Abedi H R等[9]和Kalantari A R等[10]发现,在低应变速率条件下低密度钢的热塑性变形的主要恢复机制是动态回复,而在高应变速率条件下较高的形变储存能使动态再结晶更为明显。同时,在热塑性变形过程中应变诱导相变产生的晶粒细化和流变应力的软化行为极为显著,堆垛层错能影响动态回复进而影响动态再结晶[10]。这些因素增大了研究低密度钢动态再结晶行为的难度。Li Y P等[7]发现,低密度钢在低应变速率条件下热压缩应变达到一定的临界值后,其变形流变应力出现明显的上升趋势。钢铁材料高温压缩时加工硬化和动态回复以及动态再结晶软化之间的平衡,使其流变应力达到峰值后逐渐减小而后趋于平缓[11, 12]。其原因是,应变到达试样表面与砧面接触面积增大使摩擦系数提高,然而修正流变应力曲线也不能完全将其消除[13,14]。

1 实验方法

热压缩试验用钢为Fe-26.64Mn-9.78Al-2.88Ni-1.3Si-0.9C和9Mn27Al10Ni3Si(质量分数,%)。用真空感应炉熔炼-铸造后锻造成板坯(初锻温度1150℃,道次锻造比大于3,终锻温度≥850℃),使用QT5635线切割机从水冷后的板坯切割出直径为8 mm长度为15 mm的热压缩试样。在Gleeble-3500热模拟机上进行单道次压缩实验(实验工艺:加热至1250℃均质3 min,以30℃/s的冷却速度分别冷却到850、900、950、1000、1050℃后,在每个温度下分别以0.01、0.1、1、5 s-1的变形速率进行恒温热压缩实验),工程应变均为0.61(真应变为0.92),热压缩结束后将试样水淬。用线切割机沿热压缩试样的中心部位切开,制成金相试样;将其打磨-抛光后用3.5%的硝酸酒精腐蚀,用BX51型荧光显微镜和SNE-3200NB扫描电镜观察试验钢的微观组织,并取点进行EDS分析;然后将试样切割成直径为3 mm的圆形薄片,打磨-双喷减薄后用JEM-2100F场发射透射电子显微镜分析实验钢的微观结构。

2 实验结果和讨论

2.1 实验钢锻态的组织结构特征

图1

图1

实验钢锻态的显微组织

Fig.1

Microstructure morphology of experimental steel in forging state (a) forged microstructure, (b) distribution of austen-ite grain size, (c) analysis results of XRD, (d) phase equilibrium diagram

表1 9Mn27Al10Ni3Si奥氏体基低密度钢的室温相组成(原子分数, %)

Table 1

| Phase | γ | δ | κ-carbides |

|---|---|---|---|

| Content | 80.5 | 3.7 | 15.8 |

图1d给出了使用Factsage7.3软件绘制的实验钢平衡图。实验钢为γ+δ双相钢,其κ-碳化物的析出温度约962℃,γ→α相变温度约964℃,β-Mn脆性相的析出温度约642℃。

2.2 高温压缩的塑性变形特征

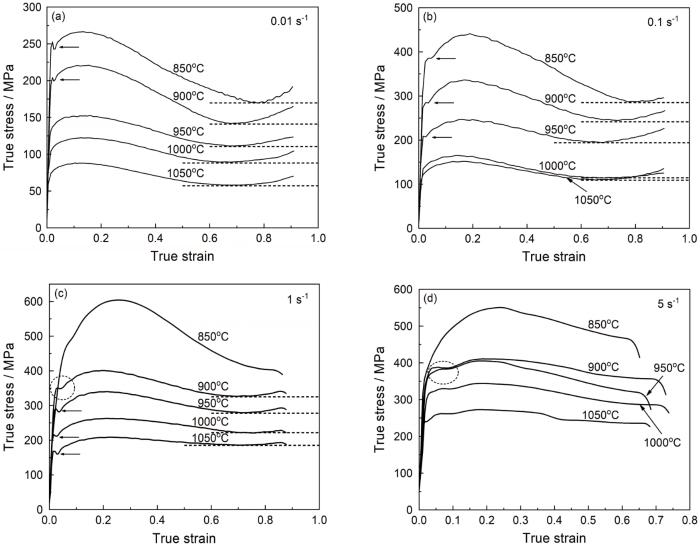

图2

图2

实验钢的热压缩流变应力曲线

Fig.2

Hot compression flow stress curve of experimental steel

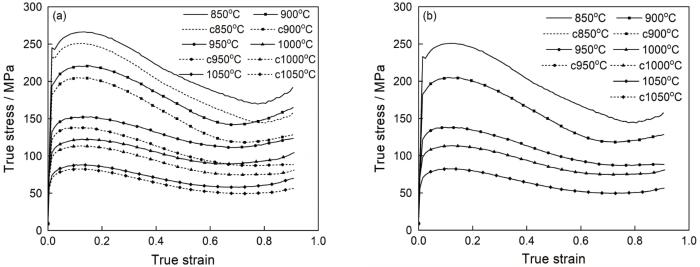

图3

图3

实验钢在0.01 s-1条件下热压缩流变应力曲线的修正

Fig.3

Correction of hot compression rheological stress curve of experimental steel under the condition of 0.01 s-1 (a) before and after friction correction, (b) before and after temperature correction (imaginary point line is the corrected curve)

摩擦修正公式为

式中

变形热修正公式为

式中

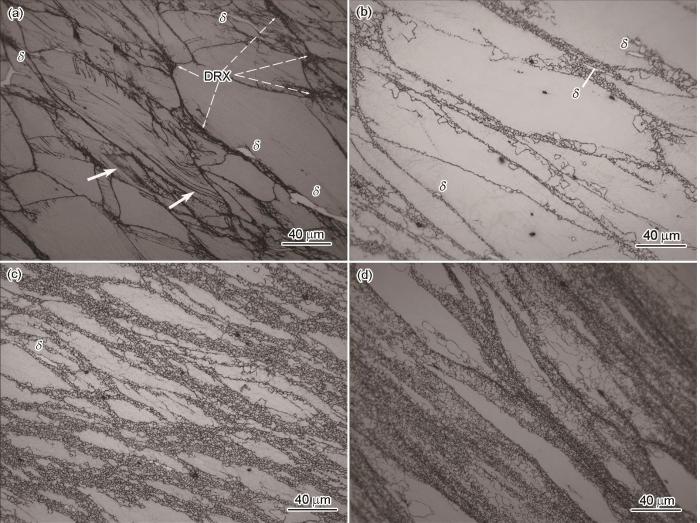

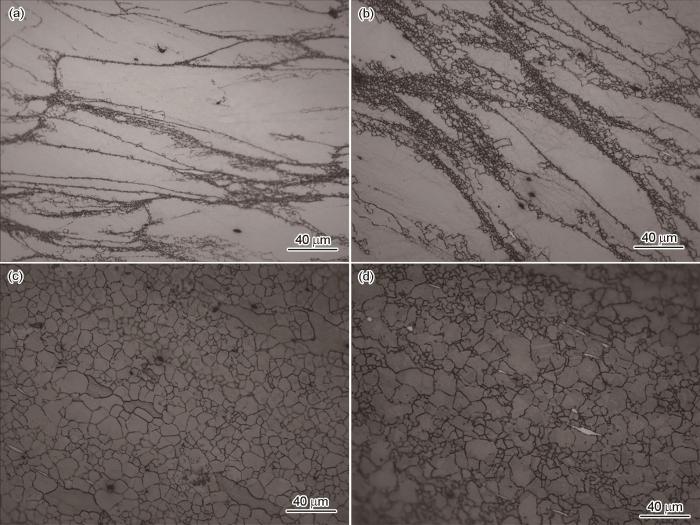

如图4a所示,实验钢在850℃、0.01 s-1条件下热压缩时只在部分区域发生奥氏体动态再结晶,奥氏体晶粒内发生极为显著的加工硬化(如图4a白色箭头所示的奥氏体未再结晶区的局部变形带)。如图4a~c所示,实验钢在850℃、0.01~5 s-1条件下热压缩时均发生部分动态再结晶,而且随着应变速率的提高动态再结晶的体积分数随之显著提高;此外,在0.01~5 s-1条件下热压缩时原始晶粒的晶界处均出现大量的链状组织。在钢铁的动态再结晶过程中,当原始晶界完全被新晶粒(即形成链状组织)覆盖时,再结晶晶粒的形核和长大必须由细小的再结晶晶粒的晶界处触发。而低密度钢的应变温度较低时其堆垛层错能较低[35],位错的滑移和交滑移受到抑制,位错在晶界处的堆积能促进动态再结晶的过程[24]。而实验钢在850℃、0.01~1 s-1条件下热压缩时出现的链状组织和局部变形带表明,其动态再结晶和动态回复受到显著抑制,从而使流变应力出现上述的异常增大。

图4

图4

实验钢在850℃不同应变速率条件下热压缩后的显微组织

Fig.4

Microstructure morphologies after hot compression of experimental steel under the condition of different strain rates at 850℃ (DRX: dynamic recrystallization) (a) 0.01 s-1 (ε=0.9), (b) 0.1 s-1 (ε=0.9), (c) 1 s-1 (ε=0.9), (d) 5 s-1 (ε=0.67)

实验钢的形变储存能随着应变速率的提高而增加,奥氏体动态再结晶的驱动力增加;同时,κ-碳化物没有充足的时间粗化和析出[16];从而促进了动态再结晶晶粒形核,使奥氏体动态再结晶晶粒的数量增加和动态再结晶的软化作用增强,上述流变应力异常增大的现象逐渐消失。

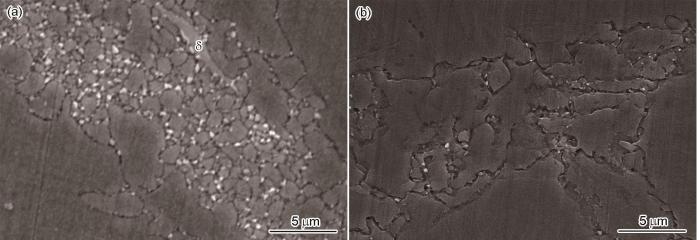

图5

图5

实验钢在850℃热压缩后的SEM照片

Fig.5

SEM image after hot compression of experimental steel under the condition of 850℃ and (a) 0.01 s-1 (ε=0.9), (b) 0.1 s-1 (ε=0.67)

如图3a和图6所示,在0.01 s-1条件下热压缩时,随着变形温度的提高实验钢再结晶的驱动力增大,使奥氏体动态再结晶晶粒的数量显著增加和尺寸显著增大。如图6b和c所示,在1000~1050℃热压缩时变形温度较高使奥氏体动态再结晶的驱动力较大,而且热压缩温度高于κ-碳化物析出的温度使得在热压缩过程中没有第二相的动态析出,从而使实验钢的热压缩组织为完全动态再结晶。显然,实验钢在1000~1050℃、0.01~1 s-1条件下热压缩时流变应力的上述异常增大与κ-碳化物的析出无关。其原因可能是,在较高温度热压缩时因κ-碳化物固溶到奥氏体晶粒溶质原子和位错的交互作用而发生固溶强化,使实验钢的应变达到一定的临界值后流变应力轻微增大。

图6

图6

实验钢在0.01 s-1条件下热压缩后的金相组织

Fig.6

Metallographic structure of experimental steel after hot compression under the condition of 0.01 s-1 and (a) 900℃, (b) 950℃, (c) 1000℃, (d) 1050℃

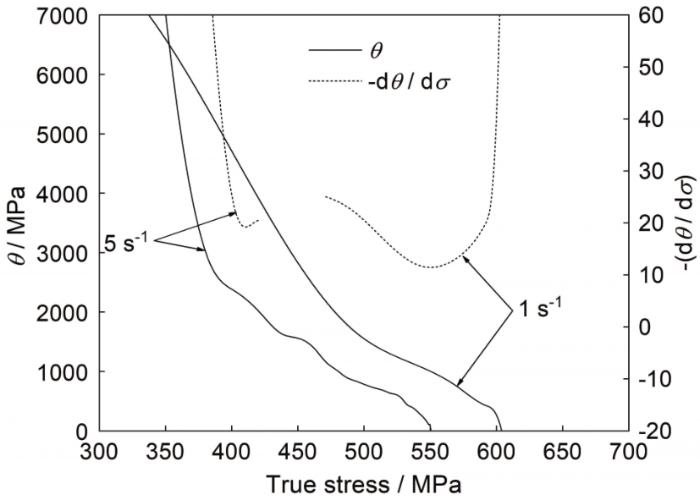

图7

图7

实验钢在850℃、1~5 s-1条件下热压缩后的θ-σ和(-dθ/dσ)-σ曲线

Fig.7

θ-σ and (-dθ/dσ)-σ curve of experimental steel after hot compression under the condition of 850℃ and 1~5 s-1

2.3 高温压缩变形机制

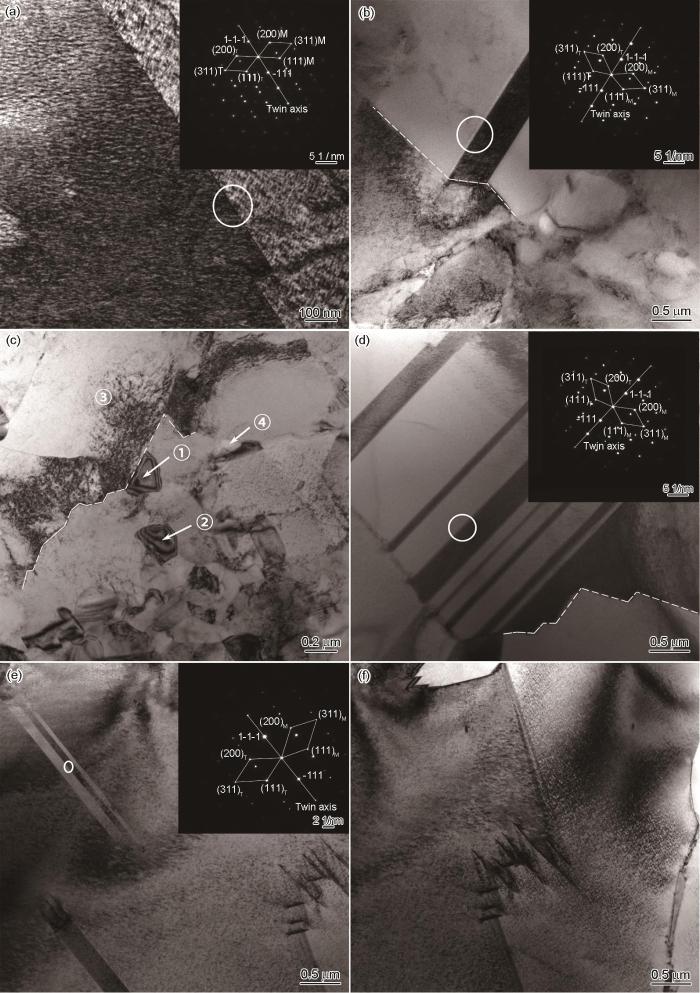

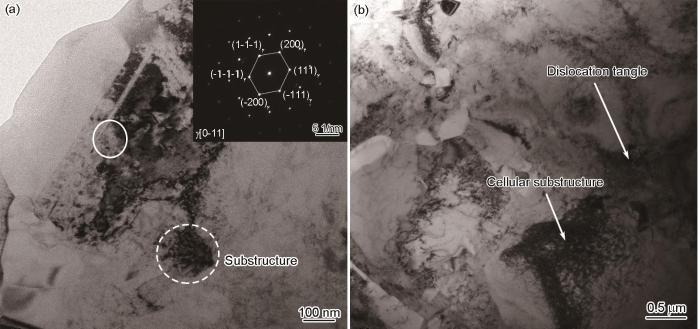

图8

图8

实验钢在850℃热压缩后的TEM组织

Fig.8

TEM microstructure after hot compression of experimental steel at 850℃ and (a~c) 0.01 s-1 (ε=0.9), (d~f) 5 s-1 (ε=0.67)

表2 图6和图7中TEM图像各点的EDS分析

Table 2

| Element | Point 1 | Point 2 | Point 3 | Point 4 | Point 5 | Point 6 |

|---|---|---|---|---|---|---|

| Fe | 65.116 | 64.416 | 63.057 | 54.599 | 53.360 | 54.067 |

| Mn | 17.917 | 26.358 | 25.776 | 29.348 | 30.951 | 30.342 |

| Al | 10.056 | 6.422 | 7.090 | 15.386 | 15.110 | 14.937 |

| Ni | 5.018 | 1.884 | 2.388 | 0.457 | 0.492 | 0.484 |

| Si | 1.891 | 0.918 | 1.687 | 0.208 | 0.086 | 0.167 |

| Phase | γ | γ | γ | κ-carbide | κ-carbide | κ-carbide |

在钢铁的动态再结晶过程中形成的链状组织,使动态再结晶的形核和长大受到抑制。上述孪生现象表明,实验钢的堆垛层错能较低,而低层错能材料热塑性变形时位错的滑移和交滑移受到抑制,位错在晶界处的堆积促进了动态再结晶的过程[24]。而实验钢在850℃、0.01~1 s-1条件下热压缩时动态再结晶和动态回复均受到显著抑制,是κ-碳化物与奥氏体动态再结晶竞争的结果。

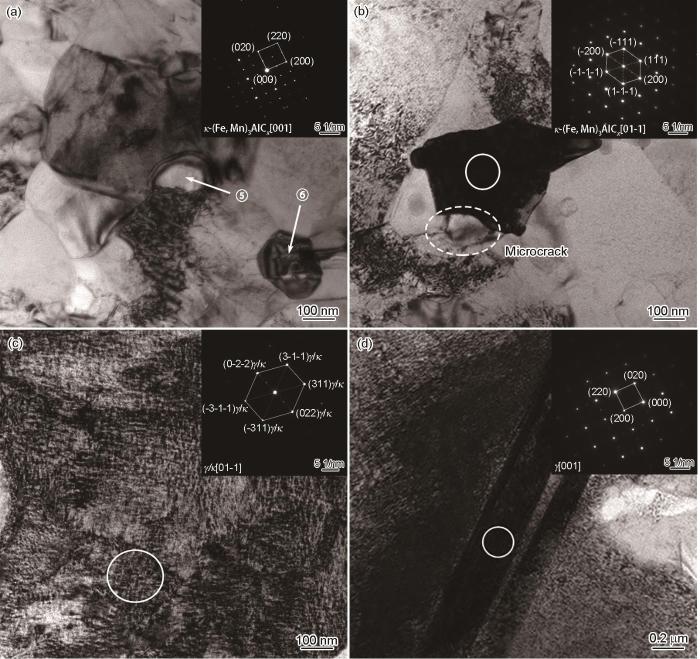

图9

图9

实验钢在850℃、0.01 s-1 (ε=0.9)条件下热压缩后的TEM组织

Fig.9

TEM microstructure after hot compression of experimental steel under the conditions of 850℃ and 0.01 s-1 (ε=0.9) (a, b) intergranular κ-carbides, (c) intracrystalline κ-carbides, (d) deformation band

在850℃、0.01 s-1条件下热压缩过程中晶粒内κ-碳化物的调幅分解析出(图9c)消耗了奥氏体晶粒内大量的形变储存能,极大地阻碍了奥氏体再结晶晶粒的生长。如表3所示,由于奥氏体晶界处和晶粒内κ-碳化物的粗化和析出,实验钢在850℃、0.01~1 s-1条件下热压缩时奥氏体动态再结晶的平均晶粒尺寸均较低,在高应变速率条件下热压缩时较高的形变存储能使奥氏体动态再结晶的临界应变较小。同时,κ-碳化物粗化和析出的现象减弱[16]促进了奥氏体再结晶晶粒的形核和长大。由于实验钢在850℃高应变速率条件下热压缩时孪生现象更为显著,而κ-碳化物动态析出和粗化的现象减弱,使κ-碳化物对动态再结晶的抑制减弱以及大量的孪生现象促进动态再结晶的形核和长大,从而在高应变速率条件下热压缩时奥氏体动态再结晶比在低应变速率条件下更为显著。

表3 实验钢在850℃热压缩时奥氏体再结晶晶粒的平均尺寸

Table 3

| Strain rate/s-1 | 0.01 | 0.1 | 1 | 5 |

|---|---|---|---|---|

| Average grain size/μm | 10.28 | 9.66 | 9.00 | 12.13 |

| Time of hot compression/s | 90 | 9 | 1 | 0.3 |

如图9d所示,实验钢在850℃、0.01 s-1条件下热压缩时在奥氏体晶粒内出现少量微带,其特征是在微带附近的位错密度较高。微带结构为合金原子的扩散提供了通道,从而极大地促进了κ-碳化物的粗化[16, 17]。此外,晶粒内κ-碳化物的析出显著提高了奥氏体晶粒的硬度[17, 42]。显然,晶粒内κ-碳化物的动态析出使奥氏体晶粒的硬度提高以及晶界处κ-碳化物的粗化和析出对奥氏体动态再结晶的抑制和奥氏体晶界的钉扎,使实验钢在850~950℃、0.01~1 s-1条件下热压缩时流变应力异常增大。随着应变速率的提高实验钢孪生现象的增加和κ-碳化物粗化和析出减弱,促进了奥氏体动态再结晶的形核和长大,从而使奥氏体动态再结晶的体积分数增大以及上述流变应力异常增大现象逐渐减弱甚至消失。

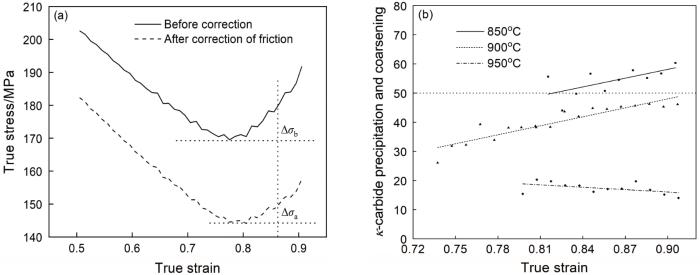

图10

图10

实验钢在1050℃、5 s-1 (ε=0.7)条件下热压缩后的TEM组织

Fig.10

TEM microstructure after hot compression of experimental steel under the conditions of 1050℃ and 5 s-1 (ε=0.7) (a) deformation band and substructure, (b) cellular substructure and dislocation tangle

2.4 依据第一性原理的研究

前文提到,除了κ-碳化物的粗化与析出能显著增加使流变应力产生的应变硬化率影响流变应力异常增大外,摩擦系数的增大也是流变应力异常增大的重要原因。因此,本文依据第一性原理进行了研究。如图11a所示,本文设定修正前某一应变的流变应力与流变应力异常增大前的应力之间的差值作为摩擦系数和κ-碳化物对上述现象的总影响(∆σb),修正后某一应变的流变应力与流变应力异常增大前的应力之间的差值作为κ-碳化物对上述现象的影响(∆σa),κ-碳化物对其影响的比例为η(η=∆σa/∆σb)。

图11

图11

第一性原理研究示意图和κ-碳化物对流变应力异常增大的影响

Fig.11

Schematic diagram of first principle research (a) and effect of κ-carbides on abnormal rise of flow stress (b)

依据第一性原理的研究结果表明:在较高温度热压缩时奥氏体动态再结晶与κ-碳化物的竞争使κ-碳化物的析出受到一定的抑制,从而对流变应力异常增大的影响较小,主要的影响因素是砧板与试样表面的摩擦系数。随着温度的降低κ-碳化物析出增强,因此对流变应力异常增大的影响提高,并随着应变的增大其影响比例随之提高。显然,实验钢在850℃、0.01 s-1条件下热压缩时流变应力异常增大主要受κ-碳化物粗化和析出的影响;在850℃、0.1~1 s-1条件下热压缩时流变应力异常增大主要受摩擦系数的影响;这表明,在合金材料热压缩过程中流变应力达到一定的临界值后出现异常增大不仅与摩擦系数有关,还与第二相的析出有关,且两者对流变应力的影响都不能忽视。

3 结论

(1) 9Mn27Al10Ni3Si奥氏体基低密度钢在850℃、0.01~5 s-1条件下热压缩过程中高应变速率热压缩时孪生现象对奥氏体动态再结晶的促进、低应变速率热压缩时κ-碳化物的析出和粗化对奥氏体动态再结晶的抑制,使其动态再结晶的体积分数随着应变速率的提高而增大。

(2) 实验钢在850~950℃、0.01~1 s-1条件下热压缩过程中摩擦系数的增大和κ-碳化物的析出和粗化使其应变硬化率显著增加,应变达到临界值后流变应力呈增大的趋势,随着应变速率的提高κ-碳化物的析出减弱,使上述现象逐渐减弱甚至消失。随着热压缩温度的降低κ-碳化物对流变应力异常增大的影响显著提高,在850℃、0.01 s-1条件下热压缩时流变应力异常增大主要受κ-碳化物的影响。

(3) 实验钢在850℃、5 s-1条件下热压缩时大量的位错塞积使其动态再结晶启动的临界应力值小于1 s-1,动态再结晶的软化作用使应变硬化率迅速降低甚至低于1 s-1,从而使峰值应力低于1 s-1。

(4) 实验钢在850℃、0.01 s-1条件下热压缩时奥氏体晶界棱角处的κ-碳化物沿晶界粗化为尖锐的多边形形貌,奥氏体晶粒与尖锐的多边形κ-碳化物交界处微裂纹的萌生对低密度钢的热加工性能有不利的影响。

参考文献

Fe-Al-Mn-C lightweight structural alloys: a review on the microstructures and mechanical properties

[J].

Research situation of Fe-Mn-Al-C system low-density high-strength steel

[J].

Fe-Mn-Al-C系列低密度高强钢的研究现状

[J].

Current state of Fe-Mn-Al-C low density steels

[J].

Microstructure evolution of a medium manganese steel during thermomechanical processing

[J].

Hot deformation and dynamic recrystallization behavior of austenite-based low-density Fe-Mn-Al-C Steel

[J].

Exploring the influence of Al content on the hot deformation behavior of Fe-Mn-Al-C steels through 3D processing map

[J].

Continuous dynamic recrystallization in low density steel

[J].

Microstructure evolution and room temperature mechanical properties of a thermomechanically processed ferrite-based low density steel

[J].

Deformation mechanism and nano-scale interplay of dual precipitation during compressive deformation of a duplex lightweight steel at high strain rate

[J].

Hot-workability of super-304H exhibiting continuous to discontinuous dynamic recrystallization transition

[J].

Correcting the stress-strain curve in hot compression process to high strain level

[J].

Correcting the stress-strain curve in hot compression test using finite element analysis and Taguchi method

[J].

Dynamic microstructural evolution and recrystallization mechanism during hot deformation of intermetallic-hardened duplex lightweight steel

[J].

Dynamic recrystallization and precipitation behaviors during hot deformation of a κ-carbide-bearing multiphase Fe-11Mn-10Al-0.9C lightweight steel

[J].

Hot deformation of a Fe-Mn-Al-C steel susceptible of κ-carbide precipitation

[J].

Strain hardening during hot compression through planar dislocation and twin-like structure in a low-density high-Mn steel

[J].

Partitioning of C into κ-carbides by Si addition and its effect on the initial deformation mechanism of Fe-Mn-Al-C lightweight steels

[J].

Phase transformations in FeMnAlC austenitic steels with Si addition

[J].

Brittle intermetallic compound makes ultrastrong low-density steel with large ductility

[J].

Novel ultra-high-strength (ferrite + austenite) duplex lightweight steels achieved by fine dislocation substructures (Taylor lattices), grain refinement, and partial recrystallization

[J].

Effect of aging on the microstructure and deformation behavior of austenite base lightweight Fe–28Mn-9Al-0.8C steel

[J].

A review of dynamic recrystallization phenomena in metallic materials

[J].

Interactions between twins and dislocations during dynamic microstructure evolution for hot shear-compression deformation of Fe-38Mn austenitic steel

[J].

Effects of strain rates and twins evolution on dynamic recrystallization mechanisms of austenite stainless steel

[J].

Role of twinning on dynamic recrystallization and microstructure during moderate to high strain rate hot deformation of a Ti-modified austenitic stainless steel

[J].

High manganese and aluminum steels for the military and transportation industry

[J].

Hot deformation characterization of duplex low-density steel through 3D processing map development

[J].

Hot deformation behavior of Fe-8Mn-3Al-0.2C steel

[J].

Fe-8Mn-3Al-0.2C轻质高强钢的热变形行为

[J].

Influence of hot deformation on dynamic recrystallization behavior of 300M steel: Rules and modeling

[J].

Characterization of hot deformation behavior of 410 martensitic stainless steel using constitutive equations and processing maps

[J].

A new method for evaluation of friction in bulk metal forming

[J].

The thermal and metallurgical state of steel strip during hot rolling: Part II. Factors influencing rolling loads

[J].

The stacking fault energy (SFE) calculation model for Fe-Mn-Al-C low-density steels based on thermodynamics theory

[J].

基于热力学理论的Fe-Mn-Al-C系低密度钢层错能计算模型

[J].

Influences of grain/particle interfacial energies on second-phase particle pinning grain coarsening of polycrystalline

[J].

Concurrent grain growth and coarsening of two-phase microstructures; large scale phase-field study

[J].

Influence of κ-carbide interface structure on the formability of lightweight steels

[J].

Influence of aluminum content on stacking fault energy and mechanical twin of low-density Fe-Mn-Al-C steels

[J].

Al含量对Fe-Mn-Al-C系低密度钢层错能及形变孪晶的影响

[J].

Recrystallization in AISI 304 austenitic stainless steel during and after hot deformation

[J].

Recrystallization, precipitation and flow behavior of D3 tool steel under hot working condition

[J].

Spinodal decomposition and mechanical properties of an austenitic Fe-30%Mn-9wt.%Al-0.9%C alloy

[J].

The stacking fault energy (SFE) calculation model for Fe-Mn-Al-C low-density steels based on thermodynamics theory

[J].

基于热力学理论的Fe-Mn-Al-C系低密度钢层错能计算模型

[J].

High dislocation density–induced large ductility in deformed and partitioned steels

[J].A wide variety of industrial applications require materials with high strength and ductility. Unfortunately, the strategies for increasing material strength, such as processing to create line defects (dislocations), tend to decrease ductility. We developed a strategy to circumvent this in inexpensive, medium manganese steel. Cold rolling followed by low-temperature tempering developed steel with metastable austenite grains embedded in a highly dislocated martensite matrix. This deformed and partitioned (D and P) process produced dislocation hardening but retained high ductility, both through the glide of intensive mobile dislocations and by allowing us to control martensitic transformation. The D and P strategy should apply to any other alloy with deformation-induced martensitic transformation and provides a pathway for the development of high-strength, high-ductility materials.Copyright © 2017 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.