric field

[J].

Determination of the peltier coefficient of germanium in a vertical Bridgman-Stockbargerfurnace

[J].

Numerical simulation andvalidation of the Peltier pulse marking of solid/liquid interfaces

[J].

Pattern selection in fingered growth phenomena

[J].

Determination of the peltier coefficient of germanium in a vertical Bridgman-Stockbargerfurnace

[J].