316L奥氏体不锈钢具有良好的韧性、塑性、焊接性以及耐腐蚀性能,可用于制造核电站中的热交换器和第四代核反应堆等设备[1]。

在研究316L不锈钢的拉伸以及疲劳特性过程中,观察到了动态应变时效(Dynamic strain aging,DSA)现象[10~17]。Li等[11]的高温低周疲劳试验结果表明,DSA效应发生在250~600℃的较宽温度范围内;应变速率为2×10-4/s时的热活化能值表明,DSA的活性在循环硬化阶段减弱,在软化阶段增强。Nagesha等[12]进行了316L不锈钢的单轴低周疲劳试验,探讨了在不同温度条件下的DSA现象并对比分析了温度对位错微观结构形式的影响。结果表明,在300~550℃位错表现出明显的平面结构;当温度提高到400~600℃时,微观结构为胞状结构。Hong等[13,14]对316L不锈钢的研究得出了类似的结论。Hong等还探讨了DSA效应对316L不锈钢疲劳寿命的影响,发现DSA现象的存在使疲劳寿命降低。陈凌等[15]对316L不锈钢的研究表明,420℃时材料的DSA强化最为显著,同时其循环特性依赖温度和加载历史。Jiang等[16]对316L疲劳蠕变性能的研究表明,动态应变时效预变形处理能有效减小材料的循环应变幅值,提高材料的强度和延长疲劳蠕变寿命。

先前对316L不锈钢DSA效应的研究主要集中在温度、应变幅值以及应变速率等对单轴疲劳性能的影响,而路径对DSA效应影响的研究鲜有报道[17]。本文进行316L不锈钢600℃圆路径不同应变范围下的低周疲劳实验,用透射电子显微镜(TEM) 观察疲劳失效后的显微组织,研究位错结构的应变路径以及应变范围相关性并讨论非比例路径下DSA效应的微观机理。

1 实验方法

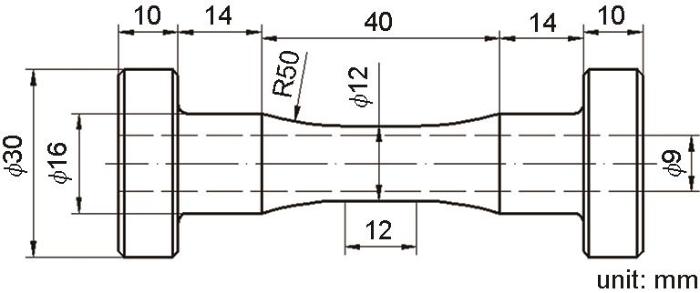

实验材料为316L奥氏体不锈钢,将其加工成薄壁圆管试样进行多轴低周疲劳实验。试件的尺寸及形状,如图1所示。

图1

图2

图2

Fig.2

Semi-life hysteretic loops under circular loading for equivalent strain ranges 0.7% and 1.0%

疲劳实验后,对疲劳标距段断口附近的显微组织进行TEM观察。在疲劳样品标距区,用火花线切取厚度为500 μm的薄片;用SiC砂纸沾水将其磨至50 μm,再截成直径为3 mm 的小圆片;最后用MTP-1型双喷减薄仪减薄出TEM 薄膜样品。TEM观察在FEI Tecnai F20透射电镜上进行,工作电压为200 kV。

2 结果和讨论

2.1 位错结构相关性

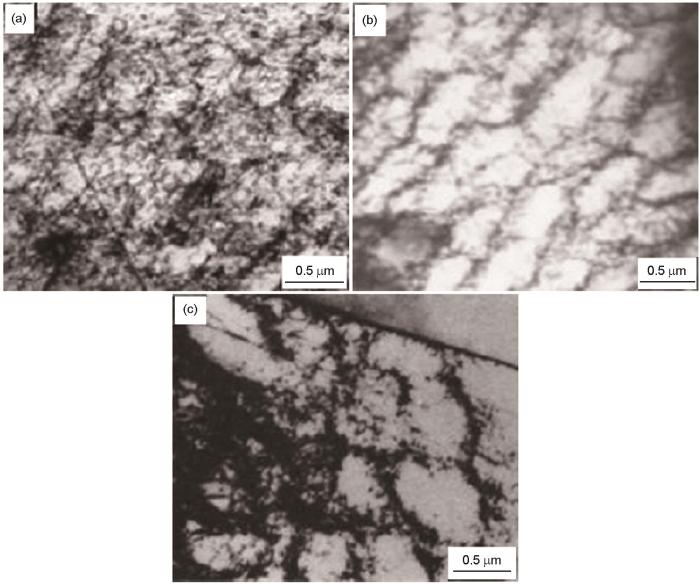

先前采用TEM技术,针对316L不锈钢的单轴室温、600℃以及圆路径室温下疲劳失效后的微观组织,如图3所示。

图3

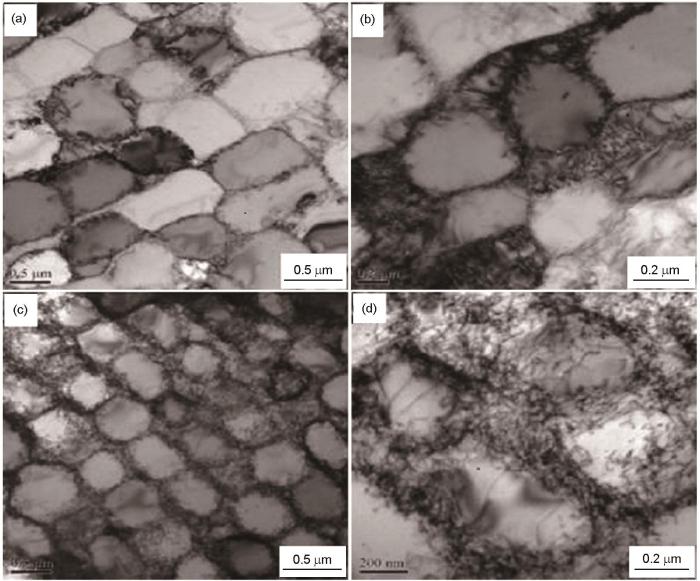

图4

图4

不同应变范围下疲劳断口附近的位错结构

Fig.4

Dislocation structure near fatigue fracture for different equivalent strain ranges (a) (b)

2.2 应变幅值相关性

2.3 DSA效应路径相关性的微观机理

在单轴加载中滑移方向单一,可动位错不易逃脱溶质原子气团,使其受阻于障碍物的等待时间长,偏聚到被阻拦可动位错周围的溶质原子数目较多。随着空位浓度的提高部分溶质原子的扩散速度远大于可动位错速度,已钉扎位错拖曳着溶质原子气团运动而较难脱钉,因此DSA现象较弱、应力跌幅较低,锯齿类型仅表现为A型锯齿[18];而圆路径加载下,剪应变作用的引入使位错间相互作用增强,材料中点缺陷增多,溶质原子活性提高,单位时间内偏聚到被阻拦可动位错周围的溶质原子数目增多,DSA现象比单轴路径更完全,如图2所示。同时,圆路径滞回线中锯齿波稠密,锯齿类型呈现出多元化的特点,压缩阶段锯齿类型由A型经过B型逐渐过渡为C型,拉伸阶段锯齿类型由A型逐渐过渡为C型,且压缩阶段的锯齿跌幅更大。

在圆路径下,随着应变幅值的增大塑性变形机理由非DSA状态下的波形滑移模式转变为DSA状态下的平面滑移模式,促进了位错胞和亚晶粒结构的形成(图4),与单轴路径相比材料疲劳寿命显著降低。

3 结论

(1) 在316L不锈钢的多轴疲劳实验中,室温单轴加载形成了脉络状位错结构,而圆路径下则表现出了胞状位错结构。在600℃单轴加载的变形以平面滑移方式为主,位错呈现均匀的条带状,而在圆路径下则表现出等轴胞状位错结构,显著降低了材料抵抗变形的能力,在等效应变范围1.0%下疲劳寿命较单轴路径下的寿命降低了81%。

(2) 位错组态的形成受加载路径和应变幅值共同影响。在600℃单轴路径等效应变范围1.0%条件下材料表现出条带状疲劳位错组态,而在圆路径等效应变范围0.7%条件下材料即表现出了胞状位错结构。

(3) 在600℃圆路径条件下观察到显著的DSA效应,在等效应变范围1.0%条件下最大应力跌幅较单轴路径增加了680%;在压缩阶段锯齿类型由A型、B型,逐渐过渡为C型,比拉伸阶段的DSA现象更为明显。

参考文献

Study on microstructure and tensile properties of 316L stainless steel fabricated by CMT wire and arc additive manufacturing

[J].

Fretting fatigue behavior of 316L stainless steel under combined loading conditions

[J].

High cycle fatigue and ratcheting interaction of laser powder bed fusion stainless steel 316L: Fracture behaviour and stress-based modelling

[J].

McKinnell, U. Ramamurty. Fatigue strength of additively manufactured 316L austenitic stainless steel

[J].

Cyclic deformation and fatigue behavior of 316L stainless steel processed by surface mechanical rolling treatment

[J].

On nonproportional cyclic properties of type 316 stainless steels

[J].

316不锈钢的非比例循环特性

[J].

Evaluation of the creep-fatigue damage mechanism of Type 316L and Type 316LN stainless steel

[J].

Low-cycle fatigue life prediction for 316L stainless steel using strain-based model

[J].

基于应变的316L不锈钢低周疲劳寿命预测方法

[J].

Definition of non-proportionality of strain path based on microstructures analysis

[J].

基于微结构分析定义应变路径非比例度

[J].

Review on relationship between dynamic strain aging and environmentally assisted cracking of structural materials used in nuclear power plants

[J].

动态应变时效对核电材料环境致裂影响的研究现状与进展

[J].

Cyclic deformation behavior and dynamic strain aging of 316LN stainless steel under low cycle fatigue loadings at 550℃

[J].

A comparative study of isothermal and thermomechanical fatigue on type 316L(N) austenitic stainless steel

[J].

Dynamic strain aging under tensile and LCF loading conditions, and their comparison in cold worked 316L stainless steel

[J].

Dynamic strain aging effect on the fatigue resistance of type 316L stainless steel

[J].

Investigation about low cycle fatigue behavior of 316l steel at room and elevated temperature

[J].

316L钢室温和中温环境下应力控制的低周疲劳行为研究

[J].

Dynamic strain aging in stress controlled creep-fatigue tests of 316L stainless steelunder different loading conditions

[J].

Dynamic strain aging of 316l stainless steel under circular loading

[J].

316L不锈钢圆路径下的动态应变时效分析

[J].

Dynamic strain aging of 316l stainless steel during uniaxial fatigue process at 600℃

[J].

316L不锈钢单轴疲劳动态应变的时效分析

[J].

The dependence of dislocation microstructure on plastic strain amplitude in cyclically strained copper single crystals

[J].