高熵合金(HEAs)的出现大大拓宽了新型合金的设计范畴。高熵合金具有优异的机械性能,如高强度、良好的延展性、耐高温及耐腐蚀等,已成为目前最为热门的研究领域[1~3]。与传统合金相比,HEAs一般至少由四五种主要元素构成,且每种元素含量大概在5%到35%之间[1]。多种组元易于形成高的混合熵,有利于简单固溶体的形成,如Fe50Mn30Co10Cr10[4]、Fe20Co20Ni41Al19[5]、WNbMoTa[6]等四元合金。由于含有多种主要元素,HEAs通常缺乏化学长程有序[7],但存在复杂的短程有序现象,在合金凝固时,小范围内(0.2~0.3 nm)某些元素的配对(如Al-Ni、Cr-Fe)偏向更大[8]。短程有序会造成“摩擦强化”,将持续影响塑性变形的整个过程,进而提高合金的屈服强度,却不降低其塑性[9]。而且各元素原子尺寸不一,使得HEAs晶格畸变严重,产生固溶强化作用,使得HEAs具有高的硬度和强度。

FeNiCoCr系合金是最典型的一类HEAs,具有优异的结构稳定性[10]、机械性能[11~13]以及耐腐蚀性等[14]。通过Al添加使合金表现出独特的鸡尾酒效应[3]。Al为FCC结构,若FeNiCoCr系合金中添加适量Al元素,其晶体结构会由FCC向BCC转变,硬度也随之提高[1,15~18]。当Al添加量较少时,合金的结构不变,屈服强度、断裂强度得以提高,是由于Fe、Ni、Co、Cr的原子半径相近,而Al的原子半径较大,会导致置换固溶强化作用。此外,Al元素的添加会提高合金的层错能,有研究表明Al0.1CoCrFeNi 的堆垛层错能只有6~21 mJ/m2 [19],而Al0.3CoCrFeNi的堆垛层错能约为51 mJ/m2 [20]。层错能对合金变形机制有显著影响,降低层错能将使位错从交滑移转为平面滑移,进一步降低层错能还会导致孪晶转变,甚至发生马氏体相变。

鉴于此,本文采用低速湿混+热压烧结法制备(FeNiCoCr)100-x Al x (x=0、5)高熵合金,并对其进行时效处理,研究Al含量和时效处理对合金微观组织和力学性能的影响。

1 实验方法

采用商用Fe、Ni、Co、Cr、Al粉末(纯度均≥99.5%,平均粒度分别为150、75、48、50、110 μm)为原料,制备(FeNiCoCr)100-x Al x (x=0、5)高熵合金,分别命名为Al0和Al5合金。按照摩尔比称量粉末后装入不锈钢球磨罐,以无水乙醇为过程控制剂,采用行星式球磨机进行低能球磨混粉,球磨机转速为150 r/min,球磨时间为4 h,球磨介质为不锈钢磨球,球料比为5∶1。球磨结束后真空干燥,然后装入石墨模具进行真空热压烧结。以10℃/min的升温速率从室温升温至900℃保温0.5 h,调节压力为15 MPa,保温结束后随炉冷却即可。阿基米德排水法测量合金致密度均超过98%。对Al0和Al5合金进行时效处理,从室温升温至700℃保温12 h,然后随炉冷却。

采用D/max2200PC型X-射线衍射仪(XRD)进行物相分析。采用能谱仪(EDS)表征合金的元素分布。通过电子背散射衍射仪(EBSD)和Channel 5软件进行微观组织表征。使用FEM-7000型图像显微硬度仪测量硬度,载荷为9.8 N,保荷15 s,每个样品测量10次,去掉最大值及最小值,然后取其平均值作为合金的硬度。采用Q1212型电子拉力万能试验机测量室温压缩性能、弯曲强度和断裂韧性。压缩试验试样尺寸为ϕ4 mm×6.2 mm的圆柱体,压缩速率为0.1 mm/min。采用三点弯曲法测量弯曲强度,测量样品尺寸为长25 mm、宽4 mm、高6.2 mm,跨距为20 mm,加载速率为0.75 mm/min。采用单边缺口梁法测量断裂韧性,非标准试样尺寸为长25 mm、宽4 mm、高6.2 mm,缺口(U型)深度约为高度的1/3,跨距为20 mm,加载速率为0.75 mm/min。

2 结果与讨论

2.1 微观组织分析

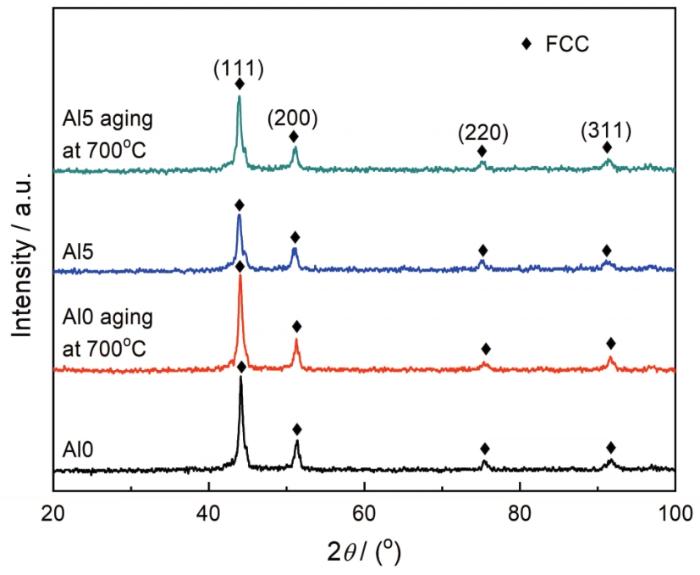

图1

图1

时效前后 (FeNiCoCr)100-x Al x (x=0、5)高熵合金的XRD谱

Fig.1

XRD spectra of (FeNiCoCr)100-x Al x (x=0, 5) high-entropy alloys before and after aging

图2为时效前后(FeNiCoCr)100-x Al x (x=0、5)高熵合金的EDS面扫描元素分布图。由图可见,合金中的Co元素分布相对较为均匀,而Ni、Cr元素整体分布均匀但局部区域存在元素偏聚。Chen 等[25]发现合金化速率与冶金因素中元素的熔点最为相关,在Cu0.5NiAlCoCrFeTiMo合金体系中,元素的合金化顺序为:Al→Cu→Co→Ni→Fe→Ti→Cr→Mo。对于(FeNiCoCr)100-x Al x 合金,Cr元素的熔点最高(2128.15 K),因此其合金化速率要低于Ni、Co元素,也即Cr元素为何存在小区域偏聚现象。Fe元素均独立成团分布,这可能是由于使用了商用Fe粉,粉体尺寸(~150 μm)明显大于Ni、Co、Cr粉体的尺寸,且低能球磨并不能有效破碎Fe粉,加之烧结过程中各元素低的相互扩散率,以及较短的高温保温时间,阻碍了其扩散[26],进而造成了烧结后Fe元素严重偏聚。

图2

图2

时效前后(FeNiCoCr)100-x Al x (x=0、5)高熵合金的EDS面扫描元素分布图

Fig.2

EDS element maps of (FeCoNiCr)100-x Al x (x=0, 5) high-entropy alloys Al0 (a, b) and Al5 (c, d) before aging (a, c) and after aging (b, d)

烧结态和时效态Al5合金中Al元素分布不均,部分区域Al元素呈块状富集,这同样归因于Al粉颗粒较大,由于Al熔点最低,合金化速率最高,故偏聚程度相对较轻。观察发现烧结态和时效态Al5合金中部分Al块状富集区同时富Ni,而其他三种元素贫瘠,分析可能形成了B2结构的NiAl沉淀物[27]。

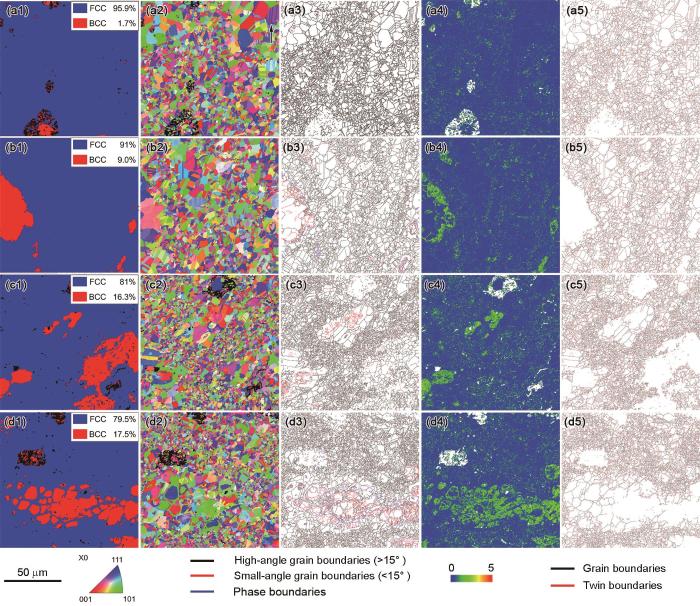

图3为时效前后(FeNiCoCr)100-x Al x (x=0、5)高熵合金的EBSD图。从图3a1~d1相组成图可以看出,合金均由FCC相与少量体心立方相(BCC)相组成。由于BCC相含量较低,图1中BCC相的衍射峰强度较弱,所以显示不明显。BCC相的出现与粉末合金化程度不高以及烧结温度与时效温度低有关。烧结态Al5合金中BCC相含量明显高于烧结态Al0合金,可能受烧结态Al5合金中形成了B2结构的NiAl沉淀物影响。Elaf等[28]使用透射电子显微镜(TEM)原位加热块状Al0.3CoCrFeNi合金,发现在700~900℃之间的较高退火温度下,首先形成了富铬沉淀物,然后才形成NiAl共沉淀物。由于EBSD测试区域小,且考虑到合金元素Fe、Al的不均匀分布,EBSD测试相含量结果必然与合金真实的相含量有一定的偏差。

图3

图3

时效前后(FeNiCoCr)100-x Al x (x=0、5)高熵合金的EBSD图(a1~d1)相位图,(a2~d2)反极图(IPF)图,(a3~d3)晶界和相界图(黑线代表大角度晶界,红线代表小角度晶界,蓝线代表相界),(a4~d4)KAM图,(a5~d5)FCC相中晶界和孪晶界图(黑线代表相界,红线代表60°<111>孪晶界)

Fig.3

EBSD maps of (FeNiCoCr)100-x Al x (x=0, 5) high-entropy alloys Al0 (a, b) and Al5 (c, d) before aging (a, c) and after aging (b, d) (a1~d1) phase maps, (a2~d2) inverse pole figure (IPF) maps, (a3~d3) grain boundaries and phase boundaries maps (The black line represents high-angle grain boundaries, the red line represents small-angle grain boundaries, and the blue line represents phase boundaries), (a4~d4) KAM diagram, (a5~d5) diagram of grain boundaries and twin boundaries in FCC phases (The black line represents phase boundaries, and the red line represents 60°<111> twin boundaries)

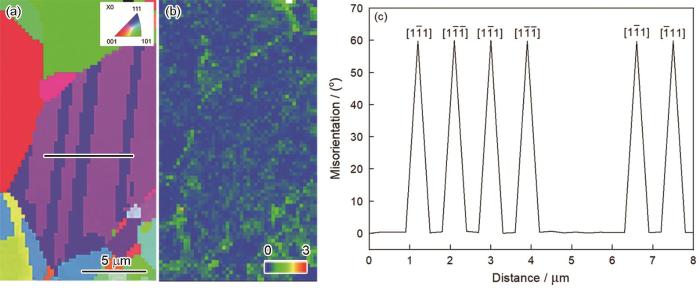

图4

图4

烧结态FeNiCoCr高熵合金局部EBSD图(a)取向成像图;(b)图(a)对应的KAM图;(c)孪晶界取向差图

Fig.4

EBSD diagram of sintered FeNiCoCr high-entropy alloys (a) orientation imaging image, (b) KAM image corresponding to image (a), and (c) twin boundary orientation difference image

图5为合金的取向差角度分布图和晶粒尺寸分布图,从图5a1~d1取向差角度分布图可以看出,烧结态Al0、时效态Al0、烧结态Al5、时效态Al5合金中FCC相60°±2°取向差角度含量分别为47.5%、46.5%、40.7%、39.4%。不含Al元素的合金60°孪晶含量更多,说明Al元素的加入提高了FeCoNiCr系合金的堆垛层错能,这是由于Al层错能高(172 mJ/m2 [35]),且Al添加会导致局部的化学有序化和相分离,限制部分位错的形成[19]。时效后Al0、Al5合金的小角度晶界明显增加,与图3a3~d3的分析结果一致。从图5a2~d2的晶粒尺寸分布图可以看出,烧结态Al0的平均晶粒尺寸相比于烧结态Al5更大,时效后Al0、Al5两种合金的平均晶粒尺寸略有增大。

图5

图5

时效前后(FeNiCoCr)100-x Al x (x=0、5)高熵合金的取向差角度分布图(a1~d1)和晶粒尺寸分布图(a2~d2)

Fig.5

Misorientation angle distribution diagram (a1~d1) and grain size distribution map (a2~d2) of the (FeNiCoCr)100-x Al x (x=0, 5) high-entropy alloys. Al0 before aging (a1~a2), Al0 after aging (b1~b2), Al5 before aging (c1~c2) and Al5 after aging (d1~d2)

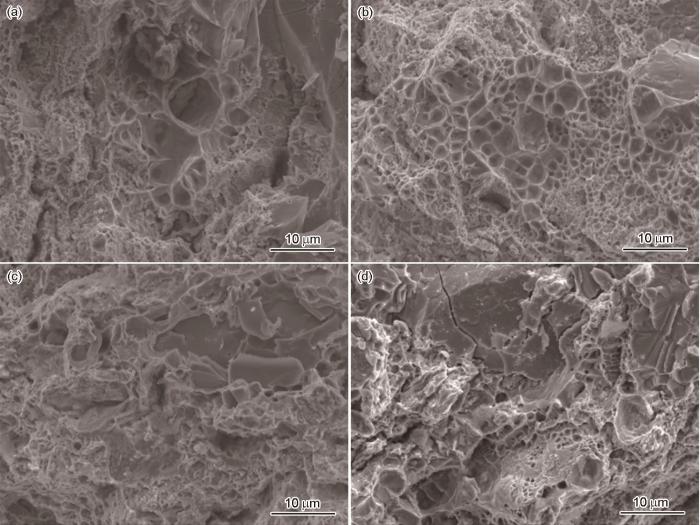

图6

图6

时效前后(FeNiCoCr)100-x Al x (x=0、5)高熵合金弯曲试样断口形貌

Fig.6

Fracture morphologies of (FeCoNiCr)100-x Al x (x=0, 5) high-entropy alloys after bending tests Al0 before aging (a), Al0 after aging (b), Al5 before aging (c), and Al5 after aging (d)

2.2 力学性能分析

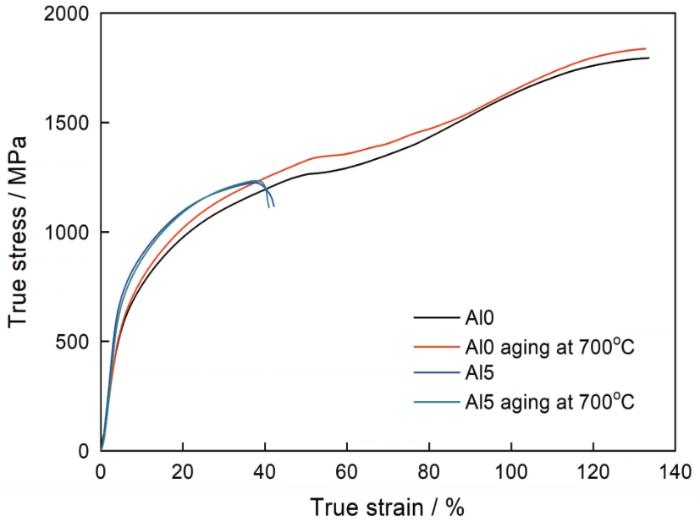

图7为时效前后(FeNiCoCr)100-x Al x (x=0、5)高熵合金的压缩真应力应变图(测试发现烧结态及时效态Al0合金未发生断裂)。由图可见,烧结态及时效态Al0合金的压缩真屈服强度分别达526 MPa和545 MPa,最大真应变量均超过130%(未发生断裂)。烧结态及时效态Al5合金的压缩真屈服强度分别达662 MPa和666 MPa,最大真应变量为38.8%±3.4%和42.5%±1.5%,最大真抗压强度为1182±42 MPa和1227±5 MPa。

图7

图7

时效前后(FeNiCoCr)100-x Al x (x=0、5)高熵合金的压缩真应力应变曲线

Fig.7

Compression true stress-strain curves of (FeNi-CoCr)100-x Al x (x=0, 5) high-entropy alloys before and after aging

烧结态Al5合金比烧结态Al0合金的屈服强度更高(提高了约25.9%),而塑性大幅降低。屈服强度提高的原因是多方面的。屈服强度(σtotal)可以由诸如内在晶格摩擦(σLF),固溶强化(σSSS),晶界强化(σHP),位错强化(σdislo)和颗粒弥散强化(σdisp)等强化因子决定[22]。在忽略σdislo和σdisp时,σtotal与晶粒直径(D)之间符合Hall-Petch公式,即:

其中,σ0可看作单晶体屈服强度,KHP为与晶界构造相关的常数。

Hall-Petch公式表明提高屈服强度有三条途径:即提高σ0,提高KHP,降低D。通过添加Al,合金屈服强度提高正好可以同时满足上述三条途径。首先,Al原子掺杂会使CoCrFeNi合金形成置换固溶强化,进而σ0增加(Al0.1CoCrFeNi和Al0.3CoCrFeNi合金的σ0分别为83 MPa[36]和95 MPa[37]),即屈服强度增加。然后,由于D的减小(2.93 µm减小到2.00 µm),也会使屈服强度增加。此外,Al元素加入后,CoCrFeNi HEA会形成高数量密度的Ni-Al纳米团簇,克服纳米团簇引发的相干应变场需要额外的应力,增大了Hall-Petch公式中KHP值(Al0.1CoCrFeNi和Al0.3CoCrFeNi合金的KHP分别为0.464 MPa·m1/2 [36]和0.824 MPa·m1/2 [37]),导致屈服强度提高[38,39]。此外,Al5合金中少量的BCC相在一定程度上发挥了背应力强化以及异质强化[31]的作用,也有助于提高屈服强度。但是Al的过多添加会造成FCC相含量减少以及FCC相中退火孪晶数量减少,会对提高屈服强度产生不利的影响。时效后Al0、Al5合金屈服强度略有提高,最大真应变量变化不明显。屈服强度的提高是由于高KAM值BCC相的增加形成了背应力强化以及位错强化所致。

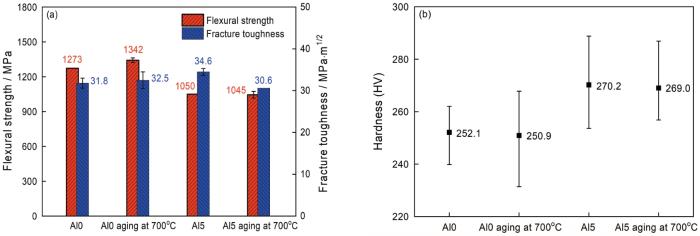

图8为时效前后(FeNiCoCr)100-x Al x (x=0、5)高熵合金的弯曲强度、断裂韧性和硬度。由图8a可以看出,Al元素的加入会显著降低合金的弯曲强度。而时效处理略微改善了Al0合金的弯曲强度和断裂韧性。时效处理后,Al0具有最佳的综合性能,弯曲强度和断裂韧性分别为1342±20 MPa和32.5±2.0 MPa·m1/2。从图8b可以看出,烧结态Al0、Al5合金,硬度分别为252.1HV和270.2HV。加入Al元素后硬度增加,是由于Al原子半径比Fe、Ni、Co、Cr原子更大,尺寸不匹配造成了固溶强化,以及与NiAl共沉淀物的存在有关。观察发现,时效处理对Al0、Al5合金的硬度影响不大。

图8

图8

时效前后(FeNiCoCr)100-x Al x (x=0、5)高熵合金的弯曲强度、断裂韧性和硬度

Fig.8

(a) Flexural strength, fracture toughness, and (b) hardness of (FeNiCoCr)100-x Al x (x=0, 5) high-entropy alloys before and after aging

表1为热压烧结和电弧熔炼法制备的FeNiCoCr合金微观组织和力学性能对比。由表1可见,电弧熔炼法[40~43]制备的FeNiCoCr合金基本为FCC单相,晶粒尺寸较大,屈服强度和维氏硬度都较低。Li等[40]通过电弧熔炼结合过冷凝固的方式获得了具有较高屈服强度的FeNiCoCr合金,高屈服强度归因于细晶强化和BCC相的沉淀作用[40]。本文通过热压烧结法制备的FeNiCoCr合金具有更高的力学性能,屈服强度比电弧熔炼法提高了约250%,硬度增加了约100HV。性能的提高主要归因于细晶强化(晶粒尺寸降低了两个数量级)和产生了BCC沉淀,克服BCC沉淀引发的相干应变场需要额外的应力,增大了Hall-Petch公式中KHP值导致屈服强度提高[38,39]。

表1 热压烧结和电弧熔炼制备FeNiCoCr合金微观组织和力学性能的差异

Table 1

| Preparation method | Phase composition | Grain size /μm | Compression engineering yield strength /MPa | Vickers hardness (HV) |

|---|---|---|---|---|

| Hot-pressing sintering (in this study) | FCC matrix+BCC phase precipitation | ~3 | 534 | 252 |

| Arc melting [40] | Single FCC phase | >400 | 137 | - |

| Arc melting+Supercooled solidification [40] | FCC matrix+BCC phase precipitation | 5~10 | 455 | - |

| Arc melting [41] | Single FCC phase | - | 145 | 141 |

| Arc melting [42] | Single FCC phase | ∼100 | 156 | 156 |

| Arc melting [43] | Single FCC phase | - | 155 | 133 |

3 结论

(1) 烧结态及时效态(FeNiCoCr)100-x Al x (x=0、5)高熵合金的微观组织均由FCC相和少量BCC相组成,其中FCC相中均存在孪晶,且未添加Al的合金中孪晶比例相对较高;添加Al的合金中BCC相相对较高,且时效处理后出现大量小角度晶界。

(2) (FeNiCoCr)100-x Al x (x=0、5)高熵合金均表现出优异的压缩性能,FeCoNiCr合金压缩真屈服强度为526 MPa,最大真应变量超过130%。(FeCoNiCr)95Al5合金具有更高的压缩真屈服强度(662 MPa),同时依然表现出良好的真应变量(38.8%±3.4%)。时效处理后两种合金屈服强度都略有提升。

(3) 时效态FeNiCoCr合金具有最佳的综合性能,其压缩真屈服强度为545 MPa,最大真应变量超过130%,弯曲强度和断裂韧性分别为1342±20 MPa和32.5±2.0 MPa·m1/2。烧结态(FeNiCoCr)95Al5合金的硬度高于烧结态FeNiCoCr合金,700℃时效处理对合金硬度的影响不明显。

参考文献

Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes

[J].

Microstructural development in equiatomic multicomponent alloys

[J].

Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off

[J].

Multistage work hardening assisted by multi-type twinning in ultrafine-grained heterostructural eutectic high-entropy alloys

[J].

Refractory high-entropy alloys

[J].

Absence of long-range chemical ordering in equimolar FeCoCrNi

[J].

Deviation from high-entropy configurations in the atomic distributions of a multi-principal-element alloy

[J].Santodonato, Louis J. Oak Ridge Natl Lab, Instrument & Source Div, Oak Ridge, TN 37831 USA. Santodonato, Louis J.; Tang, Zhi; Liaw, Peter K. Univ Tennessee, Dept Mat Sci & Engn, Knoxville, TN 37996 USA. Zhang, Yang Univ Illinois, Dept Nucl Plasma & Radiol Engn, Urbana, IL 61801 USA. Feygenson, Mikhail; Neuefeind, Joerg C. Oak Ridge Natl Lab, Chem & Engn Mat Div, Oak Ridge, TN 37831 USA. Parish, Chad M. Oak Ridge Natl Lab, Div Mat Sci & Technol, Oak Ridge, TN 37831 USA. Gao, Michael C. Natl Energy Technol Lab, Albany, OR 97321 USA. Gao, Michael C. URS Corp, Albany, OR 97321 USA. Weber, Richard J. K. Mat Dev Inc, Evanston, IL 60202 USA. Weber, Richard J. K. Argonne Natl Lab, Adv Photon Source, Argonne, IL 60439 USA.

On short-range order strengthening and its role in high-entropy alloys

[J].

Phases, microstructure and mechanical properties of Al x CoCrFeNi high-entropy alloys at elevated temperatures

[J].

Enhanced relative slip distance in gas-tungsten-arc-welded Al0.5CoCrFeNi high-entropy alloy

[J].

The ultrahigh charpy impact toughness of forged Al x CoCrFeNi high entropy alloys at room and cryogenic temperatures

[J].

Cooling rate effect on microstructure and mechanical properties of Al x CoCrFeNi high entropy alloys

[J].

Homogenization of Al x CoCrFeNi high-entropy alloys with improved corrosion resistance

[J].

Computational thermodynamics aided high-entropy alloy design

[J].

Microstructure, thermophysical and electrical properties in Al x CoCrFeNi (0≤x≤2) high-entropy alloys

[J].

Effects of Al addition on the microstructure and mechanical property of Al x CoCrFeNi high-entropy alloys

[J].

Mechanical performance of the Al x CoCrCuFeNi high-entropy alloy system with multiprincipal elements

[J].

Transmission electron microscopy characterization of dislocation structure in a face-centered cubic high-entropy alloy Al0.1CoCrFeNi

[J].

Dynamic strain aging of Al0.3CoCrFeNi high entropy alloy single crystals

[J].

Microstructure and mechanical behavior of FeNiCoCr and FeNiCoCrMn high-entropy alloys fabricated by powder metallurgy

[J].

Powder metallurgy of Al0.1CoCrFeNi high-entropy alloy

[J].

Effect of process control agents on mechanically alloyed Al0.3CoCrFeNi

[J].

Microstructures and corrosion-resistant properties of Al x-CoCrFeNi high-entropy alloys

[D].

Al x CoCrFeNi系高熵合金微观组织与耐蚀性能研究

[D].

Competition between elements during mechanical alloying in an octonary multi-principal-element alloy system

[J].

High entropy alloys obtained by field assisted powder metallurgy route: SPS and microwave heating

[J].

Microstructure and mechanical properties of twinned Al0.5CrFeNiCo0.3C0.2 high entropy alloy processed by mechanical alloying and spark plasma sintering

[J].

Insight into the kinetic stabilization of Al0.3CoCrFeNi high-entropy alloys

[J].

Analysis on the twinning of FCC metals by EBSD

[J].

FCC金属孪晶的EBSD分析

[J].

Recovery of cold-worked Al0.3CoCrFeNi complex concentrated alloy through twinning assisted B2 precipitation

[J].

Heterostructured materials: superior properties from hetero-zone interaction

[J].

Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD

[J].

Atomic mechanisms of dislocation and TB interaction in FCC metallic materials

[J].

FCC金属中位错与孪晶界交互作用的原子机制

[J].

The role of annealing twins during recrystallization of Cu

[J].

First-principles study of stacking fault energy and deformation twin energy in Al-Mg alloys

[J].

Al-Mg合金中层错和孪晶形变能的第一性原理研究

[J].通过基于密度泛函理论(DFT)的第一性原理计算了纯金属 Al和Al-Mg合金在(111)[112]滑移系的层错能和孪晶形变能, 分析了Mg含量、占位对层错能和孪晶形变能的影响. 计算选用了局域密度近似(LDA)和广义梯度近似 (GGA-PW91)2种近似方法, 发现GGA-PW91所获得的层错能与实验结果符合较好. 研究结果表明, 纯Al的层错能高于孪晶形变能, 随着孪晶层厚度的增加孪晶形变能略有提高, 6层呈完全镜面对称孪晶具有的孪晶形变能最低; Mg含量增加可使Al-Mg合金的层错能、变形孪晶形变能明显降低; Mg在Al-Mg合金中占位对结合能和形成热的影响很小, 当Mg处于层错层时略使层错能和孪晶形变能提高.

Revealing the Hall-Petch relationship of Al0.1CoCrFeNi high-entropy alloy and its deformation mechanisms

[J].

Optimizing the coupled effects of Hall-Petch and precipitation strengthening in a Al0.3CoCrFeNi high entropy alloy

[J].

Ordering-mediated local nano-clustering results in unusually large Hall-Petch strengthening coefficients in high entropy alloys

[J].

Interplay between single phase solid solution strengthening and multi-phase strengthening in the same high entropy alloy

[J].

Enhanced mechanical properties of a CoCrFeNi high entropy alloy by supercooling method

[J].

Effects of Ta addition on the microstructures and mechanical properties of CoCrFeNi high entropy alloy

[J].

Effects of Hf on the microstructure and mechanical properties of CoCrFeNi high entropy alloy

[J].