非晶态合金的弹性极限大、强度高、耐腐蚀性和耐磨性好[1~5],但是多数大块非晶合金材料在室温发生脆性断裂,因为材料中高度局域化的剪切带快速扩展。这种宏观塑性或延性的缺乏,严重影响其工程应用[6~8]。为了解决这个问题,可在这类材料中引入晶态第二相成为非晶合金复合材料[9~14]。这种第二相阻碍主剪切带的快速扩展而生成多重剪切带,最终使其塑性提高[9,11,15]。在多种非晶复合材料中,原位生成的β增强相备受关注。在这种材料中枝晶相均匀地分布在非晶基体上,使其力学性能优异和制备过程变得容易[11]。通过形变诱发相变,可增强非晶复合材料的加工硬化能力[16~20]。向非晶复合材料中添加稳定β相元素可调节相变和枝晶相的大小与分布,从而调节其整体性能[9]。在TiZr基非晶复合材料中,能稳定β相的元素有两类。一类是类金属元素,如O、C、B、Si、P和Pb;另一类是金属元素,如Fe、Ni、Sn、Ta、Nb、Y和Sc[21~23]。Oh等[19]添加Ta元素制备出β相和α相两相混合结构的TiZr基非晶复合材料,在拉伸实验中相变生成的α孪晶诱发了加工硬化能力。Liu等[24]添加Mo元素调节Ti-Zr-Cu-Ni-Be-Mo系合金的加工硬化行为和拉伸塑性,其非晶基体成分和β枝晶相体积分数都保持不变。

本文用Nb元素稳定非晶复合材料Ti45.7Zr33Ni3Cu5.8Be12.5中的β相,研究Nb元素的添加对其力学性能的影响并分析其机理。

1 实验方法

实验用材料:纯度约为99.4%的工业海绵Zr、工业海绵Ti和纯度约为99.9%的Cu、Ni、Nb和Be。

使用电弧炉在高纯度氩气气氛中熔炼(Ti45.7Zr33-Ni3Cu5.8Be12.5)(1-0.01 x)Nb x (x=0、2、4、6、8和10)合金锭,记为Nb0、Nb2、Nb4、Nb6、Nb8和Nb10。Zr和Nb元素具有高熔点和较大的固溶度,因此先将其用电弧熔化成母合金锭,然后将其余的元素Ti、Cu和Be添加其中重熔成合金锭。每种合金至少重熔4次以确保化学成分均匀性。

将合金锭放入透明的熔融石英管中进行二次熔炼。通过加压的方式将熔融金属注射到直径为8 mm的铜模具中,快速冷却制备成直径8 mm的合金棒。

使用Instron 5582万能试验机进行室温单轴压缩试验,应变速率为5×10-4 s-1。试样的尺寸为2 mm×2 mm×4 mm。为了保证数据的准确性,至少测试15个数据取其平均值。用X射线衍射仪(XRD; Philips PW1050,CuKα),透射电子显微镜(TEM; JEOL2010,20 kV)和扫描电子显微镜(SEM; LEO super 35),结合能量色散光谱(EDS)等手段测试材料变形前后的结构变化。

2 实验结果

2.1 铸态非晶复合材料的微观组织结构

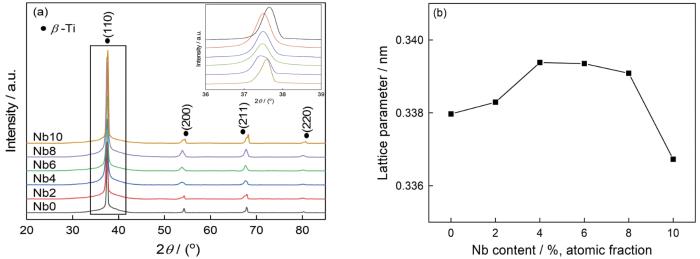

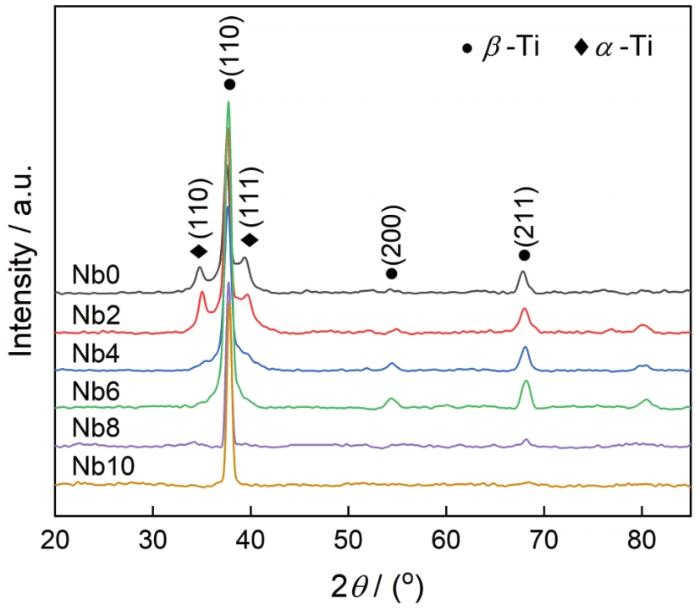

图1a给出了铸态(Ti45.7Zr33Ni3Cu5.8Be12.5)(1-0.01 x)Nb x (x=0、2、4、6、8和10)非晶复合材料的XRD谱及其(110) β 峰的放大区域。铸态样品bcc结构的β-Ti(Zr/Nb)的衍射峰,叠加在典型的非晶相的漫散射峰上。从插图可见,随着Nb元素含量的提高衍射主峰(110) β 先向左移动(Nb0~Nb4)然后向右移动(Nb4~Nb10)。利用Bragg衍射方程和晶面间距公式计算了树枝晶的晶格常数[22],图1b给出了添加Nb元素后β相树枝晶的晶格常数的变化。可以看出,添加Nb元素后β相树枝晶的晶格常数先增大(Nb0~Nb4),然后减小(Nb4~Nb10)。

图1

图1

铸态TiZr基非晶复合材料的XRD谱(插图为(100) β 峰的放大示意图)和非晶复合材料中枝晶相的晶格常数

Fig.1

XRD patterns of the as-cast TiZr-based amorphous alloy composites and inset presents the enlarged regions of the (100) β peaks (a), and lattice constants of dendrite phase of the amorphous alloy composites (b)

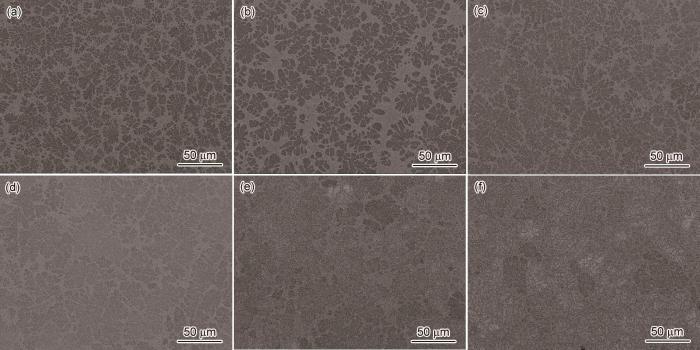

图2给出了样品微观结构的扫描电镜照片。可以看出,树枝状的晶相(较暗的区域)均匀地分布在非晶基体(较亮的区域)上。树枝晶与非晶基体两相之间只有衬度的不同,表明树枝晶和非晶基体之间的界面结合良好,没有裂纹、空洞或其他缺陷。这有利于变形过程中应力的传递,因此有利于获得优异的力学性能,如高强度和良好的塑性。

图2

图2

铸态TiZr基非晶复合材料样品的SEM照片

Fig.2

SEM micrographs of the as-cast sample of TiZr-based amorphous alloy composites (a) Nb0, (b) Nb2, (c) Nb4, (d) Nb6, (e) Nb8 and (f) Nb10

表1 Nb0~Nb10样品中枝晶相的体积分数和晶粒尺寸

Table 1

| Alloys | Nb0 | Nb2 | Nb4 | Nb6 | Nb8 | Nb10 |

|---|---|---|---|---|---|---|

| Volume fraction/% | 49 | 54 | 55 | 62 | 63 | 65 |

| Grain size/μm | 27 | 35 | 36 | 37 | 40 | 41 |

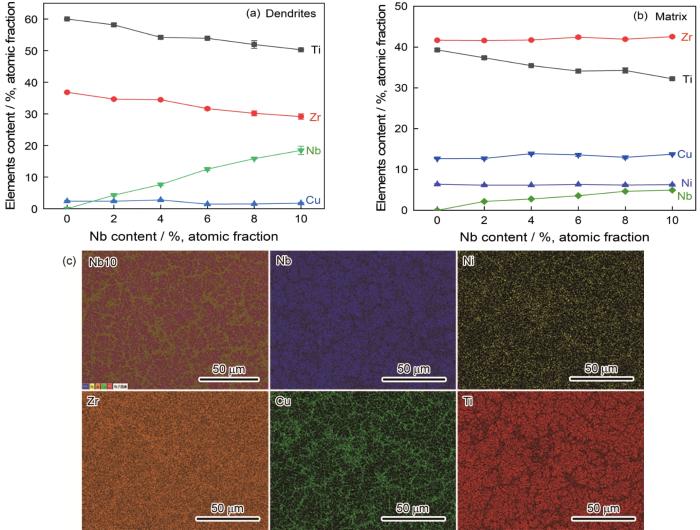

图3

图3

非晶复合材料中的枝晶相和非晶基体各种元素的含量与成分的关系和Nb10样品的能谱面扫图片

Fig.3

EDS curves of elements content as a function of Nb content in the dendrites (a), amorphous matrix (b) and EPMA mapping results of Nb10 amorphous alloy composites (c)

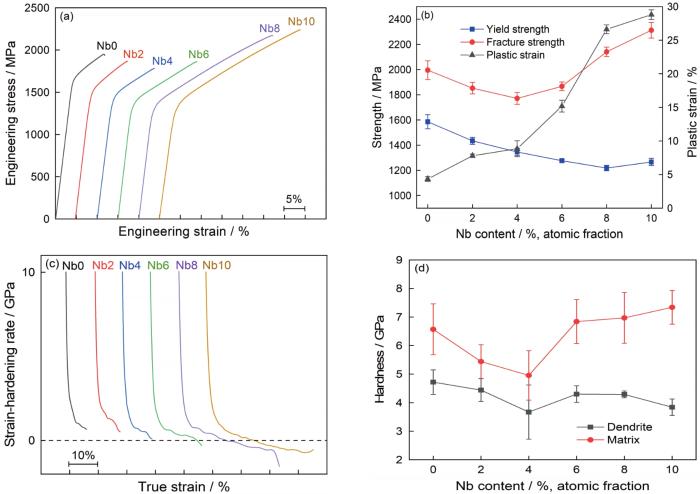

2.2 非晶复合材料的力学性能

图4a给出了非晶复合材料的室温工程应力-应变曲线。结果表明,随着载荷的增加一系列样品都在弹性变形后发生塑性变形,直至断裂。分析应力-应变曲线可得相应的力学性能参数,即屈服强度(σy)、极限断裂强度(σmax)和塑性应变量(εp),将其随着Nb元素含量的提高而产生的变化趋势绘制成曲线,如图4b所示。随着Nb元素含量的提高σy从1586 MPa降低到1266 MPa,εp从4.3%提高到28.8%。Nb0~Nb4样品的σmax从1995 MPa下降到1771 MPa,Nb4~Nb10样品的σmax从1771 MPa提高到2312 MPa。测量真应力-应变曲线并计算出样品的加工硬化率,结果如图4c所示。可以看出,随着Nb元素含量的提高样品的加工硬化能力减弱。当Nb元素的含量高于6%(原子分数)时,塑性变形时的应变硬化率低于0 GPa,表明试样发生了软化。图4d给出了通过纳米压痕实验得到的非晶复合材料的枝晶相和非晶基体的硬度变化。可以看出,随着Nb元素含量的提高Nb0~Nb4样品的枝晶相和非晶基体的硬度都降低,使非晶复合材料的强度降低(图4b)。当Nb含量达到6%(原子分数)时,枝晶相和非晶基体的硬度急剧提高。随着Nb元素含量的进一步提高枝晶相的硬度降低,而非晶基体的硬度提高。结合表1中的数据,非晶复合材料中枝晶相的体积分数的提高使Nb4~Nb10样品的σy减小,但是下降变缓。同时,基体的硬度始终比枝晶相的硬度高。

图4

图4

TiZr基非晶复合材料的力学性能变化

Fig.4

Compressive strain-stress curves (a), the corresponding parameters gained from the s-s curves (b), work-hardening rate curve (c) and nano-indentation hardness (d) of the amorphous alloy composites

每种成分选取15个样品进行压缩实验,以评估其室温压缩力学性能的可重复性。表2列出了平均值、标准差和离散系数(CV)等衡量标准。离散系数为

其中σ为标准差,μ为力学性能的平均值。可以看出,强度的可重复性总是高于塑性的可重复性。根据塑性的可重复性,非晶复合材料分为Nb0~Nb2和Nb4~Nb10两部分。随着Nb元素含量的提高Nb0~Nb2的离散系数从6.6%下降到2.73%,而Nb6~Nb10的离散系数从10.87%逐渐下降到2%左右。这表明,添加适量的Nb元素可提高TiZr基非晶复合材料力学性能的可重复性。

表2 非晶复合材料力学性能的可重复性

Table 2

| Alloys | Average | Standard deviation | CV/% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| σ0.2/MPa | σb/MPa | εp/% | σ0.2/MPa | σb/MPa | εp/% | σ0.2 | σb | εp | |

| Nb0 | 1486.66 | 1967.76 | 4.34 | 34.30 | 48.67 | 0.29 | 2.31 | 2.47 | 6.60 |

| Nb2 | 1429.52 | 1864.94 | 7.79 | 17.15 | 29.55 | 0.21 | 1.20 | 1.58 | 2.73 |

| Nb4 | 1347.71 | 1751.56 | 8.86 | 17.82 | 44.12 | 0.96 | 1.32 | 2.52 | 10.87 |

| Nb6 | 1277.94 | 1860.96 | 15.19 | 6.98 | 26.37 | 0.72 | 0.55 | 1.42 | 4.73 |

| Nb8 | 1222.10 | 2153.90 | 26.62 | 11.33 | 20.53 | 0.55 | 0.93 | 0.95 | 2.01 |

| Nb10 | 1266.86 | 2315.36 | 28.80 | 17.17 | 43.03 | 0.59 | 1.36 | 1.86 | 2.04 |

图5

图5

断裂后TiZr基非晶复合材料的XRD谱

Fig.5

XRD patterns of TiZr-based amorphous alloy composites after fracturing

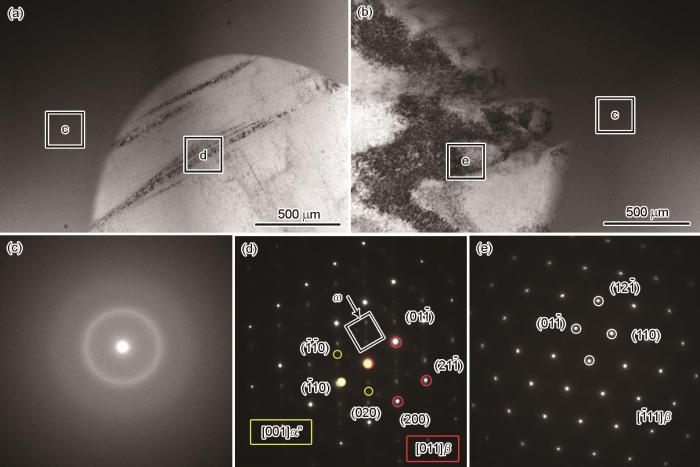

为了进一步分析Nb元素对形变诱发马氏体相变和未发生形变诱发马氏体相变的两类样品变形机制的影响,用透射电镜研究了Nb2和Nb6试样断裂后的显微组织。图6给出了断裂后的Nb2和Nb6样品的明场透射电镜显微照片和相应的选区电子衍射图。可以看出,对于具有马氏体相变的Nb2样品,具有bcc结构的β相和具有正交结构的α"相嵌入在非晶基体中,马氏体相α″的形状为平行板条。在β相中α"相聚集在非晶基体和β枝晶相的界面上,如图6a所示。根据文献[19],Nb元素抑制了变形过程中的马氏体相变,而Nb元素主要分布在β相中抑制了Nb2样品中马氏体的生长。与Nb0样品相比,生成了板条较薄但分布均匀的α"马氏体相。在图6d中也能观察到一些ω相,如方框标识所示[26]。

图6

图6

Nb2和Nb6样品断裂后的明场透射电镜照片和相应的SAED图样

Fig.6

Bright field TEM images of Nb2 (a) and Nb6 TiZr-based amorphous alloy composites after fracture (b), the corresponding SAED patterns (c) of the amorphous phase and the dendritic phase of the Nb2 (d) and the dendritic phase of the Nb6 (e)

图7

图7

TiZr基非晶复合材料压缩变形后其侧面多重剪切带的SEM照片

Fig.7

SEM micrographs of multiple shear bands on the lateral surface of TiZr-based amorphous alloy composites after deformation (a) Nb0, (b) Nb2, (c) Nb4, (d) Nb6, (e) Nb8 and (f) Nb10

3 结论

Nb元素含量的提高使TiZr基非晶复合材料中β相的晶粒尺寸增大和体积分数提高,而形变诱发β向α″的相变受到抑制。Nb元素的添加,使这种非晶复合材料的塑性大大提高而屈服强度和加工硬化能力降低。对于具有形变诱发相变的非晶复合材料,如Nb0~Nb4,小板条α″马氏体的生成能诱导生成多个剪切带,从而使其塑性提高。对于没有形变诱发相变的非晶复合材料,如Nb6~Nb10,β相中位错的生成并积累形成位错台阶,触发了多重剪切带的形成而使其塑性提高。

参考文献

Stabilization of metallic supercooled liquid and bulk amorphous alloys

[J].

Enhancing the compressive and tensile properties of Ti-based glassy matrix composites with Nb addition

[J]. J.

Effect of counterpart material on the tribological properties of Zr-based bulk metallic glass under relatively heavy loads

[J].

Effects of cryogenic temperatures on mechanical behavior of a Zr60Ni25Al15 bulk metallic glass

[J].

A structural model for metallic glasses

[J].Despite the intense interest in metallic glasses for a variety of engineering applications, many details of their structure remain a mystery. Here, we present the first compelling atomic structural model for metallic glasses. This structural model is based on a new sphere-packing scheme-the dense packing of atomic clusters. Random positioning of solvent atoms and medium-range atomic order of solute atoms are combined to reproduce diffraction data successfully over radial distances up to approximately 1 nm. Although metallic glasses can have any number of chemically distinct solute species, this model shows that they contain no more than three topologically distinct solutes and that these solutes have specific and predictable sizes relative to the solvent atoms. Finally, this model includes defects that provide richness to the structural description of metallic glasses. The model accurately predicts the number of solute atoms in the first coordination shell of a typical solvent atom, and provides a remarkable ability to predict metallic-glass compositions accurately for a wide range of simple and complex alloys.

Mg-based bulk metallic glass composites with plasticity and high strength

[J].

Difference in compressive and tensile fracture mechanisms of Zr59Cu20Al10Ni8Ti3 bulk metallic glass

[J].

Effect of annealing on the mechanical properties and fracture mechanisms of a Zr56.2Ti13.8Nb5.0Cu6.9-Ni5.6Be12.5 bulk-metallic-glass composite

[J].

Designing metallic glass matrix composites with high toughness and tensile ductility

[J].

Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glasses containing in situ formed ductile phase dendrite dispersions

[J].Results are presented for a ductile metal reinforced bulk metallic glass matrix composite based on glass forming compositions in the Zr-Ti-Cu-Ni-Be system. Primary dendrite growth and solute partitioning in the molten state yields a microstructure consisting of a ductile crystalline Ti-Zr-Nb beta phase, with bcc structure, in a Zr-Ti-Nb-Cu-Ni-Be bulk metallic glass matrix. Under unconstrained mechanical loading organized shear band patterns develop throughout the sample. This results in a dramatic increase in the plastic strain to failure, impact resistance, and toughness of the metallic glass.

Development of tough, low-density titanium-based bulk metallic glass matrix composites with tensile ductility

[J].

Novel Ti-base nanostructure-dendrite composite with enhanced plasticity

[J].

Mechanical behavior of bulk amorphous alloys reinforced by ductile particles at cryogenic temperatures

[J].

Enhanced plasticity in a Zr-based bulk metallic glass composite with in situ formed intermetallic phases

[J].

Metallic glass matrix composites

[J].

Shape memory bulk metallic glass composites

[J].

Bulk metallic glass composites with transformation-mediated work-hardening and ductility

[J].

Transformation-induced plasticity in bulk metallic glass composites evidenced by in-situ neutron diffraction

[J].

Microstructure and tensile properties of high-strength high-ductility Ti-based amorphous matrix composites containing ductile dendrites

[J].

In situ high-energy X-ray diffraction studies of deformation-induced phase transformation in Ti-based amorphous alloy composites containing ductile dendrites

[J].

Mechanical properties of Zr56.2Ti13.8Nb5.0Cu6.9Ni5.6Be12.5 ductile phase reinforced bulk metallic glass composite

[J].

Quasi-static and dynamic deformation behaviors of an in-situ Ti-based metallic glass matrix composite

[J].

Strong work-hardening behavior induced by the solid solution strengthening of dendrites in TiZr-based bulk metallic glass matrix composites

[J].

Modulating work-hardening behaviors and tensile plasticity of in-situ formed ductile dendrite Ti-based bulk metallic glass composites with tailored dendrite composition

[J].

A micromechanical model of toughening behavior in the dual-phase composite

[J].

Effects of casting temperature on the microstructure and mechanical properties of the TiZr-based bulk metallic glass matrix composite

[J].

Dendrite size dependence of tensile plasticity of in situ Ti-based metallic glass matrix composites

[J].

Effect of pre-plastic-deformation on mechanical properties of TiZr-based amorphous alloy composites

[J].

Development of plastic Ti-based bulk-metallic-glass-matrix composites by controlling the microstructures

[J].